Patents

Literature

40 results about "Fast tempo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

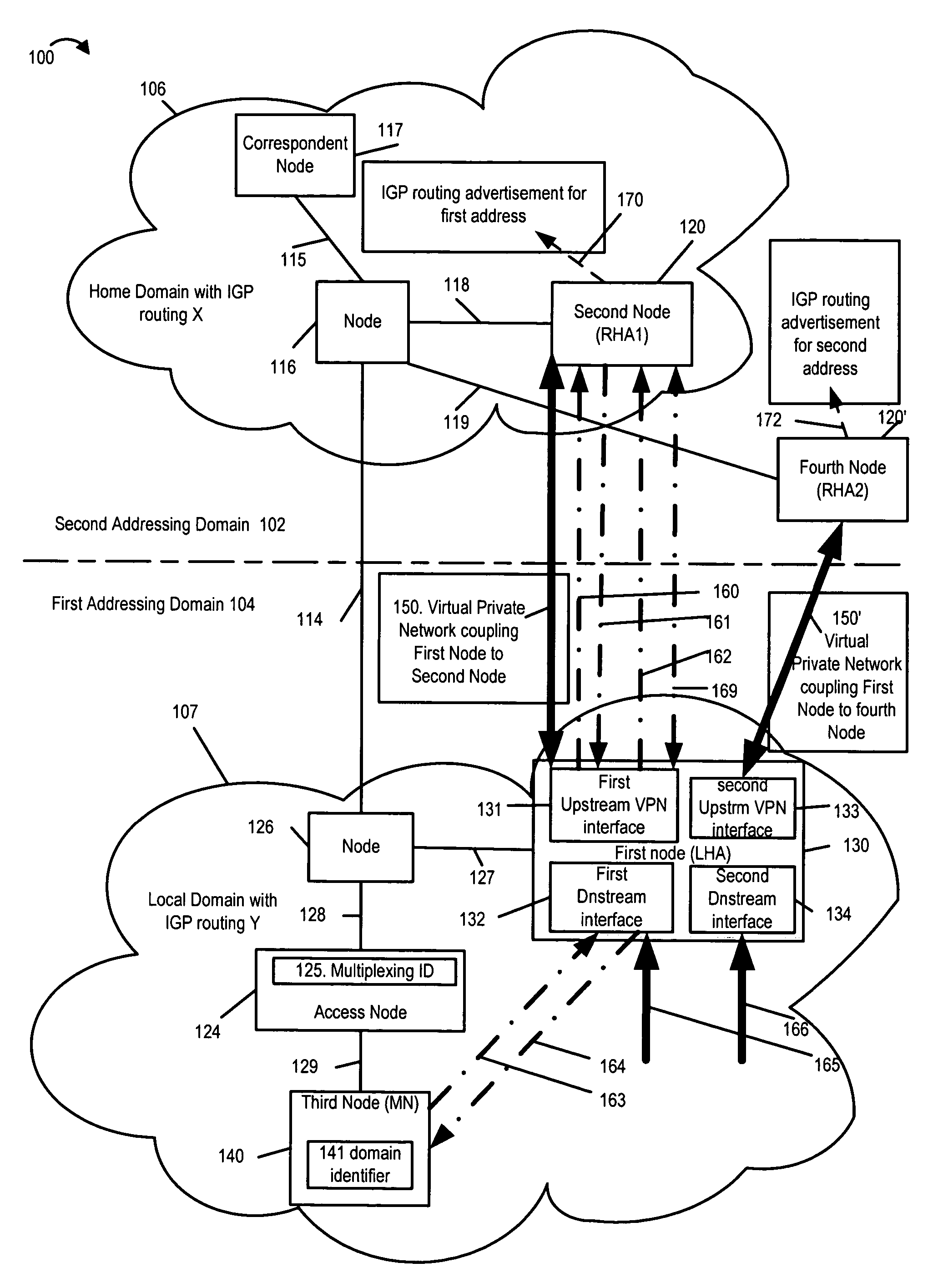

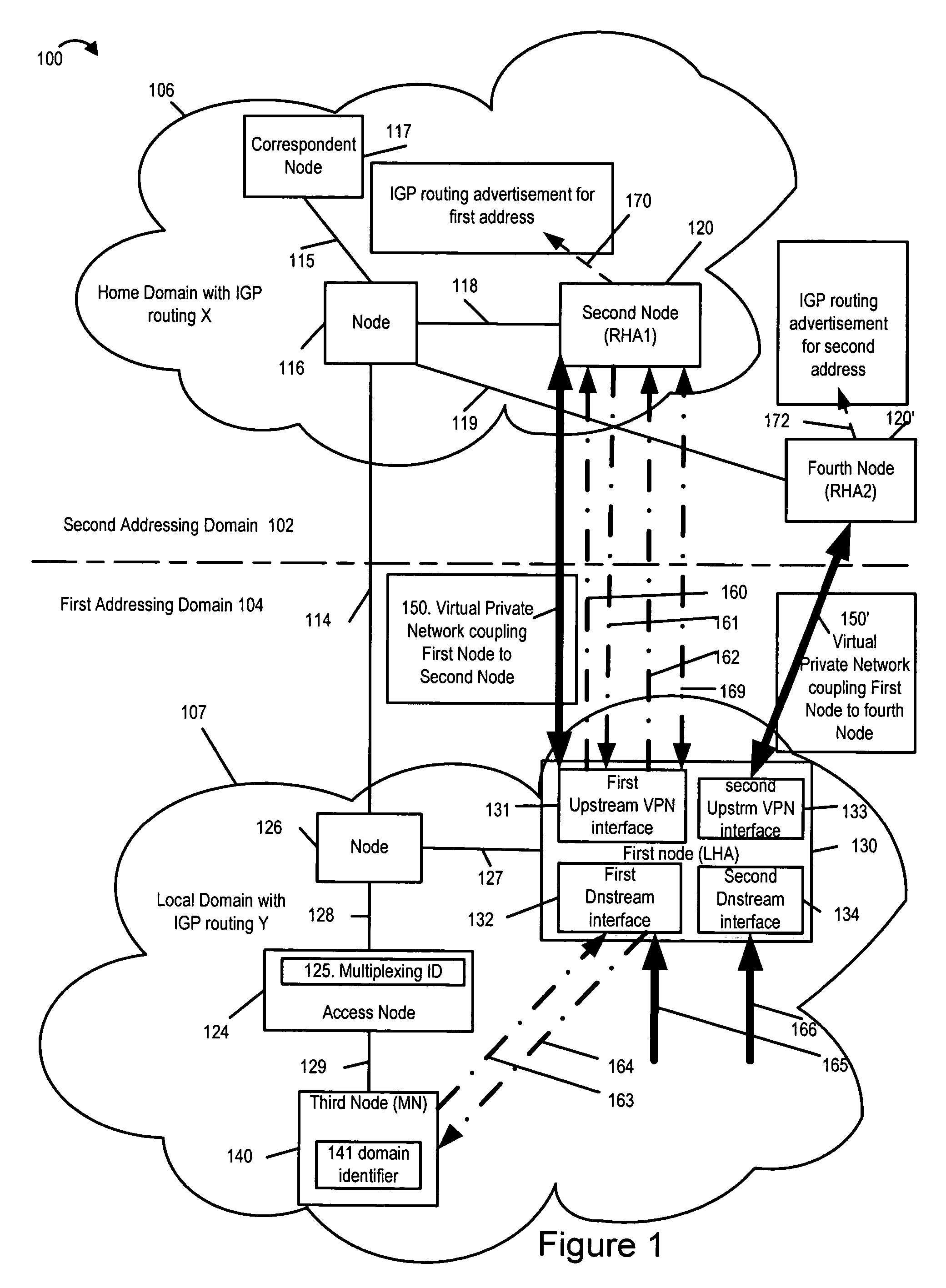

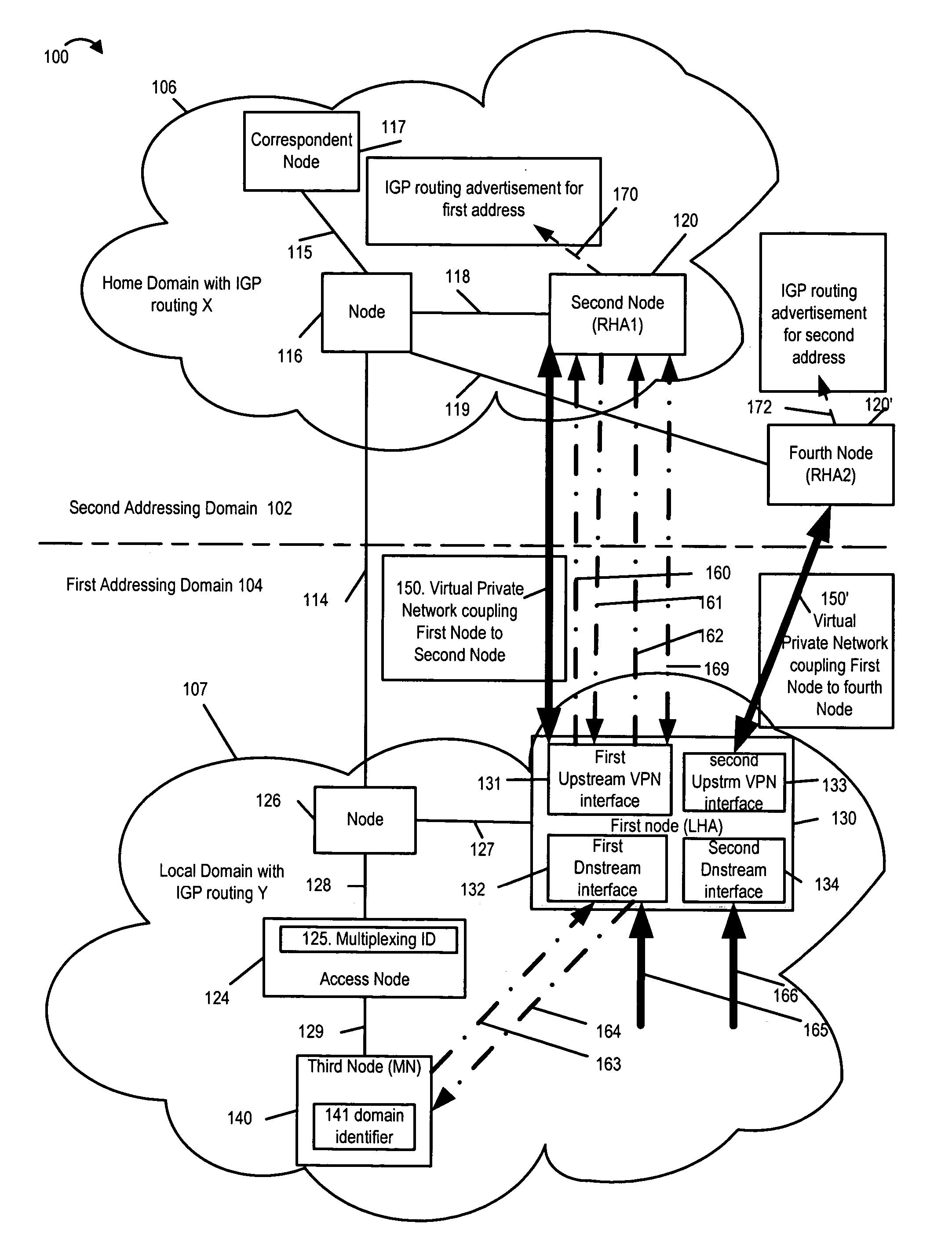

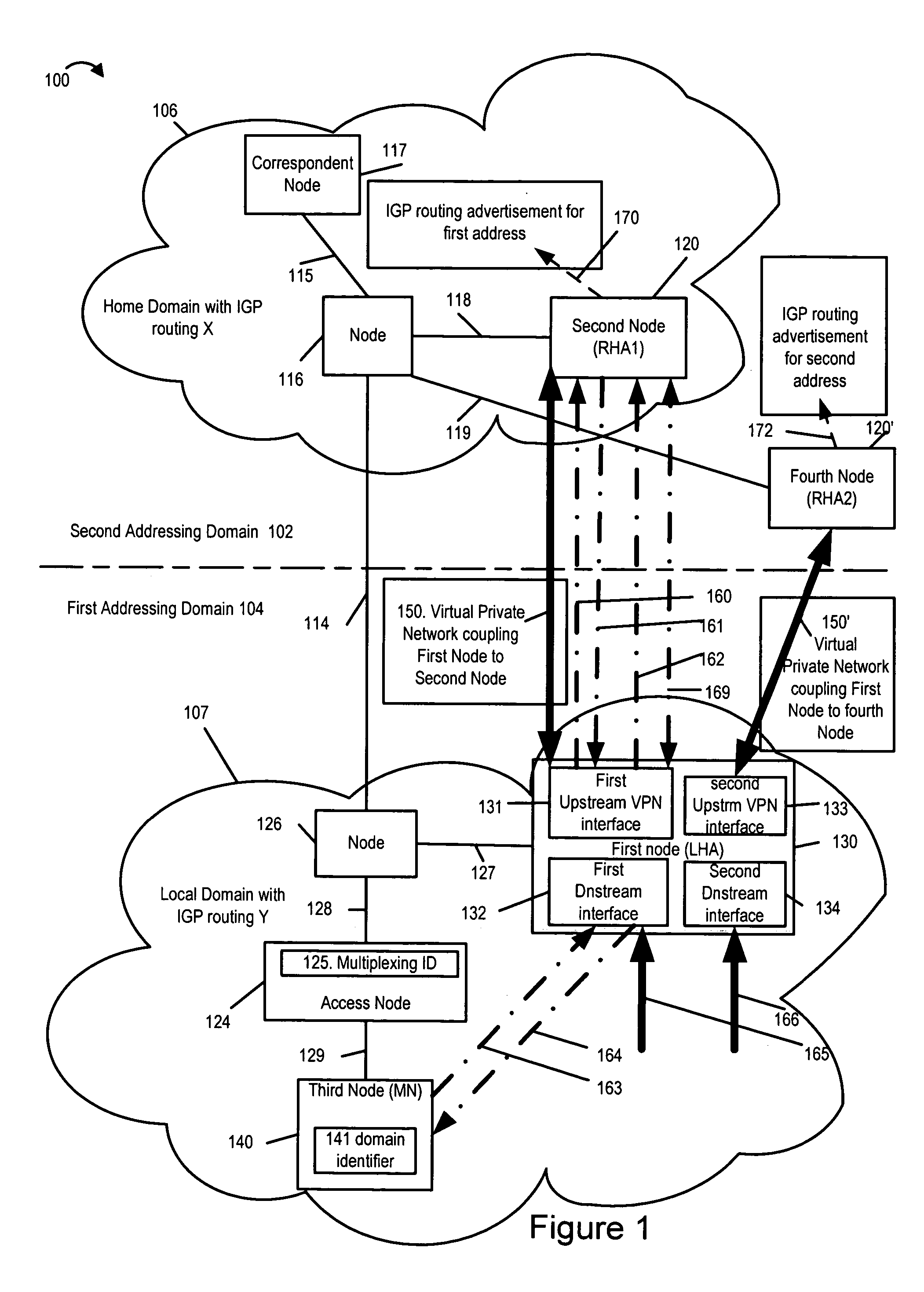

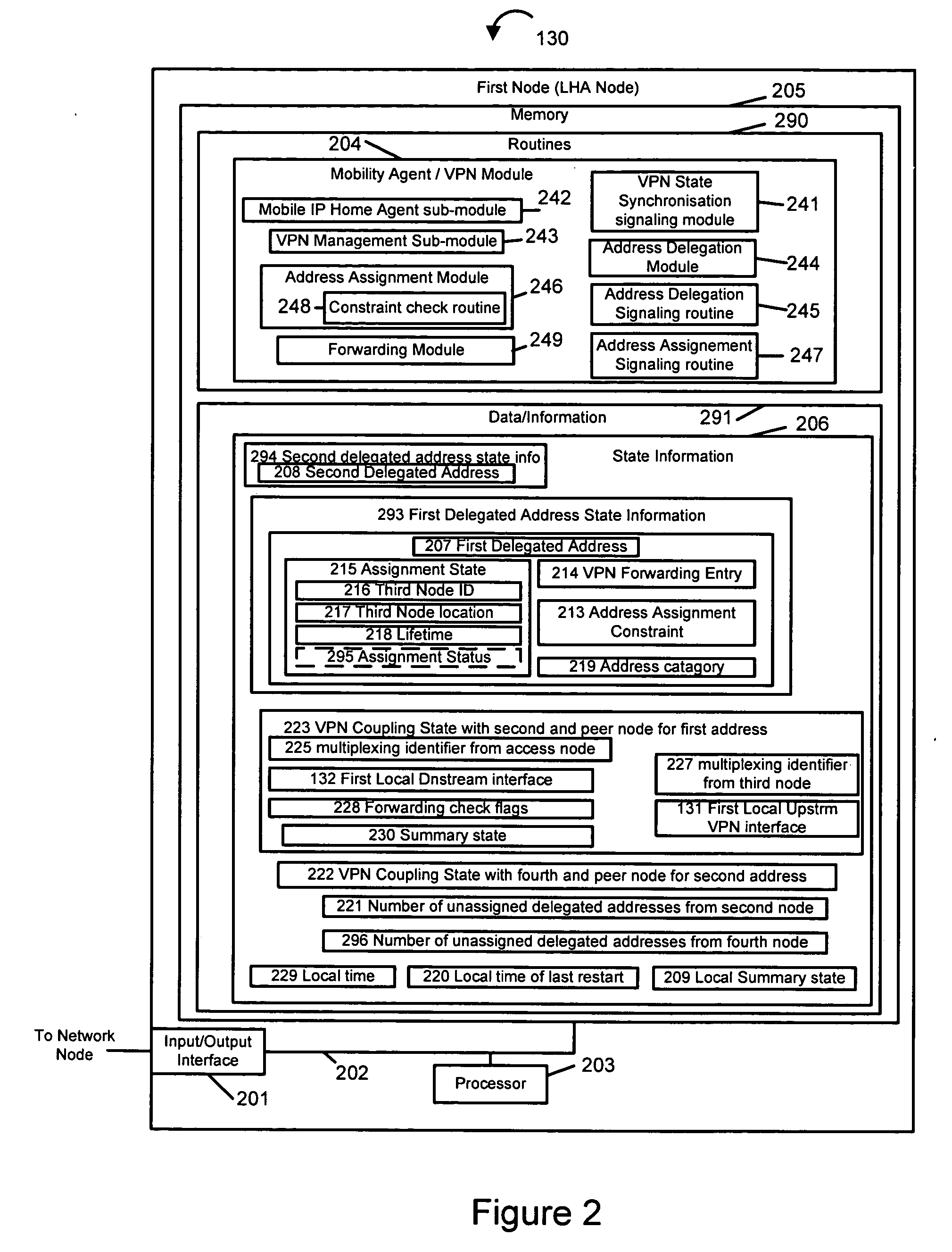

Methods and apparatus for efficient VPN server interface, address allocation, and signaling with a local addressing domain

InactiveUS7366182B2Digital data processing detailsDigital computer detailsCommunications systemFast tempo

