Patents

Literature

30results about How to "Low impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

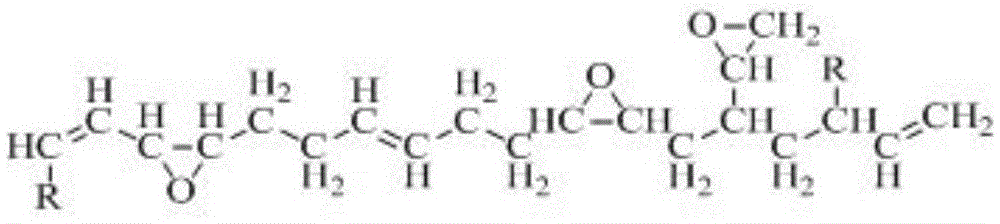

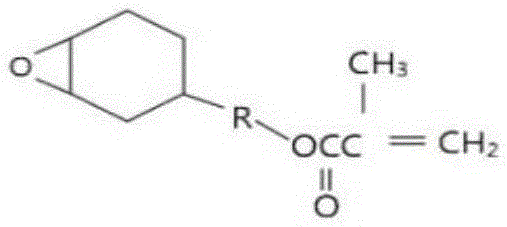

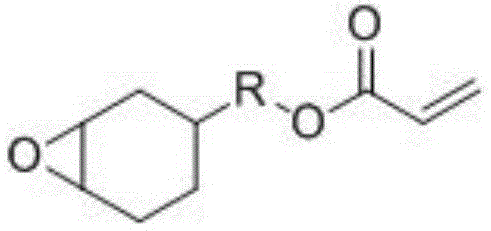

Ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin

ActiveCN104449419ASynergistic priming effect is goodIncrease the polymerization rateOrganic non-macromolecular adhesivePolyolefinFast tempo

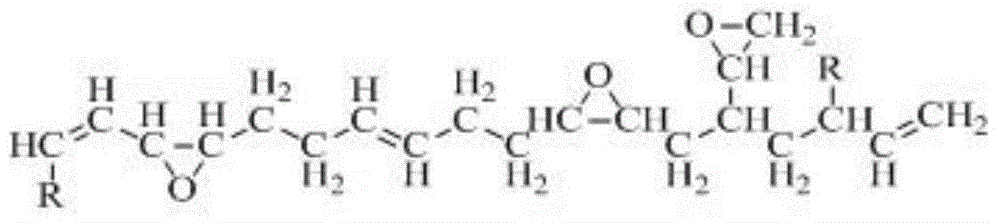

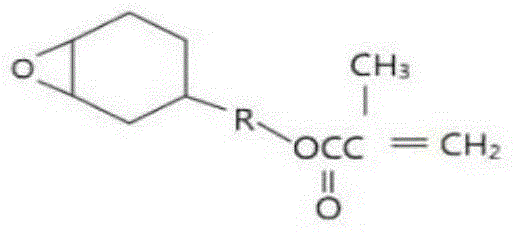

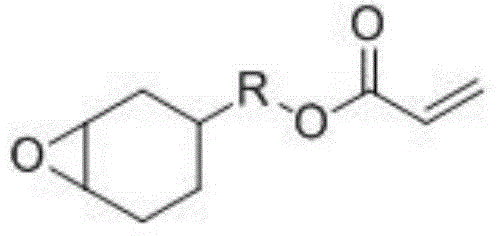

The invention belongs to the technical field of adhesives, and particularly relates to an ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin. The ultraviolet-heat dual curing optical adhesive comprises the following components in percentage by weight: 14.5%-45% of epoxidized polybutadiene resin, 10%-40% of alicyclic epoxy modified resin, 5%-15% of polyolefin liquid rubber, 25.5%-35% of an acrylic ester reactive diluent, 2.4%-3.4% of a free radical photoinitiator, 0.1%-0.2% of a cationic photoinitiator and 2%-2.5% of a peroxide initiating curing agent. The optical adhesive disclosed by the invention is relatively completely solidified at a shaded part, a dark adhesive layer part or a thick adhesive layer part, has excellent optical properties such as high refractive index and high transmittance after being solidified, has the advantages of shock resistance, low yellowing coefficient, low haze, low shrinking percentage, easiness in repairing and good flexibility, meets the requirements of optical, physical and chemical properties of display devices, and is suitable for fast-tempo and high-efficiency production processes.

Owner:信泰永合(烟台)新材料有限公司

Reinforced cement foaming board and preparation method thereof

InactiveCN103172327AGuaranteed carbonization indexStrength does not shrinkCeramic shaping apparatusCeramicwareFiberPolymer science

The invention relates to a reinforced cement foaming board and a preparation method thereof. The reinforced cement foaming board comprises the following components in percentage by weight: 27.00-35.50% of water, 28.0-61.0% of Portland cement, 0-32.70% of coal ash at grade I or a mixture of coal ash and recycled filler, 0-2.00% of wollastonite powder, 0.10-0.30% of fiber, 0.37-0.65% of ammonium stearate, 1.00-2.00% of a mixture of 10 parts of calcium sulphate and 1 part of calcium formate, 0.10-0.20% of naphthalenesulfonate formaldehyde condensation compound, 0.90-1.20% of hydrogen peroxide and reinforcement net. The reinforced cement foaming board provided by the invention has the advantages of low apparent density, low heat conductivity coefficient, good noise reduction effect, high strength, no crack and shock resistance.

