Oblique giant-scale engineering tyre

A kind of engineering tire, giant technology, applied in tire parts, reinforcement layer of pneumatic tires, transportation and packaging, etc. Safe driving and service life, etc., to achieve the effect of small elongation coefficient, tear resistance and other performance enhancements and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

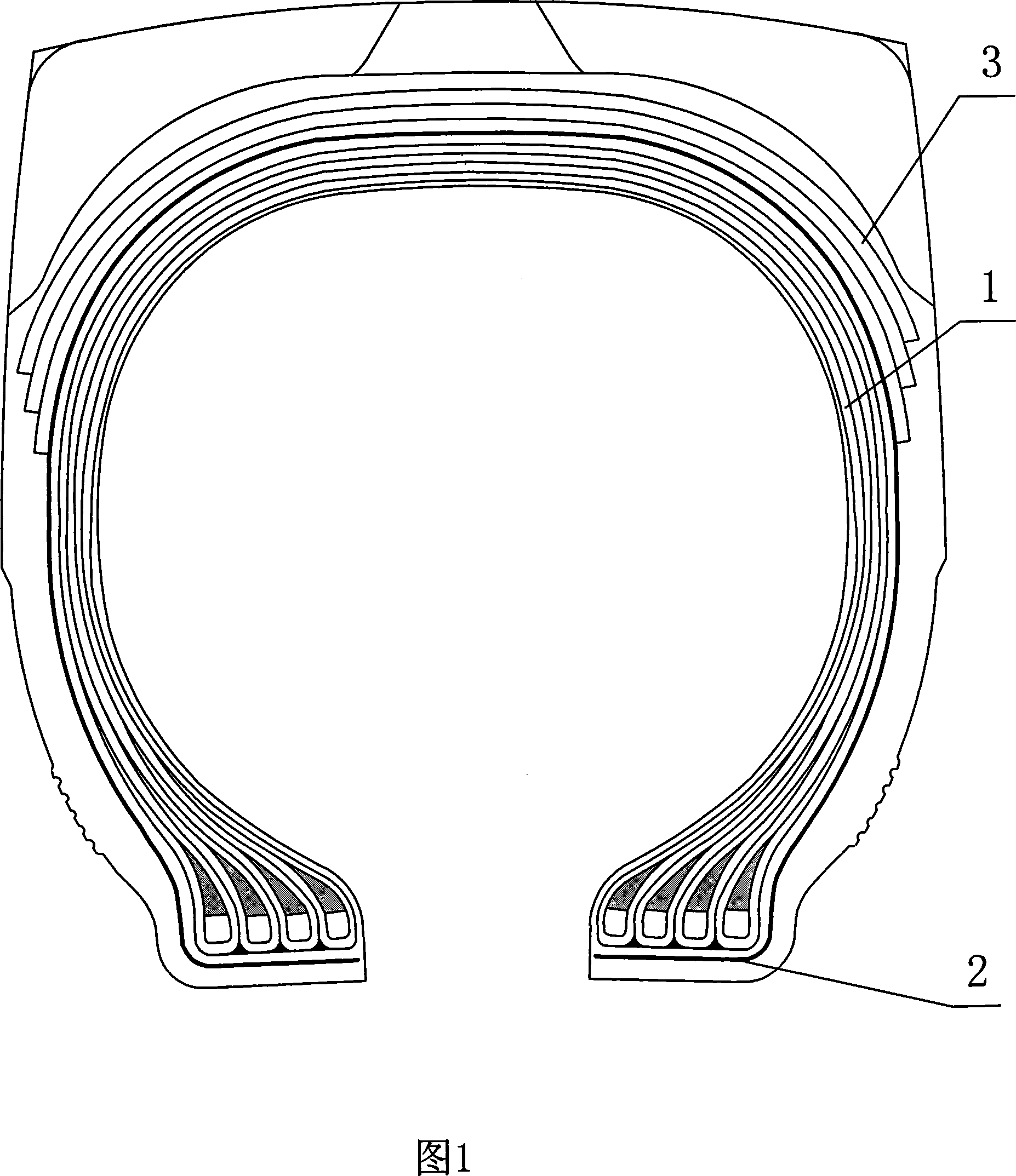

[0010] As shown in Figure 1, the oblique giant engineering tire of the present invention has a rim diameter of ≥ 35 ", and it includes 1 to 4 layers of buffer layers 3, 22 to 40 layers of carcass ply 1 made of cord tubes, the said Carcass ply 1 includes 2 to 10 layers of carcass ply inner layer, 16 to 36 layers of carcass ply middle layer, 2 to 10 layers of carcass ply outer layer, and the carcass ply outer layer includes 2 to 4 layers of carcass Cord outer layer 2 and carcass cord outer layer with 4-8 layers of turned-up bead rings, among which, the carcass cord inner layer, carcass ply middle layer and carcass cord outer layer of turned-up bead rings are all made of Nylon material, and in the outer layer 2 of the carcass ply 2, there are 1 to 4 layers of the cord tube as the reinforcing layer with the cord material of aramid fiber, and the reinforcing layer is arranged at the outermost end of the carcass ply 1, so The aramid fiber wire diameter that adopts is 0.76~0.8mm; The...

Embodiment 2

[0012] As shown in Figure 1, the oblique giant engineering tire of the present invention has a rim diameter of ≥ 35 ", and it includes 1 to 4 layers of buffer layers 3, 22 to 40 layers of carcass ply 1 made of cord tubes, the said Carcass ply 1 includes 2 to 10 layers of carcass ply inner layer, 16 to 36 layers of carcass ply middle layer, 2 to 10 layers of carcass ply outer layer, and the carcass ply outer layer includes 2 to 4 layers of carcass Cord outer layer 2 and carcass cord outer layer with 4 to 8 layers of turned-up bead rings, among which, buffer layer 3, carcass ply inner layer, carcass cord middle layer and carcass cord outer layer of turned-up bead rings The cords are all made of nylon material, and in the outer layer 2 of the carcass ply 2, there are 2 to 4 layers of the cord tube as the reinforcement layer with the cord material being aramid fiber, and the reinforcement layer is located at the end of the carcass ply 1. At the outer end, the diameter of the arami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com