Owner:QUALCOMM INC

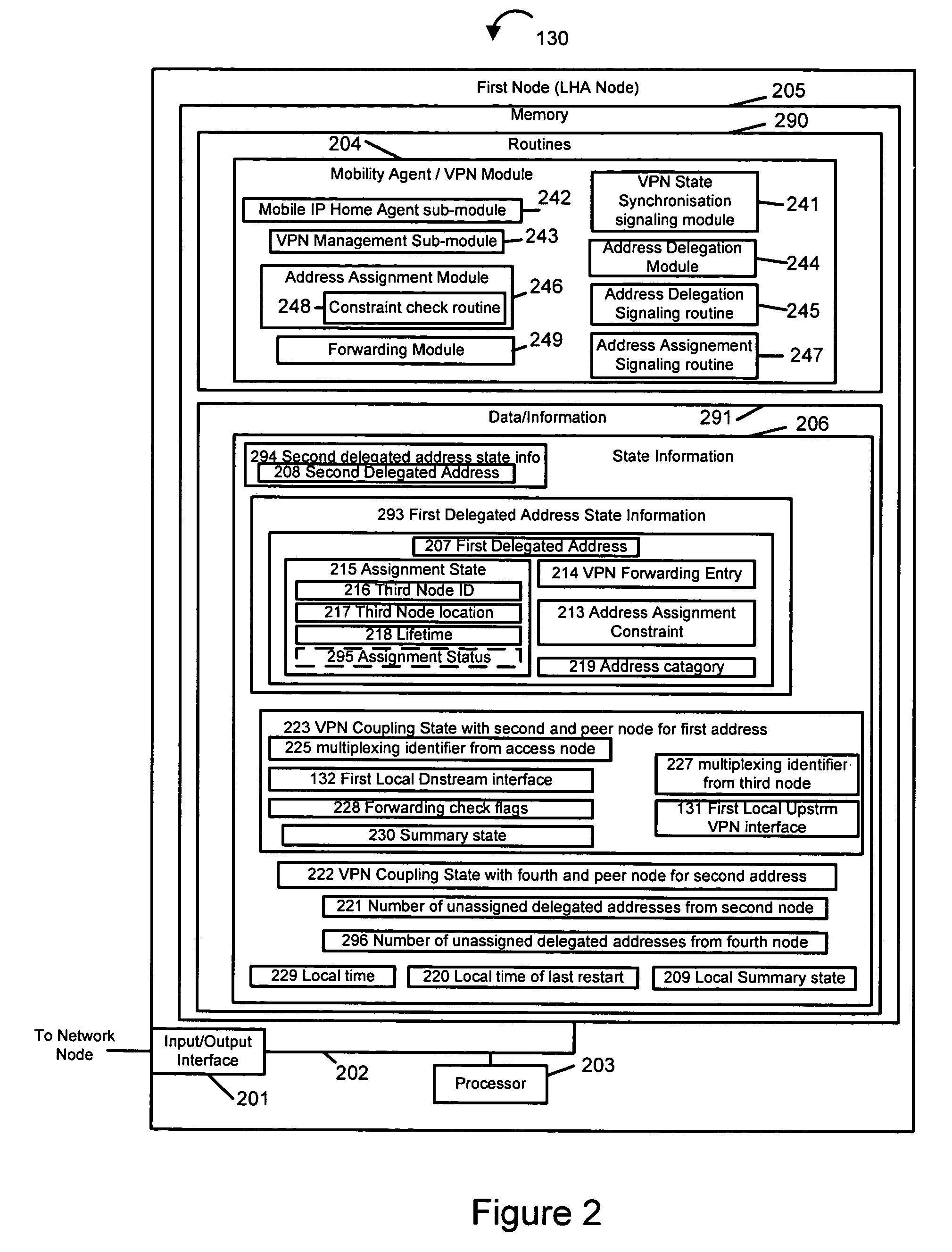

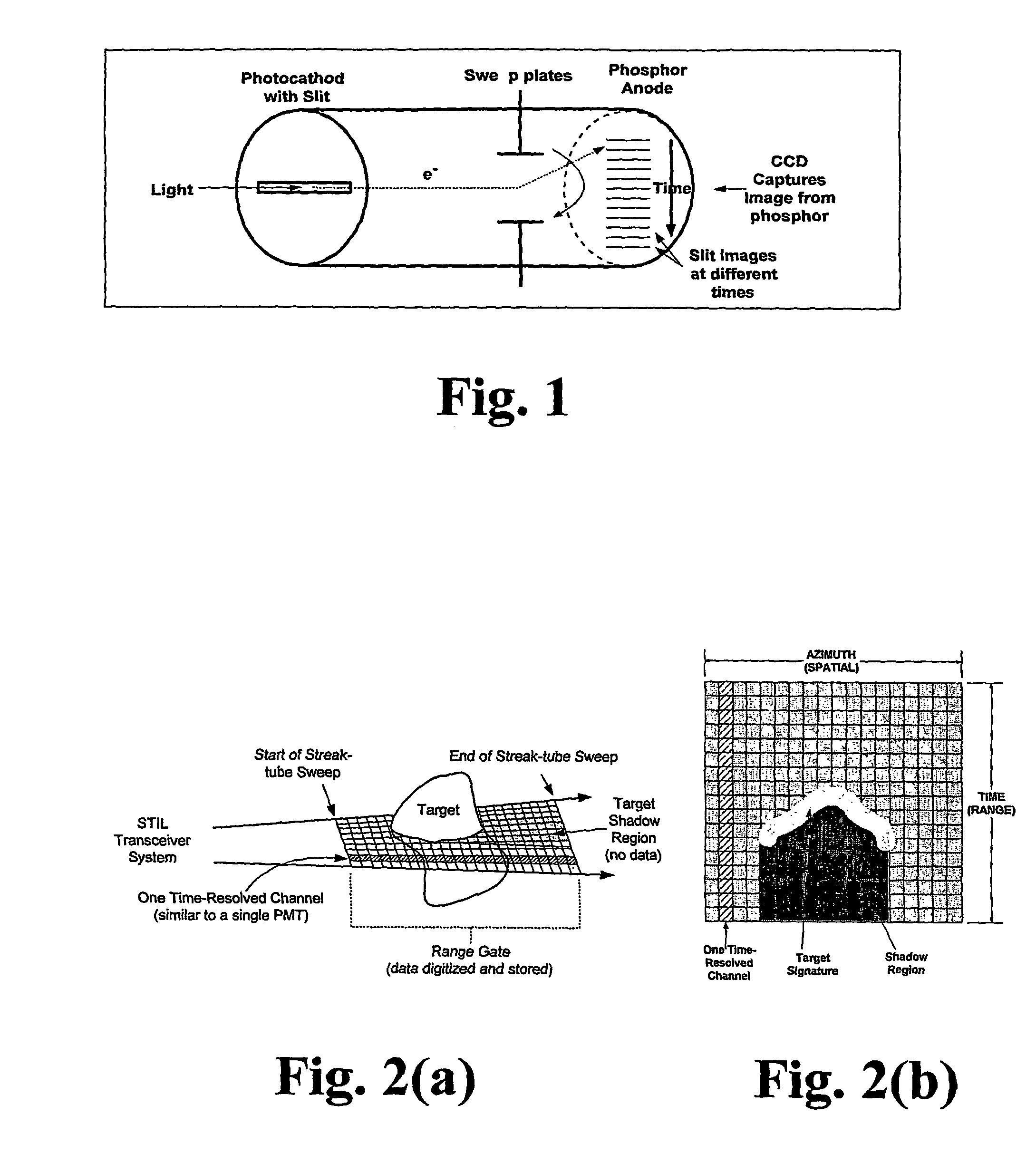

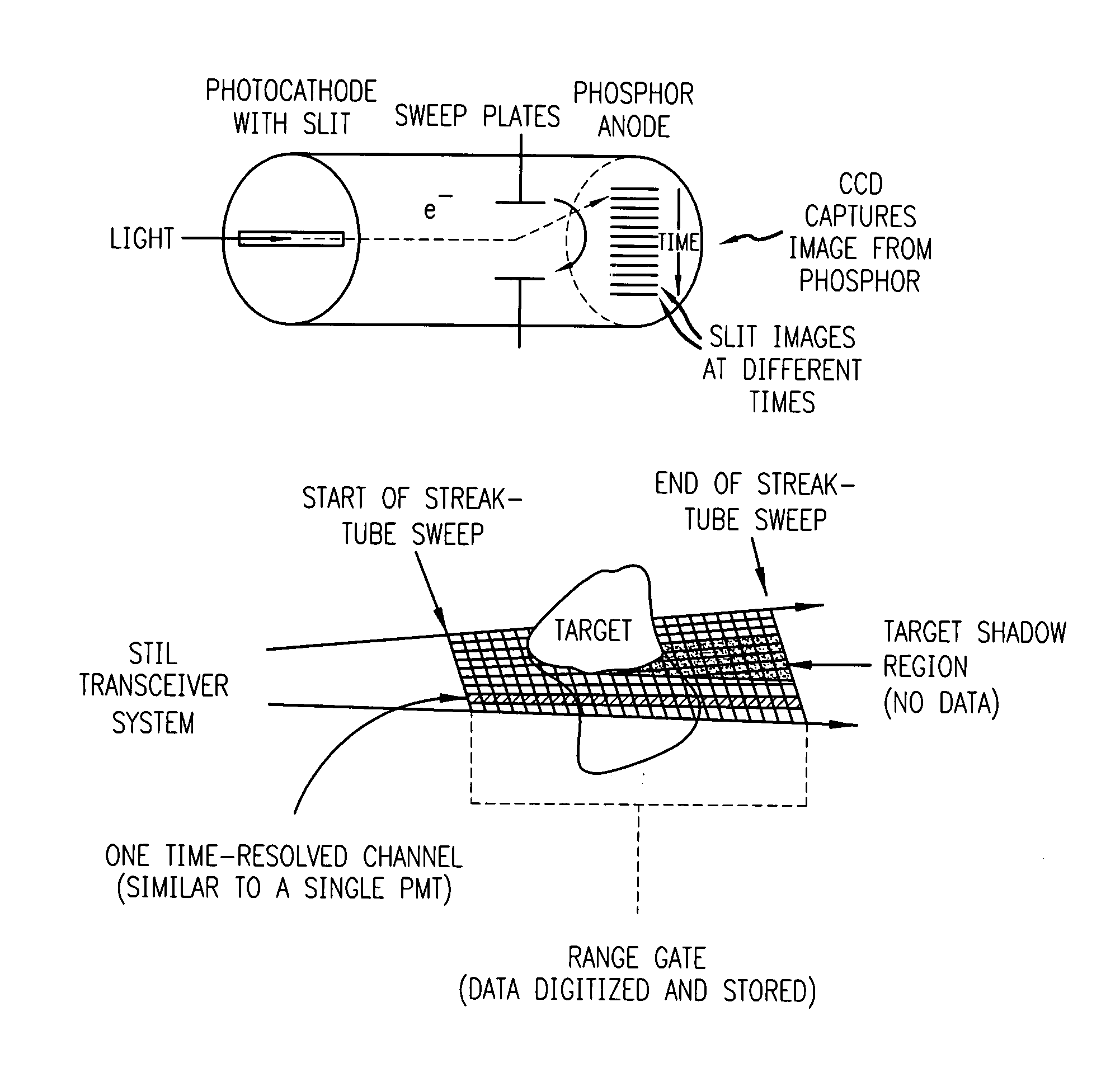

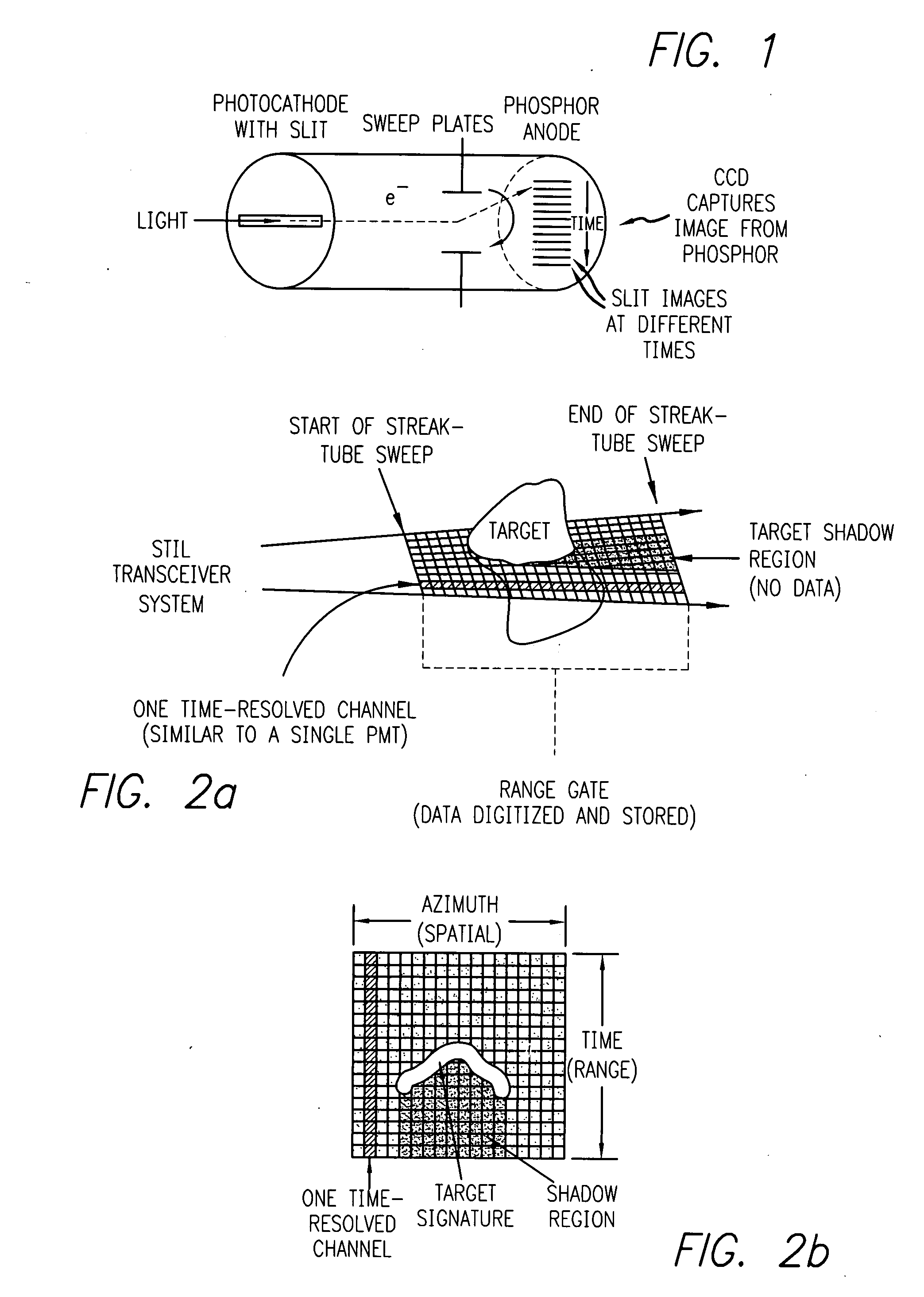

Very fast time resolved imaging in multiparameter measurement space

InactiveUS7227116B2Minimal lossEasy to optimizePolarisation-affecting propertiesPolarisation spectroscopyWavefront sensorFast tempo

Plural electronic or optical images are provided in a streak optical system, as for instance by use of plural slits instead of the conventional single slit, to obtain a third, fourth, etc. dimension—rather than only the conventional two, namely range or time and azimuth. Such additional dimension or dimensions are thereby incorporated into the optical information that is to be streaked and thereby time resolved. The added dimensions may take any of an extremely broad range of forms, including wave-length, polarization state, or one or more spatial dimensions—or indeed virtually any optical parameter that can be impressed upon a probe beam. Resulting capabilities remarkably include several new forms of lidar spectroscopy, fluorescence analysis, polarimetry, spectropolarimetry, and combinations of these, as well as a gigahertz wavefront sensor.

Owner:ARETE ASSOCIATES INC

Methods and apparatus for efficient VPN server interface, address allocation, and signaling with a local addressing domain

InactiveUS20060034297A1Digital data processing detailsDigital computer detailsCommunications systemFast tempo

Owner:QUALCOMM INC

Very fast time resolved imaging in multiparameter measurement space

InactiveUS20080035834A1Minimal lossEasy to optimizeOptical measurementsRadiation pyrometryFluorescenceFast tempo

Plural electronic or optical images are provided in a streak optical system, as for instance by use of plural slits instead of the conventional single slit, to obtain a third, fourth etc. dimension—rather than only the conventional two, namely range or time and azimuth. Such additional dimension or dimensions are thereby incorporated into the optical information that is to be streaked and thereby time resolved. The added dimensions may take any of an extremely broad range of forms, including wavelength, polarization state, or one or more spatial dimensions—or indeed virtually any optical parameter that can be impressed upon a probe beam. Resulting capabilities remarkably include several new forms of lidar spectroscopy, fluorescence analysis, polarimetry, spectropolarimetry, and combinations of these.

Owner:ARETE ASSOCIATES INC

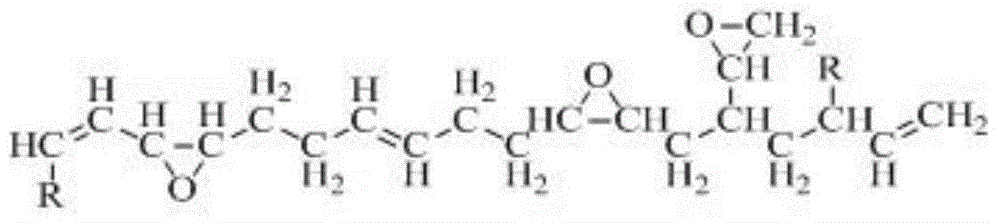

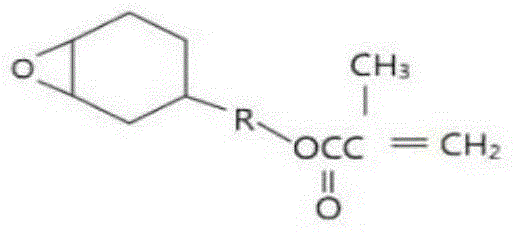

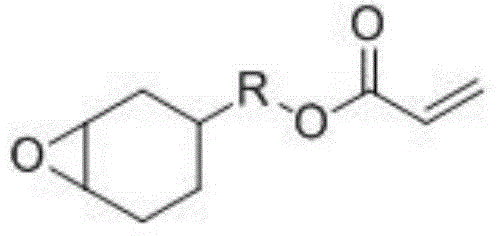

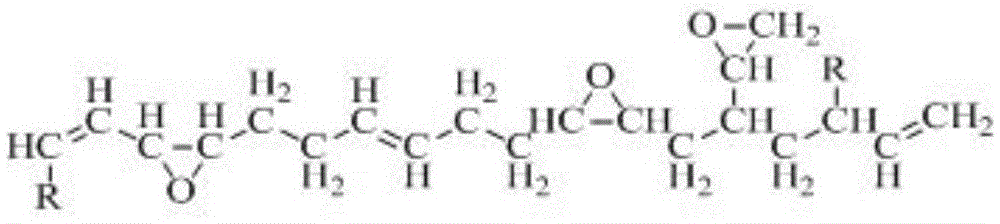

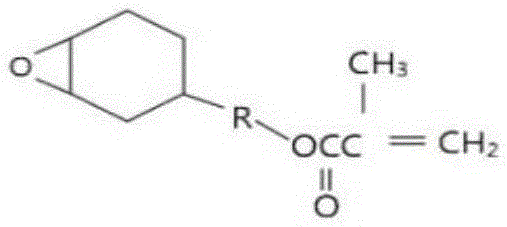

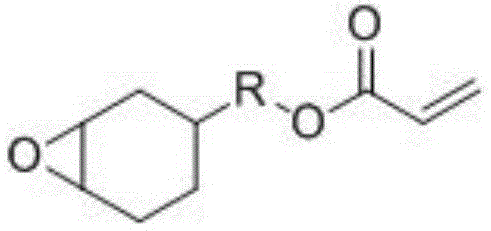

Ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin

ActiveCN104449419ASynergistic priming effect is goodIncrease the polymerization rateOrganic non-macromolecular adhesivePolyolefinFast tempo

The invention belongs to the technical field of adhesives, and particularly relates to an ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin. The ultraviolet-heat dual curing optical adhesive comprises the following components in percentage by weight: 14.5%-45% of epoxidized polybutadiene resin, 10%-40% of alicyclic epoxy modified resin, 5%-15% of polyolefin liquid rubber, 25.5%-35% of an acrylic ester reactive diluent, 2.4%-3.4% of a free radical photoinitiator, 0.1%-0.2% of a cationic photoinitiator and 2%-2.5% of a peroxide initiating curing agent. The optical adhesive disclosed by the invention is relatively completely solidified at a shaded part, a dark adhesive layer part or a thick adhesive layer part, has excellent optical properties such as high refractive index and high transmittance after being solidified, has the advantages of shock resistance, low yellowing coefficient, low haze, low shrinking percentage, easiness in repairing and good flexibility, meets the requirements of optical, physical and chemical properties of display devices, and is suitable for fast-tempo and high-efficiency production processes.

