Ceramic slurry, ceramic composite diaphragm and lithium ion battery

A ceramic slurry and slurry technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problem of uneven dispersion of ceramic particles, and achieve the effects of good adhesion, high peel strength, and improved absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

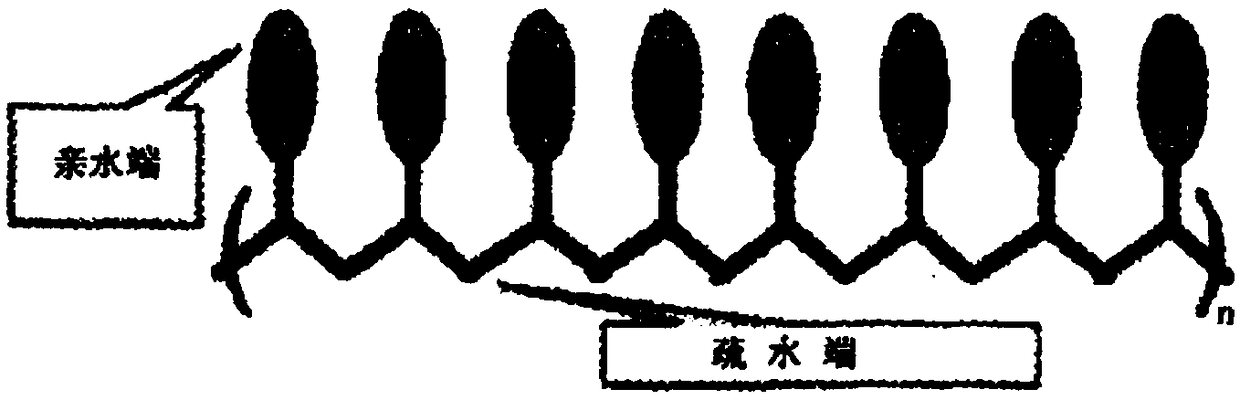

[0041] The present invention also provides a preparation method of the ceramic slurry, comprising the steps of:

[0042]Add thickener, dispersant and wetting agent into deionized water and stir to obtain a solution;

[0043] adding ceramic particles to the above solution, stirring and dispersing to obtain a ceramic dispersion;

[0044] The binder is added to the ceramic dispersion, stirred and dispersed, then defoamed and filtered to obtain a ceramic slurry.

[0045] According to some embodiments of the present invention, the preparation method of the ceramic slurry includes the following steps: firstly add the thickener, the dispersant and the wetting agent into the deionized water, and stir in the zigzag disperser at 300-600r / Min speed of stirring for 0.5h to obtain the solution; Al 2 o 3 Add the particles into the solution, first stir at 3000-4000r / min for 3 hours to obtain a ceramic dispersion; adjust the speed to 1500-2000r / min, add binder, stir for 1h, and finally re...