Owner:上海中驰建筑工程有限公司

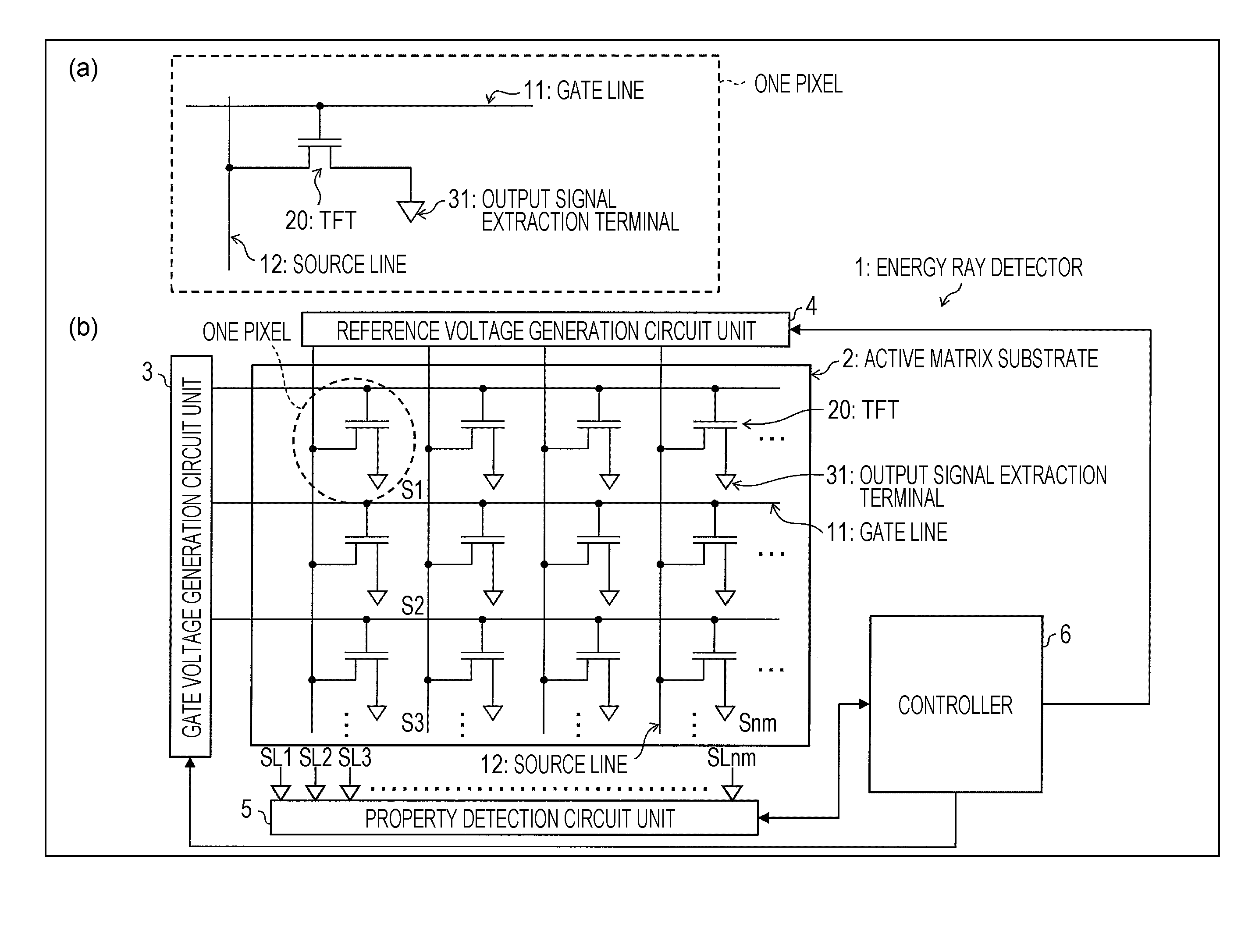

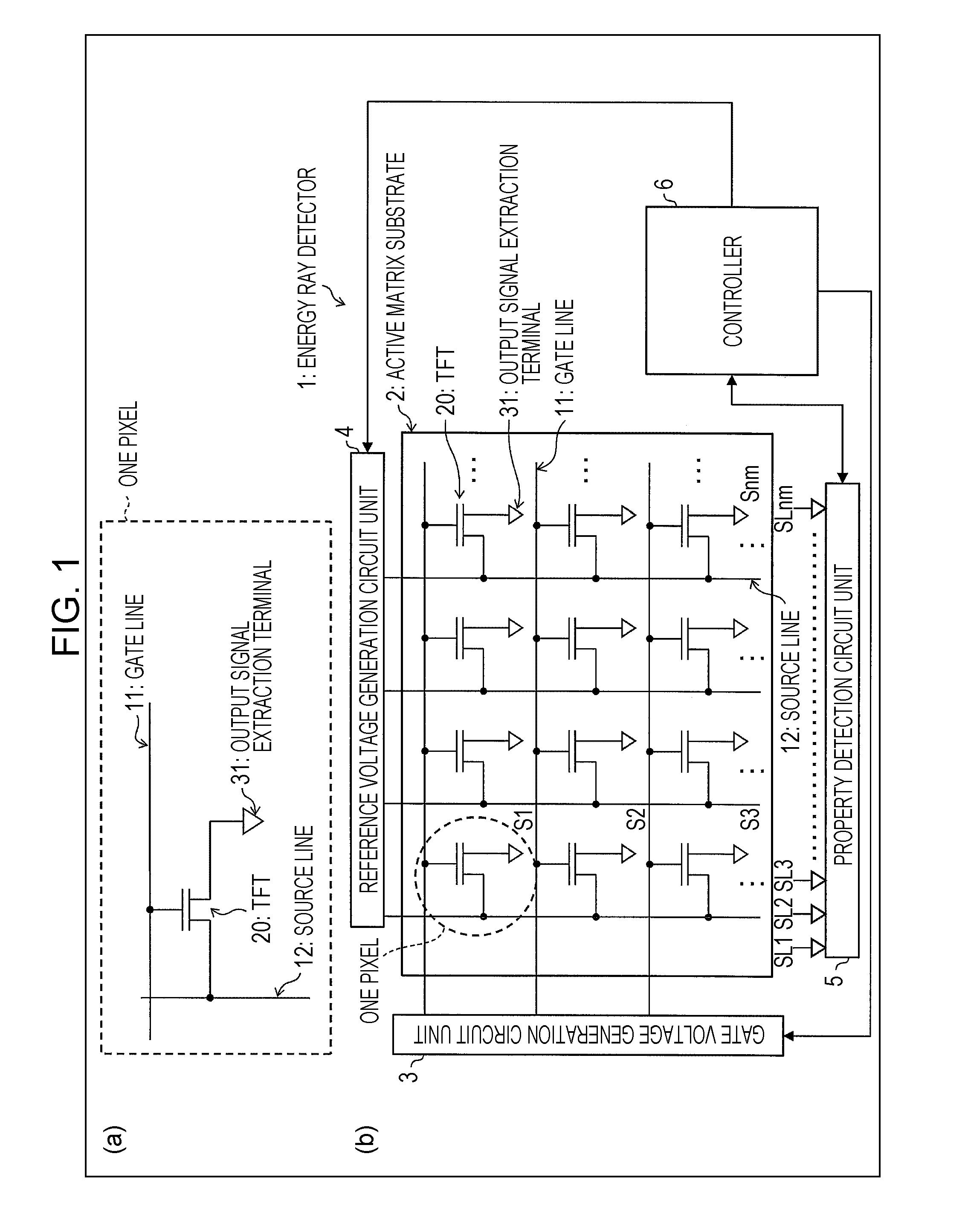

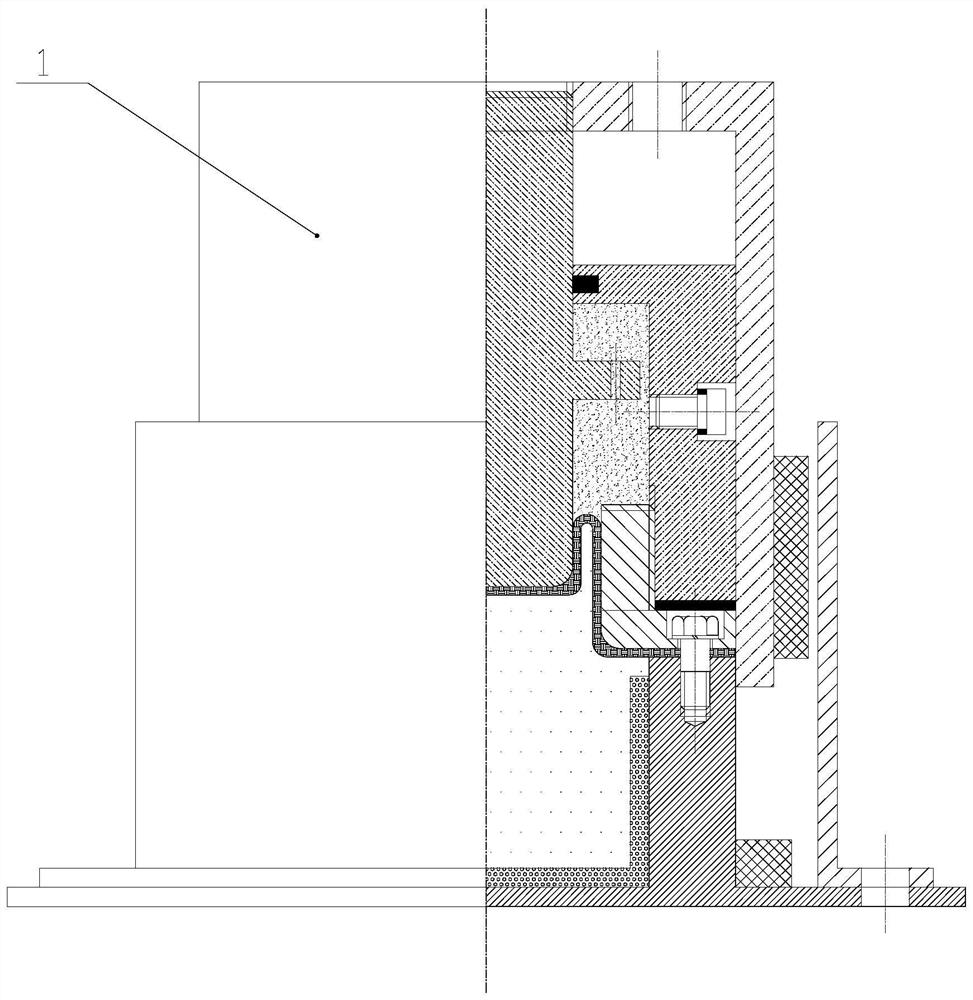

Energy ray detector

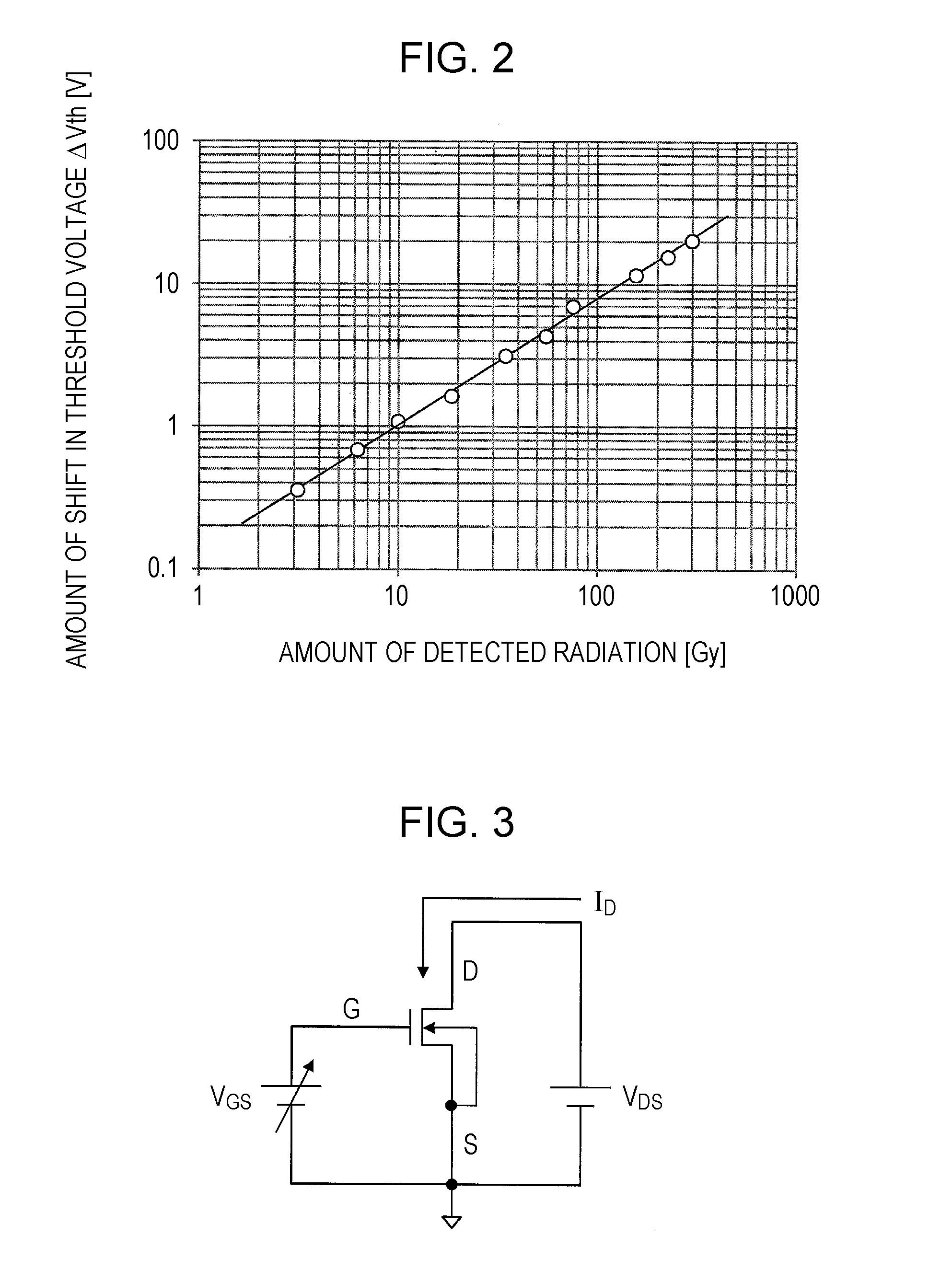

ActiveUS20160313458A1Low impact-resistanceHigh-speed reading of informationTransistorSolid-state devicesRadiationActive layer

A thin, lightweight, and highly reliable energy ray detector that enables high-speed reading is provided. An energy ray detector (1) includes TFTs (20) that are arranged in a grid pattern and that each have an active layer formed of a semiconductor having an electrical property changing in accordance with the amount of applied energy ray radiation, and a property detection circuit unit (5) and a controller (60) that detect information regarding the energy ray radiation from changes in the electrical property of the TFTs (20).

Owner:SHARP KK

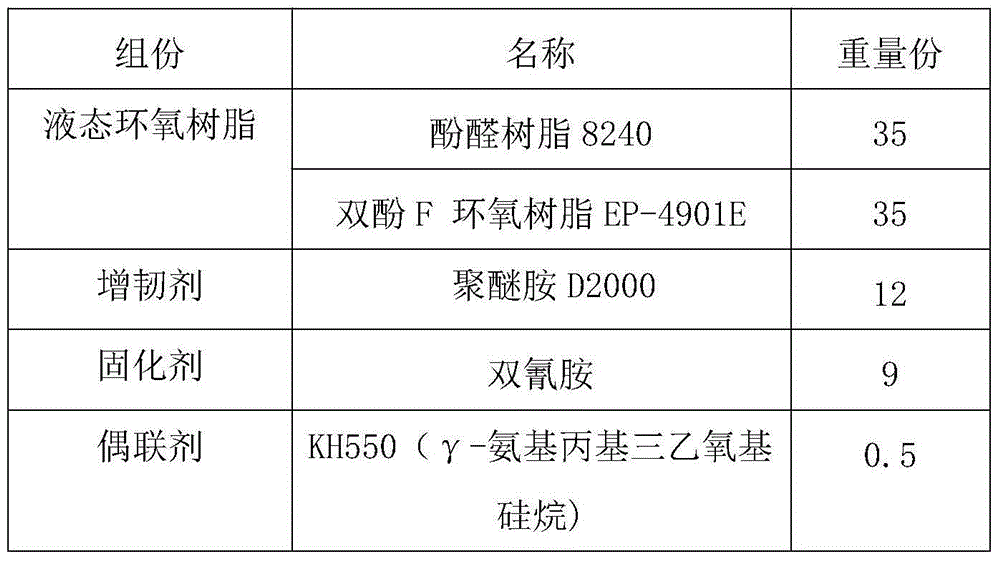

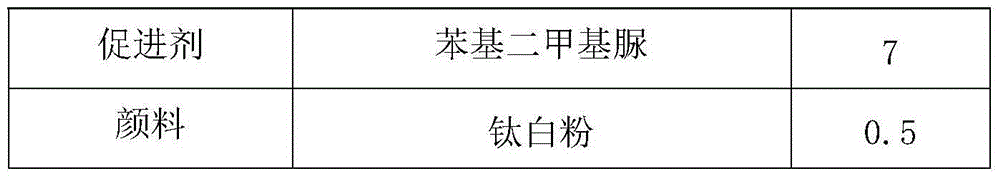

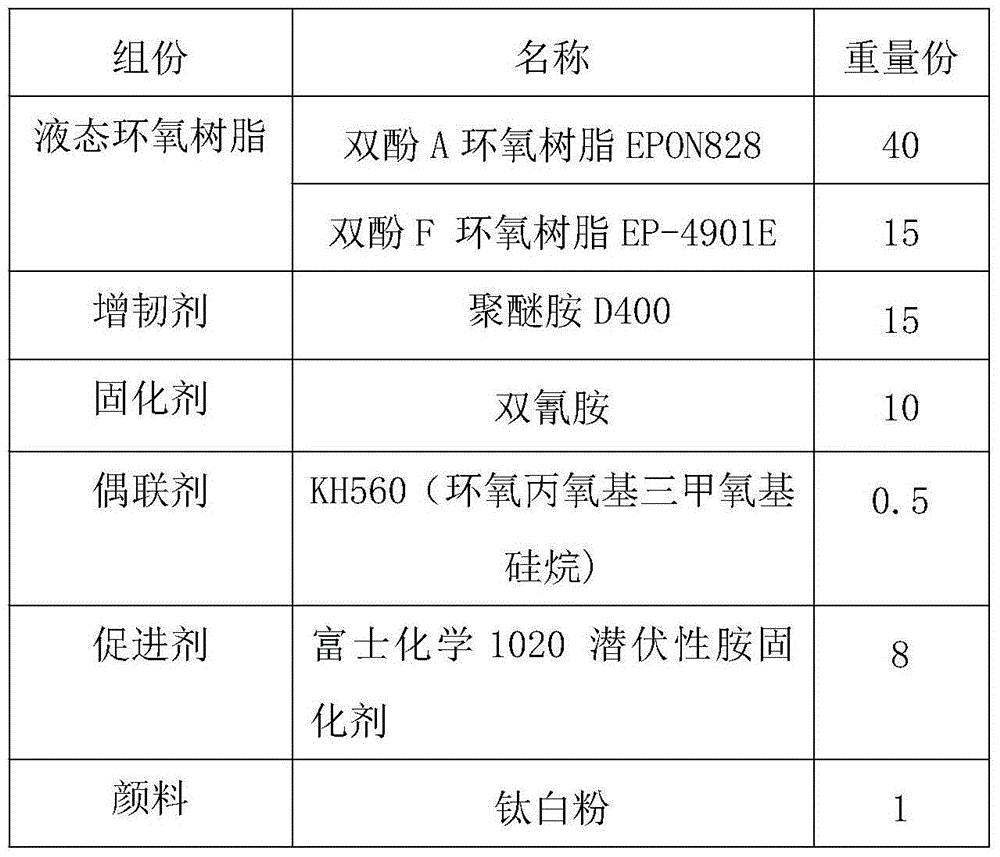

Single-component shock-resistant low-viscosity structural adhesive and preparation method thereof

InactiveCN104087223ALow viscosityImproves flexibility and impact resistanceMacromolecular adhesive additivesEpoxy resin adhesivesPliabilityChemistry

The invention relates to a structural adhesive and particularly relates to a single-component shock-resistant low-viscosity structural adhesive and a preparation method thereof, wherein the single-component shock-resistant low-viscosity structural adhesive is suitable for bonding motors and other structures. The preparation method comprises the following steps of (1) mixing liquid epoxy resin (40-80 parts) and a toughening agent (7-15 parts), and stirring at the temperature of 15-30 DEG C for 1h; (2) adding a curing agent (9-13.5 parts) while stirring, and continuing to stir at the temperature of 15-30 DEG C for 1h until uniformly mixing; (3) adding an accelerant (7-8 parts) while stirring, and continuing to stir at the temperature of 15-30 DEG C for 0.5h until uniformly mixing; and (4) adding a coupling agent (0-0.5 part) and pigment (0-1 part), and stirring at the temperature of 15-30 DEG C for 1h until uniformly mixing. Compared with the prior art, the single-component shock-resistant low-viscosity structural adhesive has the advantages that the toughening agent used by the invention is polyether amine, so that the high adhesive strength and temperature resistance of an epoxy system are remained, the viscosity of the system is reduced, and the flexibility and impact resistance of the adhesive are improved. The single-component shock-resistant low-viscosity structural adhesive is low in viscosity, and the adhesive can be coated on elements which are small in bonding gap and not easy to coat through self-permeation, so that the work efficiency can be greatly increased. A synthesis reaction process is simple, easy to operate and low in cost, and a product is wide in application range.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

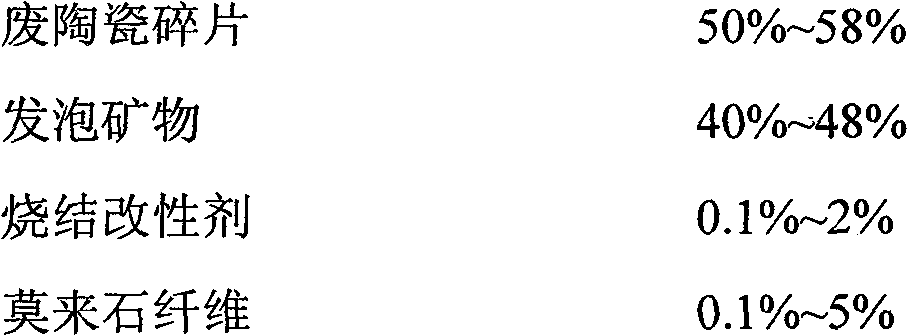

Alumina fiber-reinforced porous ceramic product and method for manufacturing product by using silt

The invention discloses an alumina fiber-reinforced porous ceramic product and a method for manufacturing the product by using silt. The alumina fiber-reinforced porous ceramic product comprises an alumina fiber-reinforced porous ceramic material comprises the following components in percentage by weight: 30 to 38 percent of silt, 20 to 28 percent of slag, 40 to 49 percent of an expansion component and 0.1 to 5 percent of alumina fibers. The preparation method of the material comprises: crushing, mixing and ball milling the silt, slag and expansion component; adding the alumina fibers into the mixture, and continuing stirring; granulating by spraying; and filling fusty sludge in a mold and firing to obtain the light fiber-reinforced porous ceramic product having uniform closed micropores. In the invention, the strength and porosity of the material are improved obviously, the density of the material is lowered, the environment pollution problem of the silt is solved, recycling comprehensive use is realized, and great economic and social benefit is created.

Owner:NANJING UNIV OF SCI & TECH

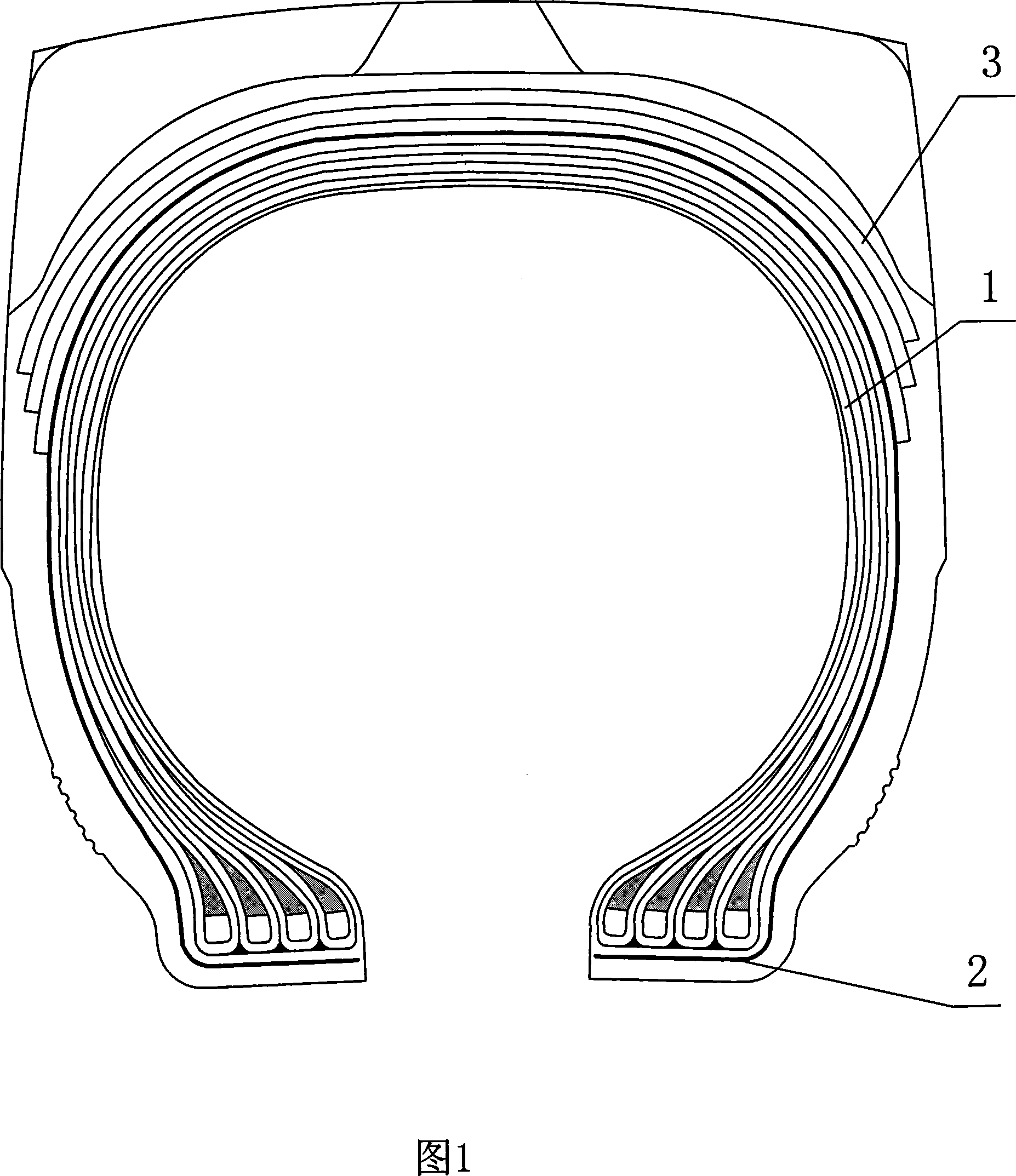

Oblique giant-scale engineering tyre

InactiveCN101229760AImprove puncture resistanceEnhanced tear resistance and other propertiesPneumatic tyre reinforcementsRolling resistanceEngineering

The invention relates to a skew giant engineering tire, which comprises a buffer layer, a matrix cord fabric layer manufactured by a cord fabric cylinder; the matrix cord fabric layer comprises a matrix cord fabric inner layer, a matrix cord fabric middle layer and a matrix cord fabric outer layer; the matrix cord fabric outer layer comprises a matrix cord fabric outer layer wrapped on an obverse side and a matrix cord fabric outer layer with travelers wrapped on a reverse side; the matrix cord fabric outer layer wrapped on the obverse side is provided at least a strengthened layer in which elastic modulus of cord threads is greater than the elastic modulus of the cord threads of the cord fabric cylinder of the cord fabric outer layer of the tire body in which travelers are wrapped on the reverse side and the cord threads of the matrix cord fabric inner layer as well as the cord threads of the matrix cord fabric middle layer; furthermore, at least one layer of the cord thread in the buffer layer is aramid material and the buffer layer is a strengthened buffer layer. The crown of the tire provided by the invention has the capability of prickling resistance and cutting resistance; service life of the tire is greatly prolonged; rolling resistance of the tire is greatly reduced; compared with the present tire adopting nylon materials as the matrix cord threads of the cord fabric outer layer, safe driving distance of the tire can be increased by over 50 percent.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

