Method for preparing monodisperse polymer microspheres

A polymer, monodisperse technology, applied in the field of preparation of monodisperse polymer microspheres, can solve the problems of complicated steps, difficult control, polydispersity, etc. The effect of mass and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

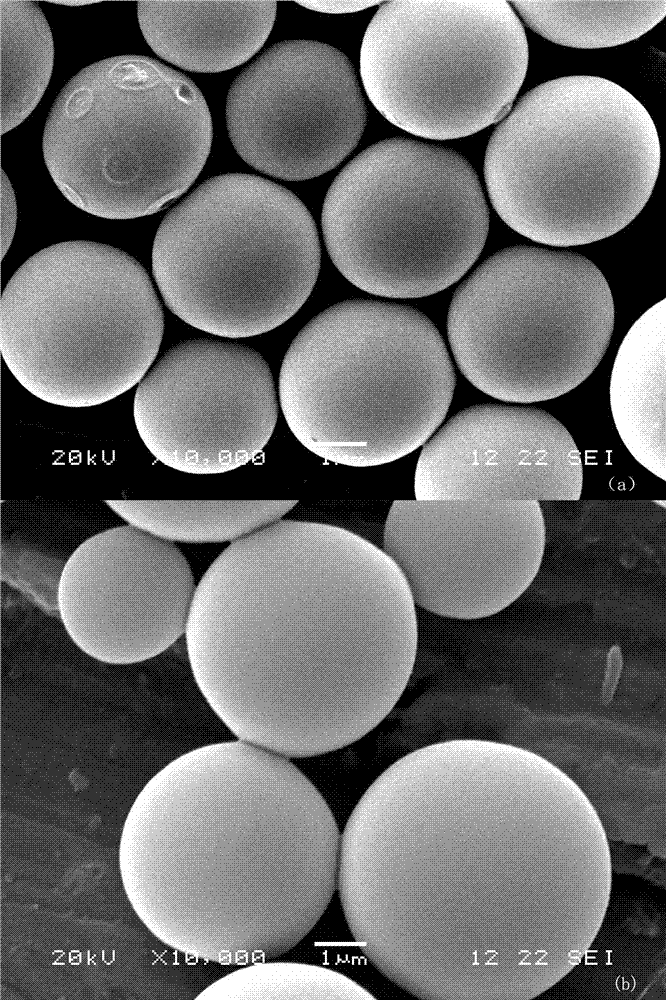

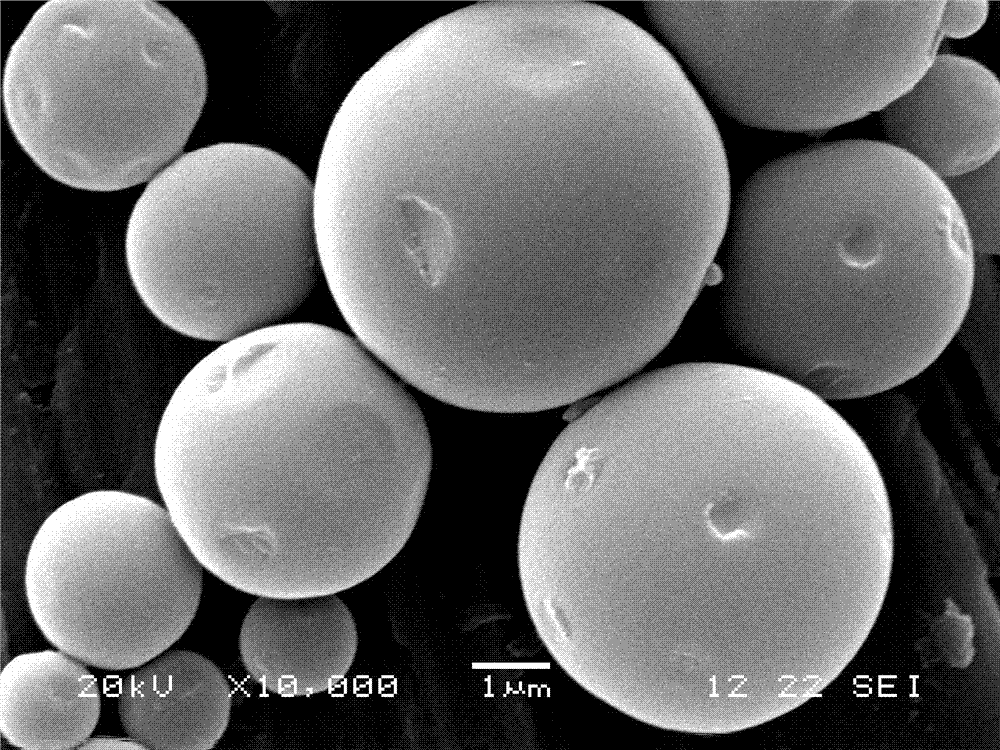

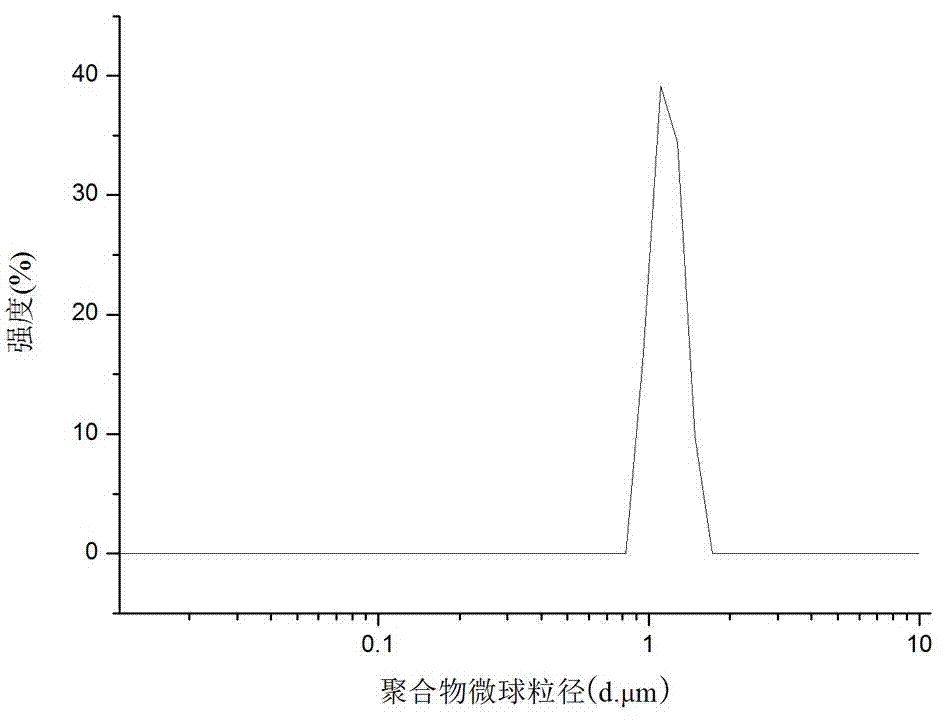

Embodiment 1

[0026] Weigh 10g of stabilizer PVP and dissolve it in the system of absolute ethanol and deionized water (732.5g), wherein the mass ratio of absolute ethanol to deionized water is 95:5, stir well and add to the impinging flow reactor, heat up to 70 degrees Celsius; 250g styrene solution (total amount is calculated as 1000g) dissolved with 7.5g initiator AIBN is added to the impingement flow reactor at one time, and the cooling is terminated after reacting at 70 degrees Celsius for 24 hours; then the obtained emulsion is passed through Ultracentrifuge at 5000r / min-7000r / min for centrifugal sedimentation, pour off the supernatant, add absolute ethanol, ultrasonically clean, repeat this several times, and dry the cleaned microspheres at 40-60 degrees Celsius to constant weight , the polystyrene microsphere powder under impinging flow conditions can be obtained; in a series of experiments, while keeping other experimental conditions unchanged, the monomer dosage was increased from ...

Embodiment 2

[0029] Weigh 10g of stabilizer PVP and dissolve it in the system of absolute ethanol and deionized water, wherein the mass ratio of absolute ethanol to deionized water is 95:5, stir evenly and add to the impinging flow reactor, and heat up to 70 degrees Celsius; Add 250g styrene solution (the total amount is 1000g) dissolved with 2.5g initiator AIBN into the impingement flow reactor at one time, react at 70 degrees Celsius for 24h and then cool to terminate; then pass the obtained emulsion through an ultracentrifuge 5000r / min-7000r / min for centrifugal sedimentation, pouring off the supernatant, adding absolute ethanol, ultrasonic cleaning, repeated operations several times, drying the cleaned microspheres at 40-60 degrees Celsius to constant weight, you can get Polystyrene microsphere powder under impinging flow conditions; in a series of experiments, while keeping other conditions unchanged, the amount of initiator AIBN was increased from 2.5g to 10g, and polystyrene microsph...

Embodiment 3

[0032] Weigh 5.0g stabilizer PVP and dissolve it in the system of absolute ethanol and deionized water, wherein the mass ratio of absolute ethanol to deionized water is 95:5, stir evenly and add it to the impinging flow reactor, and heat up to 70 degrees Celsius ; 250g styrene solution (total amount is calculated as 1000g) that is dissolved with 7.5g initiator AIBN is added in the impingement flow reactor at one time, and cooling is terminated after reacting at 70 degrees Celsius for 24 hours; then the obtained emulsion is passed through an ultracentrifuge Centrifugal sedimentation at 5000r / min-7000r / min, pour off the supernatant, add absolute ethanol, ultrasonically clean, repeat the operation several times, and dry the cleaned microspheres at 40-60 degrees Celsius to constant weight. Obtain the polystyrene microsphere powder under impinging flow condition; In a series of experiments, keep other conditions unchanged, the amount of stabilizer is increased from 5.0g to 12.5g, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com