Embodiment 1

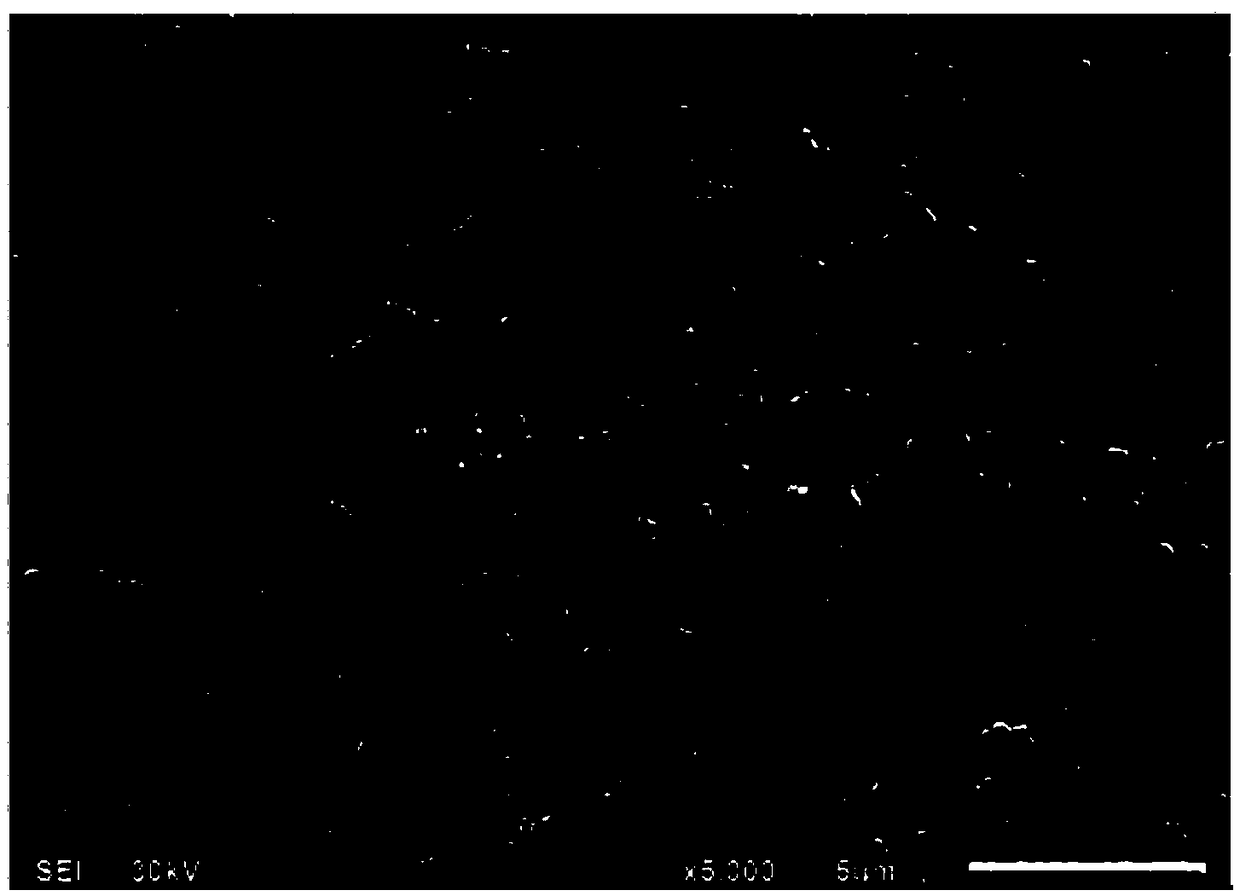

[0055] Add 100g of deionized water into the stainless steel mixing tank, turn on the speed of the zigzag stirring and dispersing machine to 500r / min, weigh 0.4g of thickener CMC, 0.1g of dispersant Tersperse2500 and 0.1g of wetting agent 1831 and add them to the mixing tank Stir and dissolve in medium for 0.5h; then add 25g Al 2 o 3 Particles (particle size 0.5μm), and adjust the mixer to 3000r / min high-speed stirring and dispersing for 3h, then adjust the speed to 2000r / min, add 1g of binder SBR and stir for 1h to stir evenly, and finally reduce the speed to 100r / min Stir at a low speed for 1 hour to eliminate air bubbles in the slurry, and then filter with a filter cloth to obtain the prepared water-based ceramic slurry (particle size: 0.6 μm) and store it for later use.

[0056] Using a micro-concave automatic coating machine, the above-mentioned water-based ceramic slurry is evenly coated on the surface of the PE diaphragm. The running speed of the PE diaphragm is 10.0m / m...