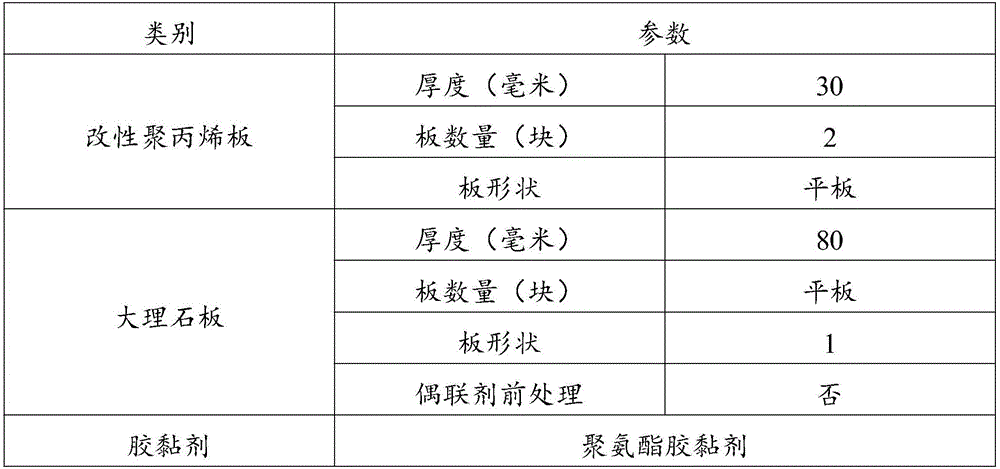

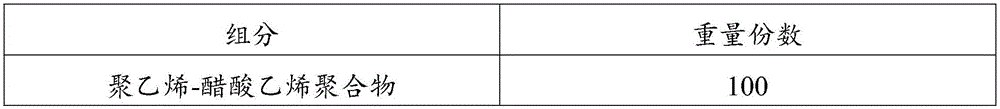

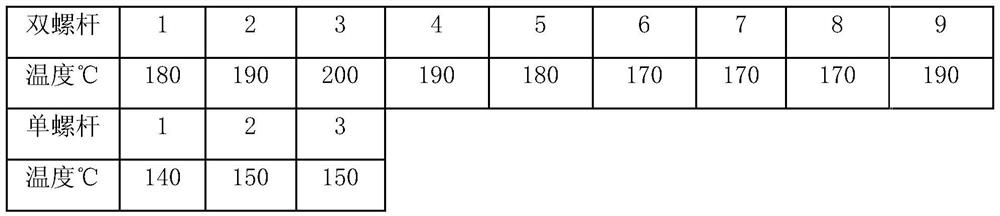

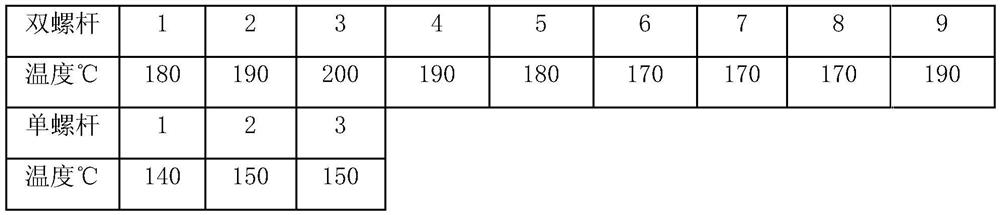

Processing method of marble polypropylene composite slab and composite slab prepared by method

InactiveCN106189036AFlexibleAvoid breakingSynthetic resin layered productsLaminationPolypropylene compositesPolymer science

The invention provides a processing method of a marble polypropylene composite slab. The marble polypropylene composite slab is formed by bonding a marble slab and a modified polypropylene slab through an adhesive. The invention provides two technical schemes, wherein one technical scheme is characterized by using the modified polypropylene slab, and three modifying methods are provided for the polypropylene slab: 1, carrying out grafting copolymerization on polypropylene and maleic anhydride; 2, carrying out melt blending on the polypropylene and a polar polymer; 3, firstly carrying out grafting copolymerization on the polypropylene and the maleic anhydride, and then carrying out melt blending on a grafted copolymer of the polypropylene and the maleic anhydride and the polar polymer; the other technical scheme is characterized by preprocessing the surface of the marble slab by using a coupling agent. The marble polypropylene composite slab prepared by the processing method has the advantages of flexibility, bending performance, difficulty in breaking, recoverability, low cost, light weight, environment protection and corrosion resistance, and can be used under various environments and occasions.

Owner:李贝

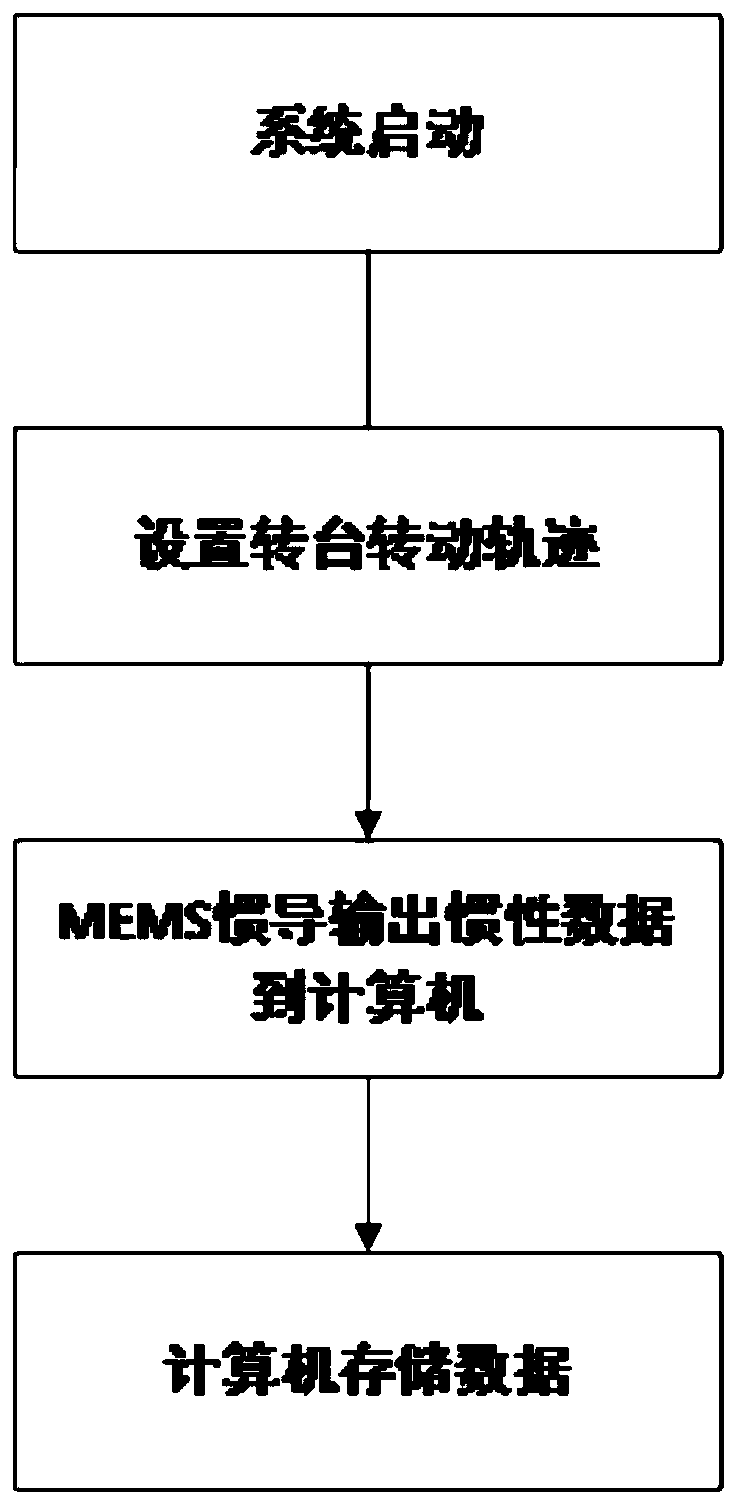

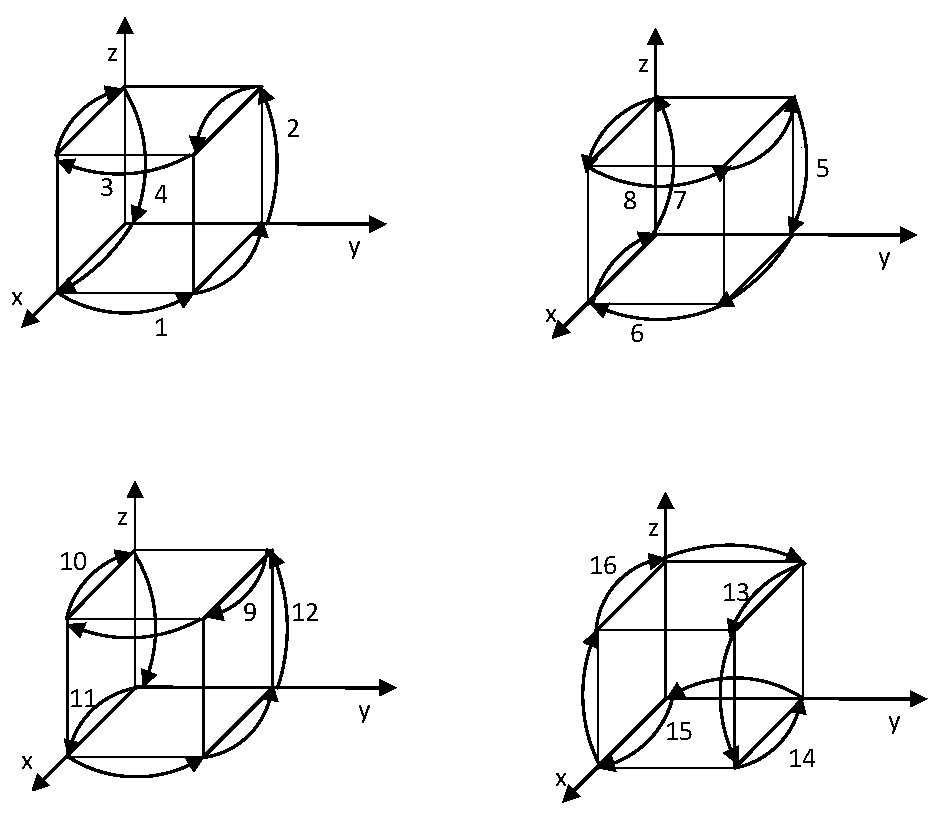

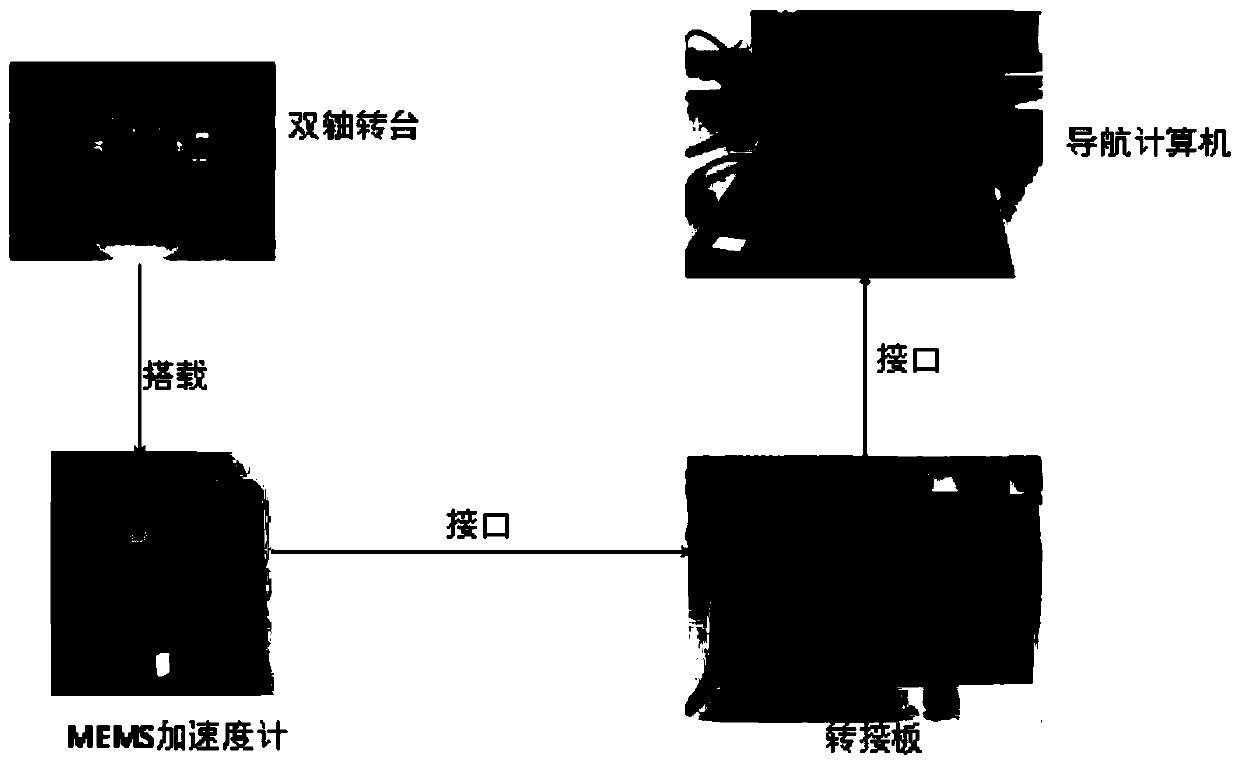

Rotation modulation method of MEMS inertial navigation system

PendingCN111397635AImprove reliabilityCompensation for zero offset errorMeasurement devicesInertial navigation systemMechanical engineering

The invention provides a rotation modulation method of an MEMS inertial navigation system. The rotation modulation method comprises the following steps: step 1, starting the system; step 2, setting arotating track of a turntable; and step 3, mounting the MEMS inertial navigation system on the turntable, acquiring data of a gyroscope and an accelerometer, and acquiring and storing the data by a computer through an adapter plate. In the invention, error modulation of the MEMS inertial navigation system is performed by using a biaxial sixteen-position continuous rotation scheme so that a zero offset error, a scale factor error and a scale factor symmetry error of the MEMES inertial navigation system are compensated.