Owner:信泰永合(烟台)新材料有限公司

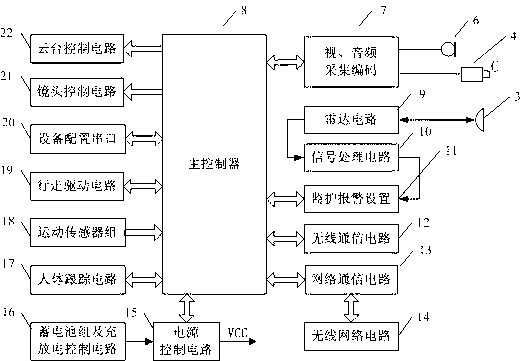

Remote monitoring robot

ActiveCN102755194AGet rid of movement restrictionsConvenience of home medical careSurgeryDiagnostic recording/measuringVideo monitoringOlder people

The invention discloses a remote monitoring robot consisting of a robot body as well as a noncontact human vital sign monitoring device, a human body tracking circuit, a remote alarm device and a remote network video monitoring device which are attached to the robot. The remote monitoring robot can be used for automatically or remotely tracking a monitored objet and monitoring main vital signs of the monitored object in a noncontact mode in a certain distance; the monitored person can freely move in a certain range, so that action limitation of the conventional monitoring device on the monitored person is eliminated; and when the vital sign parameters are abnormal, emergency signals can be automatically transmitted to a far end through the existing mobile communication network and Internet. The remote monitoring robot can be widely applied to remote monitoring of old people living alone and sick and weak groups, and provides great convenience for household medical nursing in the aging and fast-tempo society.

Owner:山东省普来特能源与电器研究院

Seafood-containing soup can and manufacturing method thereof

The invention relates to a seafood-containing soup can and a manufacturing method thereof. The soup can is characterized by comprising a soup material containing dissolved xanthan gum and cooked seafood, wherein the mass concentration of the cooked seafood is between 10 and 50g / L, and the mass concentration of the xanthan gum is between 4 and 5g / L. The manufacturing method of the soup can comprises the following steps of: 1) preparing the soup material containing the dissolved xanthan gum; 2) treating seafood; and 3) preparing a finished product can. The soup can can be manufactured into salty taste, spicy taste, sweet taste and other different tastes. In the invention, the seafood is manufactured into a soup can which has delicious taste and rich nutrition, is convenient, quick and safe to eat; and the soup can saves labor in household kitchen, meets the requirement on consumers, fulfills the demands of fast-tempo society, and provides new developing space for seafood manufacture.

Owner:OCEAN UNIV OF CHINA

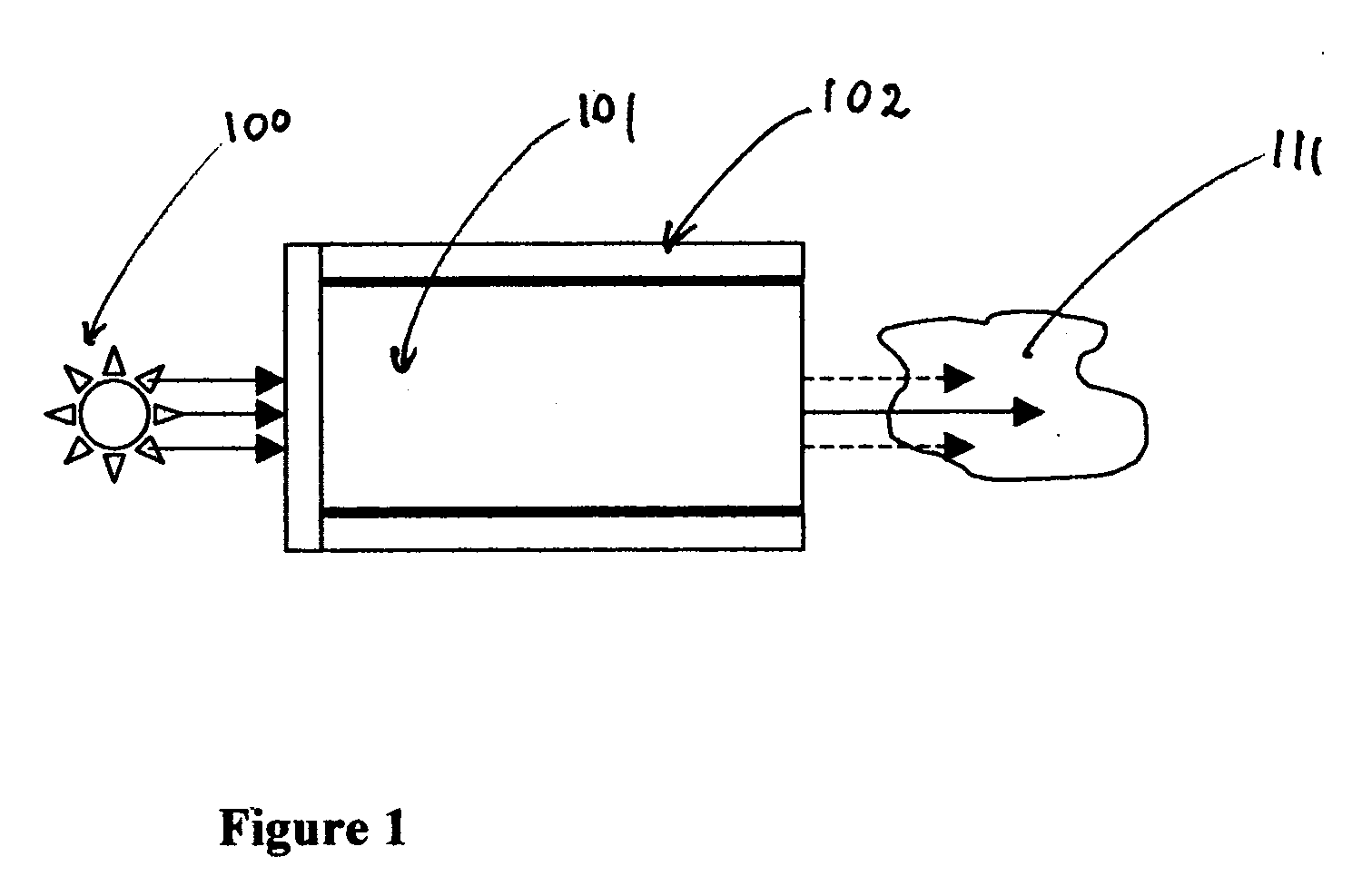

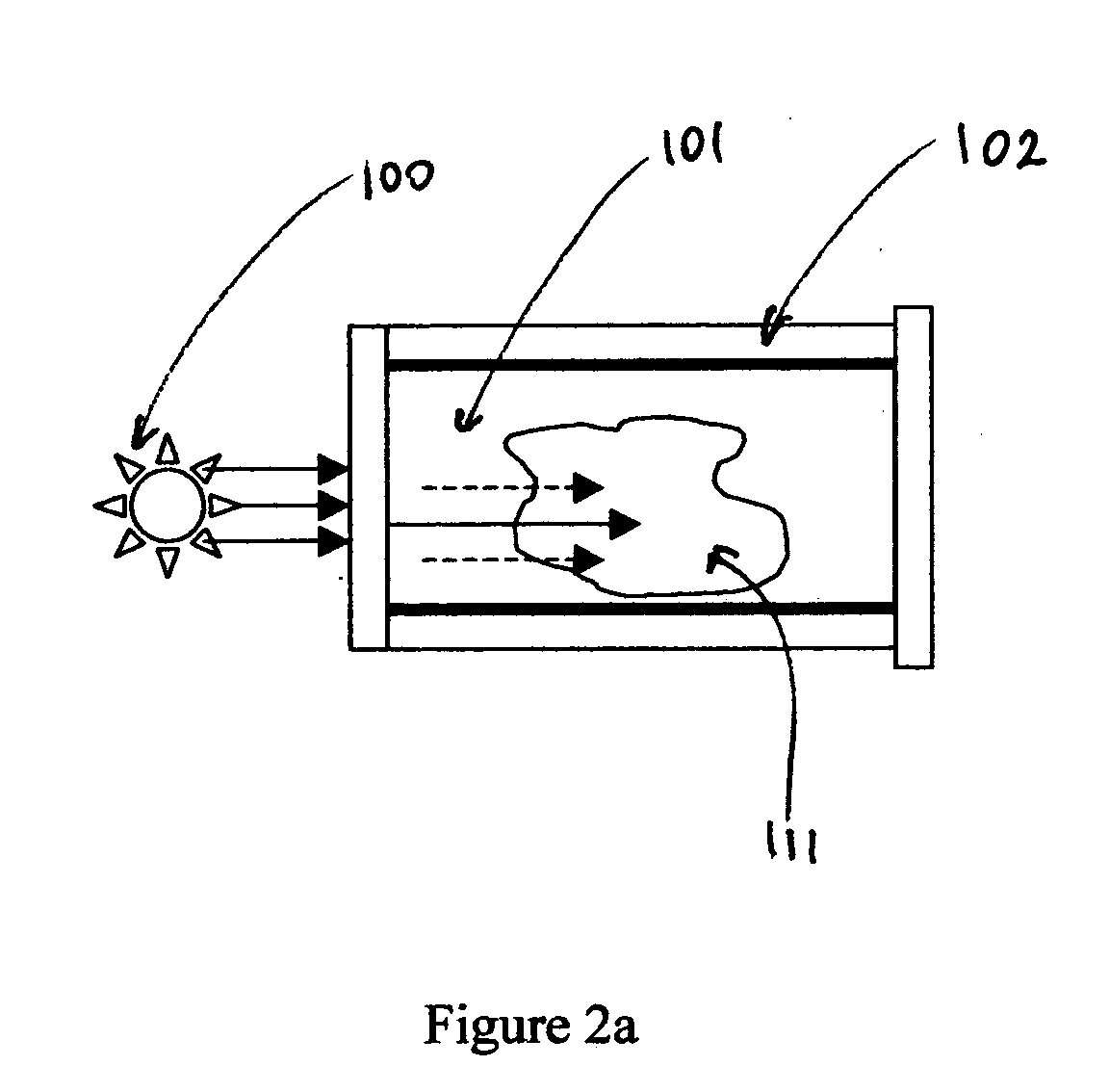

Rapid cryo-heating devices and their applications

This invention discloses cryo-heating phototreatment devices and methods for cooling and heating objects in a very rapid timescale, from femtosecond to subsecond. The cryo-heating phototreatment device is a multiplex energy source comprising of an electromagnetic source and at least one of the members of the group of radiation sources: sonic, magnetic, electric, electroluminescent, up-converted luminescence, pressure and thermal. The electromagnetic source in the cryo-heating phototreatment device induces cooling of objects by up-converting energy luminescence and heating by absorption or interaction of electromagnetic radiation with objects. The invention also proposes a method of an enhancement of the up-converted energy cooling and heating processes by surface plasmon resonance of conducting nanostructures. The proposed devices and methods of very rapid cooling and heating can be applied in biomedical technologies and health care. The invention also includes applications of the disclosed herein method to up-conversion energy cooling of electronic components and photon detector devices.