Embodiment 2

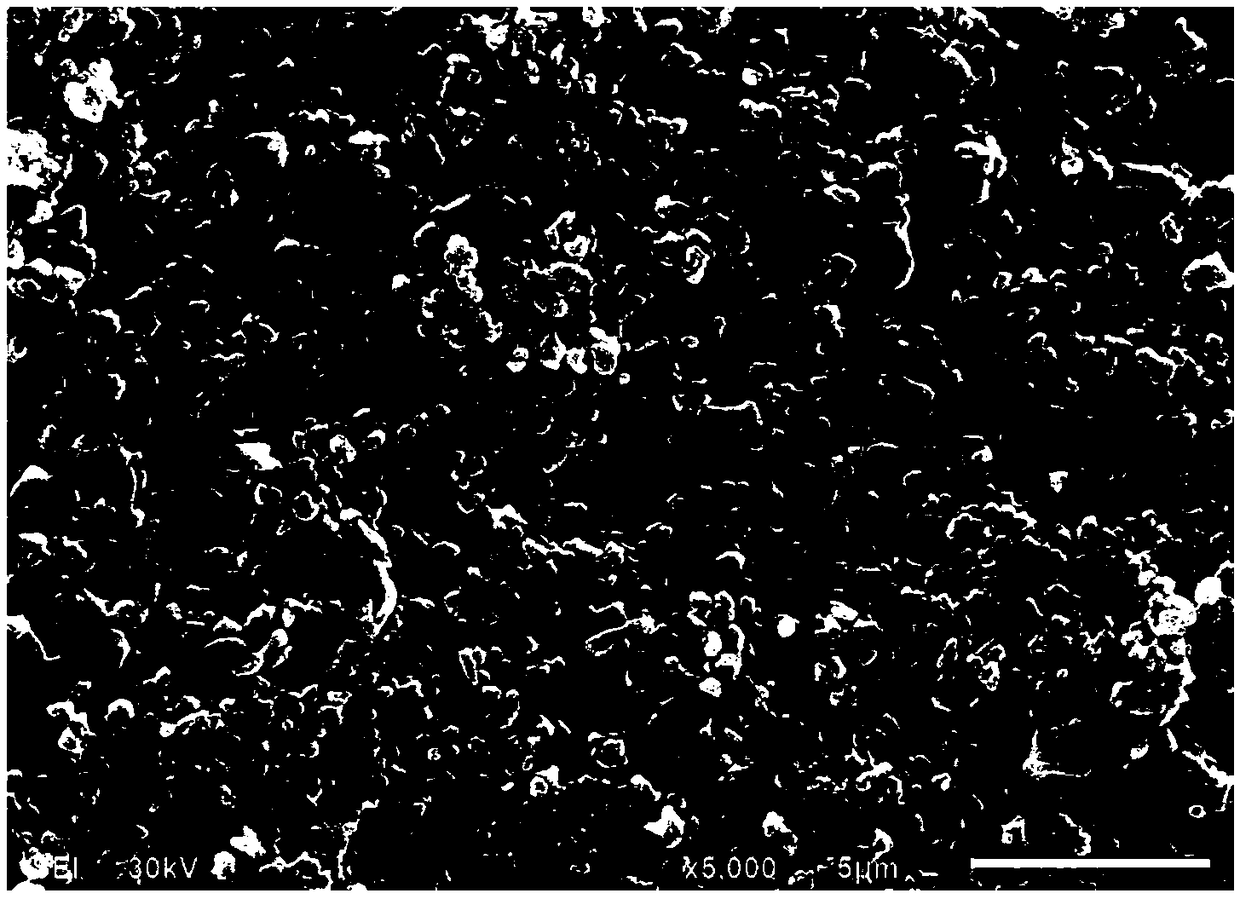

[0058] Add 100g of deionized water into the stainless steel mixing tank, turn the speed of the zigzag stirring disperser to 500r / min, weigh 0.5g of thickener CMC, 0.2g of dispersant Tersperse2500 and 0.2g of wetting agent 1831 and add them to the mixing tank Stir and dissolve in medium for 0.5h; then add 35g Al 2 o 3 Particles (particle size 0.5μm), and adjust the mixer to 3000r / min high-speed stirring and dispersing for 3h, then adjust the speed to 2000r / min, add 2g of binder SBR and stir for 1h to stir evenly, and finally reduce the speed to 100r / min Stir at a low speed for 1 hour to eliminate air bubbles in the slurry, and then filter with a filter cloth to obtain the prepared water-based ceramic slurry (particle size: 0.8 μm) and store it for later use.

[0059] Using a micro-concave automatic coating machine, the above-mentioned water-based ceramic slurry is evenly coated on the surface of the PE diaphragm, the base film is running at a speed of 8.0m / min, and the hot air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com