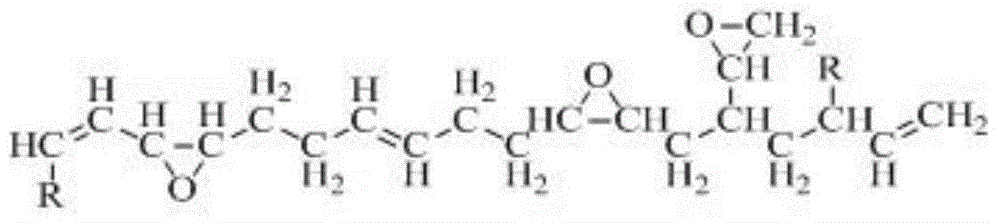

Ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin

A polybutadiene resin, dual-curing technology, used in adhesives, non-polymer organic compound adhesives, etc., can solve the problem that the light transmittance, refractive index, and haze optical properties of the cured product cannot meet the requirements, and it is suitable for occasions. There are limitations, slow post-curing speed, etc., to meet the requirements of optical and physical and chemical properties, reduce equipment investment, and achieve uniform reaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

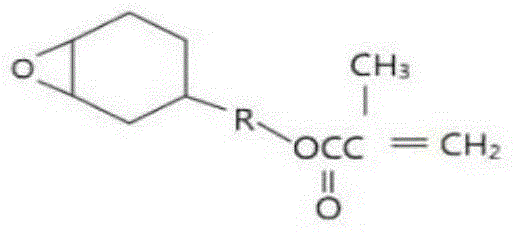

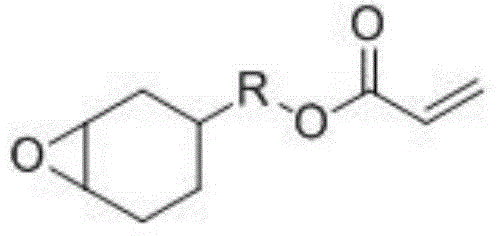

[0035] A kind of UV-heat dual curing optical adhesive containing epoxidized polybutadiene resin, its composition comprises by weight percentage: 45% of epoxidized polybutadiene resin, 10% of cycloaliphatic epoxy modified acrylate , liquid polybutadiene rubber 5%, acrylate reactive diluent HPMA 12%, acrylate reactive diluent IBOMA 23%, cationic photoinitiator 2610.1%, free radical photoinitiator TPO 0.7%, free radical photoinitiator 1841.7 % and peroxide-initiated curing agent 1,1-bis(tert-butyl peroxide)-3,3,5-trimethylcyclohexane 2.5%.

[0036] 45% epoxidized polybutadiene resin, 10% cycloaliphatic epoxy modified acrylate, 5% liquid polybutadiene rubber, 12% acrylate reactive diluent HPMA and 23% acrylate The active diluent IBOMA is added to the double planetary power mixing mixer and stirred evenly at a speed of 500-1000r / min; 1.7% free radical photoinitiator 184, stir evenly; cool down to 25°C, add 2.5% peroxide to initiate curing agent 1,1-bis(tert-butyl peroxide)-3,3,5-t...

Embodiment 2

[0038] A kind of UV-heat dual curing optical adhesive containing epoxidized polybutadiene resin, its composition comprises by weight percentage: 20% of epoxidized polybutadiene resin, 32% of cycloaliphatic epoxy modified acrylate , liquid polybutadiene rubber 12%, acrylate reactive diluent HPMA 8%, acrylate reactive diluent IBOA 23%, cationic photoinitiator 2610.2%, free radical photoinitiator TPO 1%, free radical photoinitiator 184 2.8% and tert-butyl peroxide (2-ethylhexanoate) 2%.

[0039] 20% epoxidized polybutadiene resin, 32% cycloaliphatic epoxy modified acrylate, 12% liquid polybutadiene rubber, 8% acrylate reactive diluent HPMA and 23% acrylic acid Add the ester active diluent IBOA into the dual planetary power mixing mixer and stir evenly at a speed of 500-1000r / min; under light-shielding conditions, add 0.2% cationic photoinitiator 261 and 1% free radical photoinitiator TPO in sequence and 2.8% of free radical photoinitiator 184, stir evenly; cool down to 25°C, add 2...

Embodiment 3

[0041] A kind of UV-heat dual curing optical adhesive containing epoxidized polybutadiene resin, its composition comprises by weight percentage: epoxidized polybutadiene resin 40%, alicyclic epoxy modified methacrylate 14%, liquid polyisoprene rubber 8%, acrylate reactive diluent HPMA 7.5%, acrylate reactive diluent PET4A 25%, cationic photoinitiator 261 0.1%, free radical photoinitiator TPO0.4%, free Base photoinitiator 184 3% and peroxide initiated curing agent peroxide (2-ethylhexanoic acid) tert-butyl ester 2%.

[0042] 40% epoxidized polybutadiene resin, 14% cycloaliphatic epoxy-modified methacrylate, 8% liquid polyisoprene rubber, 7.5% acrylate reactive diluent HPMA and 25% % acrylate reactive diluent PET4A, put into the double planetary power mixing mixer, stir evenly at 500-1000r / min speed; Initiator TPO and 3% free radical photoinitiator 184, stir evenly; cool down to 25°C, add 2% peroxide to initiate curing agent tert-butyl peroxide (2-ethylhexanoate), and control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com