High-impact and high-fluidity polyvinyl chloride material and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, applied in the field of high-impact and high-flow polyvinyl chloride materials and their preparation, can solve problems such as difficult manufacturing, poor compatibility, and large processing temperature difference, and improve processing flow High performance, good impact resistance, good low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

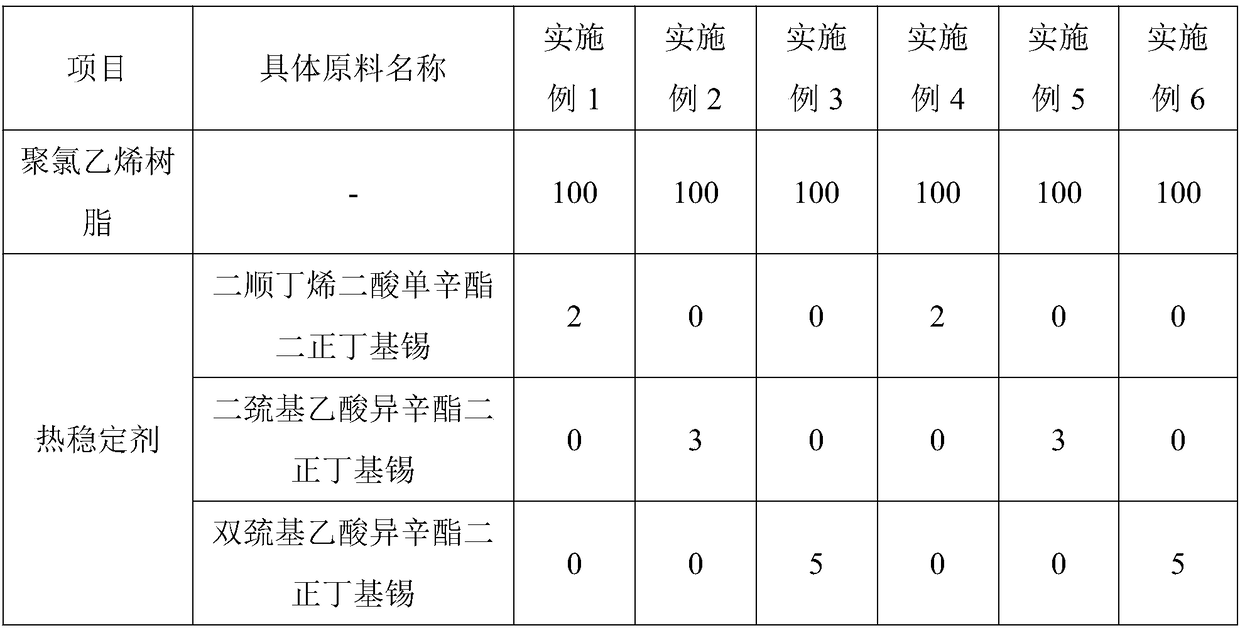

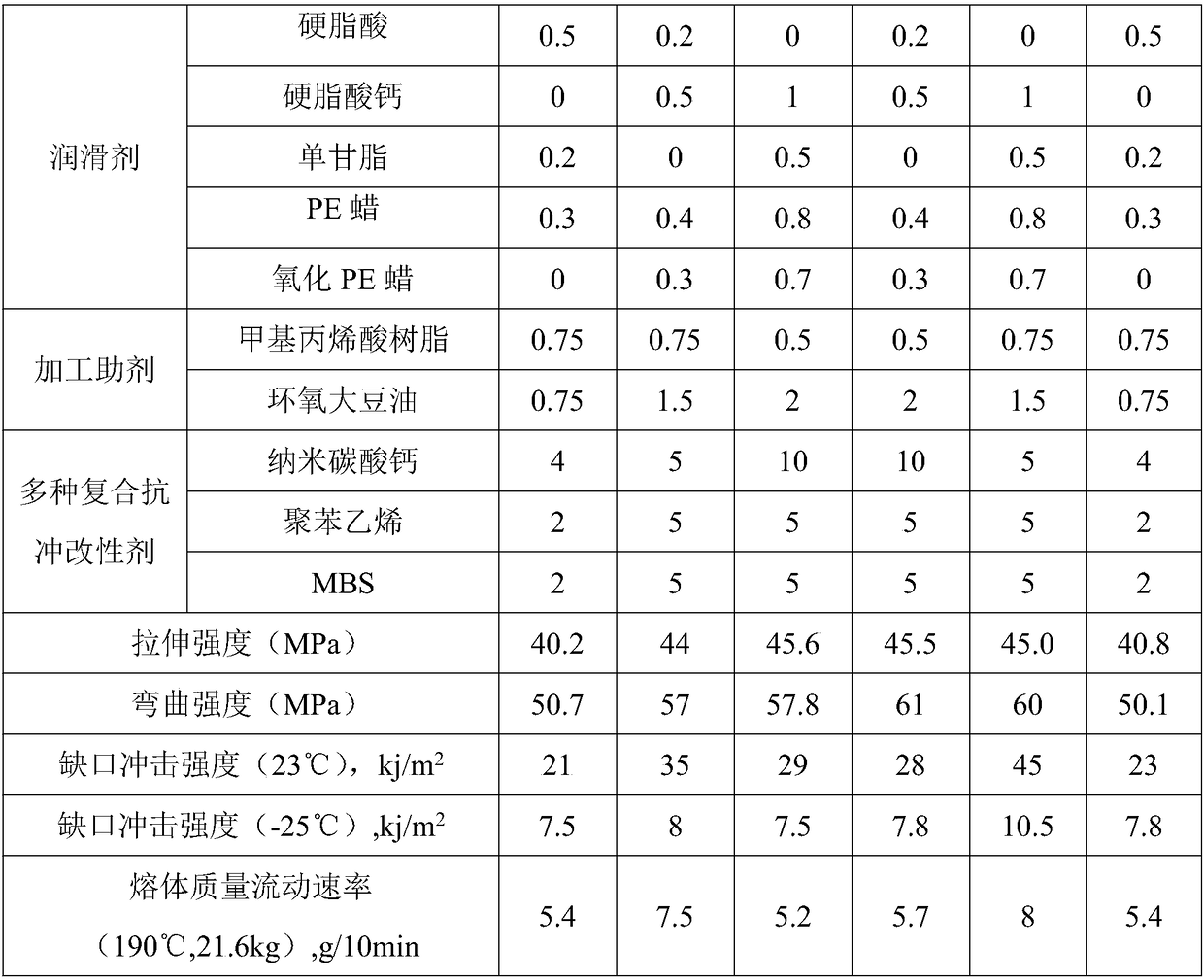

Embodiment 1

[0028] A high-impact high-flow polyvinyl chloride material, the polyvinyl chloride material is composed of the following components in parts by weight:

[0029] Polyvinyl chloride resin: 100 parts;

[0030] Heat stabilizer: 2 parts of di-n-butyltin monooctyl dimaleate;

[0031] Lubricants: internal lubrication is 0.5 parts of stearic acid, 0.2 parts of monoglyceride, external lubrication is 0.3 parts of PE wax,

[0032] Processing aids: methacrylic resin: 0.75 parts, epoxy soybean oil: 0.75 parts;

[0033] Composite impact modifier: 4 parts of nano calcium carbonate, 2 parts of polystyrene, 2 parts of MBS.

[0034] A preparation method of high-impact high-flow polyvinyl chloride material, comprising the following steps:

[0035] a. All raw and auxiliary materials are dried, and the water content is controlled below 0.1%;

[0036] b. Measure according to the design formula;

[0037] c. Put the polyvinyl chloride resin, heat stabilizer and lubricant into the high-speed mixe...

Embodiment 2

[0042] A high-impact high-flow polyvinyl chloride material, the polyvinyl chloride material is composed of the following components in parts by weight:

[0043] Polyvinyl chloride resin: 100 parts;