Owner:HUNAN AIRTOPS INTELLIGENT TECH CO LTD

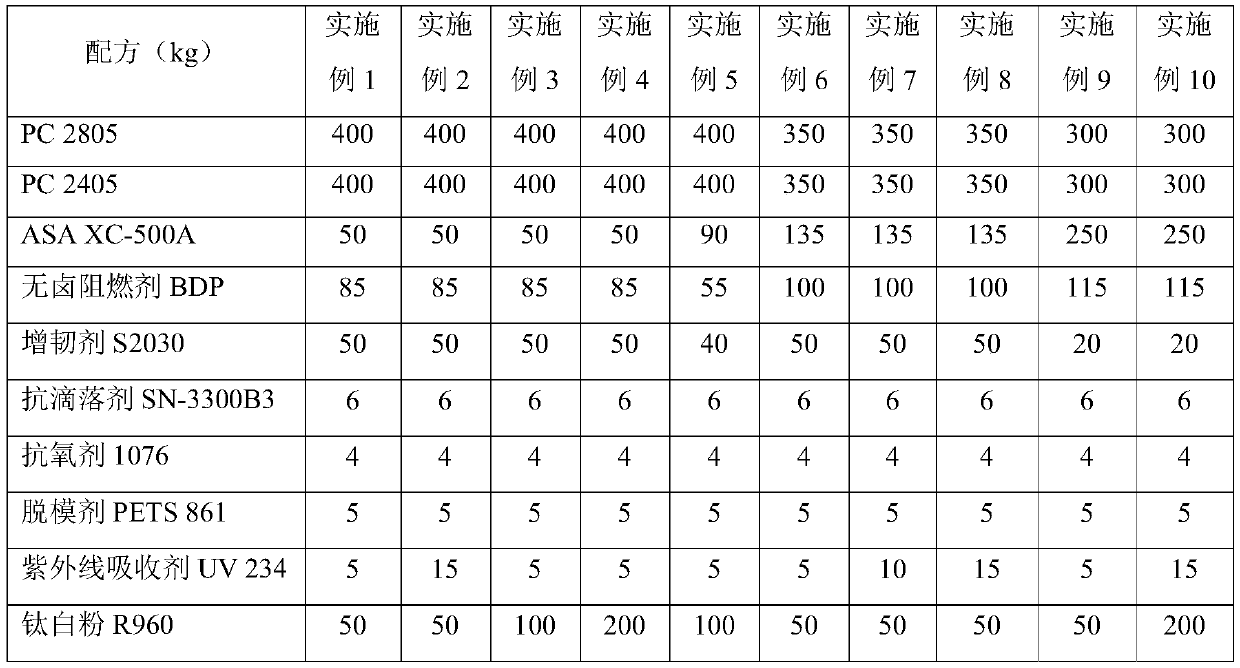

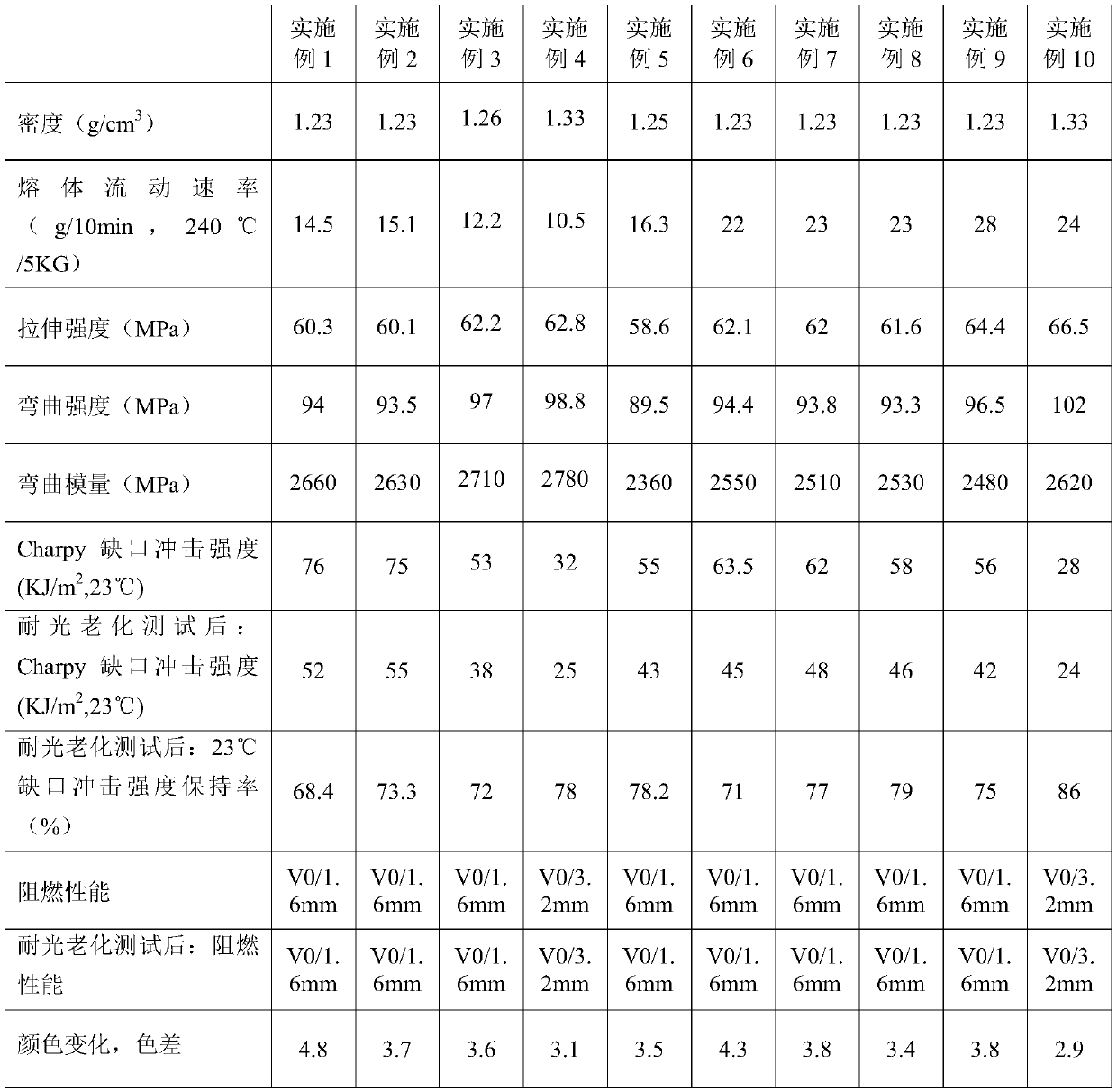

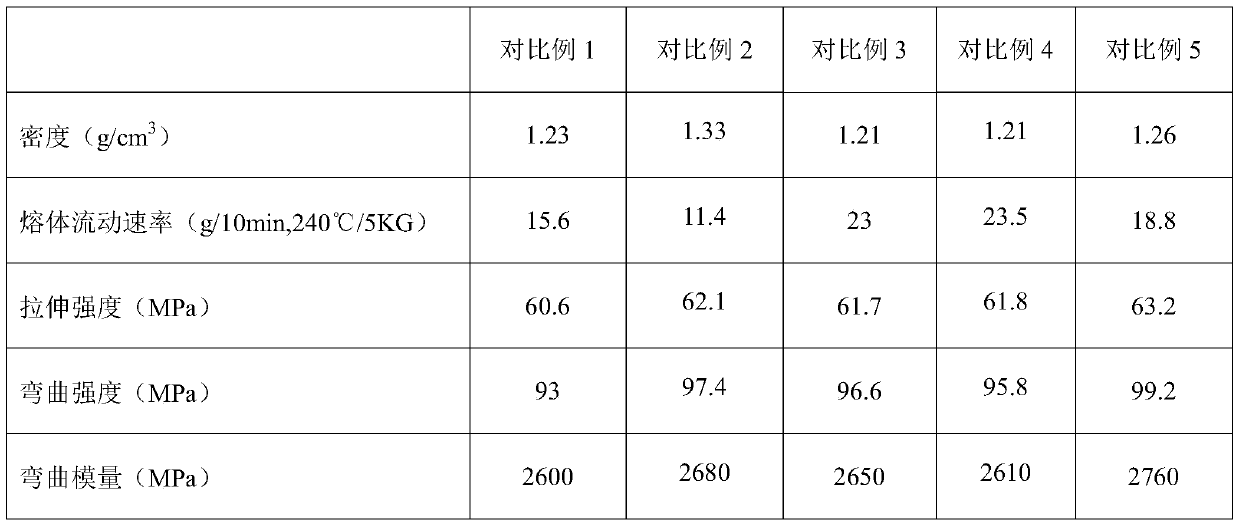

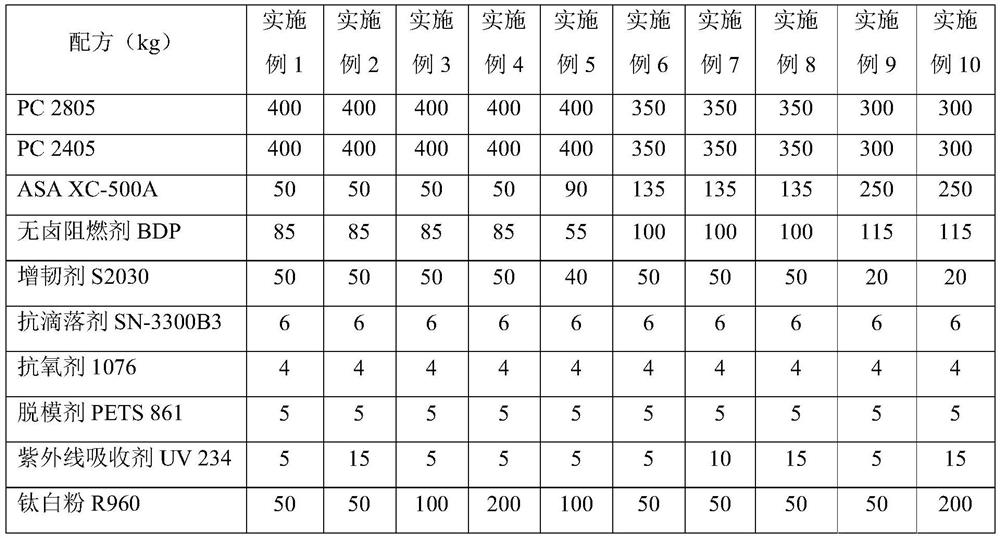

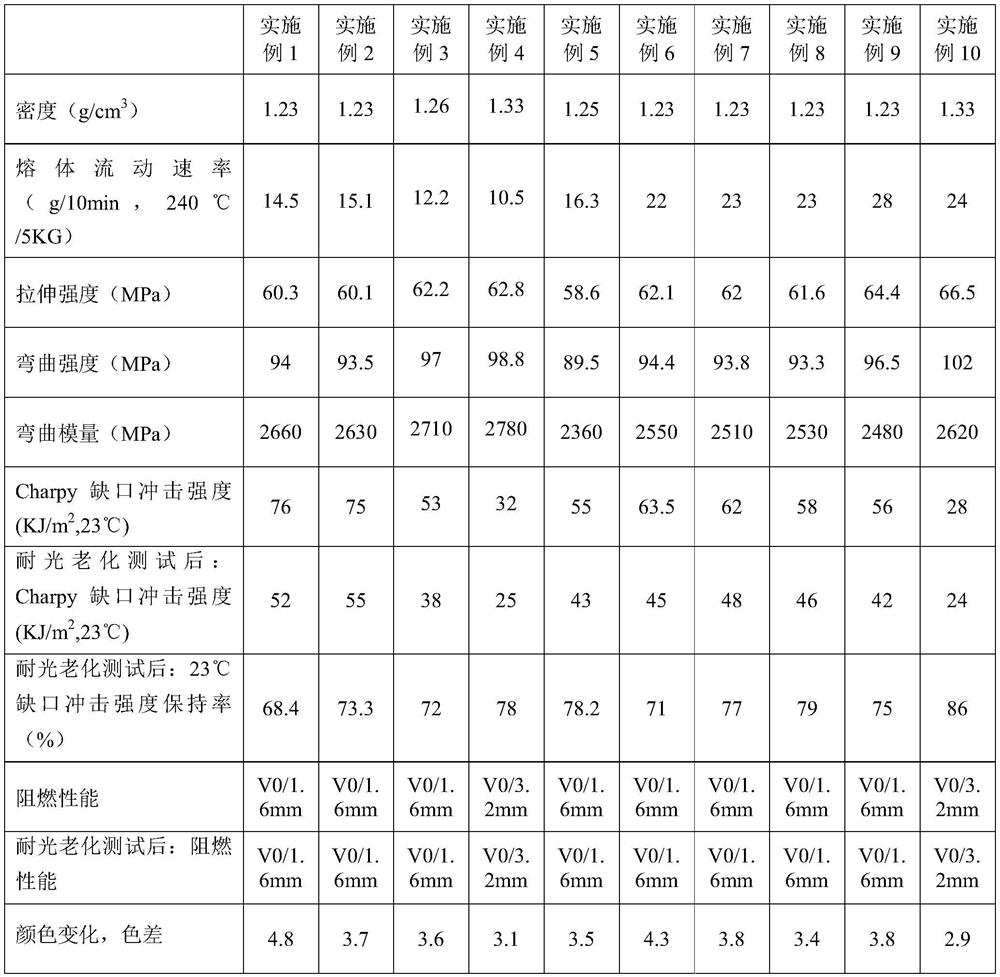

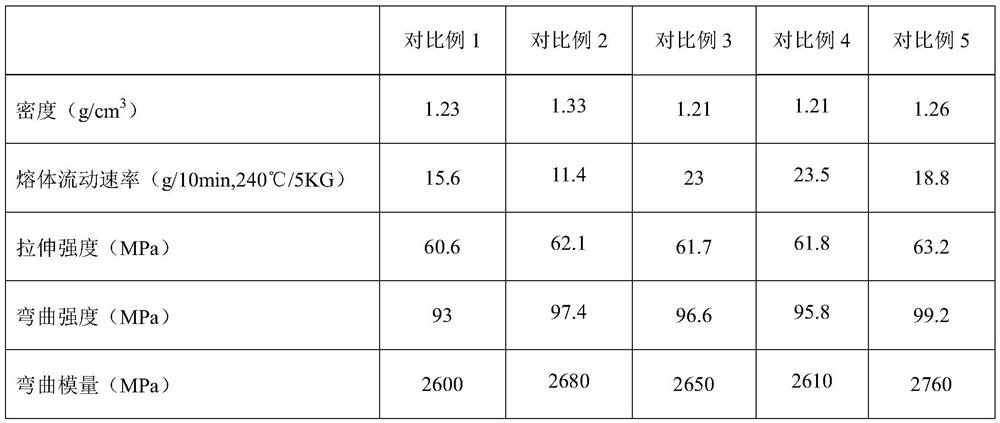

High-weather-resistance light-color halogen-free flame-retardant PC/ASA alloy material and preparation method thereof

The invention discloses a high-weather-resistance light-color halogen-free flame-retardant PC / ASA alloy material. The material is prepared from the following components by weight: 600-800 parts of PC;50-250 parts of ASA; 50-150 parts of a halogen-free flame retardant; 0-50 parts of a toughening agent; 50-200 parts of titanium dioxide; 4-8 parts of a flame-retardant anti-dripping agent; 1-10 partsof an antioxidant; 1-15 parts of a release agent; and 1-20 parts of anti-ultraviolet agent. The mass ratio of the titanium dioxide in the raw materials of the high-weather-resistance light-color halogen-free flame-retardant PC / ASA alloy material is 4.7-17%. The product surface of the high-weather-resistance light-color halogen-free flame-retardant PC / ASA alloy material has a good color retentionrate, the color difference is less than 4 after illumination for 1000 hours, and due to the increase of the content of titanium dioxide, the performance of the material and the appearance of the product can be effectively protected.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

High-performance polyvinyl chloride (PVC) plastic pipe

The invention discloses a high-performance polyvinyl chloride (PVC) plastic pipe. The high-performance PVC plastic pipe is characterized by comprising the following components in parts by weight: 20-30 parts of PVC resin, 10-20 parts of acrylic rubber, 3-4 parts of heat stabilizer, 5-10 parts of triphenyl phosphate, 5-15 parts of stearic acid, 2-6 parts of fire retardant, 10-15 parts of epoxy butyl oleate, and 10-12 parts of paraffin wax. The high-performance PVC plastic pipe prepared by the invention has excellent characteristics of high strength, good super-toughness, high-temperature resistance, impact resistance and corrosion resistance, and relative low cost; the vicat softening temperature can be up to over 120 DEG C; the problems of low temperature brittleness, impact resistance and the like of the traditional polyvinyl chloride pipe are solved.

Owner:QINGDAO HUARUI RUBBER IND EQUIP

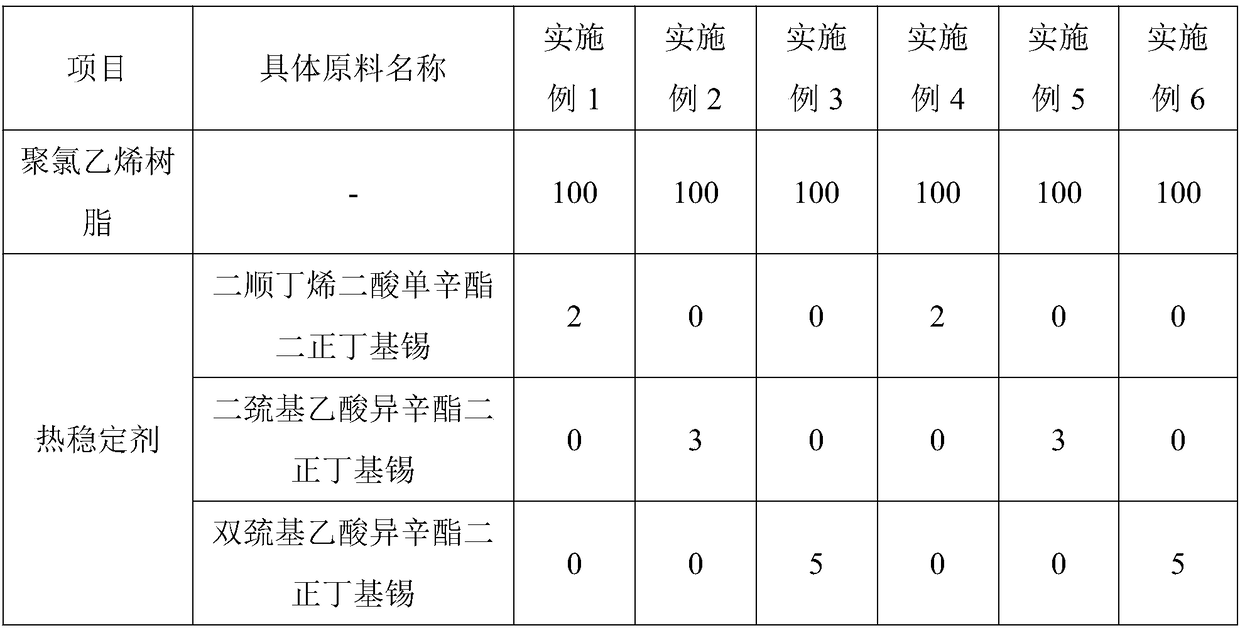

High-impact and high-fluidity polyvinyl chloride material and preparation method thereof

InactiveCN108084609ATo achieve toughening effectLarge specific surface areaPolyvinyl chlorideElectroplating

The invention discloses a high-impact and high-flow polyvinyl chloride material and preparation method thereof. The material has good high-low temperature impact resistance and excellent processing fluidity, and is a composite material which takes the polyvinyl ethylene as the base material and is blended and modified. The material is specifically prepared from the following components in parts byweight: 100 parts of polyvinyl chloride resin, 2-5 parts of heat stabilizer, 1-3 parts of lubricant, 0.5-2.5 parts of processing auxiliary, and 5-20 parts of composite impact modifier. The polyvinylchloride modified material provided by the invention can be used for preparing various pieces through an injection molding way, the traditional ABS material with expensive price is replaced, and the polyvinyl chloride material can be used for wine external package and decorative materials with an electroplating demand.