Owner:SPR ADVANCED TECH INC

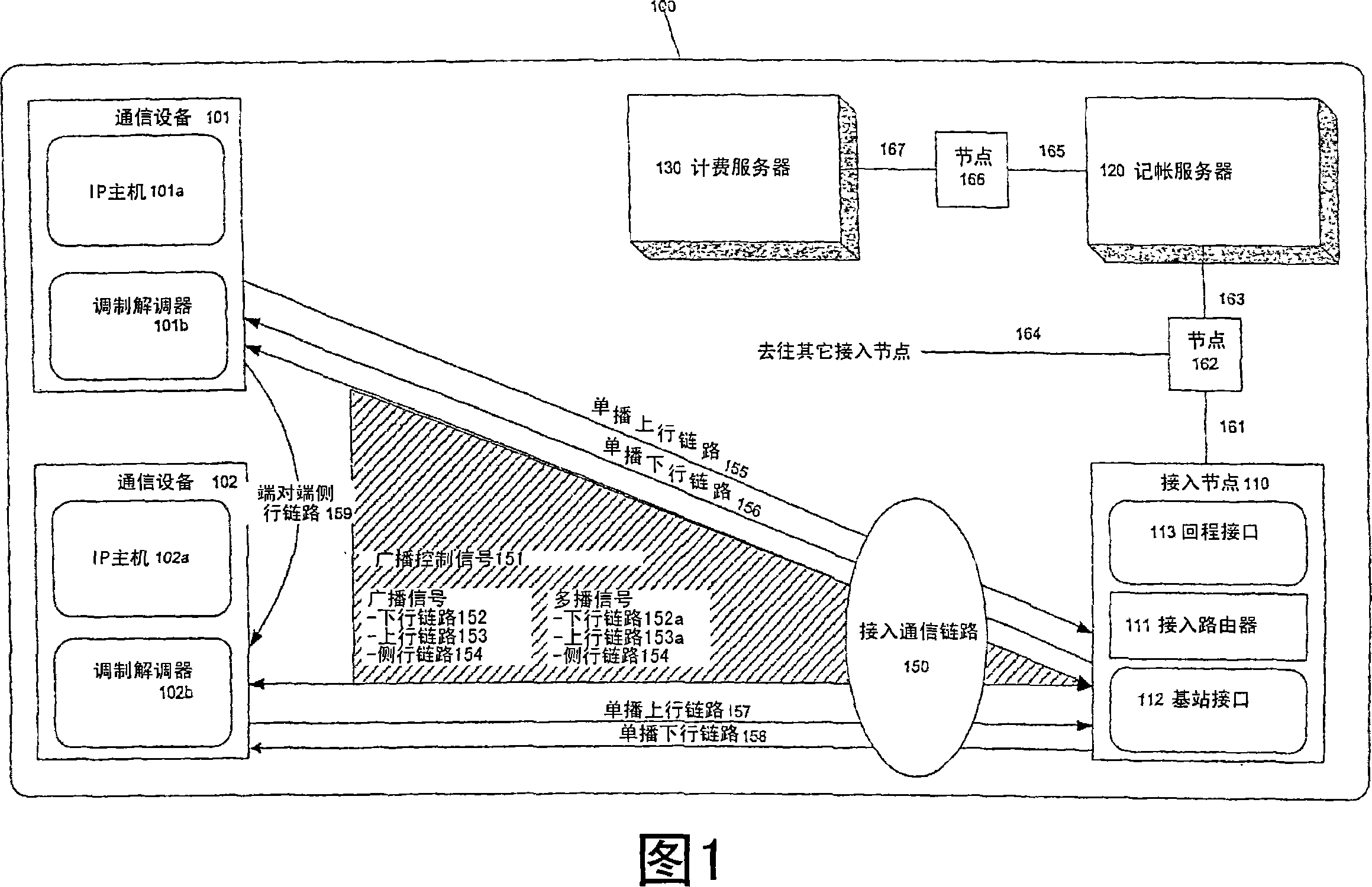

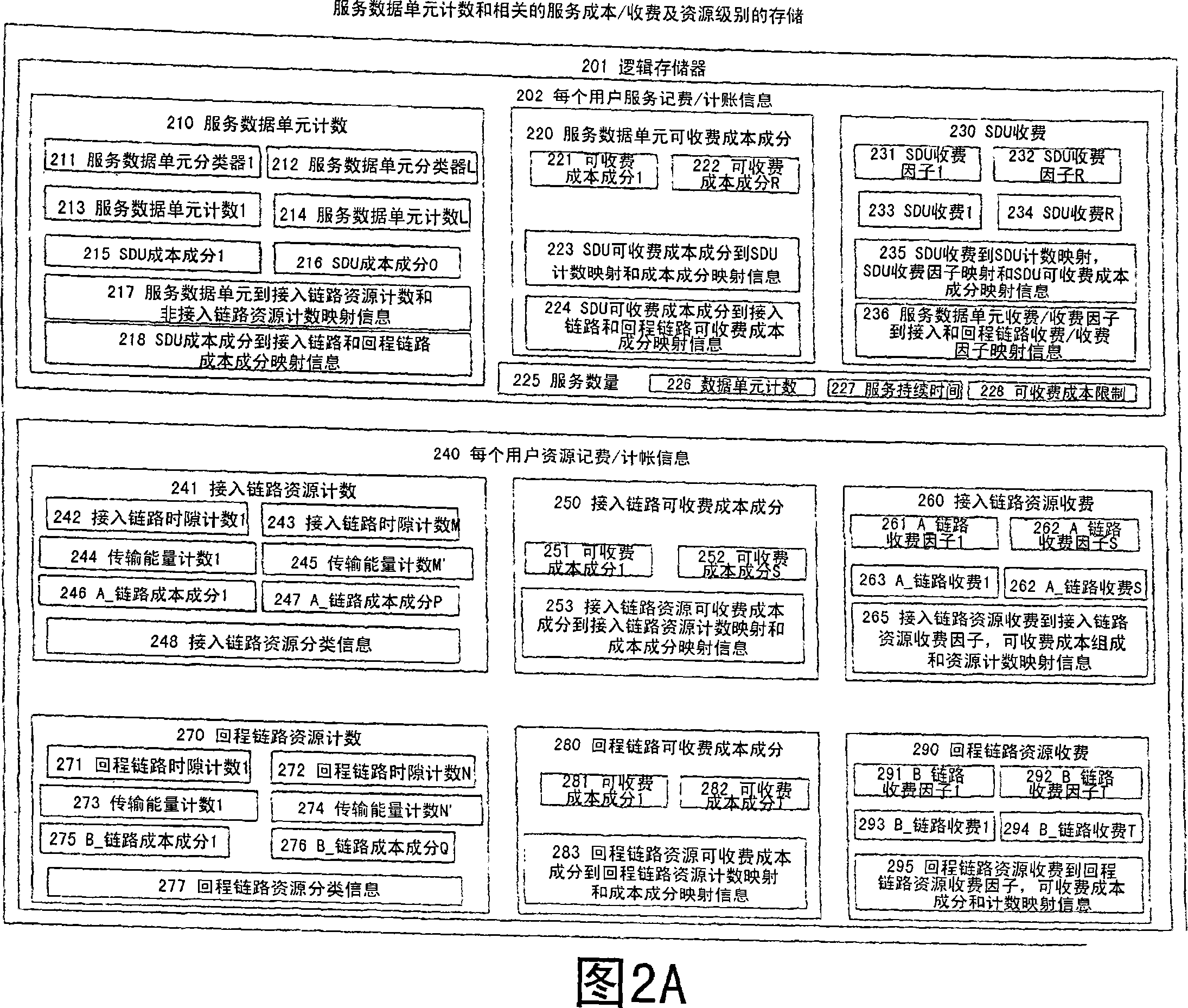

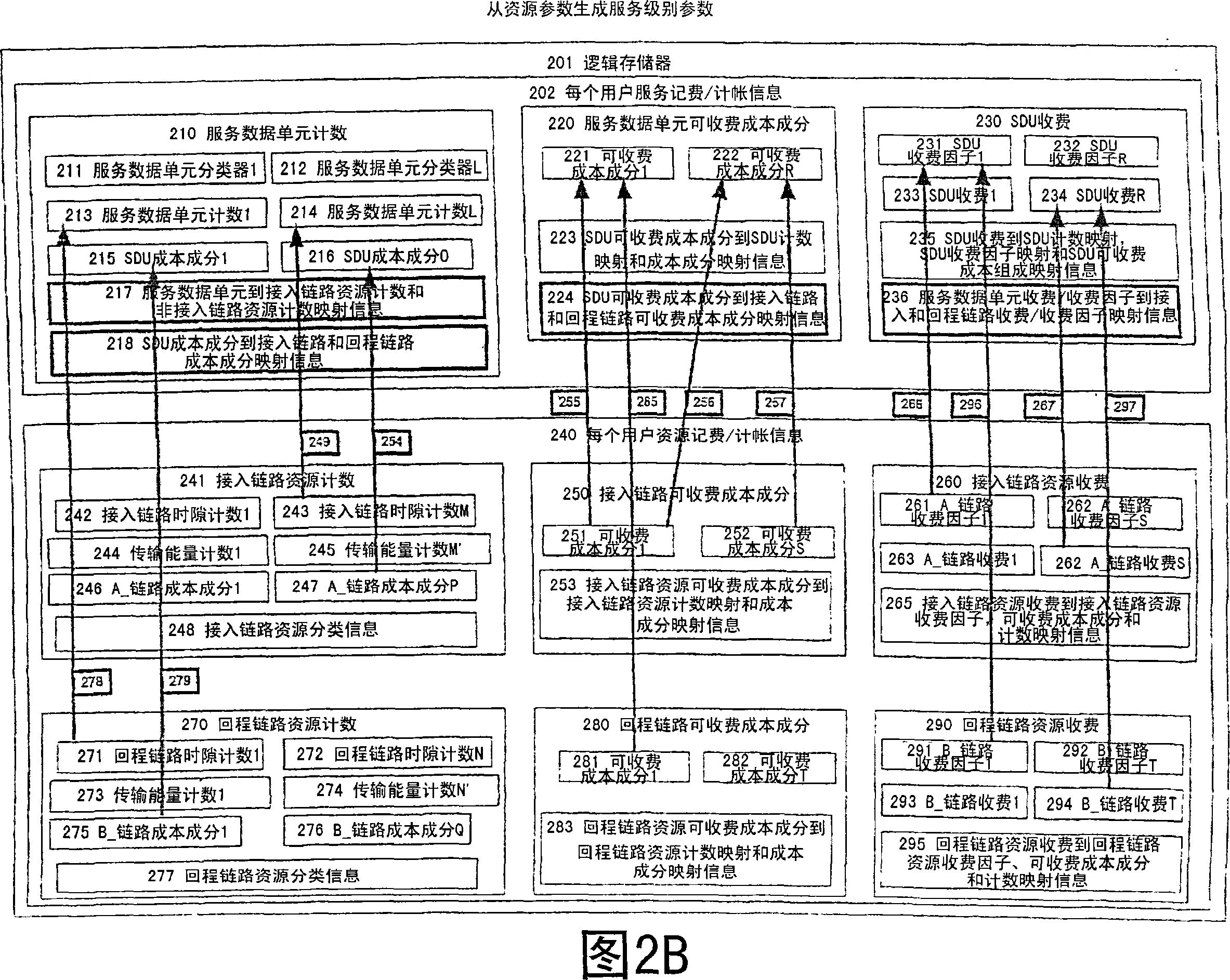

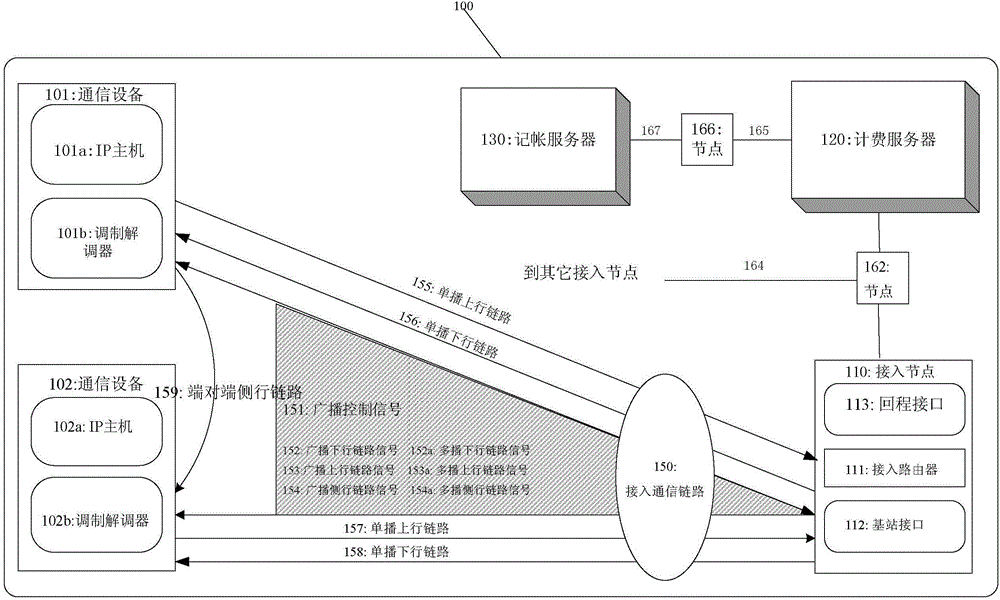

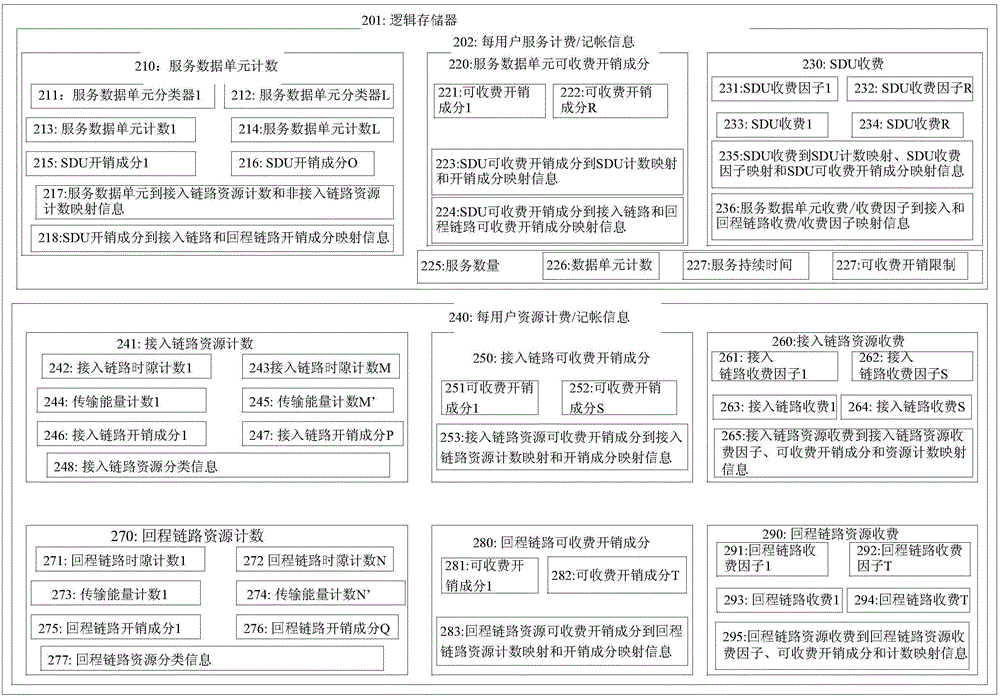

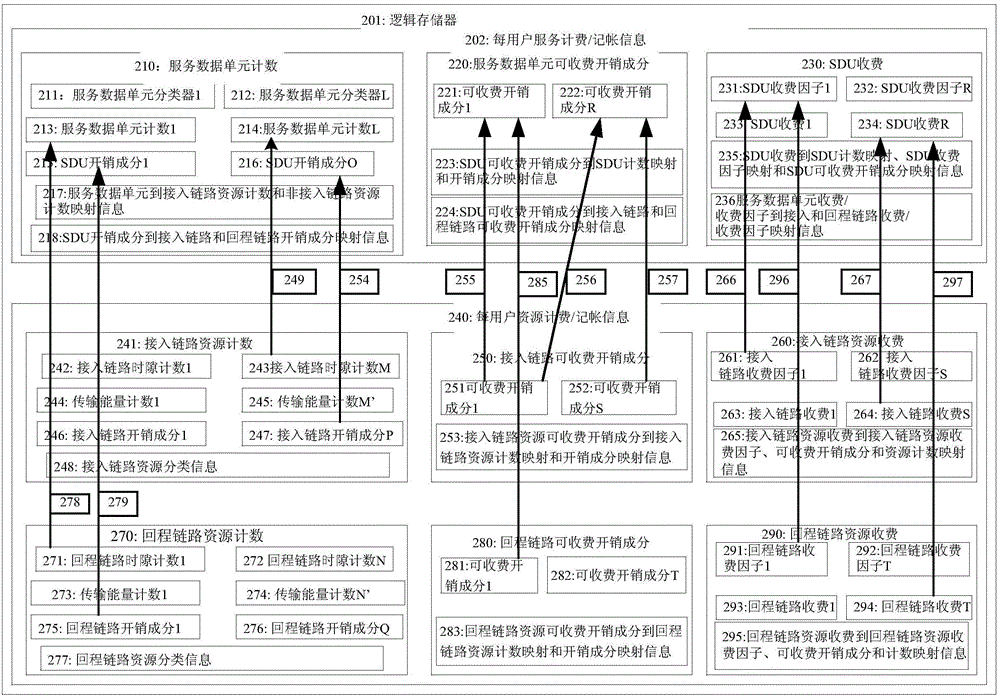

Methods and apparatus for tracking and charging for communications resource reallocation

InactiveCN101061701AIncrease costMetering/charging/biilling arrangementsAccounting/billing servicesResource utilizationFast tempo

Utilization of resources used to provide a service, and / or costs associated with providing system resources for a service, are tracked in a system where the available resources vary depending on a variety of conditions including resource utilization by other users. The methods are well suited for systems such as mobile communications systems, where the amount of resources and / or costs to a system of providing a service are dynamic and can change on a relatively rapid time scale. Resource unitization is tracked on a per subscriber basis. Service charges can be deteiinined as a function of both the amount of resources consumed and the amount of data delivered, with the amount of resources being used to deliver a fixed amount of data units varying as a function of environmental and / or other conditions. Service charges are sometimes determined as a function of the impact of providing the service to a first user on other system users.

Owner:QUALCOMM INC

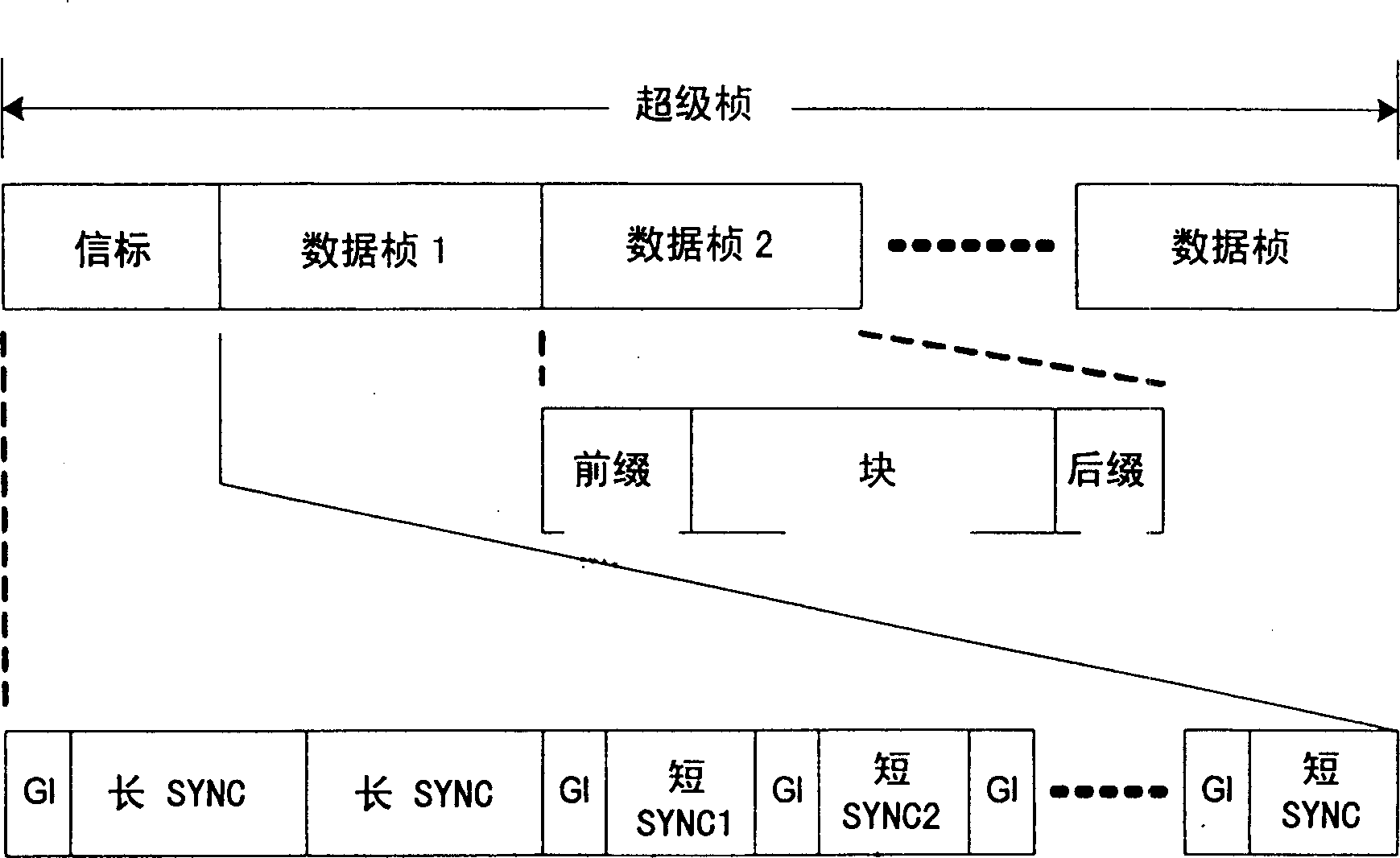

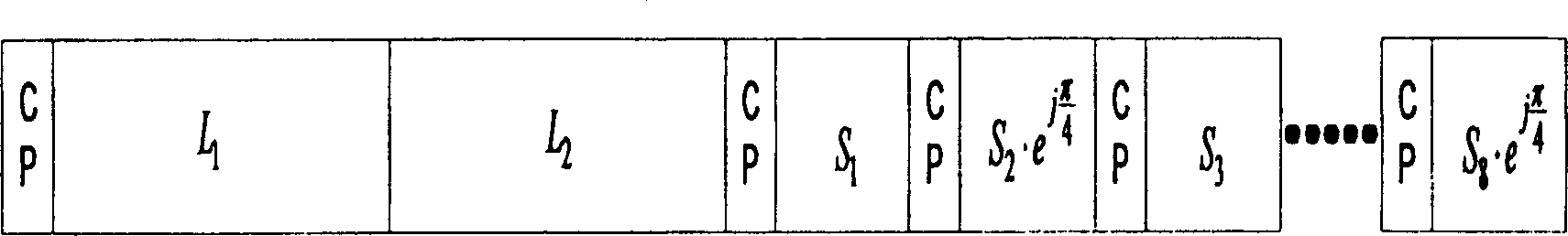

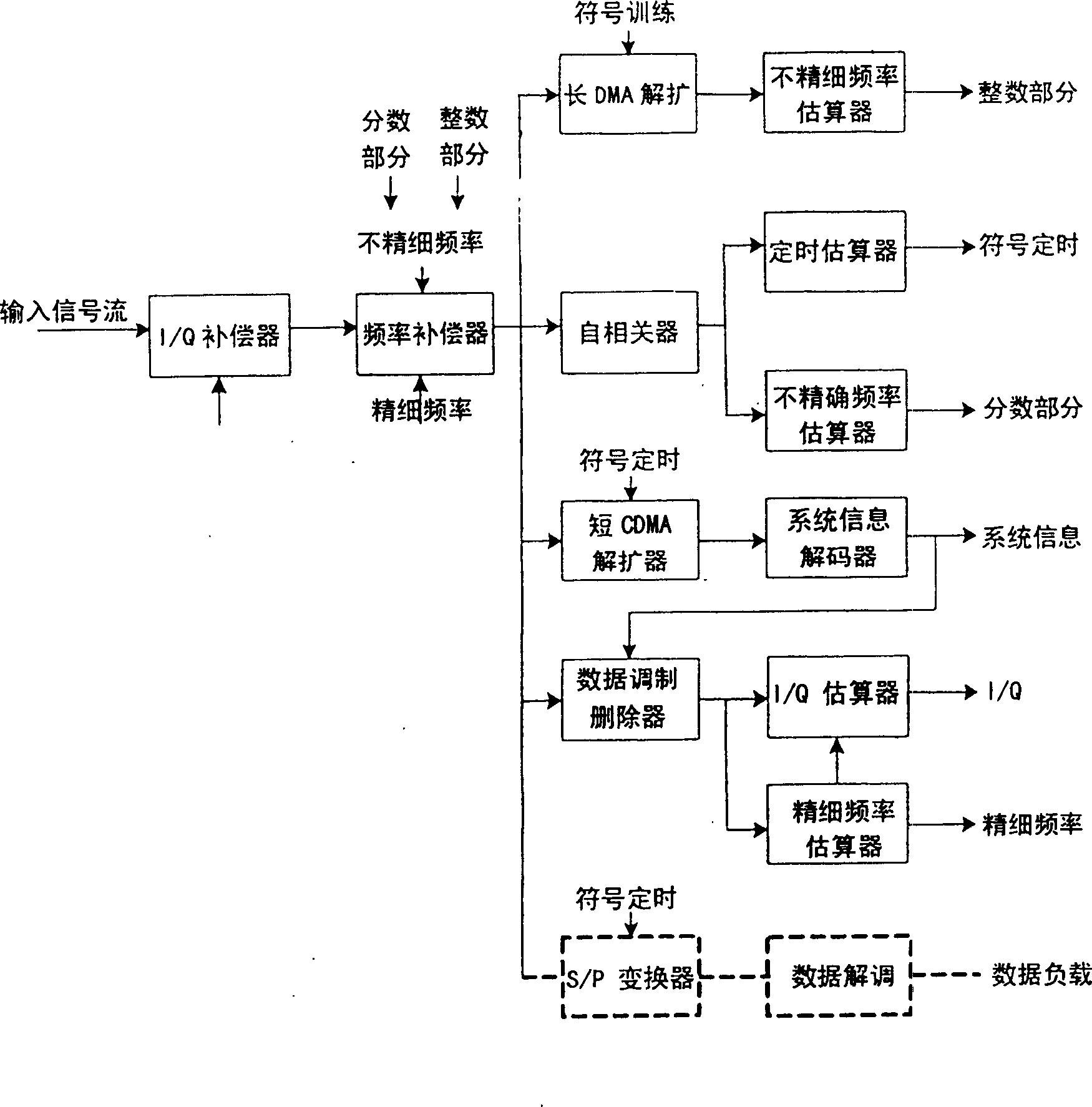

Method for making synchronization by utilizing time domain spread spectrum beacon in digital video broadcast

InactiveCN1516460AIncrease sending powerImprove robustnessTelevision system detailsColor television detailsDigital videoTime domain

The invention provides a kind of method for carrying on quick and reliable synchronization by using time region frequency expansion signal mark in digital video broadcast, the signal mark includes long synchronization and the short synchronization signs: the long one is used in quick time and frequency capture, the short one is used in the precise estimation of residual deviation, I / Q unbalanced and other hardware nonideal characteristics. Some important system parameter such as FFT block length and the protection interval length are coded in the short synchronization sign in order to support variant system work mode.

