A kind of preparation method of the functional paste of sheet type electrostatic suppressor

An electrostatic suppression, chip technology, applied in the direction of resistors, resistor manufacturing, overvoltage protection resistors, etc., can solve the problems of complex manufacturing process and high cost, and achieve fast response, strong impact resistance, and good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

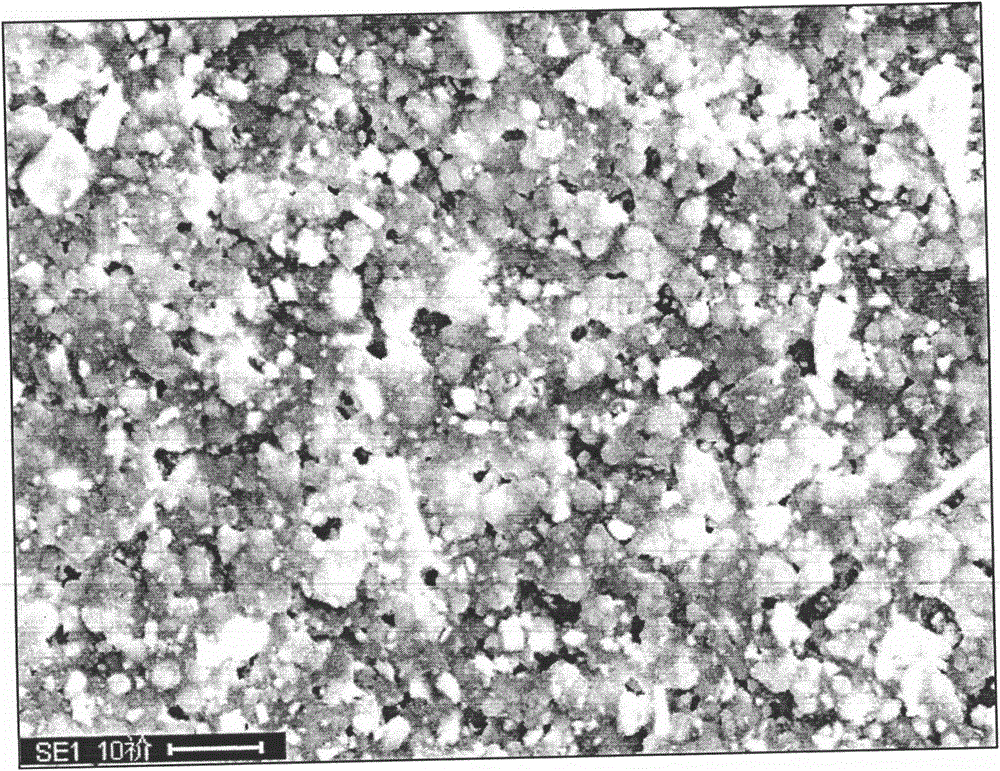

Image

Examples

preparation example Construction

[0031] A method for preparing functional slurry for a chip electrostatic suppressor, using a three-phase composite material system of glass, metal and ceramics with non-linear resistance characteristics, ceramic phases and glass phases containing various oxides to ensure that the material system in When a low voltage is applied, it exhibits high resistance, and a suitable metal phase ensures that the material exhibits a low resistance state when a high voltage is applied: at 20V, the resistance is generally above 10GΩ, which ensures that no static electricity occurs in the normal working circuit , the leakage current is as low as the nanoampere level, which has obvious advantages compared with zinc oxide varistors.

[0032] In addition, the appropriate ratio of metal powder, glass powder and ceramic powder is used to ensure that the metal powder is covered by ceramic phase, so that no ohmic contact will be formed during the electrostatic shock process, which greatly improves th...

Embodiment 1

[0034] In the embodiment of the present invention, the preparation method of the functional slurry of the chip-type electrostatic suppressor, the steps are as follows:

[0035] Step (1): According to the mass ratio, mix lead oxide 30, aluminum oxide 30, silicon dioxide 4, boron trioxide 15, and zinc oxide 2 first, then add deionized water, and use an agate jar planetary ball mill for 1.5 hours , the rotating speed is 300 rpm, and the obtained ball milling mixture is dried at 80°C for later use;

[0036] Step (2): preparing ceramic powder, including the following sub-steps,

[0037] Step (2.1): Raise the raw material dried in step (1) to 1000°C within 2.5 hours and keep it warm for 0.5 hours, then cool naturally to obtain white ceramics;

[0038] Step (2.2): vibrate and grind the ceramics obtained in step (2.1) so that the particle size is less than 2mm, and then use an agate pot planetary ball mill for 3 hours at a speed of 350 rpm, dry at 80°C, and crush through an 80-mesh s...

Embodiment 2

[0043]In the embodiment of the present invention, the preparation method of the functional slurry of the chip-type electrostatic suppressor, the steps are as follows:

[0044] Step (1): According to the mass ratio, mix lead oxide 35, aluminum oxide 40, silicon dioxide 5, boron trioxide 20, and zinc oxide 4 first, then add deionized water, and use agate jar planetary ball mill for 2 hours, The rotating speed is 322 rpm, and the obtained ball milling mixture is dried at 100°C for use;

[0045] Step (2): preparing ceramic powder, including the following sub-steps,

[0046] Step (2.1): Raise the raw material dried in step (1) to 1200°C within 2 hours and keep it warm for 1 hour, then cool naturally to obtain white ceramics;

[0047] Step (2.2): vibrate and grind the ceramics obtained in step (2.1) so that the particle size is less than 2mm, and then use an agate pot planetary ball mill for 4 hours at a speed of 387 rpm, dry at 100°C, and crush through a 100-mesh sieve for later u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com