Mullite fiber reinforced porous ceramic product and method for preparing mullite fiber reinforced porous ceramic product from waste ceramics

A technology of mullite fiber and porous ceramics, which is applied in the field of ceramic products, can solve the problems of low toughness of porous ceramic materials, limit the application range of materials, and high brittleness, achieve low density, realize comprehensive utilization of resources, improve mechanical properties and The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

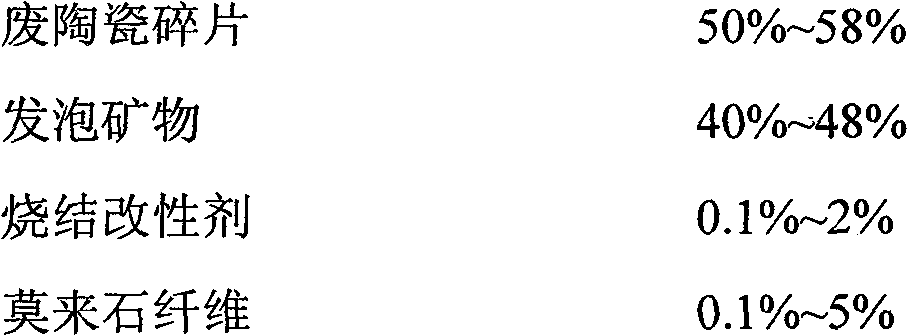

Method used

Image

Examples

Embodiment 1

[0022] Select the waste ceramic fragments (glazed) 16% (glazed), (unglazed) 34%, tremolite 17%, dolomite 6%, pottery clay 23%, add 0.4 % Silicon carbide powder, crush and mix, ball mill for 20 hours, add 0.5% mullite fiber and continue to stir for 8 minutes, after drying and granulation, after aging, pour the mud into a detachable and split-type refractory combined mold, and fire at 1220℃ , The bulk density of the cold-worked ceramic material product is 0.6g / cm3, the flexural strength is 7MPa, and it is frozen and thawed in water at -20℃~20℃ for 3 hours, 5 cycles, without damage, which proves its excellent frost resistance.

Embodiment 2

[0024] Select the waste ceramic fragments (glazed) 16% (glazed), (unglazed) 34%, tremolite 17%, dolomite 6%, pottery clay 23%, add 0.4 % Silicon carbide powder, crush and mix, ball mill for 20 hours, add 5% mullite fiber and continue to stir for 8 minutes, after drying and granulation, after aging, pave the mud into a detachable and split type refractory composite mold, and fire at 1220℃ , The bulk density of the cold-worked ceramic material product is 0.6g / cm3, the flexural strength is 11.5MPa, and it is frozen and thawed in water at -20℃~20℃ for 6 hours, 10 cycles, without damage, which proves its excellent frost resistance.

Embodiment 3

[0026] Select the waste ceramic fragments (glazed) 18% (glazed), (unglazed) 40%, tremolite 16%, dolomite 6%, pottery clay 20%, add 1.4 % Silicon carbide powder, crush and mix, ball mill for 20 hours, add 0.5% mullite fiber and continue to stir for 8 minutes, after drying and granulation, after aging, pour the mud into a detachable and split-type refractory combined mold, and fire at 1220℃ , The bulk density of the cold-worked ceramic material product is 0.65g / cm3, the flexural strength is 7.8MPa, and it is frozen and thawed in water at -20℃~20℃ for 6 hours, 10 cycles, without damage, which proves its excellent frost resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com