Owner:TIMI TECH

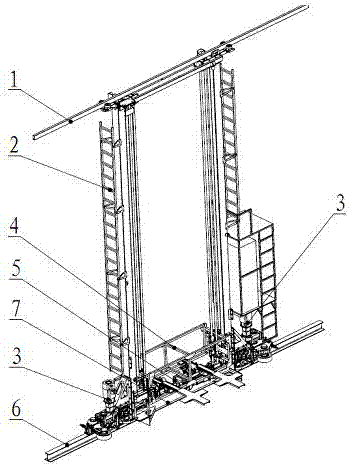

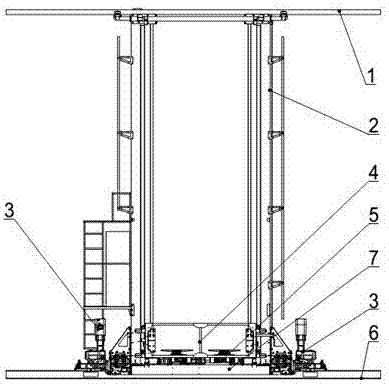

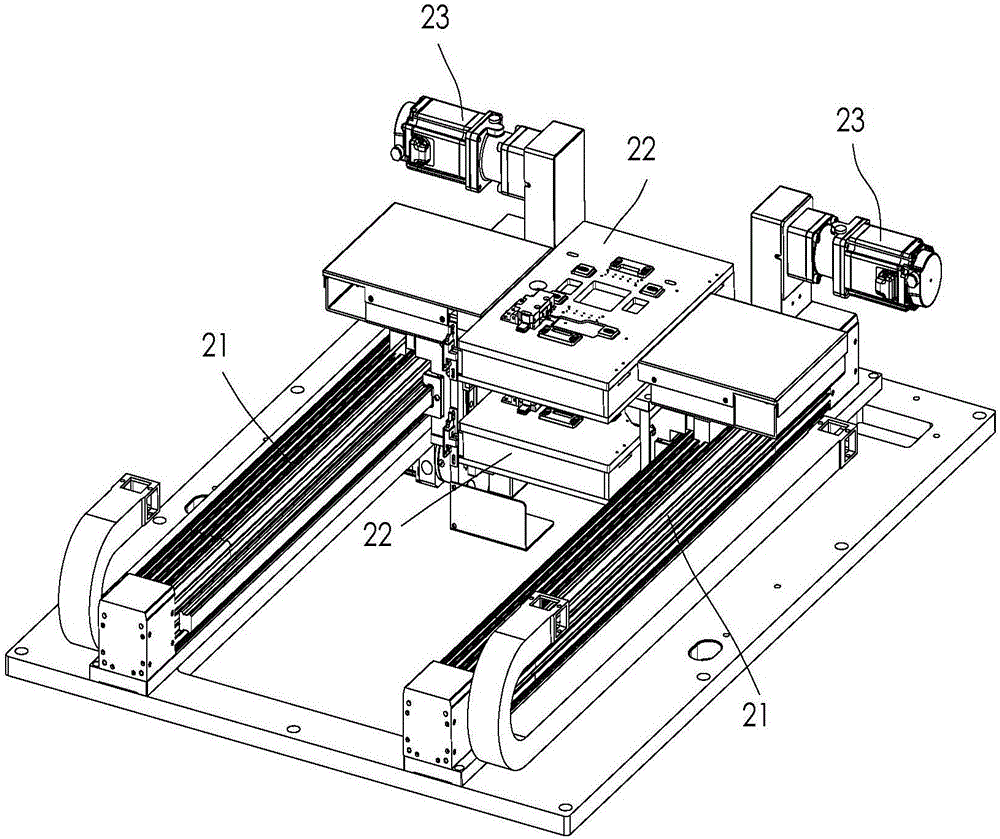

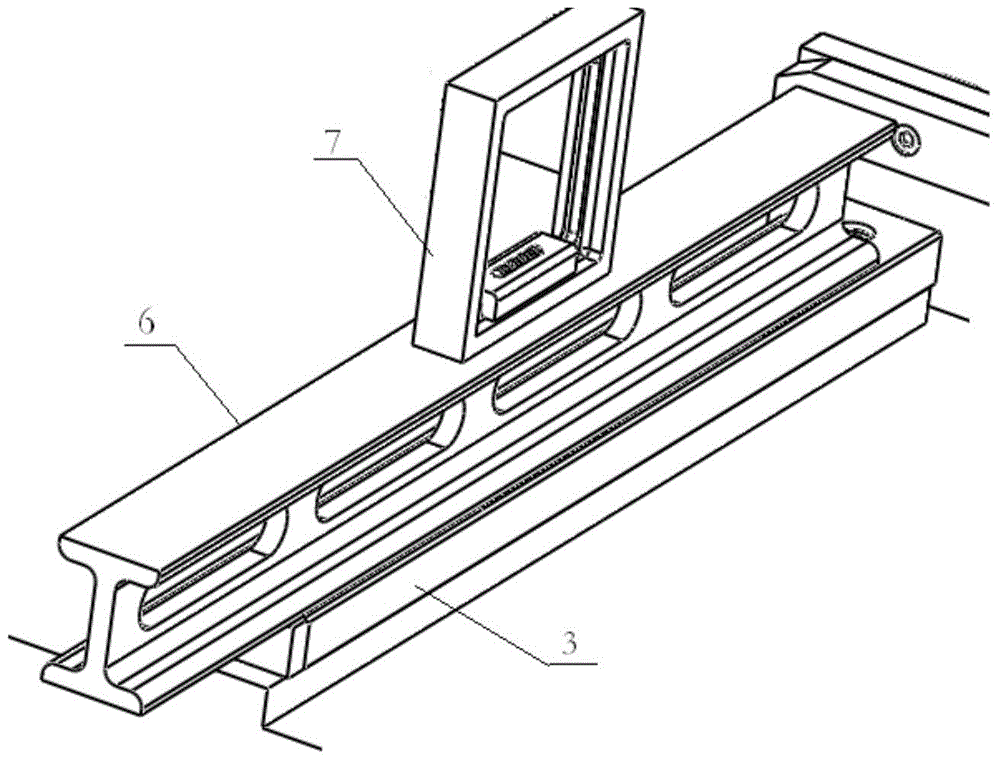

High speed stacker for semisteel blank storeroom

PendingCN107572450ASolve vulnerableResolution timeSafety devices for lifting equipmentsDrive wheelFast tempo

The invention relates to a high speed stacker for a semisteel blank storeroom and solves the problem that in the prior art, the stacker is complex in structure and unstable to operate, affects the precision of goods allocations and is not suitable for the fast-tempo demand of the semisteel blank storeroom. The high seed stacker is characterized in that a horizontal driving device is mounted on a portal frame mechanism; a good carrying table mechanism is double stations and double forks; the amount of compression of an adjusting compression spring can adjust the positive pressure between a driving wheel and a driven wheel and a ground rack; the acceleration can reach 2m / second squared; and a rectifying wheel anti-tipping wheel is mounted in a bearing wheel assembly. The high speed stacker provided by the invention has the beneficial effects that the high speed stacker solves the problems of great impact, non-synchronous operation, severe vibration of equipment, inaccurate stop positionof the equipment non-synchronous drive and loud noise as a result of high-speed operation, meets the demands on blank storage and fast tempo of transferring work in a semisteel vulcanizing workshop, is compact in structure and accurate to position, achieves stable high-speed and high-acceleration operation of a driving device, and is steady to operate, small in noise, safe and reliable, and the using rate of a three-dimensional storeroom and the stacking efficiency are increased.

Owner:SHENYANG BLUE SILVER IND AUTOMATION EQUIP SHARE

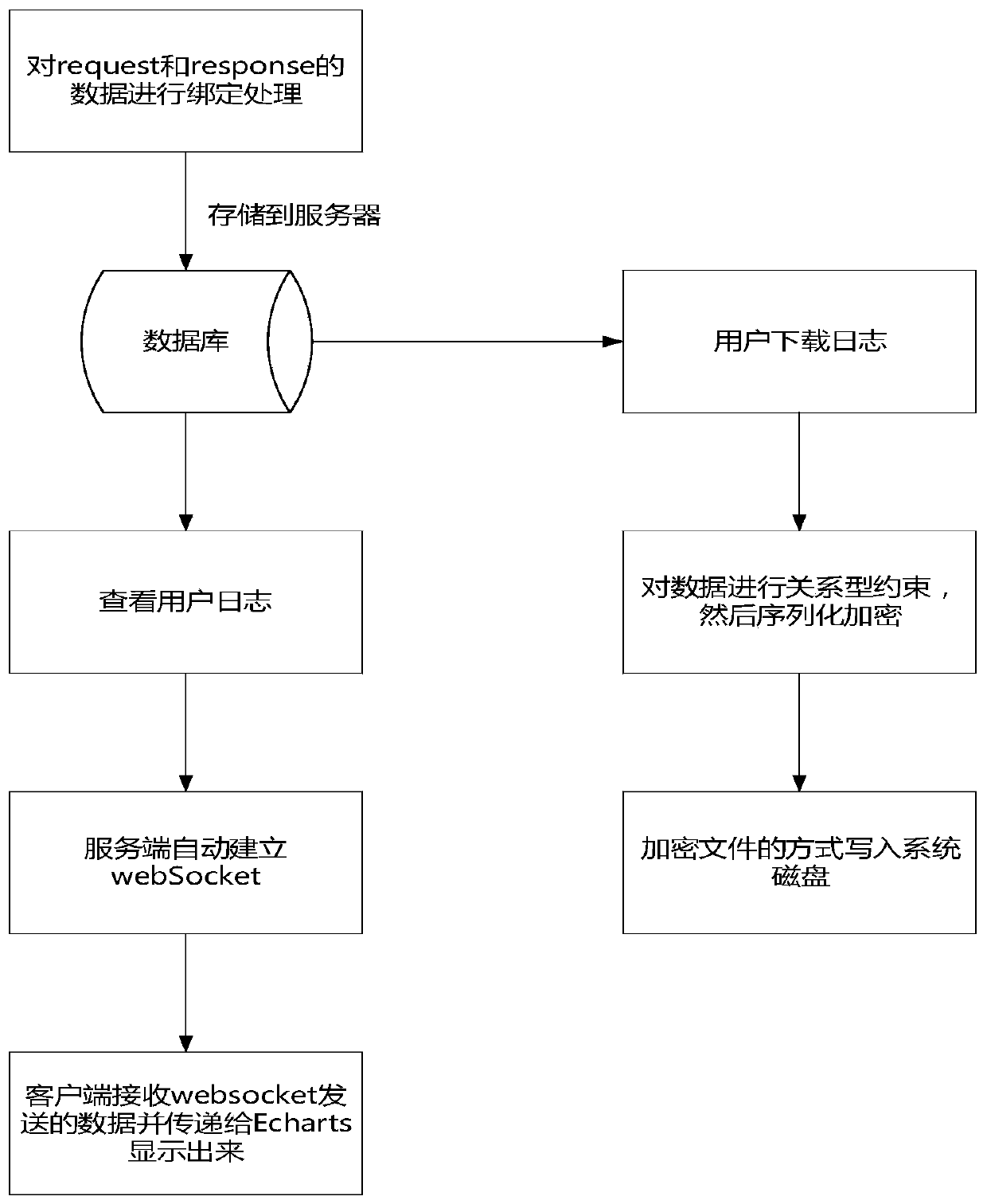

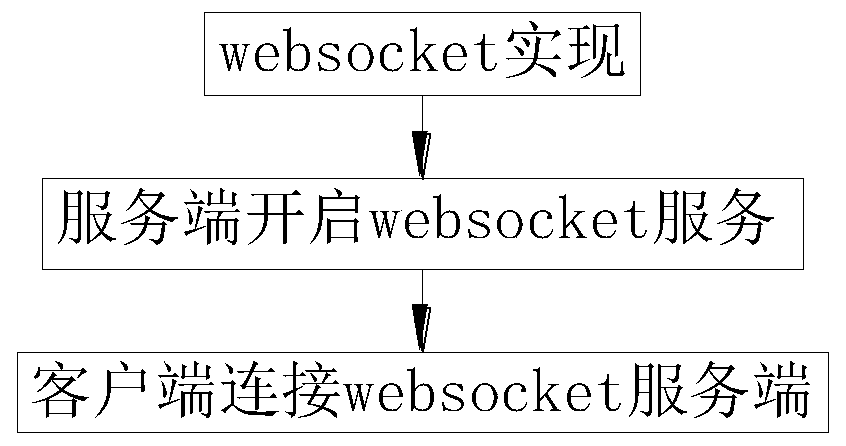

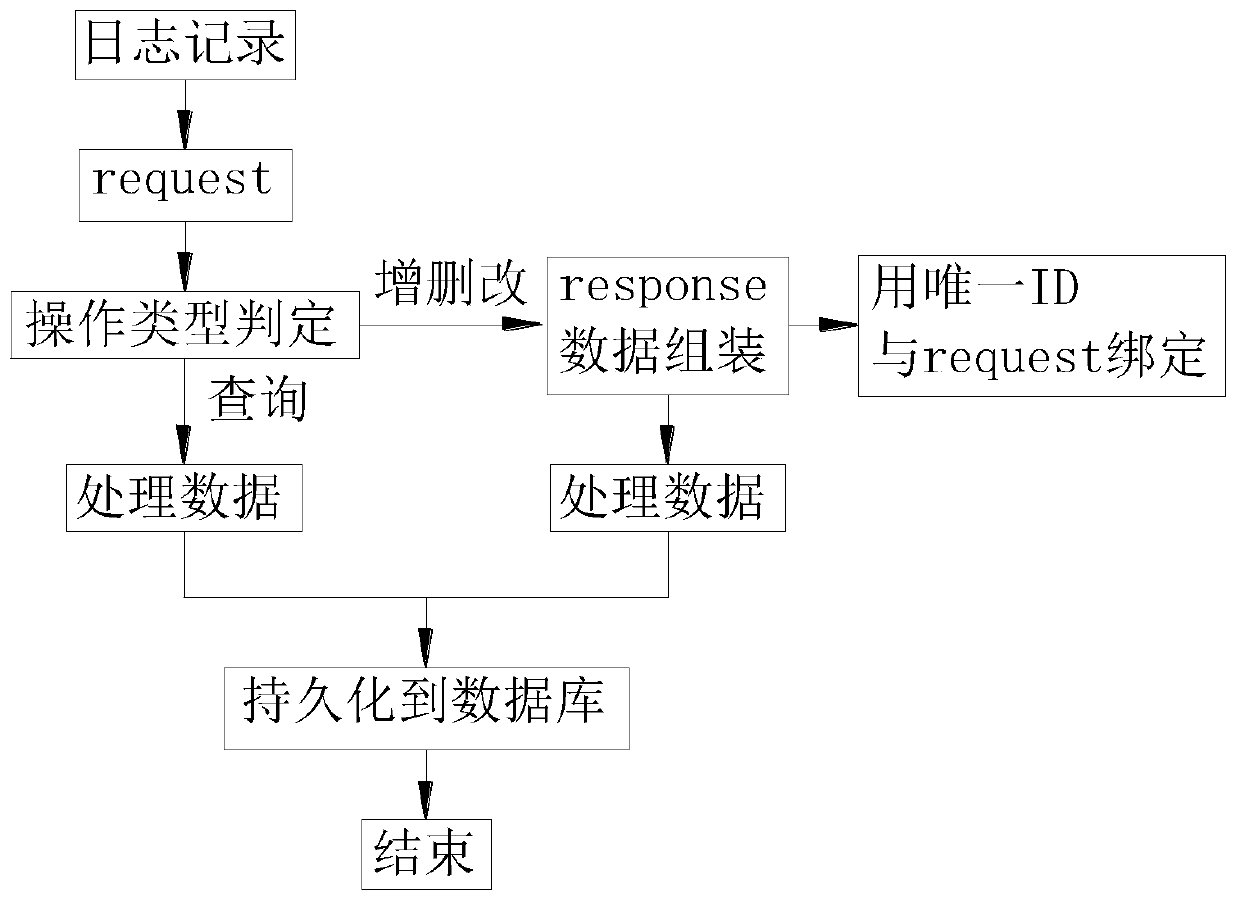

An MES system performance and log data monitoring method

ActiveCN109739728AMonitor service performanceMonitor usage frequencyHardware monitoringManufacturing computing systemsFast tempoSerialization

The invention relates to an MES system performance and log data monitoring method. The MES system performance and log data monitoring method comprises the following steps of obtaining page data of logmonitoring; transmitting the page data; binding and processing the request data and the request data; performing relational constraint on the data, performing serialized encryption, and compressing the log data into a log file in a specific format. According to the method, a serialized encryption mode is adopted for downloading of the log file, a user only needs to select time for downloading andcan download log information, the log user cannot open or modify the log information and can analyze the log information only through a software supplier, analyzed data are assembled, and the problemcan be located and solved in the fastest time.

