A double-stage vibration isolation buffer

A shock absorber and vibration isolation technology, which is applied in the direction of shock absorbers, solid shock absorbers, shock absorbers, etc., can solve the problems of low energy conversion rate and longitudinal impact resistance of vibration isolation buffers, and improve the energy conversion rate With impact resistance, strong bearing capacity and good vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

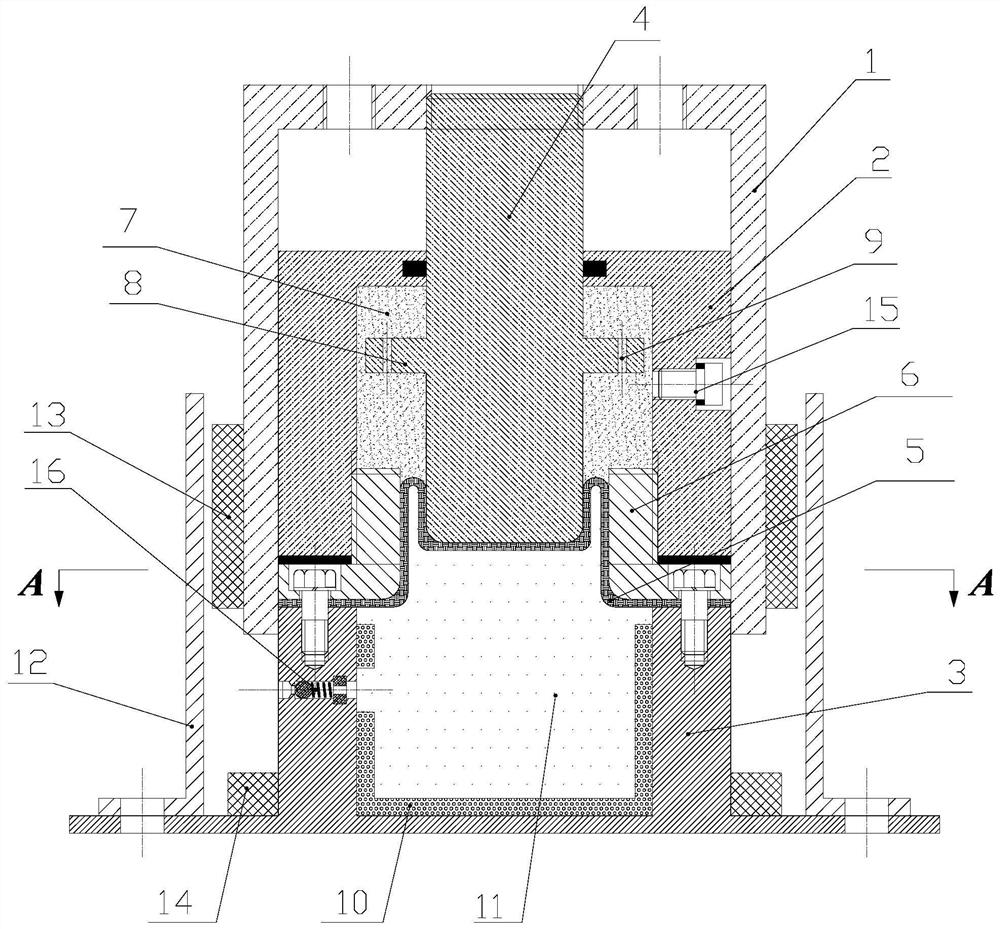

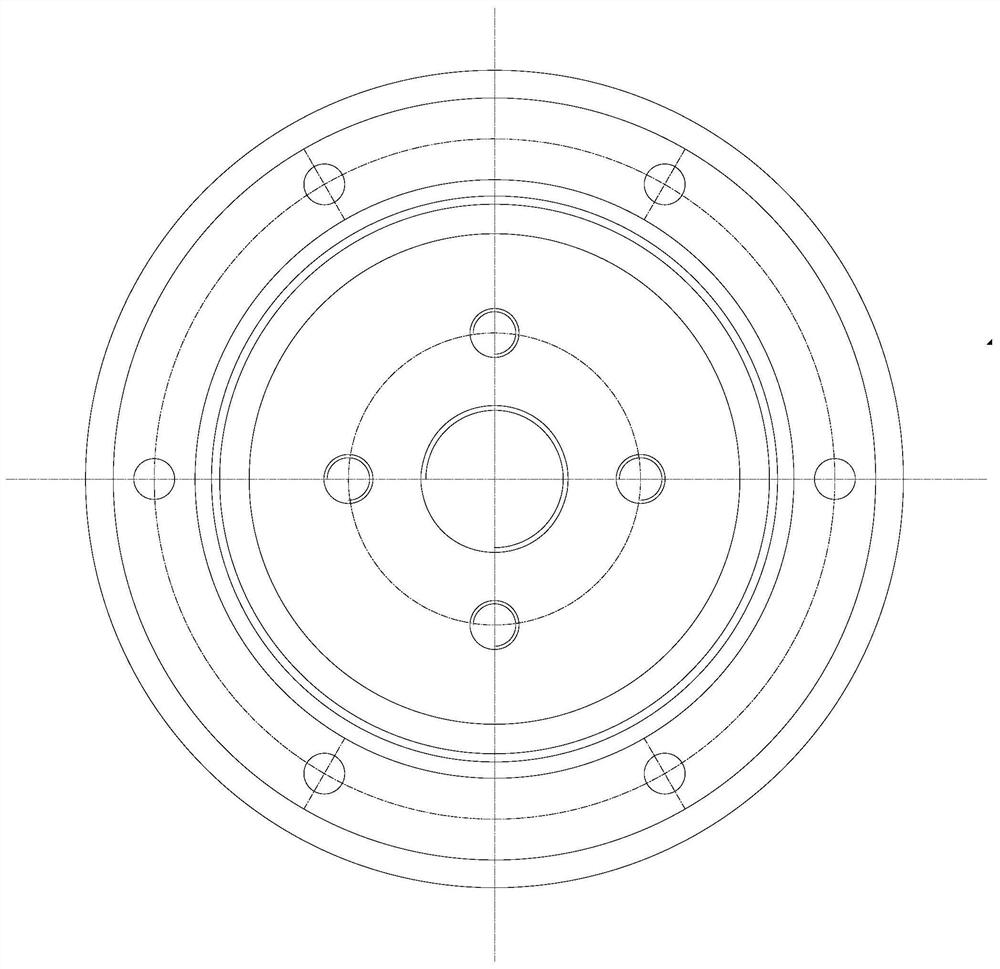

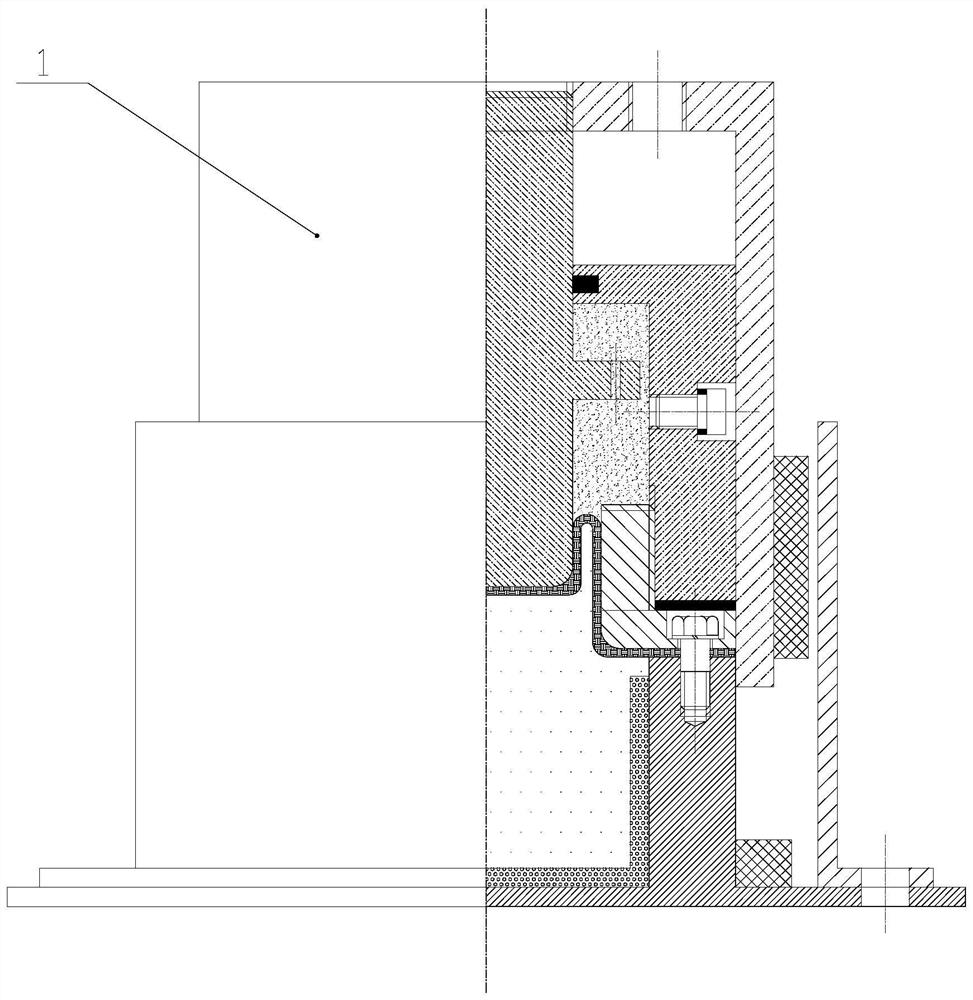

[0022] Specific implementation mode one: combine Figure 1~5 Describe this embodiment, a two-stage vibration isolation buffer, which includes a guide cylinder 1, a first-stage cylinder 2, a second-stage cylinder 3, a piston 4, a composite diaphragm 5 and a connecting end cover 6, wherein the first-stage cylinder 2 and the secondary cylinder 3 are arranged up and down, the lower part of the connecting end cover 6 is set between the two cylinders and fixedly connected with the secondary cylinder 3, and the upper part of the connecting end cover 6 is inserted into the primary cylinder 2 inside and fixedly connected to the inner wall of the primary cylinder 2, the guide cylinder 1 is coaxial and sleeved outside the two cylinders, the piston 4 slides up and down in the primary cylinder 2 and the upper part of the piston 4 passes through The primary cylinder 2 is fixedly connected to the guide cylinder 1, and the composite diaphragm 5 is fixedly sandwiched between the connecting end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com