Owner:宜宾天亿新材料科技有限公司

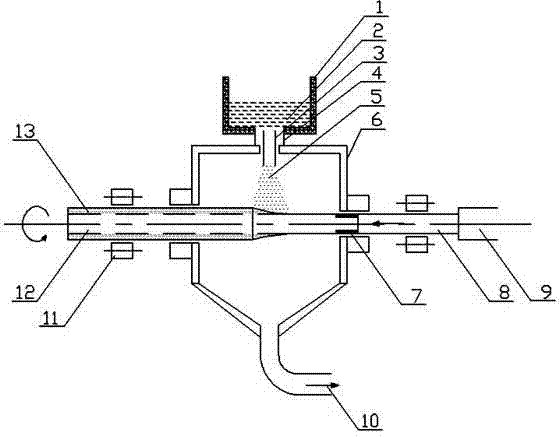

Steel-aluminum composite hydraulic prop and manufacturing method and device thereof

InactiveCN104707963ASimple structureSimple processProps/chocksMedium frequencyVolumetric Mass Density

The invention discloses a method for manufacturing a steel-aluminum composite hydraulic prop and belongs to the technical field of hydraulic props. The method comprises the steps of 1, smelting a spraying layer material; 2, conducting core blank surface pretreatment; 3, conducting spray deposition; 4, obtaining a sample. The invention further discloses a device for manufacturing a steel-aluminum composite hydraulic prop. The device comprises a medium-frequency induction furnace, wherein a deposition chamber is arranged below the medium-frequency induction furnace, a liquid guiding pipe communicated with the deposition chamber is arranged on the bottom of the medium-frequency induction furnace and located in an atomizer, and the atomizer is arranged between the medium-frequency induction furnace and the deposition chamber. The invention further discloses a steel-aluminum composite hydraulic prop manufactured with the method and device. The steel-aluminum composite hydraulic prop has the advantages of being low in overall density, high in specific strength, resistant to shock and high in abrasion resistance and corrosion resistance. The device for manufacturing the steel-aluminum composite hydraulic prop is simple in structure and easy to use and popularize. The method for manufacturing the steel-aluminum composite hydraulic prop is simple.

Owner:JIANGSU SHUNDA MACHINERY EQUIP

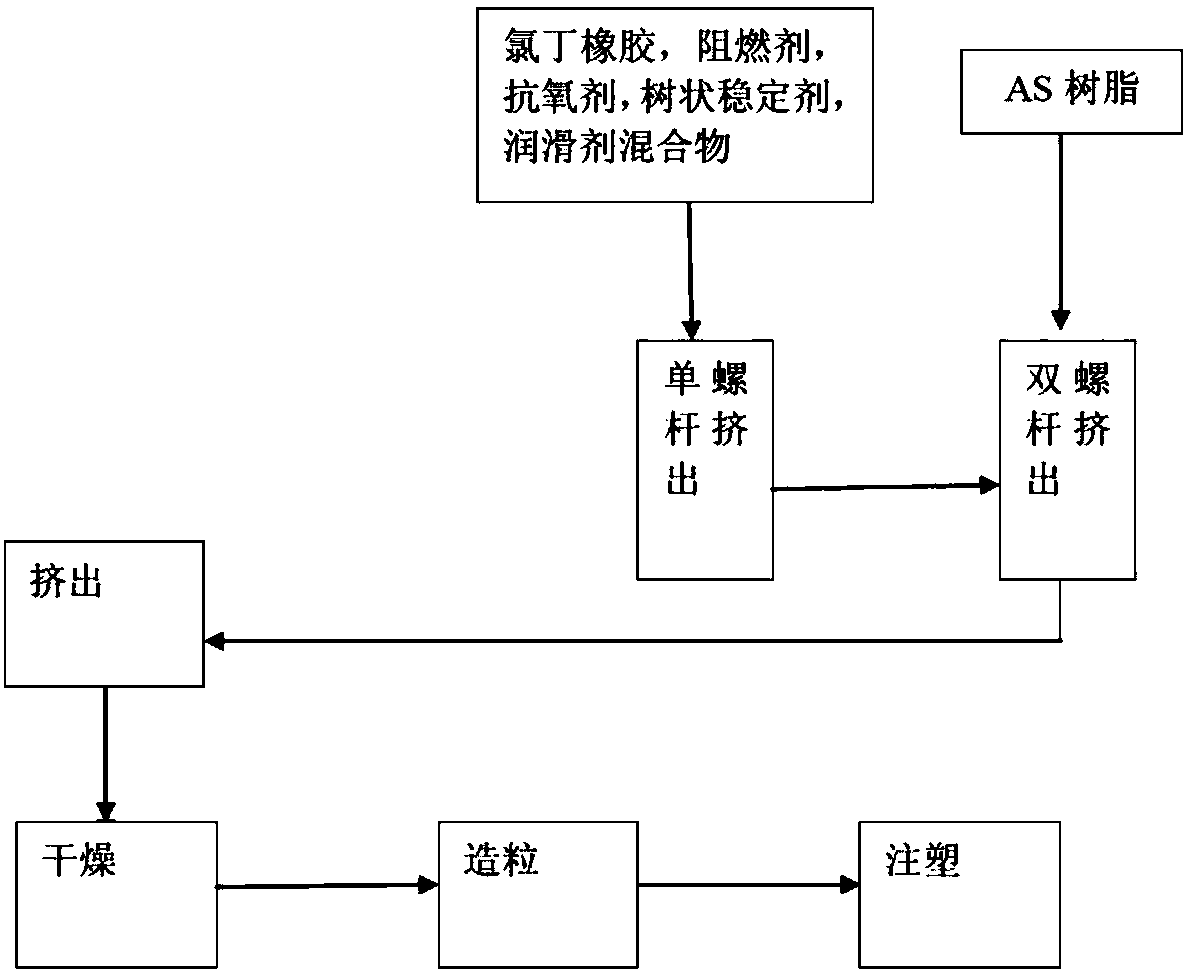

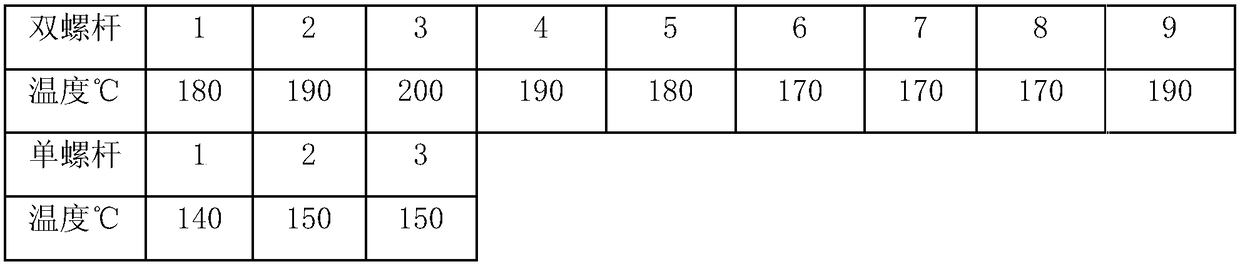

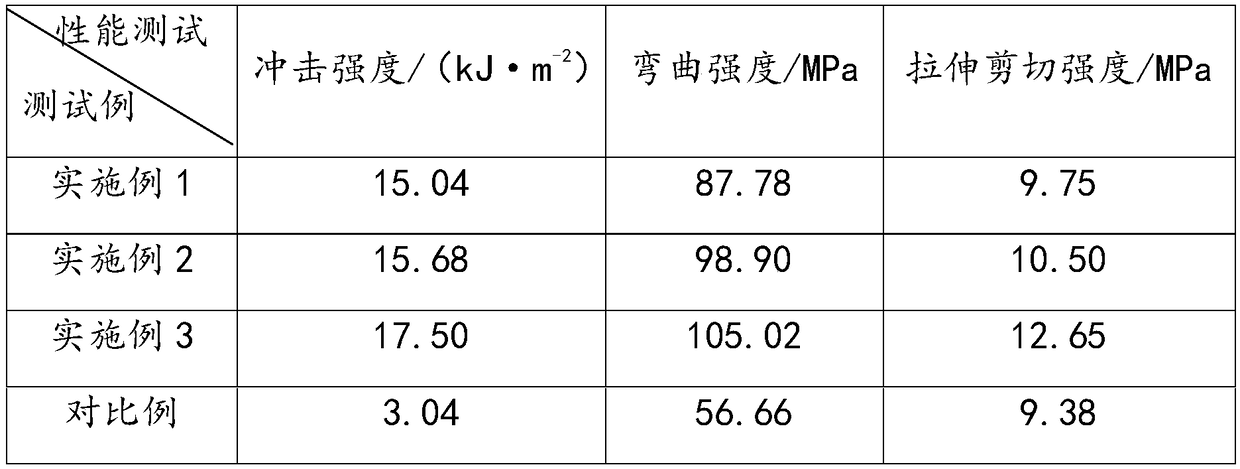

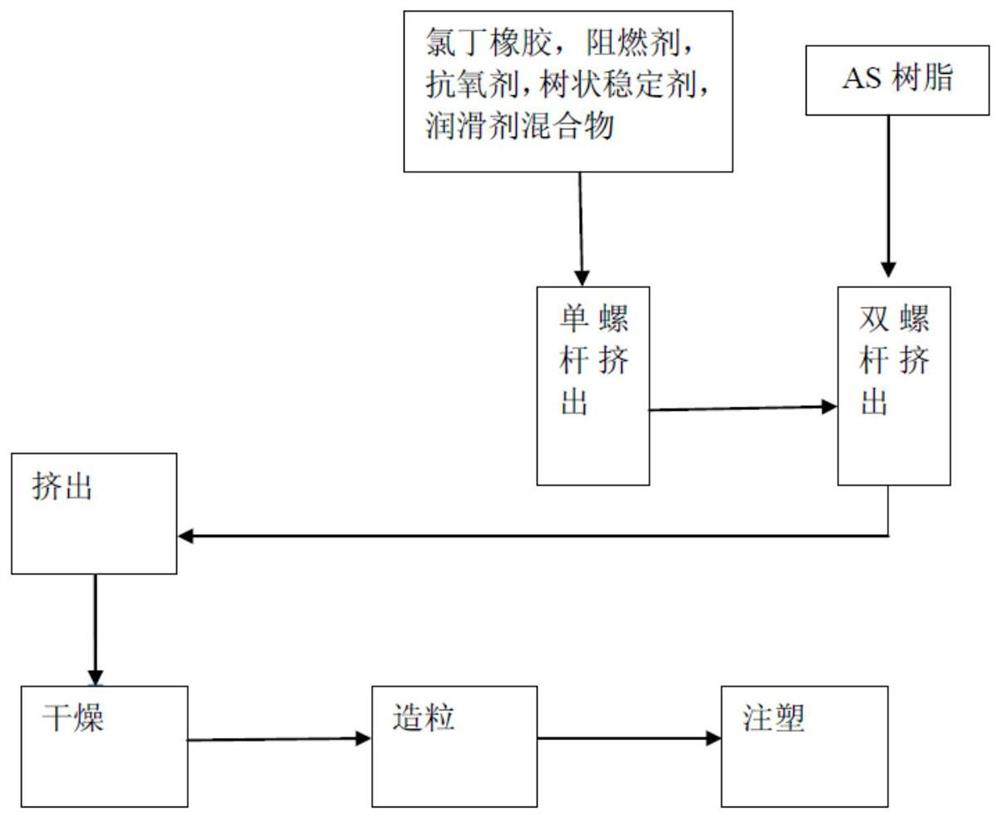

Environment-friendly, flame-retardant and injection-molding-grade ACS modified material

ActiveCN108530789ALow impact resistancePlay the role of anti-aging decompositionDecompositionPolyvinyl chloride

The invention relates to an environment-friendly, flame-retardant and injection-molding-grade ACS modified material. The environment-friendly, flame-retardant and injection-molding-grade ACS modifiedmaterial comprises, by weight, 45-65 parts of acrylonitrile-styrene copolymer, 15-35 parts of neoprene, 8-12 parts of brominated flame retardant, 3-5 parts of antimonic flame retardant, 0.2-1 part oflubricant, 0.1-1 part of antioxidant, 1-3 parts of environment-friendly compound special stabilizer and 3-6 parts of toughening agent, wherein the environment-friendly compound special stabilizer is prepared by calcium stearate, zinc stearate, magnesium hydroxide, hydrotalcite and an anti-aging agent according to the mass ratio of (35-45):(35-45):(6-12):(3-8):(3-8). The environment-friendly, flame-retardant and injection-molding-grade ACS modified material has the advantages that by using the neoprene to replace polyvinyl chloride, flame retardance is achieved while a toughening effect is achieved; the environment-friendly compound special stabilizer can meet REAH and RoHS environment protection requirements and are quite good in thermal stability, less prone to decomposition and applicable to injection molding.

Owner:青岛海纳新材料有限公司

Mullite fiber reinforced porous ceramic product and method for preparing mullite fiber reinforced porous ceramic product from waste ceramics

InactiveCN101955372BImprove mechanical propertiesIncreased durabilitySolid waste disposalCeramicwareFiberSocial benefits

Owner:NANJING UNIV OF SCI & TECH

A UV-heat dual curing optical adhesive containing epoxidized polybutadiene resin

ActiveCN104449419BImprove bindingUniform responseOrganic non-macromolecular adhesivePolyolefinAdhesive

Owner:信泰永合(烟台)新材料有限公司

High-strength steel plate material used for automobile loading part

The invention discloses a high-strength steel plate material used for an automobile loading part. Elements of the high-strength steel plate material include, by weight percent, 0.6%-0.8% of carbon, 0.9%-1.3% of silicon, 0.2%-0.4% of nickel, 2.4%-3.5% of manganese, 0.06%-0.08% of iridium, 0.1%-0.2% of aluminum, 0.04%-0.05% of zirconium, 0.2%-0.3% of copper, 0.6%-1.2% of magnesium, smaller than or equal to 0.015% of sulfur, smaller than or equal to 0.015% of phosphorus and the balance iron and inevitable impurities. By means of the high-strength steel plate material used for the automobile loading part, the casting quality of a casting is good, the yield is high, the casting cost is low, the shock-resistance bearing capability is good, and the high-strength steel plate material is high in safety when used as the automobile loading part and is worthy of being popularized.