Owner:武汉益模科技股份有限公司

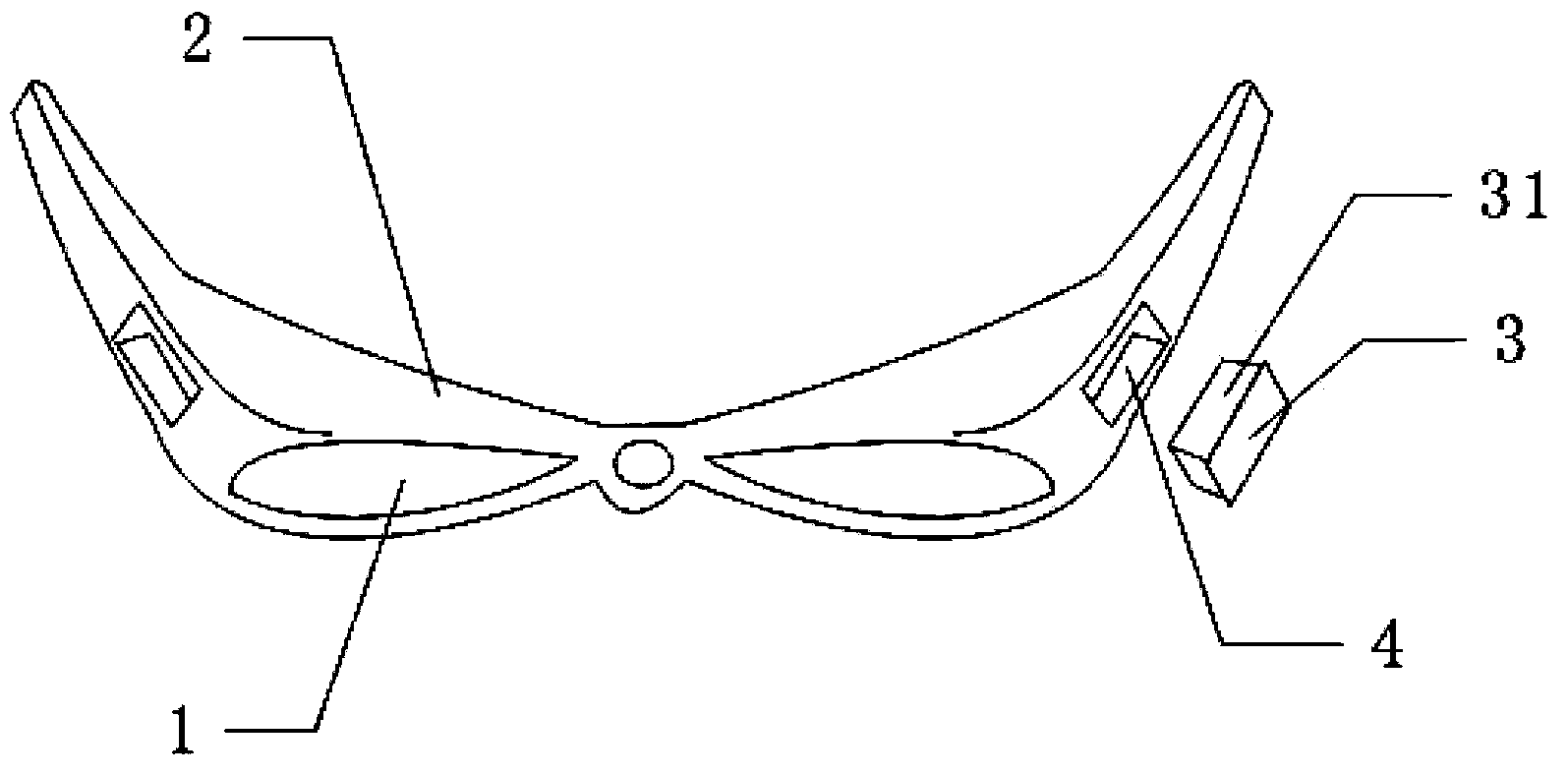

Glasses with moisture retention function

InactiveCN103631027AIncrease humidityRelieve fatigueNon-optical adjunctsNon-optical partsRetention functionFast tempo

The invention relates to the technical field of glasses, particularly glasses with moisture retention function. The glasses include lenses, a spectacle frame and a liquid storage box. One side of the spectacle is provided with a notch; the liquid storage box is detachably arranged in the notch; the liquid storage box is provided with a box cover; and the box cover is provided with a plurality of micro holes. The liquid storage box contains moisturizing eye drops and has an elastic hollow structure. According to the invention, the daily used glasses are added with the liquid storage box; the storage box contains liquid to moisturize the eyes and alleviate eye fatigue; the glasses have the advantages of simple structure, reasonable design and beautiful appearance, and is suitable for usage by people with fast tempo of modern life.

Owner:西安秦昊电子技术有限责任公司

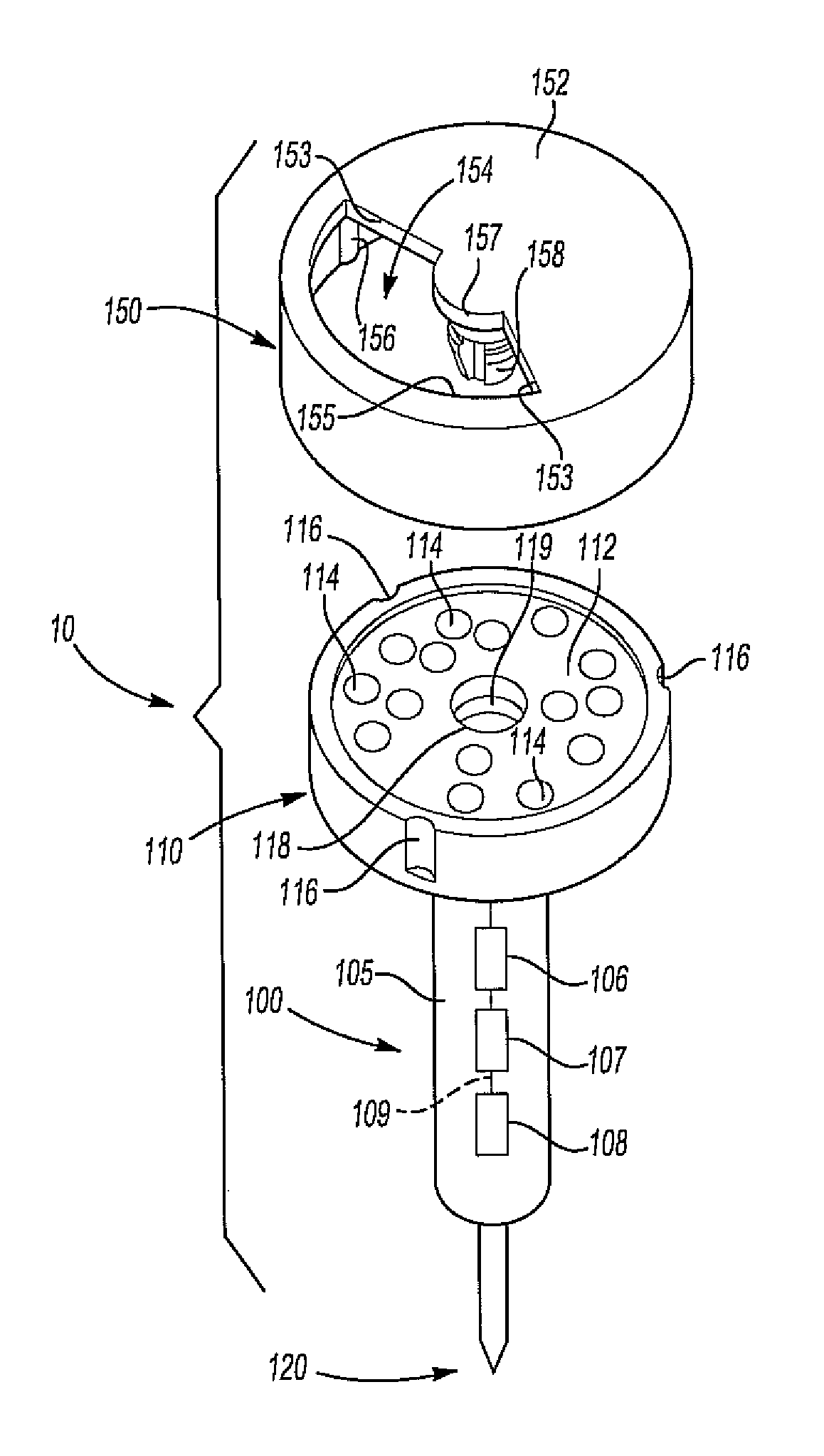

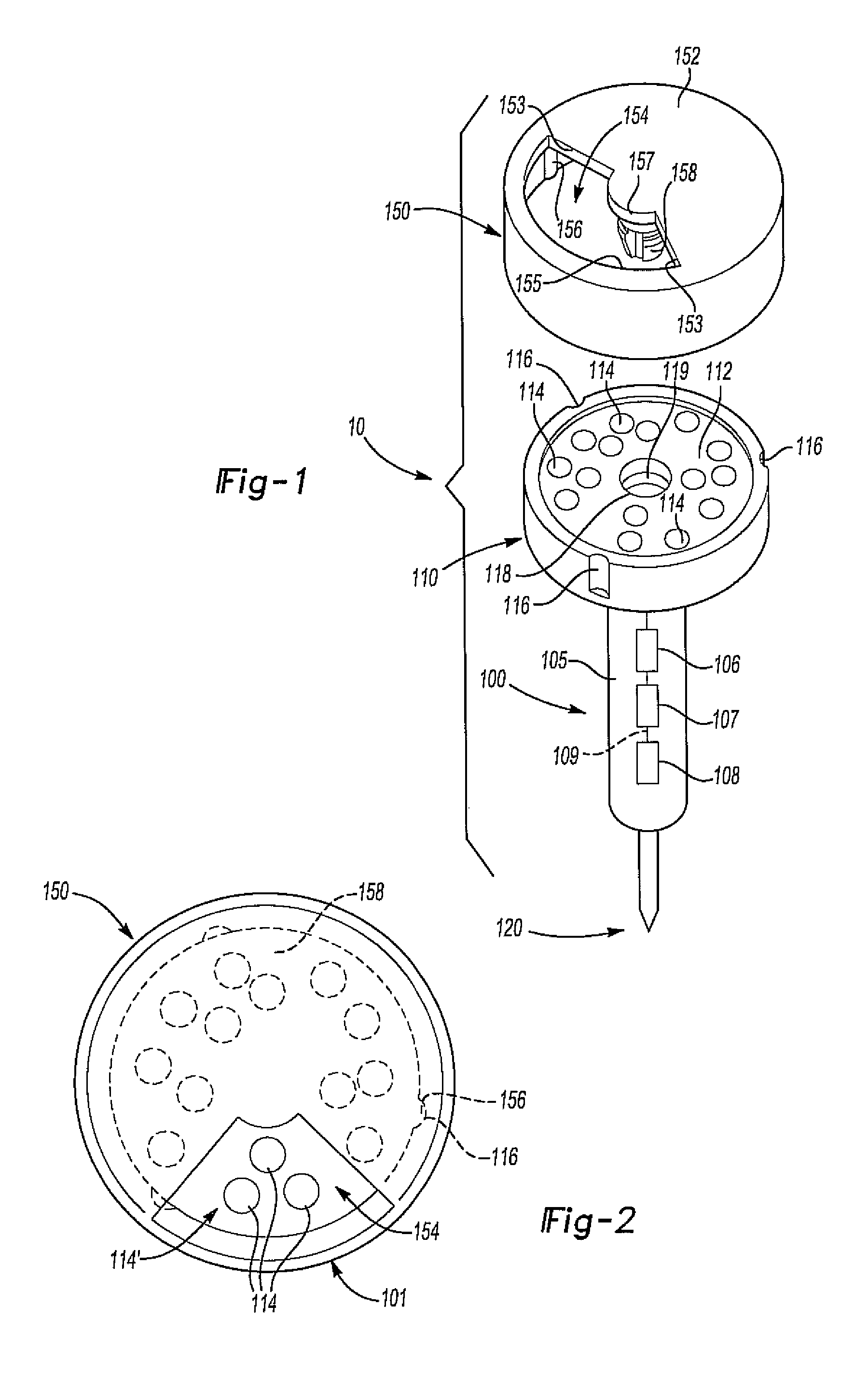

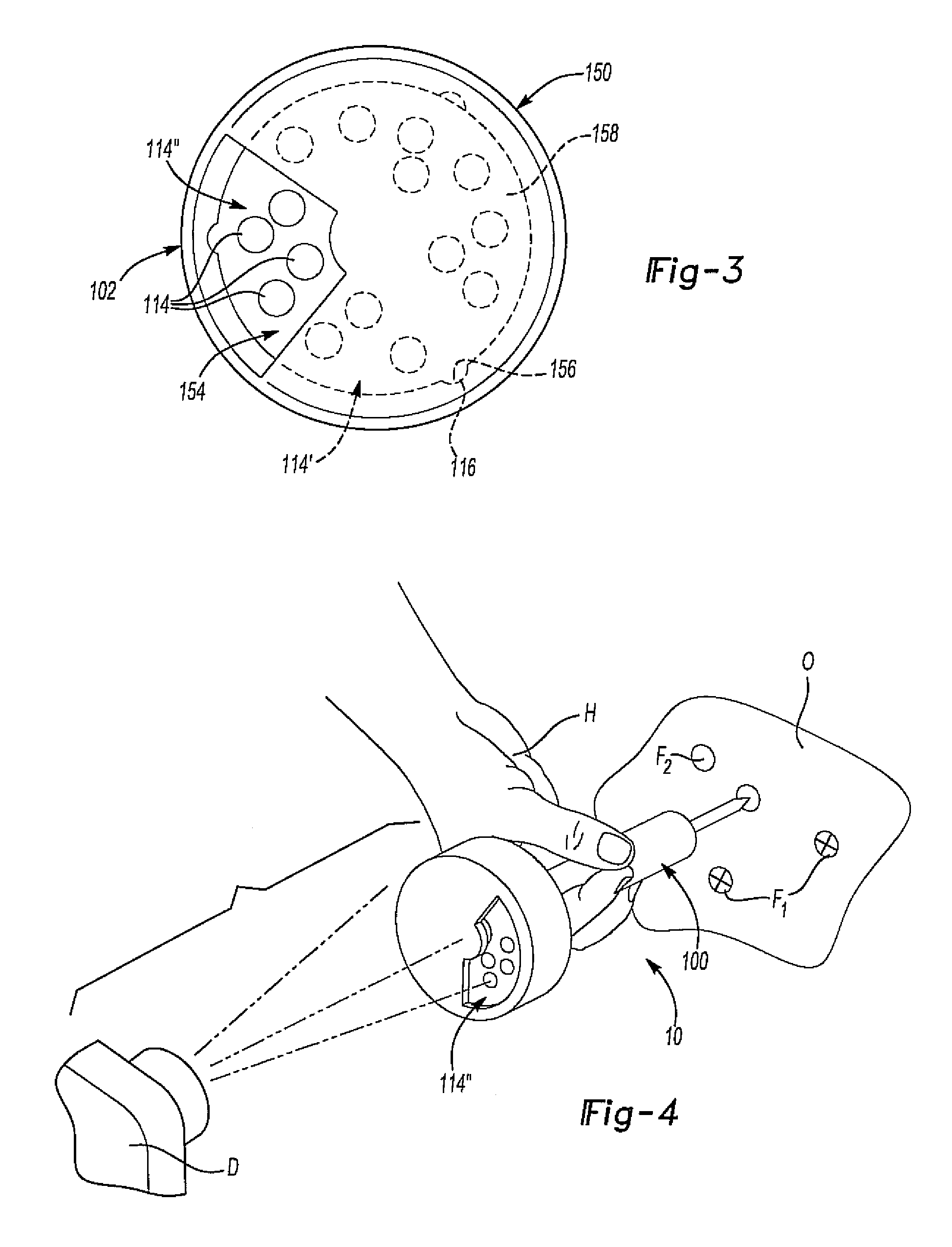

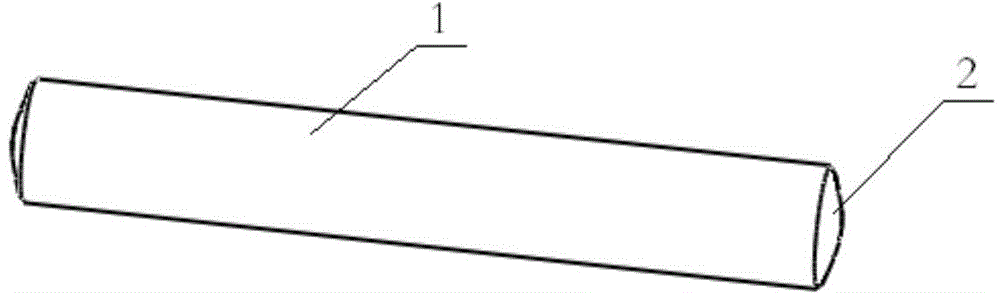

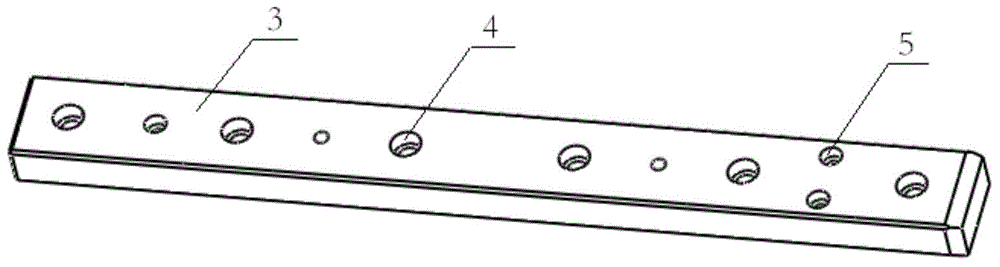

Adaptive feature recognition tool

ActiveUS9330448B2Easy to placeEasy and generally quick countingImage enhancementImage analysisDigital imagingFast tempo

The present invention provides an adaptive feature recognition tool that can be used to determine the location and / or count discrete features on an object being manufactured in a relatively quick time fashion. The tool can include an elongated rigid member that has a first end with a generally planar surface, the generally planar surface having a plurality of contrast targets thereon. The elongated rigid member can also have a second end for placement at a desired location, for example placement on a plurality of features whose number and / or location(s) on the object is desired. In addition, an exposure device that is operable to expose specific subsets of the plurality of contrast targets to a line-of-sight digital imaging device can be included.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA

