Novel composite material for improving underwater antiknock performance of wading buildings

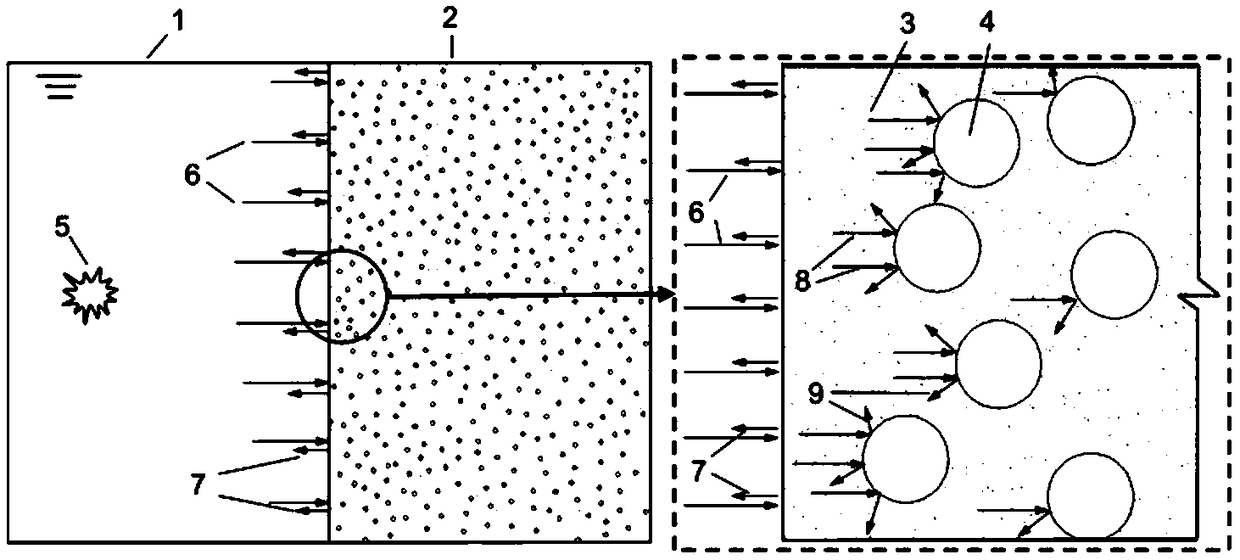

A technology for composite materials and buildings, which is applied to new materials for underwater anti-blast protection and its application in wading buildings. It can solve the problem of loss of clipping protection performance, low strength of foam concrete, and difficulty in resisting short-distance underwater Explosion load and other problems, to achieve the effect of improving underwater anti-blast performance, controllable cost, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

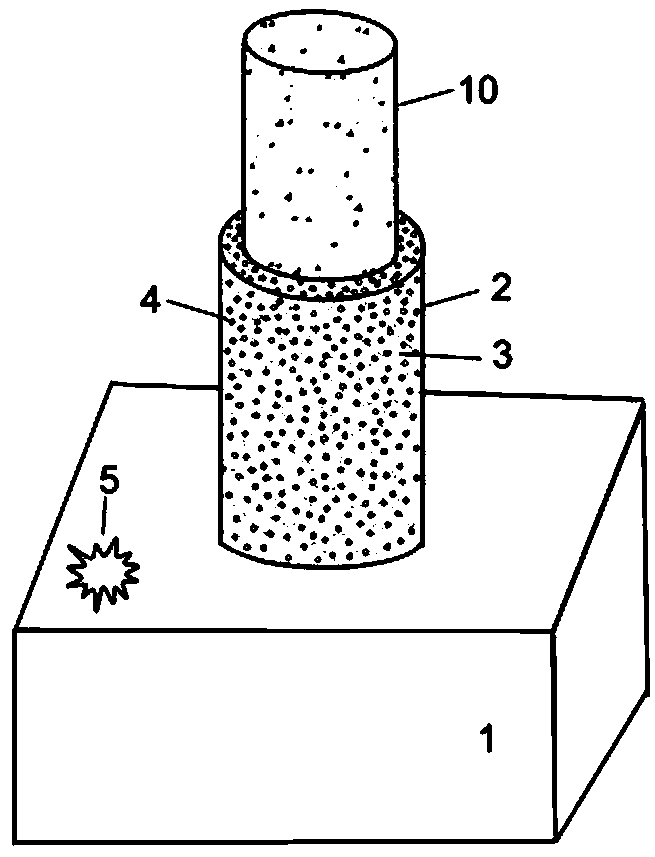

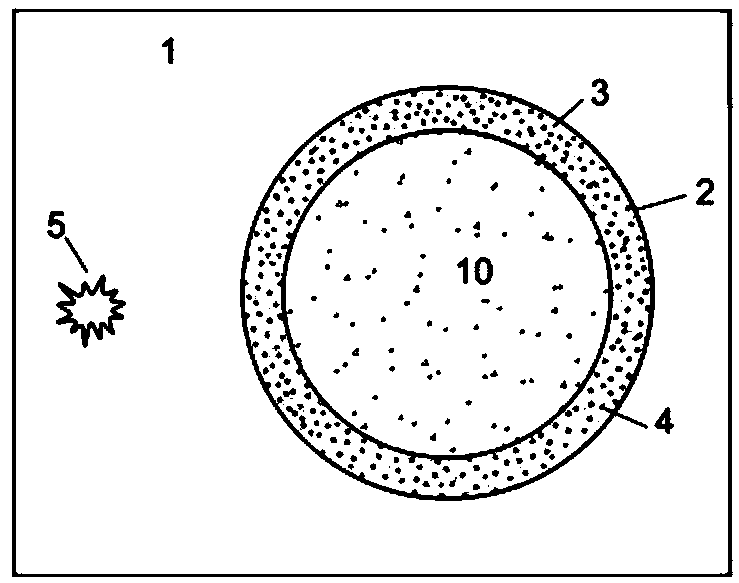

[0034] Such as figure 2 , 3 As shown, the design characteristic parameters of a bridge pier are: the elevation of the top of the pier is 1286m, the elevation of the bottom of the pier is 1266m, the section of the pier is circular, and the radius is 1.0m. Follow the steps below to implement:

[0035] The new composite material of the present invention is used within the thickness of 0.3m outside the bridge pier as the pier protection layer; the main body of the pier is made of ordinary concrete material.

[0036] During the construction of the bridge pier, zoned pouring was adopted, and new high-strength composite materials containing high-performance hollow glass microspheres were used within 0.3m outside the bridge pier; conventional pouring materials were used in the main area.

[0037] When the bridge pier is subjected to underwater explosion loads, high-strength composite materials can resist larger explosion loads. At the same time, a large number of high-performance ...

Embodiment 2

[0039] Such as Figure 4 As shown, the design characteristic parameters of an underwater tunnel are: span 13.85m, side wall thickness 0.85m, roof thickness 1.1m, floor thickness 1.2m, crest width 15m. Follow the steps below to implement:

[0040] The top surface of the tunnel and the outer wall of the side wall adopt the new composite material of the present invention as the protective layer of the tunnel, and the thickness of the protective layer is 0.3m; the main body of the tunnel adopts ordinary concrete material.

[0041] During the construction of the underwater tunnel, layered pouring is adopted, and the outer protective layer of the tunnel is made of new high-strength composite materials containing high-performance hollow glass beads; the main area of the tunnel is made of conventional pouring materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com