Owner:ANHUI HEKUANG MACHINERY

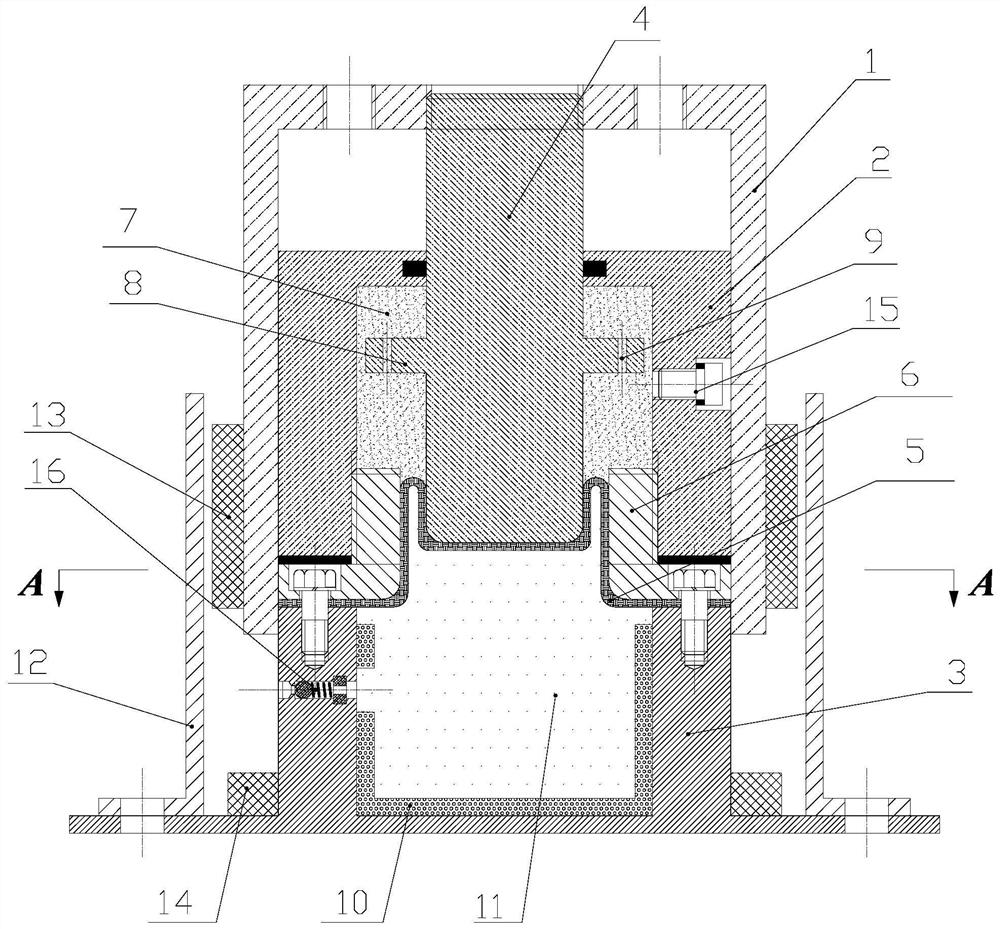

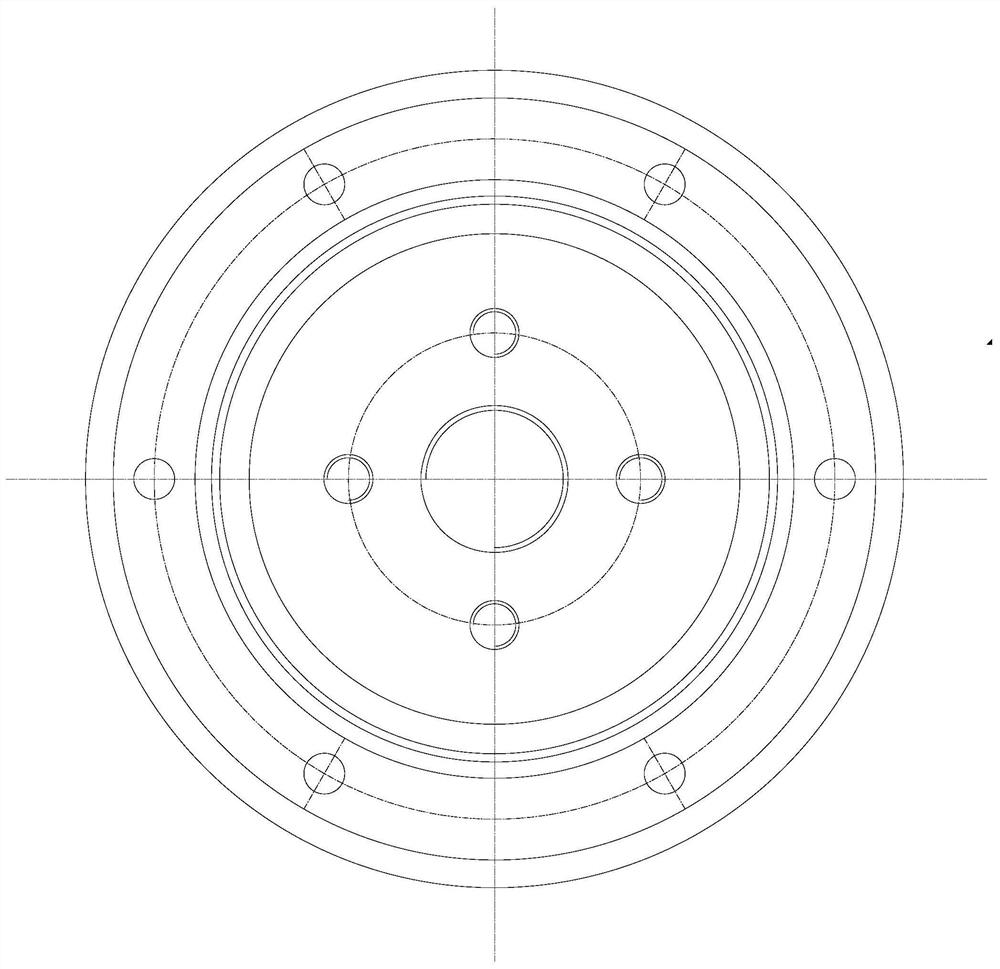

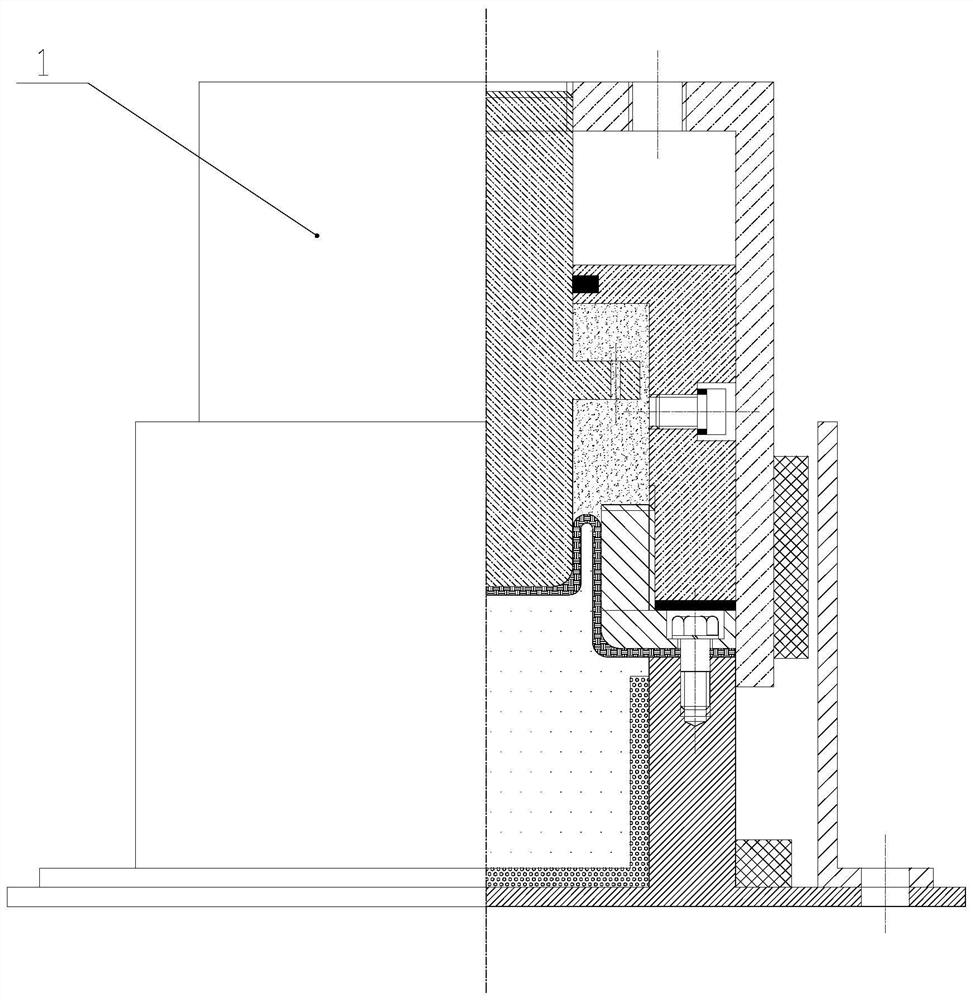

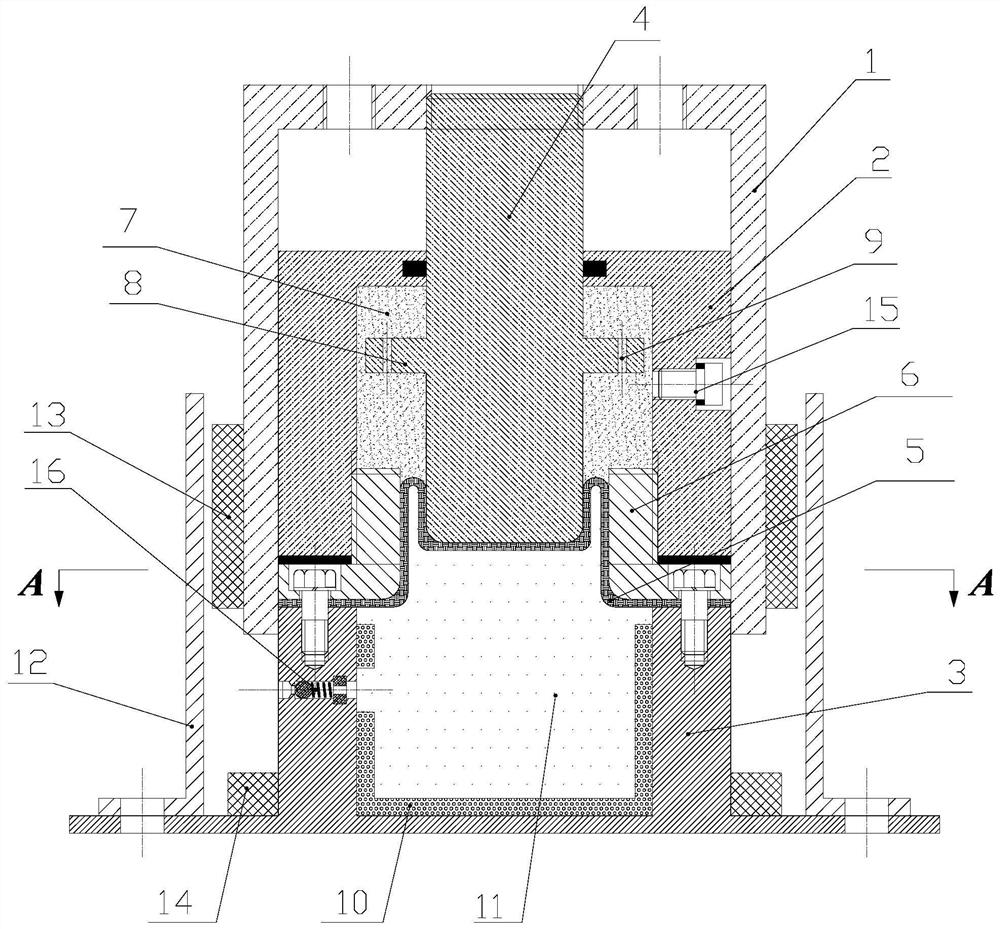

Two-stage vibration isolation buffer

ActiveCN112253665AHigh static stiffnessLow dynamic stiffnessLiquid springsSolid based dampersCylinder blockControl theory

The invention discloses a two-stage vibration isolation buffer, and belongs to the technical field of vibration isolation buffers. The problems that an existing vibration isolation buffer is low in energy conversion rate and longitudinal impact resistance are solved. The lower portion of a connecting end cover is arranged between two cylinder bodies and fixedly connected with the second-stage cylinder body, the upper portion of the connecting end cover is inserted into the first-stage cylinder body and fixedly connected with the inner wall of the first-stage cylinder body, a piston is arrangedin the first-stage cylinder body in an up-down sliding mode, and the upper portion of the piston penetrates through the first-stage cylinder body and is fixedly connected with a guide cylinder; and acomposite membrane is fixedly clamped between the connecting end cover and the second-stage cylinder body and attached to the inner wall of the connecting end cover, the upper surface of the middle of the composite membrane is attached to the bottom of the piston, and the composite membrane, the connecting end cover and the first-stage cylinder body form a closed first-stage cavity. Two closed cavities which are isolated from each other are formed, energy consumption and energy storage are achieved at the same time, and on the basis of a molecular spring, the problem that low inherent frequency and small static deformation cannot be achieved at the same time under heavy loads is solved in combination with the working principle of the energy consumption type vibration isolation buffer.

Owner:HARBIN ENG UNIV

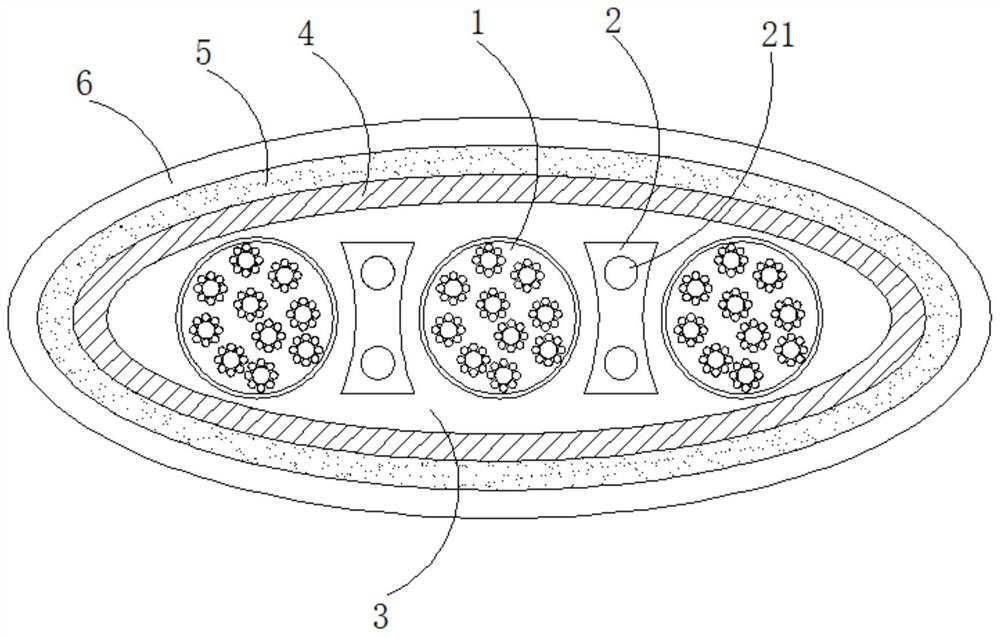

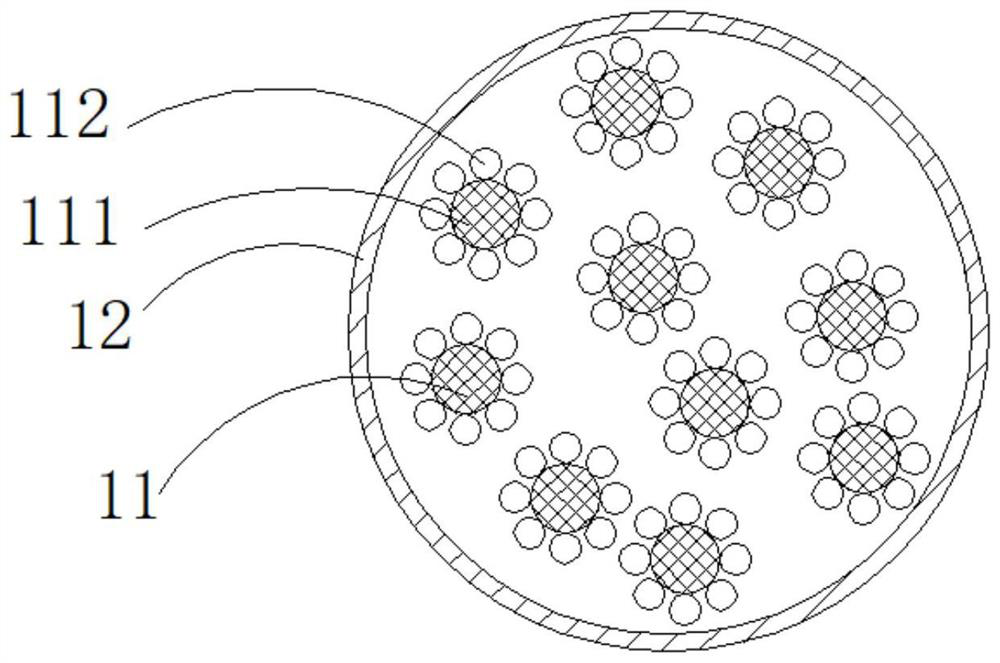

Low-creep, fatigue-resistant, bending-resistant and stretching-resistant reel flat cable

PendingCN112466519AImprove tensile propertiesGood flexibilityRubber insulatorsNon-insulated conductorsTinningElectrical conductor

The invention discloses a low-creep, fatigue-resistant, bending-resistant and stretching-resistant reel flat cable, and the cable comprises a wire core, an insulating buffer block, a filler, a cord fabric layer, a nylon pipe belt layer and a sheath; the wire core comprises a conductor and an insulating layer wrapping the conductor, and the conductor is formed by twisting an aramid fiber wire reinforcer and a plurality of strands of tinned copper wires; an insulating buffer block is arranged between the wire cores, the wire cores and the insulating buffer block are provided with a filling material, the filling material wraps a cord fabric layer, the cord fabric layer is wrapped by a nylon pipe belt layer, and the nylon pipe belt layer extrudes a sheath. According to the winding drum flat cable, the conductor structure, the insulating layer, the buffer piece and the sheath are improved; and the cable has the characteristics of low creep, fatigue resistance, bending resistance and impactresistance.