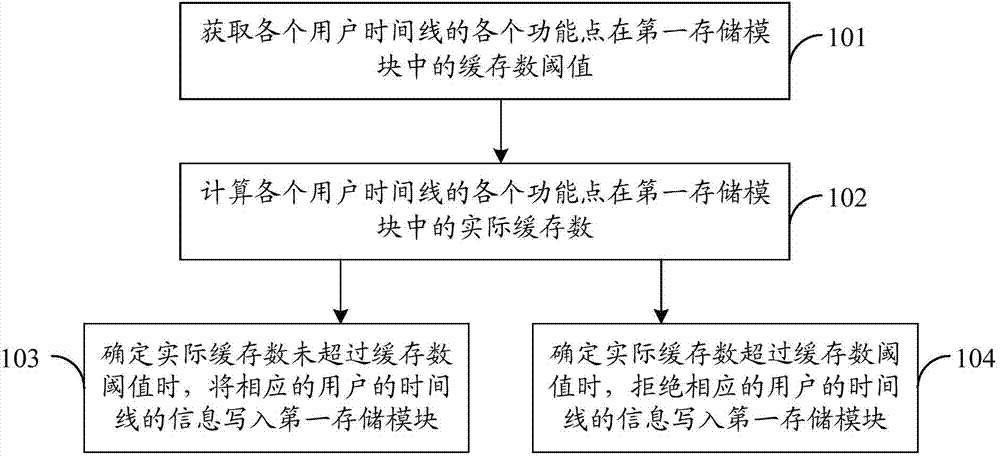

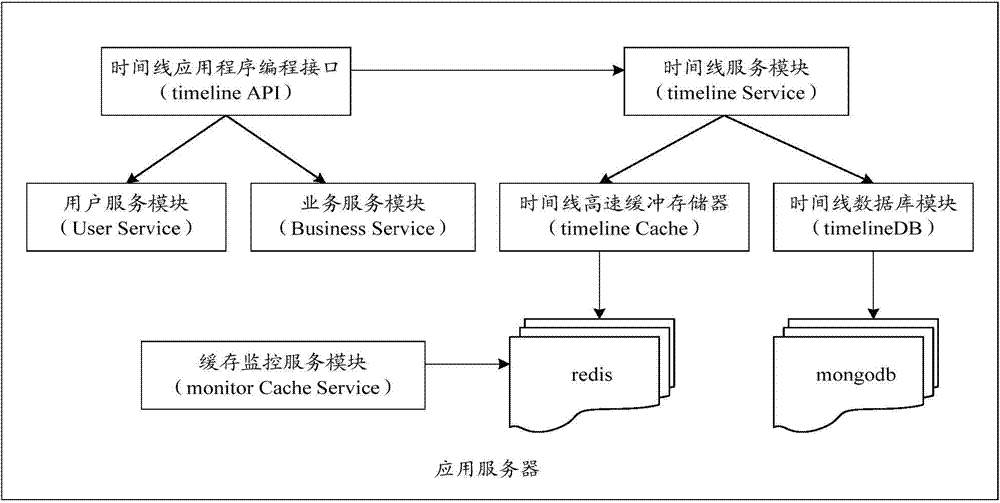

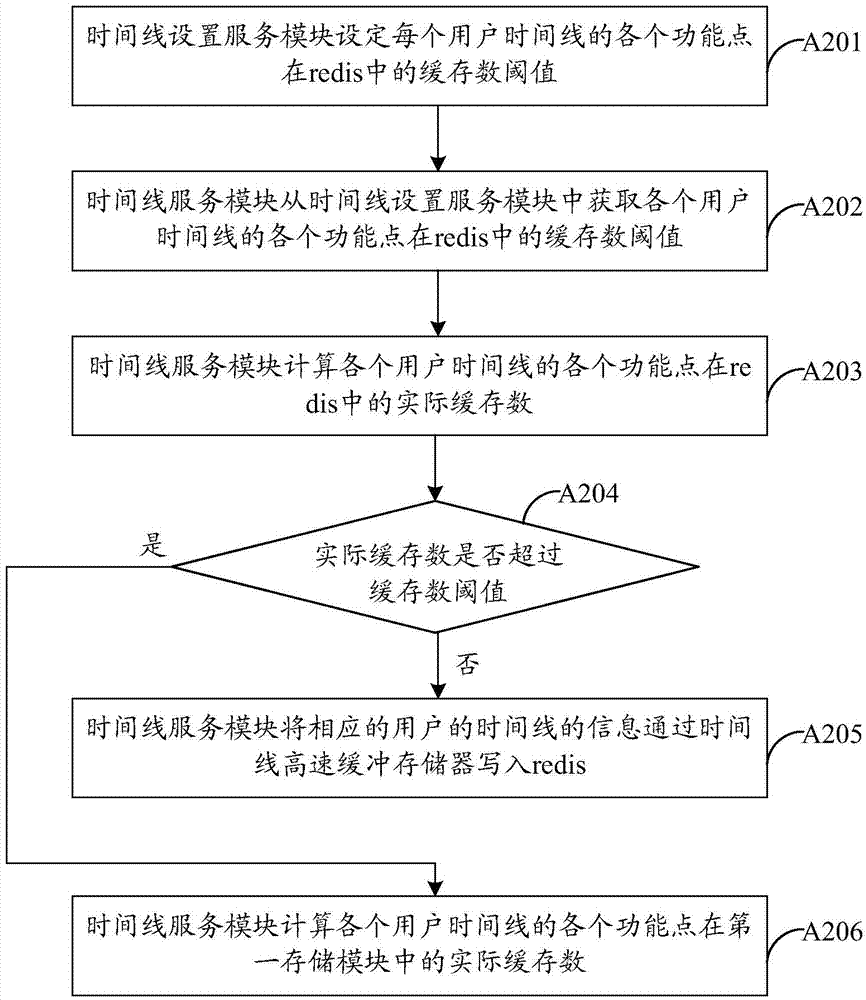

Method, device and system for controlling network resources in microblog

ActiveCN103618625AAvoid the situation that the corresponding network resources cannot be allocatedFlexible controlData switching networksMicrobloggingFast tempo

The embodiment of the invention discloses a method, device and system for controlling network resources in a microblog. The method comprises the steps that cache number threshold values in a first storage module of function points of user time lines are obtained, wherein the first storage module is used for providing information of the time lines for a user to fast read, the practical cache number of the function points of the user time lines in the first storage module is calculated, and if the practical cache number does not exceed the cache number threshold values, then the information of the corresponding user time lines can be written into the first storage module. Otherwise, if the practical cache number exceeds the cache number threshold values, the device refuses the situation that the information of the user time lines is written into the first storage module. By means of the technical scheme, the network resources can be flexibly controlled and distributed.

Owner:SHENZHEN YUNZHIJIA NETWORK CO LTD

Dateplum persimmon health food and preparation method thereof

The invention provides a dateplum persimmon health food and a preparation method of the dateplum persimmon health food. The health food is a pasty, mushy or clumpy food which is directly prepared by dateplum persimmon, wherein the health food is dark red and sweet; and the dateplum persimmon pasty food is directly drunk, and the dateplum persimmon mushy or clumpy food is directly eaten. The preparation method of the dateplum persimmon health food comprises the following steps of: cleaning, enucleating and soaking the dateplum persimmon; mashing the soaked dateplum persimmon till to be mushy, sieving by adding water, and removing filter residue, so that the dateplum persimmon mushy health food can be obtained; adding hot water or directly heating, and sterilizing by microwave or ultraviolet, so that dateplum persimmon clumpy food can be obtained; and adding water into the dateplum persimmon mushy health food or the dateplum persimmon clumpy food, and levigating the colloid, so that the dateplum persimmon pasty food can be obtained. The prepared dateplum persimmon health food has the functions of drinking and eating, so that the fast-tempo life need of modern people can be met, and the requirement of different crowds can be met.

Owner:张勃 +1

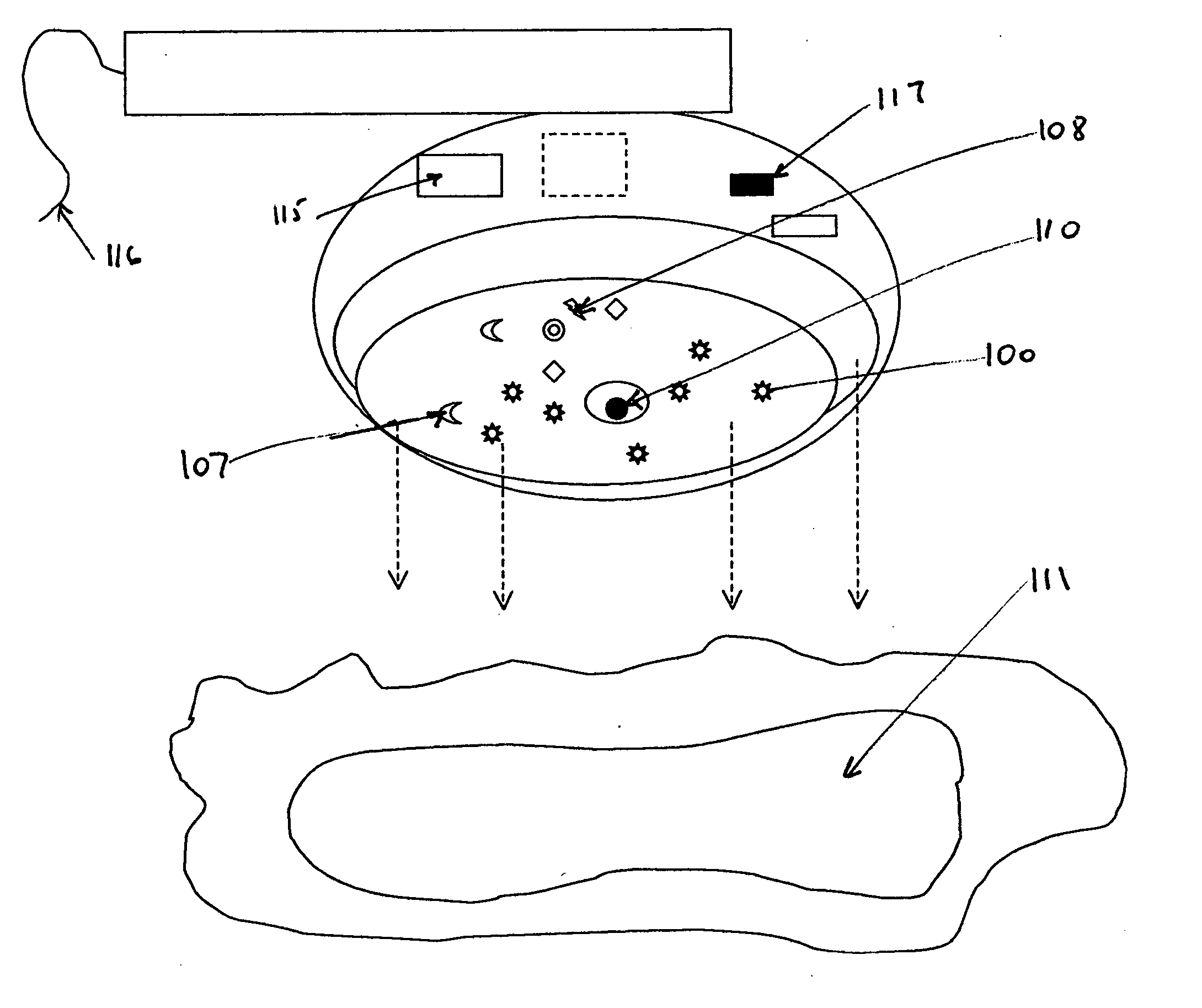

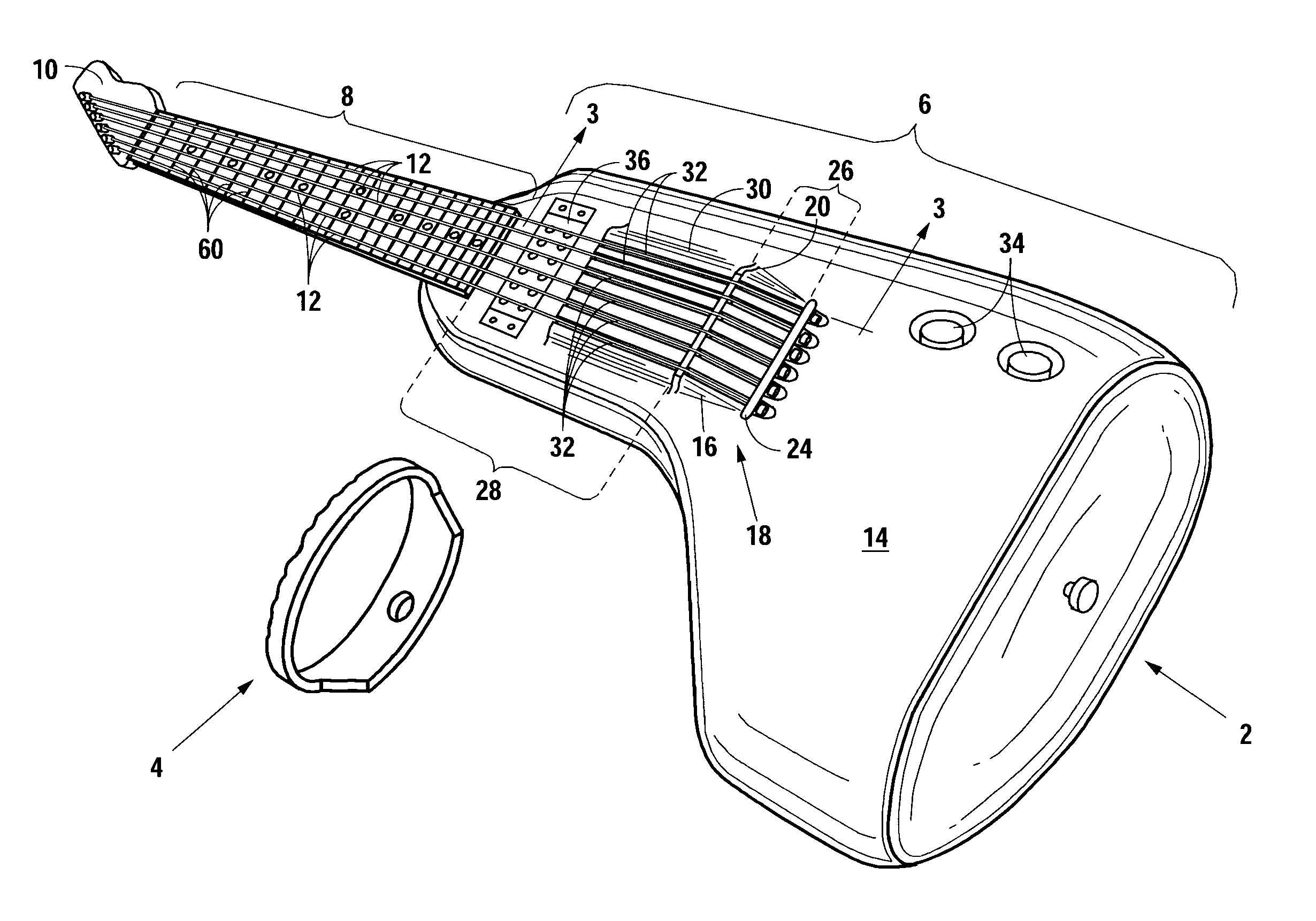

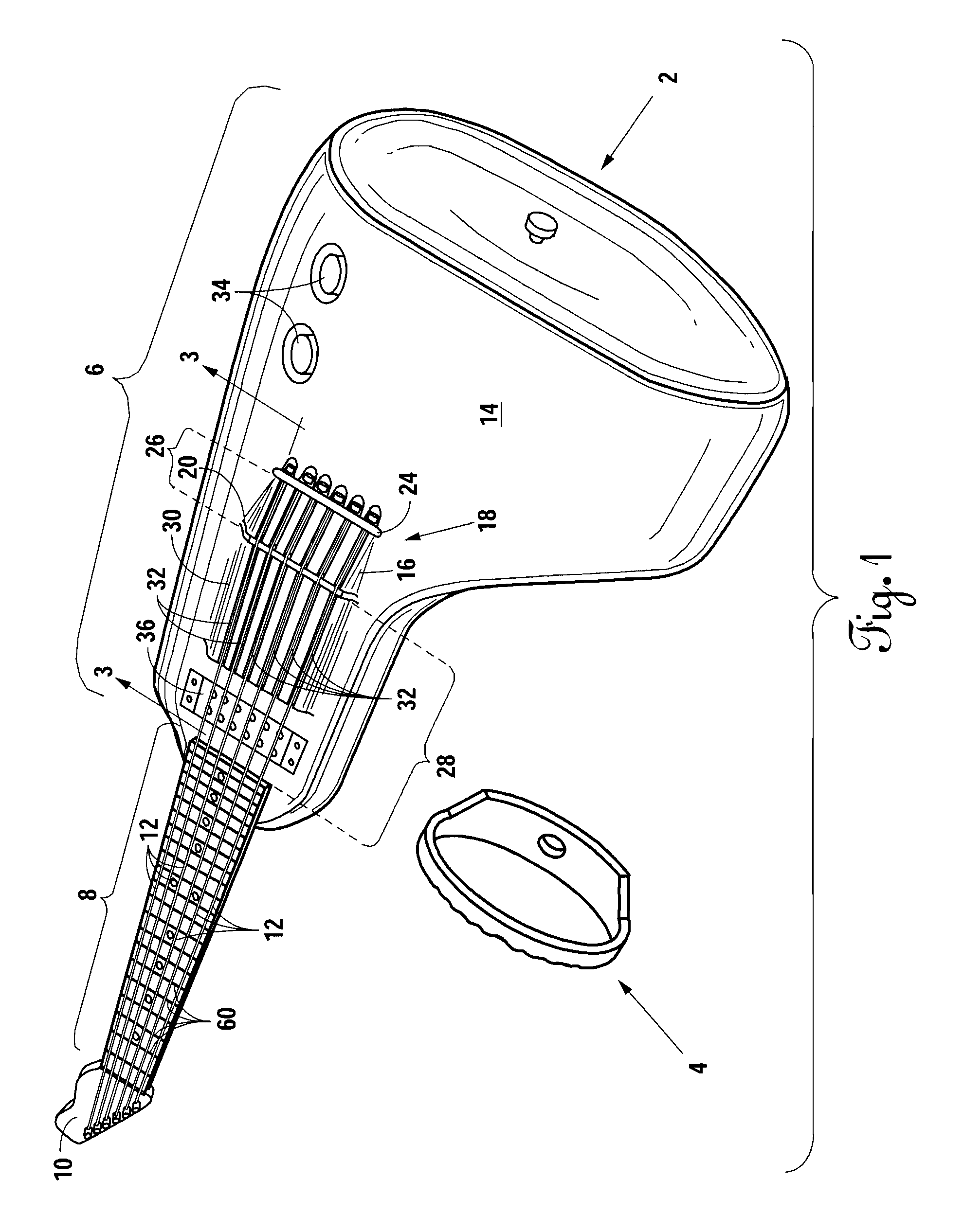

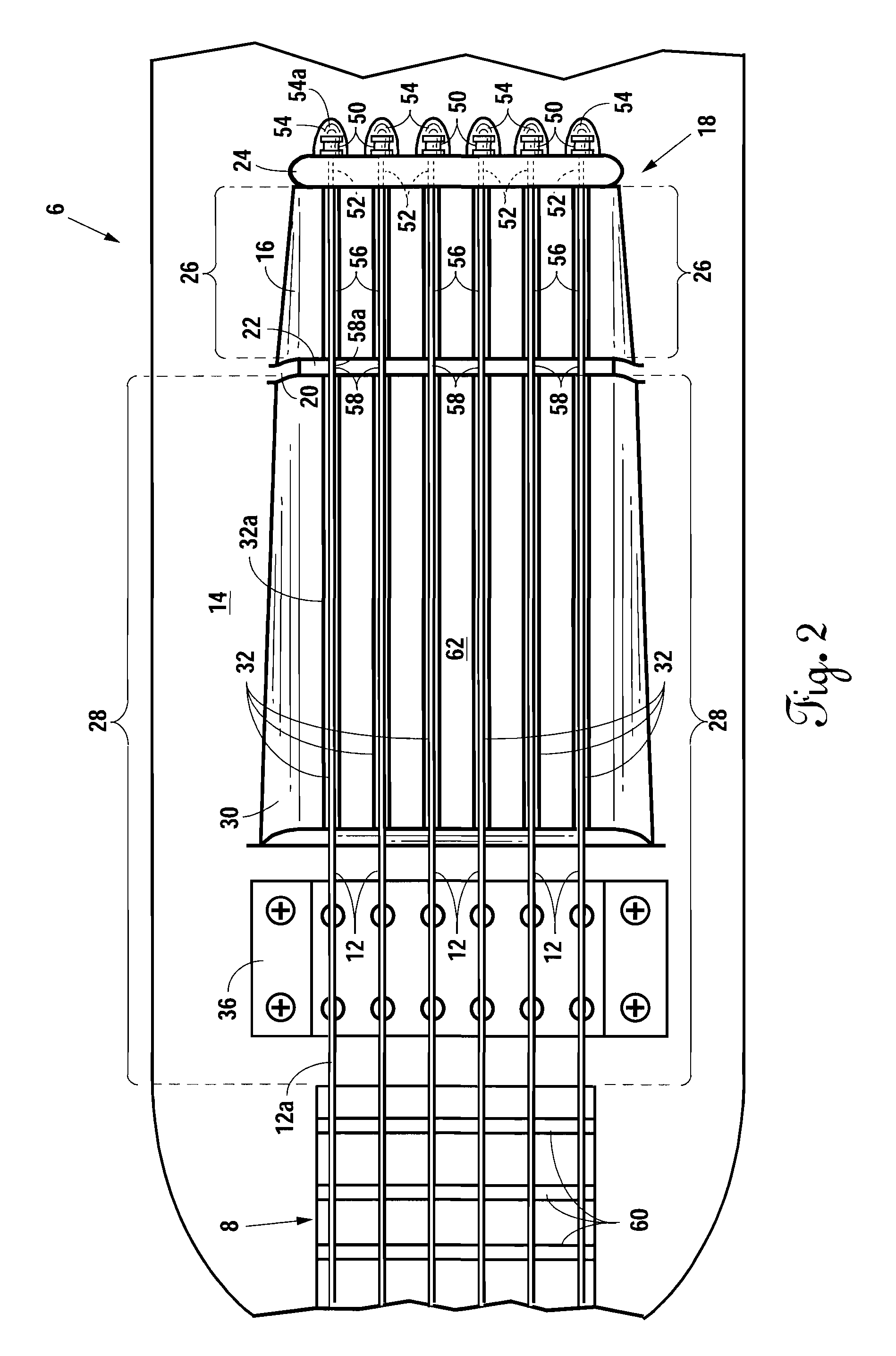

Stringed instrument for producing precise rhythmic strumming

Owner:HAMILTON ROBERT N

Method for preparing burdock bread crumbs

InactiveCN101785545AGreat tasteHigh nutritional valueDough treatmentFood preparationNutritive valuesFast tempo

The invention discloses a method for preparing burdock bread crumbs. The bitter taste of fresh burdock is removed, the mouthfeel is good, the nutrients are easily absorbed, and the bread crumbs are conveniently and quickly eaten by people and suitable for the fast tempo of the current social life. Roots of the fresh burdock are selected as a preparation raw material and then are subjected to special processing, so the nutrients contained in the roots can be absorbed by a human body; meanwhile, the product is ensured to have good taste, and has higher nutritional value and better taste, and isa green nutritious product.