[0044] Heat stabilizer: 3 parts of isooctyl dimercaptoacetate di-n-butyltin;

[0045] Lubricant: The internal lubricant is 0.2 parts of stearic acid, 0.5 parts of calcium stearate, the external lubricant is 0.4 parts of PE wax, and 0.3 parts of oxidized PE wax;

[0046] Processing aids: 0.75 parts of methacrylic resin, 1.5 parts of epoxy soybean oil;

[0047] Composite impact modifier: 5 parts of nano calcium carbonate, 5 parts of polystyrene, 5 parts of MBS.

[0048] A preparation method of high-impact high-flow polyvinyl chloride material, comprising the following steps:

[0049] a. All raw and auxiliary materials are dried, and the water content is controlled below 0.1%;

[0050] b. Measure according to the design formula;

[0051] c. Put the polyvinyl chloride resin, heat...

Embodiment 3

[0056] A high-impact high-flow polyvinyl chloride material, the polyvinyl chloride material is composed of the following components in parts by weight:

[0057] 100 parts of polyvinyl chloride resin;

[0058] Heat stabilizer: 5 parts of di-n-butyltin isooctyl dimercaptoacetate;

[0059] Lubricant: The internal lubricant is 1 part of calcium stearate, 0.5 part of monoglyceride, the external lubricant is 0.5 part of PE wax, and 0.7 part of oxidized PE wax;

[0060] Processing aids: 0.5 parts of methacrylic resin, 2 parts of epoxy soybean oil;

[0061] A variety of composite impact modifiers: 10 parts of nano-calcium carbonate, 5 parts of polystyrene, and 5 parts of MBS.

[0062] A preparation method of high-impact high-flow polyvinyl chloride material, comprising the following steps:

[0063] a. All raw and auxiliary materials are dried, and the water content is controlled below 0.1%;

[0064] b. Measure according to the design formula;

[0065] c. Put the polyvinyl chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com