Owner:湖南华菱线缆股份有限公司

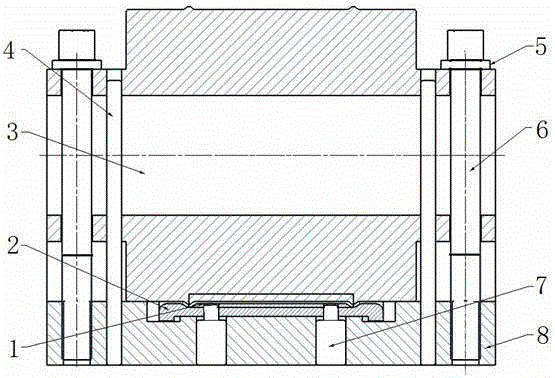

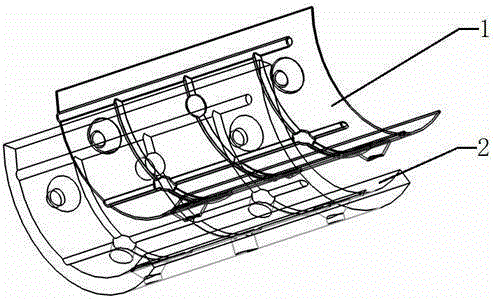

Material, device and method for steel back/carbon fiber knitted fabric self-lubricating lining bearing

InactiveCN103410863BImprove carrying capacityImprove impact resistanceCarbon fibresBearing componentsCopperPolymer

The invention relates to a half-bearing, a material, a device and a method for a steel backing / carbon fiber knitted fabric self-lubricating lining. According to the invention, the half-bearing for the steel backing lining is made by arranging a polymer self-lubricating composite material lining (1) reinforced by a layer of knit carbon fiber on the inner surface of the steel backing (2); the half-bearing lining material adopts epoxy resin as substrate and carbon fiber knitted fabric as a reinforced body, short carbon fiber is added as a secondary reinforced body, and various modification, filling and self-lubricating ingredients are added. Carbon fiber knitted fabric is used as the reinforced body for the half-bearing to increase the shear strength, the impact strength and the compression strength of the lining material; the advantages of high bearing capacity, good impact resistance, low friction coefficient, good dynamic performance and wear resistance are obtained; the mold pressing forming technology is simplified, and the operation difficulty is reduced; steel is used to replace copper to save expensive metal; lead is not used, so that the environment is protected; the inner surface of the half-bearing is made through net shape forming, so that the geometric dimension is high in stability; the recycling and reusing are convenient.

Owner:GUANGDONG UNIV OF TECH +1

Multi-element composite strengthened alloy semisteel sizing/reducing machine roller and preparation method thereof

The invention provides a multi-element composite strengthened alloy semisteel sizing / reducing machine roller and a preparation method thereof, and discloses a multi-element composite strengthened alloy semisteel roller used for a hot-rolled seamless steel pipe sizing or reducing machine. The rolleris made of a multi-element composite alloy and composite strengthened particles. Strengthening and compounding of the multi-element alloy are carried out in the smelting process, multiple elements, the composite strengthened particles and the like are evenly mixed together according to the design proportion so as to be rapidly molten in molten liquid, and the mixture and the molten liquid are fully and evenly molten to achieve strengthening and compounding. By means of the roller, consumption ofprecious metal of Ni, Mo and the like can be reduced, the performance advantages of wear resisting, corrosion resisting, invasion deformation resisting, machining and the like under high-temperature chilling are achieved, after using, the surface of the roller is bright, the service life is 1.5 times or above that of a high nickel and molybdenum alloy ductile iron steel pipe roller, the service performance is excellent, and materials are saved.

Owner:山东四方工模具材料研究院有限公司

High weather resistance light color halogen-free flame retardant pc/asa alloy material and preparation method thereof

The invention discloses a highly weather-resistant light-colored halogen-free flame-retardant PC / ASA alloy material, which is made of the following components in parts by weight: 600-800 parts of PC; 50-250 parts of ASA; 50-150 parts of halogen-free flame-retardant 0-50 parts of toughening agent; 50-200 parts of titanium dioxide; 4-8 parts of flame retardant and anti-dripping agent; 1-10 parts of antioxidant; 1-15 parts of mold release agent; UV agent. The mass ratio of the titanium dioxide in the raw material of the highly weather-resistant light-colored halogen-free flame-retardant PC / ASA alloy material is 4.7-17%. The product surface of the high weather resistance light-color halogen-free flame-retardant PC / ASA alloy material of the present invention has a good color retention rate. After 1000 hours of light, the color difference is less than 4. Due to the increase in the content of titanium dioxide, the performance of the material and the appearance of the product can be effectively protected. .

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

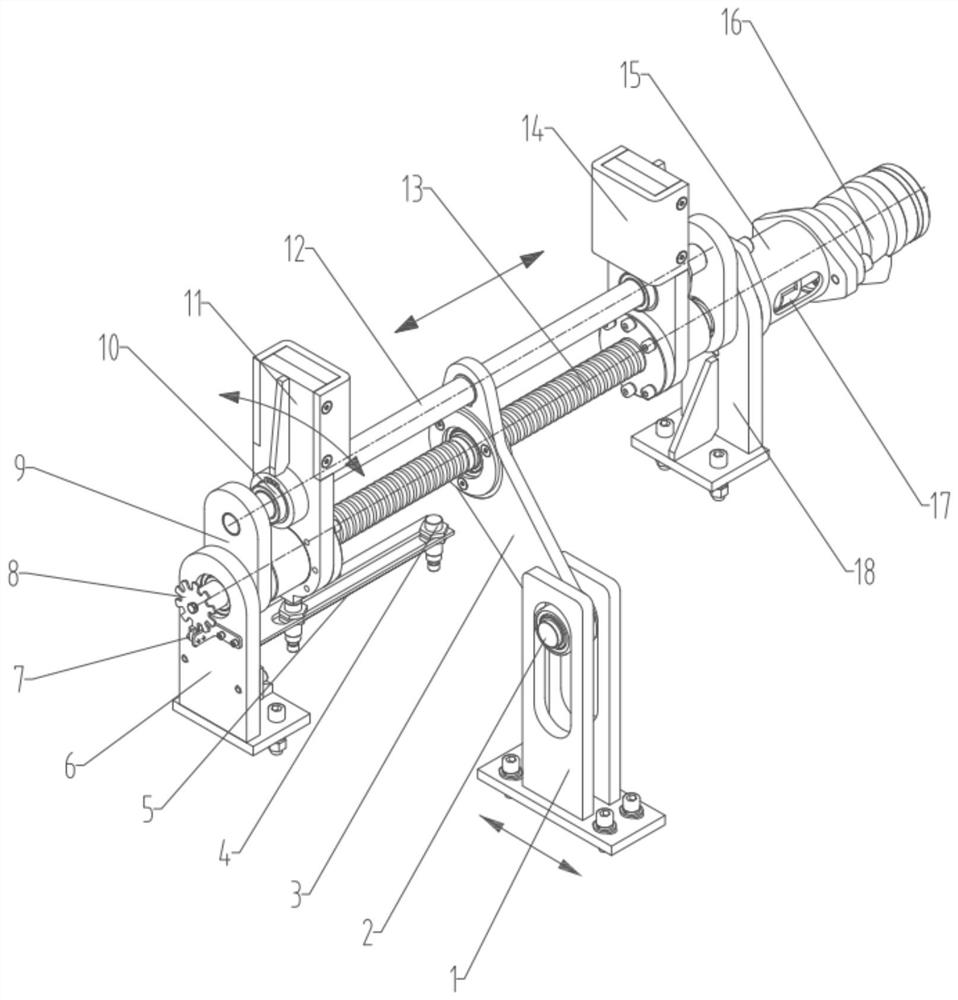

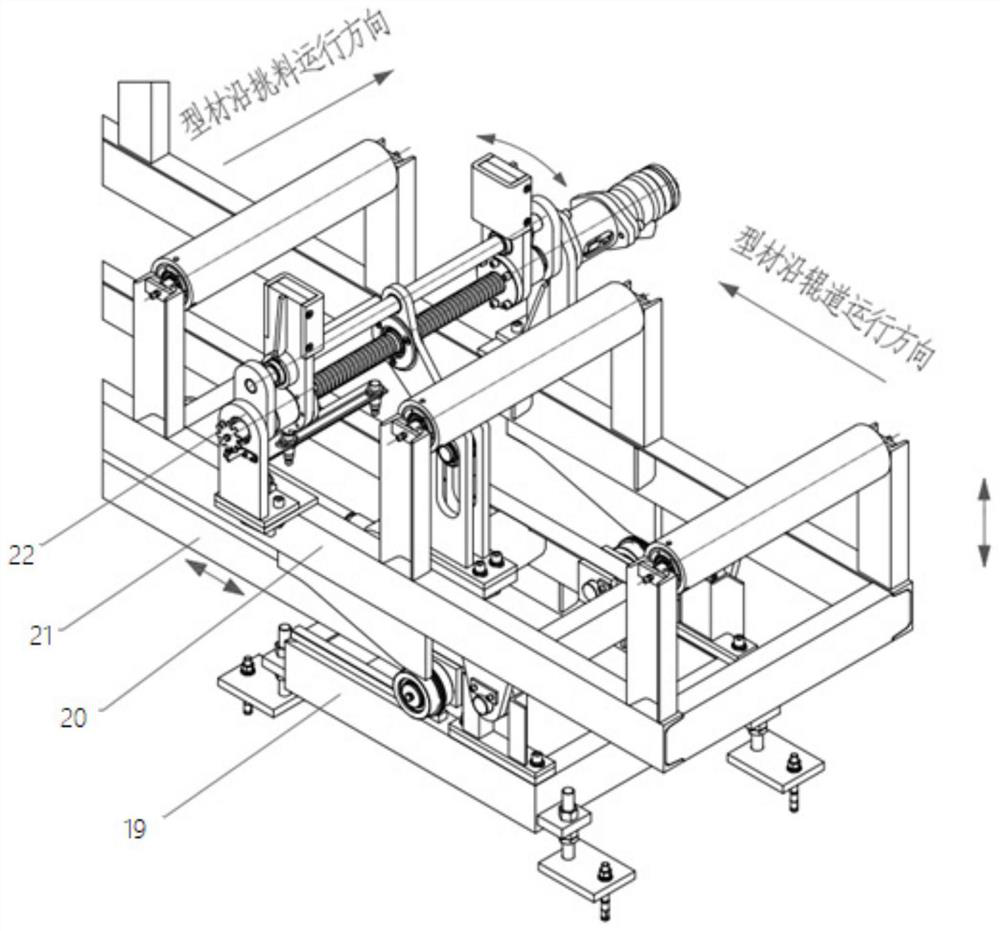

Multifunctional material clamping device assisting in discharging

PendingCN114101365AEliminate the disadvantages of service lifeLow costProcess equipmentAutomatic control

The invention relates to a multifunctional clamping device assisting in discharging, and belongs to the field of aluminum profile backward extrusion production lines. The device mainly comprises a guide seat, a crank arm, a ball screw pair, a guide optical axis, a hydraulic motor, a first bearing seat, a second bearing seat, a swing arm and a clamping plate. According to the device, the production process of discharging of the traction machine in the backward extrusion production process of aluminum profiles is improved, the defect that the service life of a material gathering felt belt of a discharging roller way is shortened in the original process is overcome, the success rate of the discharging action of the traction machine is guaranteed, the time of shutdown for troubleshooting due to unsuccessful discharging of the traction machine is greatly shortened, and the production efficiency is improved. The material clamping device is simple in structure and low in cost, has the function of detecting the width of the aluminum profile, can provide important original parameters for other finishing process equipment of the aluminum profile backward extrusion production line, and facilitates automatic control of other parts of equipment.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

Preparation method of composite material for manufacturing impact-resistant components of unmanned aerial vehicles

The invention discloses a preparation method of a composite material for manufacturing impact-resistant components of unmanned aerial vehicles. The composite material for manufacturing the impact-resistant components of the unmanned aerial vehicles is an epoxy resin composite material, and the specific preparation method comprises the following steps: firstly, uniformly mixing and stirring epoxy resin and liquid polysulfide rubber in weight ratio of 100:(5-15) to obtain toughened epoxy resin; and then adding the toughened epoxy resin as a matrix and carbon fiber reinforcement proportionally into an extruding machine and performing extrusion granulating to obtain the epoxy resin composite material. The liquid polysulfide rubber used as a toughening agent of the epoxy resin has good molecular flexibility and low solubility in the epoxy resin, and forms relatively more island phases, thereby inducing smaller influence on mechanical properties of the epoxy resin; and therefore, under an impact, a liquid polysulfide rubber toughened epoxy resin adhesive exhibits higher impact strength, and is suitable for manufacturing the impact-resistant components of the unmanned aerial vehicles.

Owner:ANHUI YUNYI AVIATION TECH CO LTD

Super-tough and super-flexible high-temperature-resistance polyvinyl chloride pipe and manufacturing technology thereof

InactiveCN103304914BSuper strong and super toughSuper toughRigid pipesChlorinated polyvinyl chloridePlasticizer

The invention relates to the technical field of plastic pipes, and in particular relates to a super-tough and super-flexible high-temperature-resistance polyvinyl chloride pipe and a manufacturing technology thereof. The super-tough and super-flexible high-temperature-resistance polyvinyl chloride pipe comprises the following components in parts by weight: 50-65 parts of polyvinyl chloride, 25-38 parts of chlorinated polyvinyl chloride, 12-18 parts of shock resistance agent, 4-10 parts of filler, 3-8 parts of stabilizing agent, 2-5 parts of plasticizer, 0.1-0.6 part of external lubricating agent, 0.1-0.6 part of internal lubricating agent and 3-7 parts of modifying agent. The pipe has the advantages of high intensity, high super-flexibility, high-temperature resistance, shock resistance, corrosion resistance and lower cost and can meet a construction requirement on an electronic pipe.

Owner:杭州联通管业有限公司

Environmentally friendly flame retardant injection molding grade ACS modified material and preparation method thereof

ActiveCN108530789BLow impact resistancePlay the role of anti-aging decompositionPolyvinyl chlorideAcrylonitrile

The invention relates to an environmentally friendly flame-retardant injection molding grade ACS modified material, which comprises the following raw material components in parts by weight: 45-65 parts of acrylonitrile-styrene copolymer; 15-35 parts of chloroprene rubber; brominated flame-retardant 8-12 parts of antimony flame retardant; 3-5 parts of antimony flame retardant; 0.2-1 part of lubricant; 0.1-1 part of antioxidant; 1-3 parts of environmentally friendly composite stabilizer; 3-6 parts of toughening agent Described environment-friendly composite special stabilizer is (35-45) according to mass ratio by calcium stearate, zinc stearate, magnesium hydroxide, hydrotalcite, antioxidant: (35-45): (6-12 ): (3-8): (3-8) ratio composition. The above-mentioned ACS modified material uses chloroprene rubber instead of polyvinyl chloride, which not only plays a role in flame retardancy, but also plays a role in toughening. The use of environmentally friendly compound special stabilizers not only meets the environmental protection requirements of REAH and RoHS, but also has very good performance. Excellent heat stabilization effect, not easy to decompose, can be used for injection molding.

Owner:青岛海纳新材料有限公司

A kind of preparation method of the functional paste of sheet type electrostatic suppressor

ActiveCN104464992BImprove performanceLower the trigger voltageResistor manufactureOvervoltage protection resistorsGranularitySuppressor

The invention discloses a preparation method of a functional slurry for a sheet-type electrostatic suppressor, which comprises the following steps: ① mixing the following compounds according to the mass component ratio: 30-40 lead oxide, 30-45 aluminum oxide, 30-45 aluminum dioxide Silicon 4-6, diboron trioxide 15-25, zinc oxide 2-6; ② Ball mill the mixture and dry it at 100°C; ③ The dried raw material is heated to 1200°C for 3 hours and kept for 1 hour, then naturally cooled ; ④ Vibrate and ball mill the ceramic material obtained from the reaction to obtain ceramic powder, and test the particle size and specific surface area; into slurry. The functional slurry developed by the invention can be applied to a chip-type electrostatic suppressor, and can withstand more than 1000 times of 8KV electrostatic shock.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

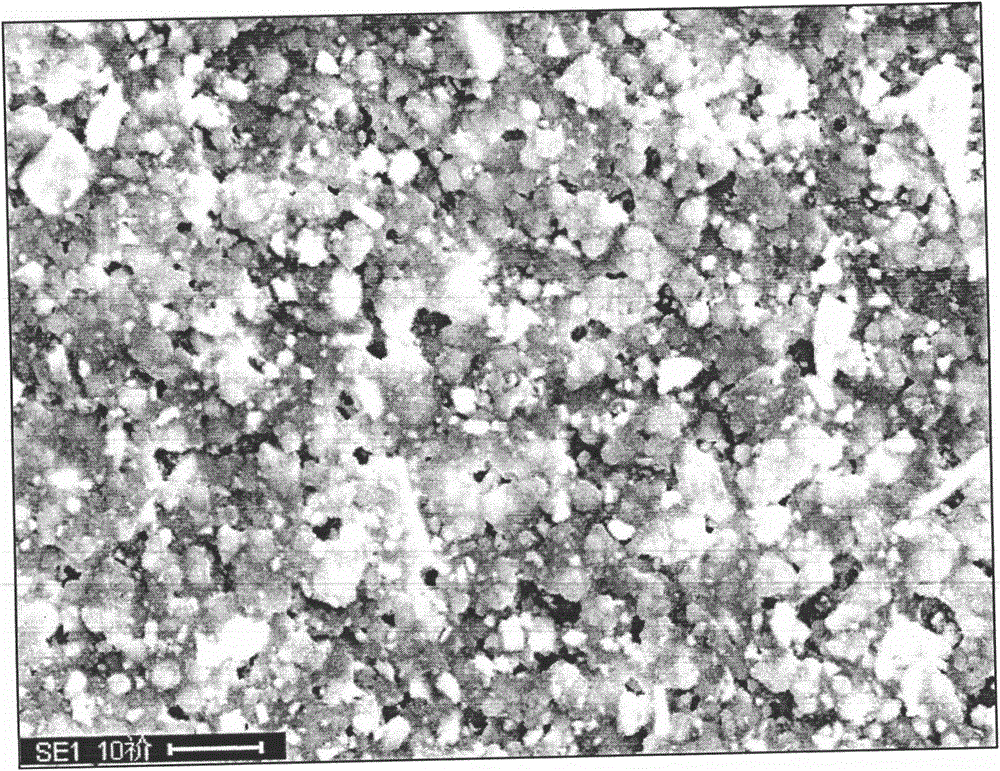

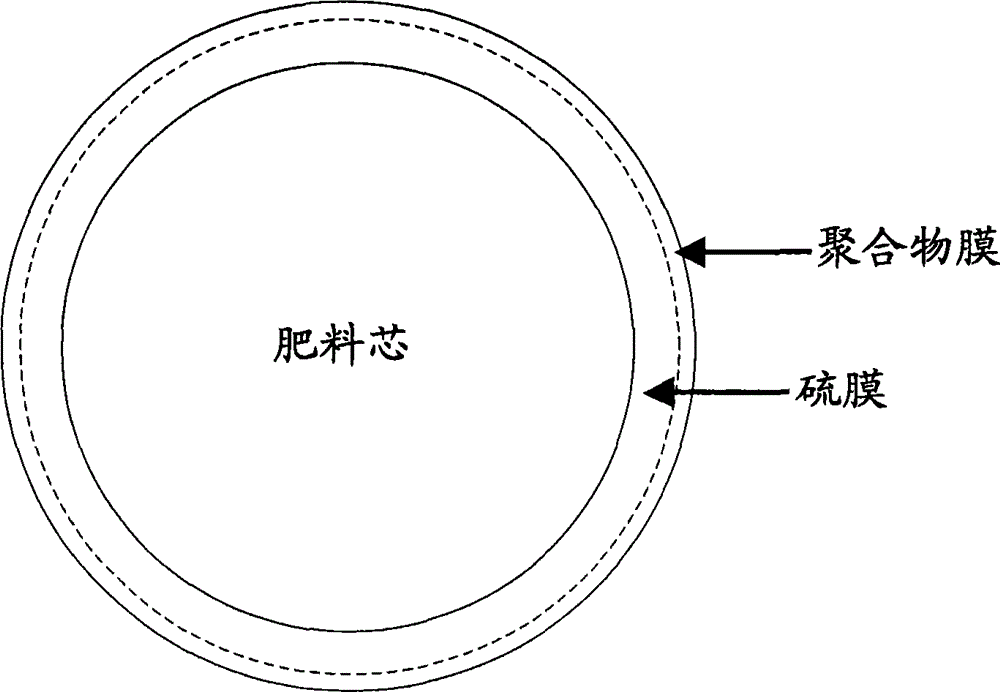

Water soluble alkyd resin-sulphur composite coating release-controlling fertiliser and method for preparing same

The invention relates to a water-soluble alkyd resin-sulfur compound capsule controlled release fertilizer and a preparation method thereof. The capsule controlled release fertilizer consists of a fertilizer core and a capsule which is outside the fertilizer core; wherein, the capsule comprises a sulfur capsule, the exterior of the sulfur capsule has a polymer film that contains water-soluble alkyd resin capsule agent and an inorganic layer that is arbitrarily arranged outside the polymer film and contains inorganic powders.

Owner:KINGENTA ECOLOGICAL ENG GRP

A nanometer quartz sand ceramic product for daily use

A nanometer quartz sand ceramic product for daily use is disclosed. The ceramic product is prepared from, by weight, 17-20 parts of quartz sand, 12-15 parts of jiaobao stone powder, 13-16 parts of albite, 8-10 parts of hollow glass microbeads, 11-13 parts of silica sol, 1-2 parts of polyvinyl alcohol, 1-2 parts of propenol, 40-45 parts of fly ash, 12-14 parts of andalusite powder, 2-3 parts of magnesium powder, 35-40 parts of white glaze balls, 6-8 parts of waste glass, 10-14 parts of Chinese medical stone, 21-25 parts of green tea, 14-17 parts of orange peel, 6-8 parts of shell powder, 4-6 parts of shrimp shell powder, 0.2-0.3 part of polyvinyl alcohol, 0.2-0.3 part of tributyl phosphate and a proper amount of deionized water. The ceramic product is high in whiteness, high in transparency, low in cost, and good in molding performance, is capable of improving antibacterial and healthcare functions of the product at the same time of meeting common using properties of daily use ceramics as products for daily use, and deserves popularization.

Owner:安徽省含山瓷业股份有限公司

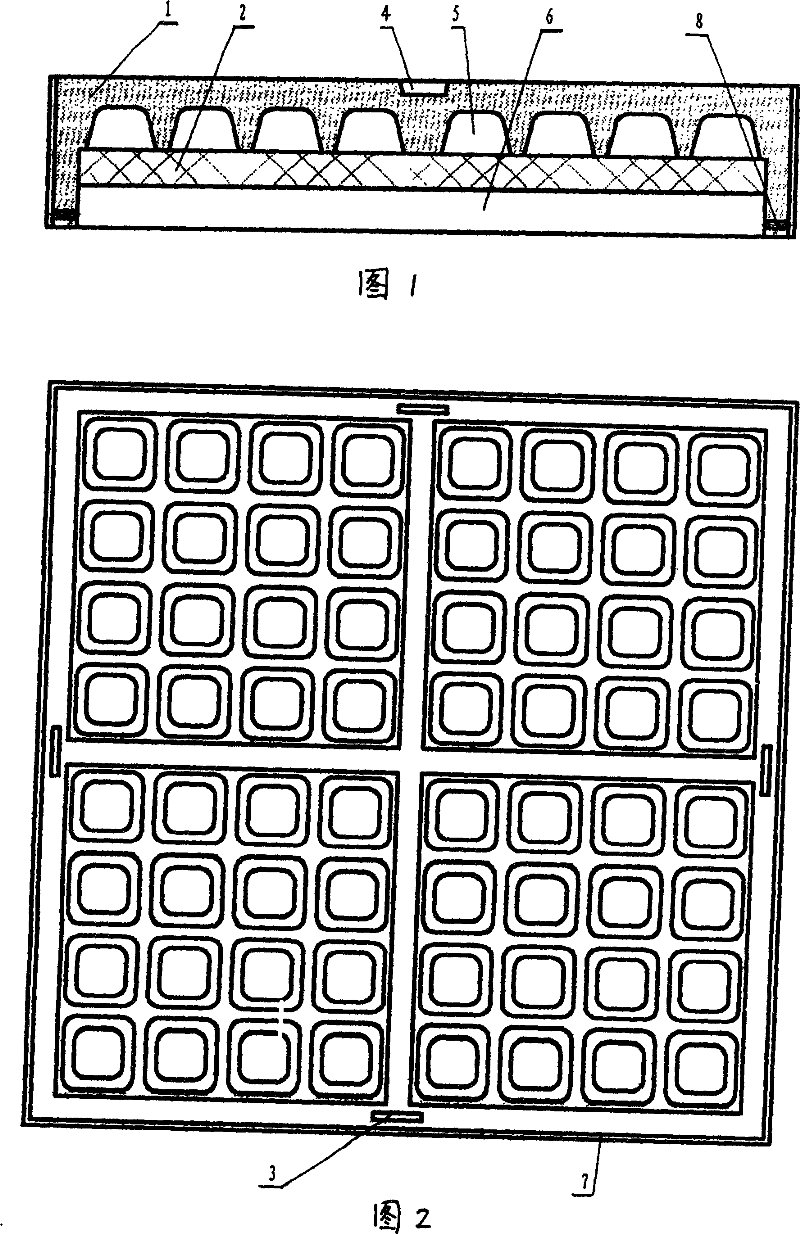

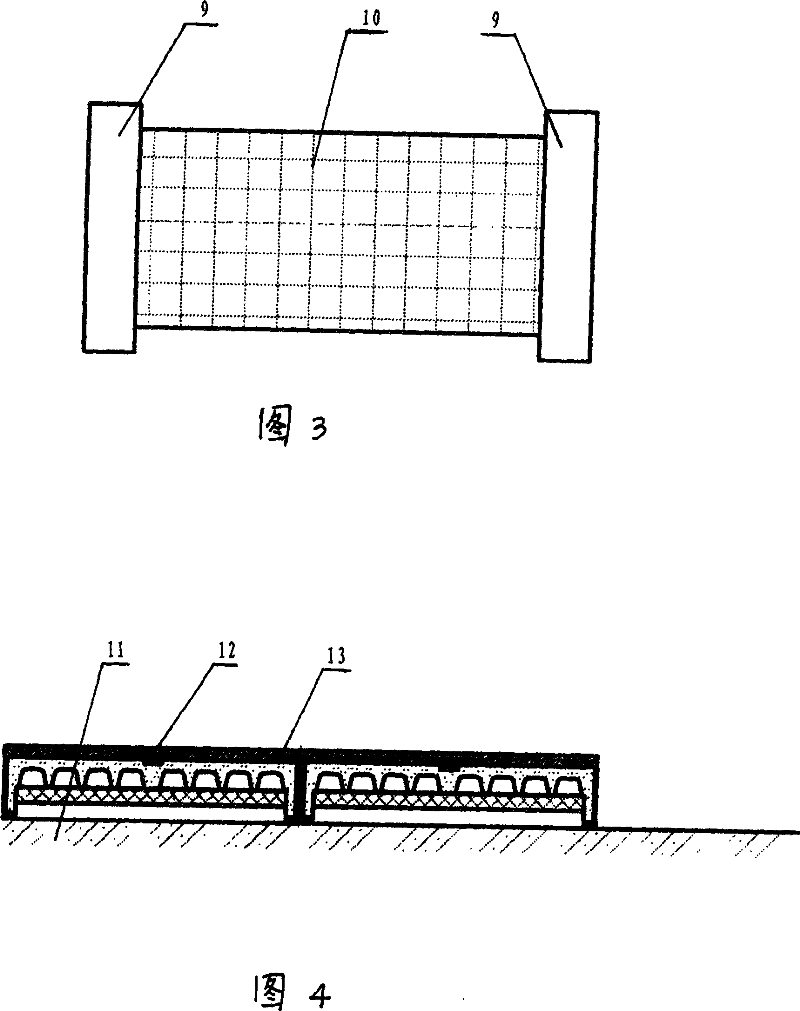

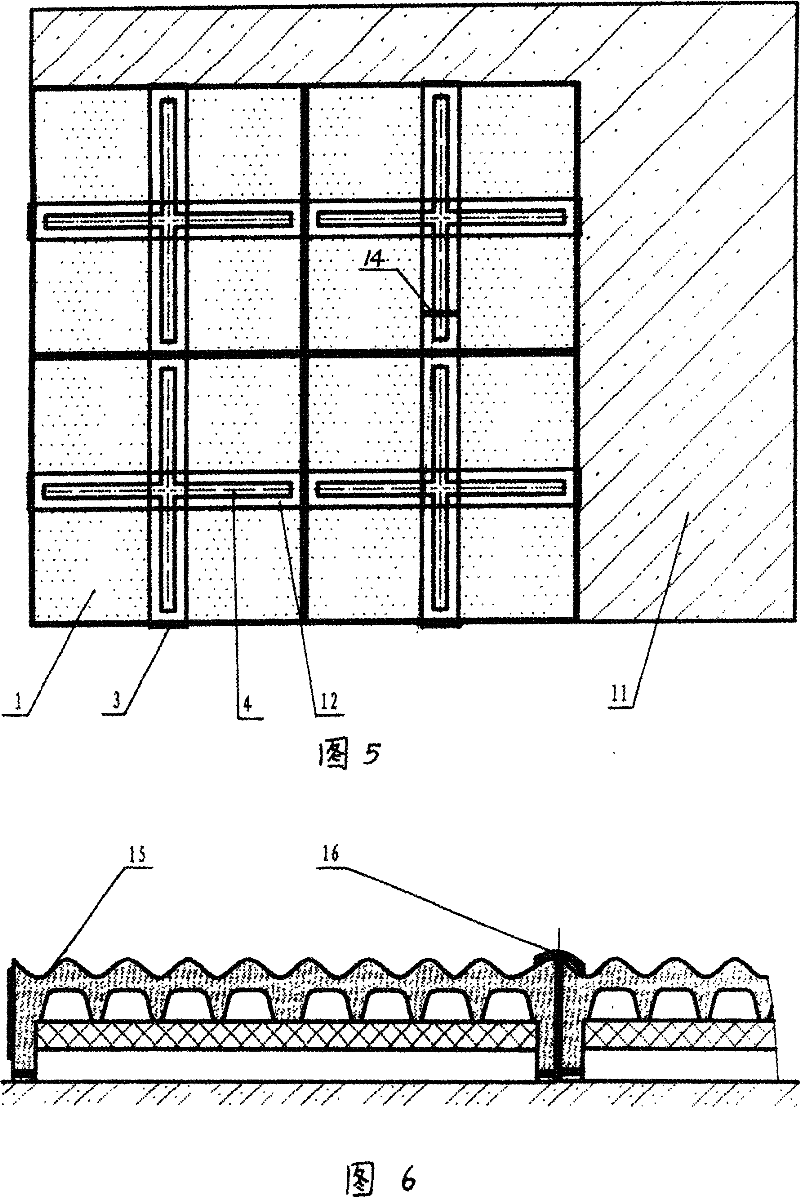

Frame filling body warm preservation heat insulation board and its construction method

The invention relates to frame filling body heat insulating board. It includes frame structure body heat insulating material, obturator heat insulating material, non cold bridge connecting piece, and edge sealing heat insulating material. The obturator heat insulating material is embedded in cavity of the frame structure body heat insulating material, and divided the cavity into enclosed type air space and open type air space. Air vent is set in open type air space and side wall of the frame structure body heat insulating material. The non cold bridge connecting piece is made up of lock catch and net band. It is set in frame structure body heat insulating material, or cross the edge sealing heat insulating material. Outer surface cross recess is set on outer surface of the frame structure body heat insulating material. The invention can apply in wall body outer heating and so on. Its advantages are light, crack resistance, sound insulation, heating, low cost, and so on. And it can satisfy country building energy conservation standard.

Owner:陈星

A double-stage vibration isolation buffer

ActiveCN112253665BHigh static stiffnessLow dynamic stiffnessLiquid springsSolid based dampersEngineeringCylinder block

The invention discloses a two-stage vibration isolation buffer, which belongs to the technical field of vibration isolation buffers. The invention solves the problems of low energy conversion rate and longitudinal impact resistance of the existing vibration isolation buffer. The lower part of the connecting end cover is set between the two cylinders and fixedly connected with the secondary cylinder body, the upper part of the connecting end cover is inserted into the primary cylinder body and fixedly connected with the inner wall of the primary cylinder body, and the piston slides up and down and is set at The first-stage cylinder and the upper part of the piston pass through the first-stage cylinder and are fixedly connected to the guide cylinder. The composite diaphragm is fixedly clamped between the connecting end cover and the second-stage cylinder and is attached to the inner wall of the connecting end cover. The composite membrane The upper surface of the middle part of the sheet is attached to the bottom of the piston, and the composite diaphragm, the connecting end cover and the first-stage cylinder form a closed first-stage chamber. This application has two sealed chambers isolated from each other, which realize energy consumption and energy storage at the same time. On the basis of molecular springs, combined with the working principle of energy consumption type vibration isolation buffer, it overcomes the low natural frequency and small vibration under heavy load. Static deformation can not have both problems.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com