Owner:QINGDAO HAOTIAN FOOD

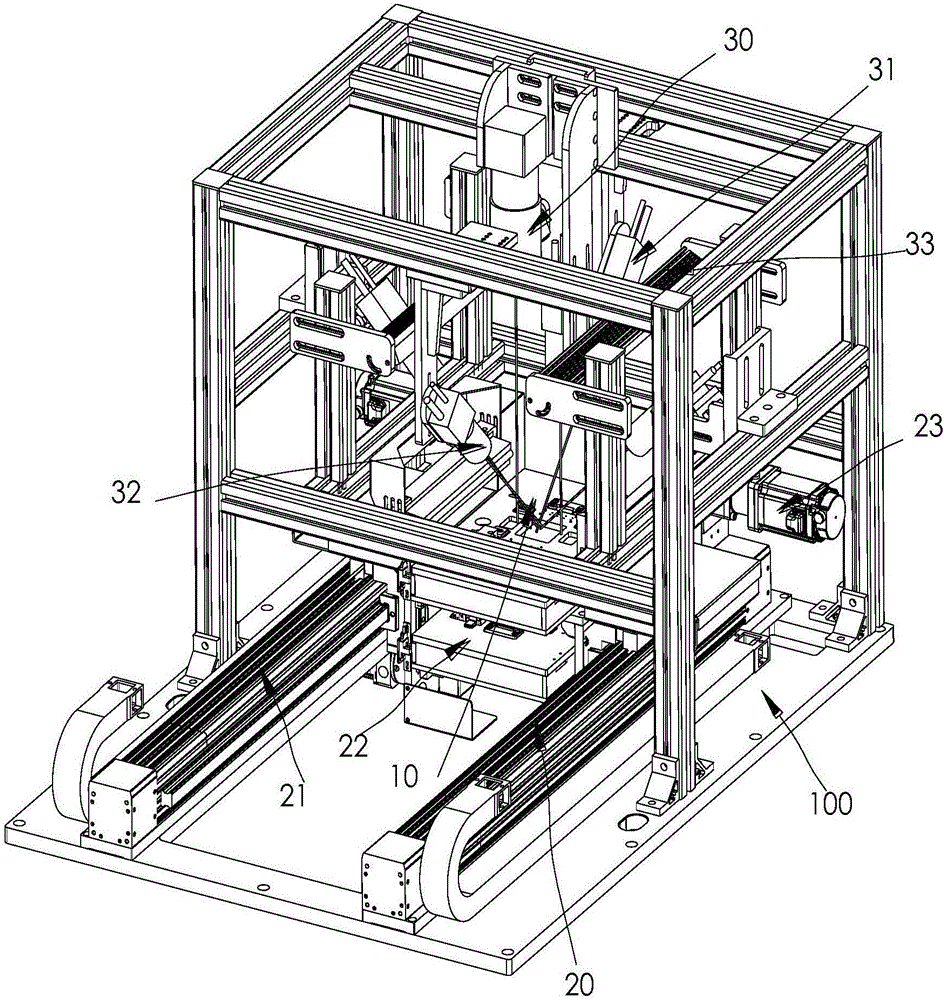

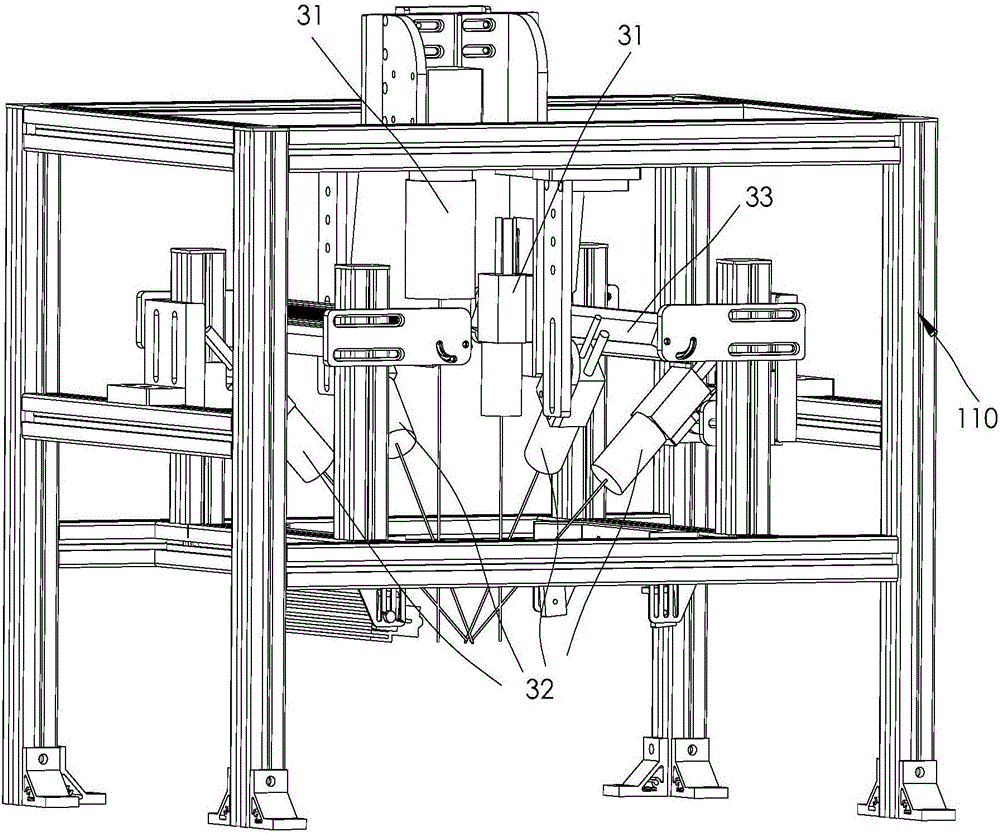

Semi-automatic screen detection machine

InactiveCN106525868AReduce standby timeHigh degree of automationOptically investigating flaws/contaminationMechanical conveyorsFast tempoSemi automatic

The invention discloses a semi-automatic screen detection machine. The semi-automatic screen detection machine comprises a machine body provided with a detection station, a conveying mechanism and a detection mechanism, wherein the conveying mechanism is mounted on the machine body and used for conveying external to-be-detected screens to the detection station, a plurality of conveying stations are formed on the conveying mechanism and enter and exit the detection station alternately and circularly, and the detection mechanism is mounted on the detection station and used for detecting the to-be-detected screens. The semi-automatic screen detection machine has the advantages of capabilities of prolonging overall detection time effectively and shortening standby time of the detection mechanism, faster tempo, higher detection efficiency and high automation degree.

Owner:深圳眼千里科技有限公司

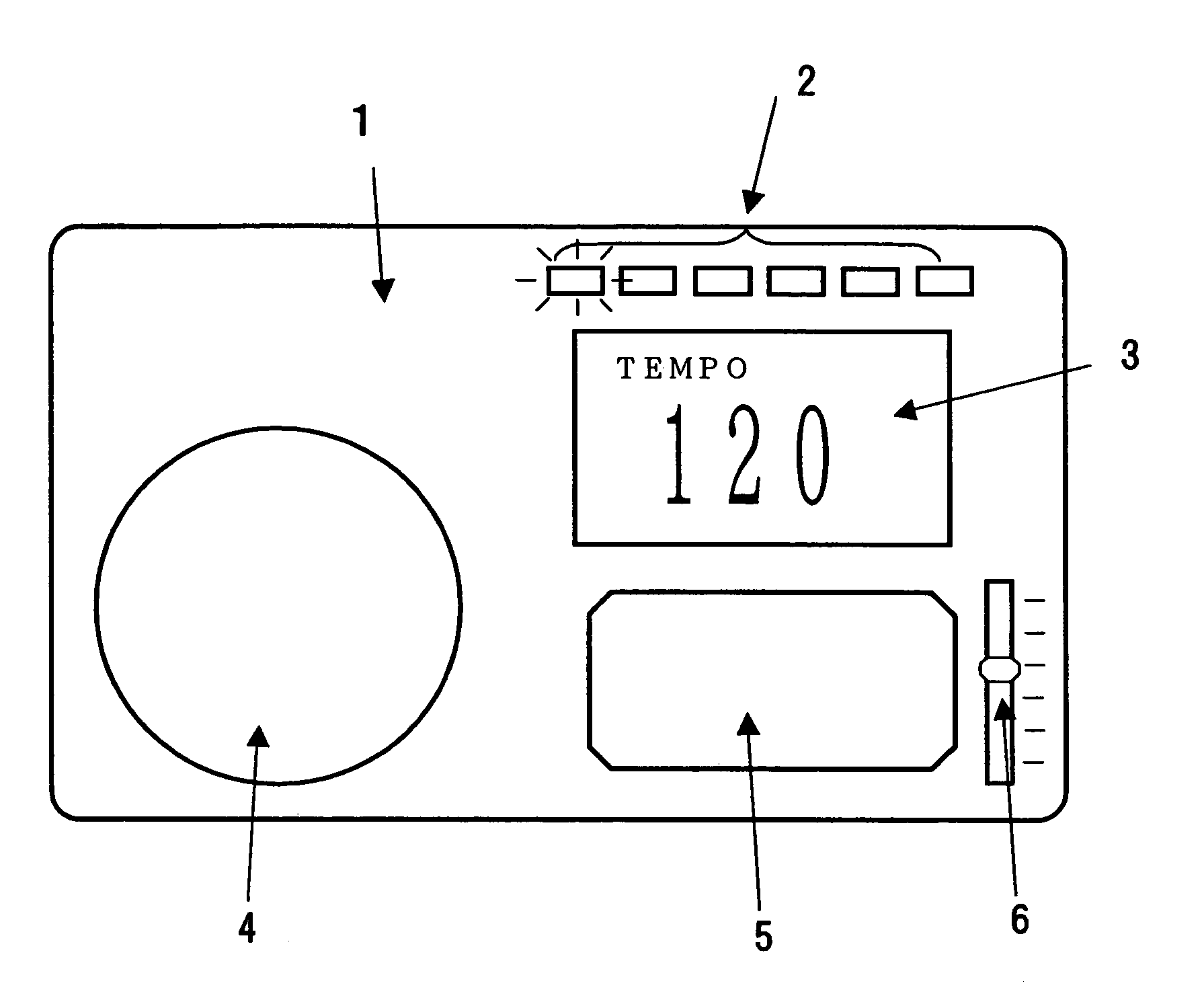

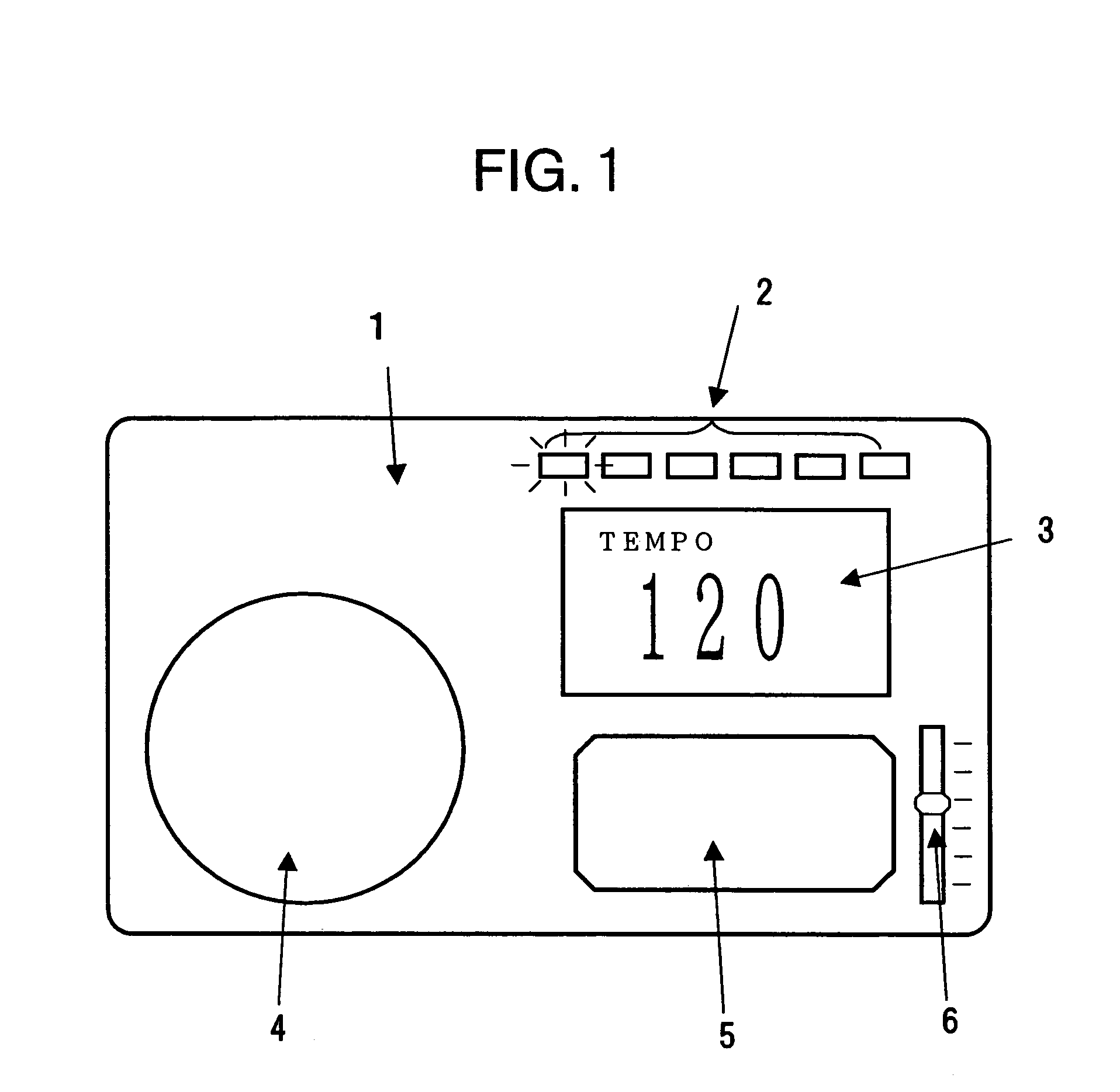

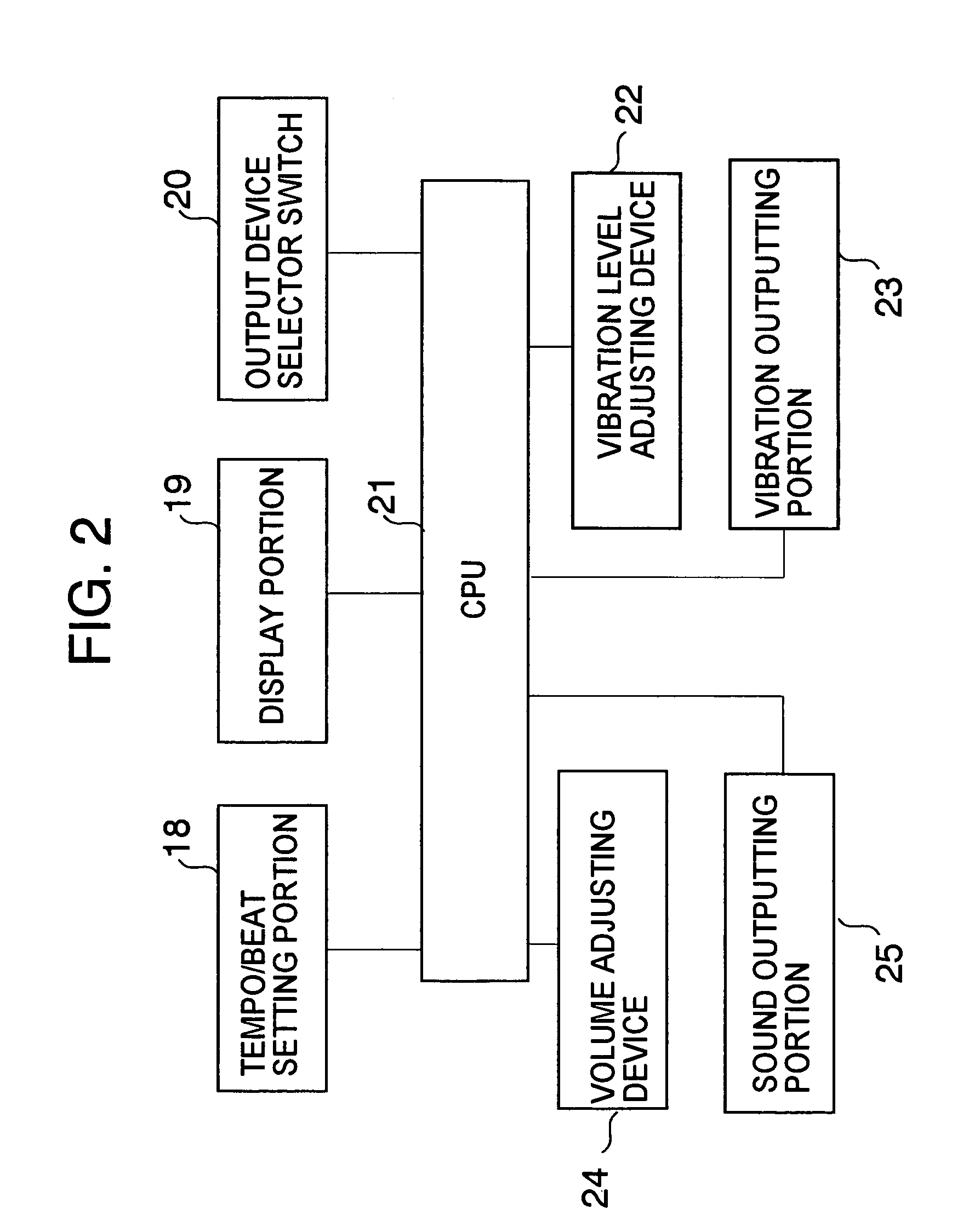

Electronic metronome

An electronic metronome has a casing including a display portion for displaying a numerical value of a tempo, a sound emitting device for emitting a sound representing the tempo, a vibration device for generating a vibration representing the tempo, and a vibration level adjusting device for adjusting the stregth of the vibratrion. The vibration is used for notifying a tempo to a user, whereby the user can master a good sense of tempo efficiently without being affected by the surrounding environment. The electronic metronome prevents the phenomenon that if a user performs a musical piece specified with a slow tempo immediately after performing a musical piece specified with a fast tempo, the user may perform the piece at a faster tempo than the originally intended slow tempo.

Owner:SEIKO INSTR INC

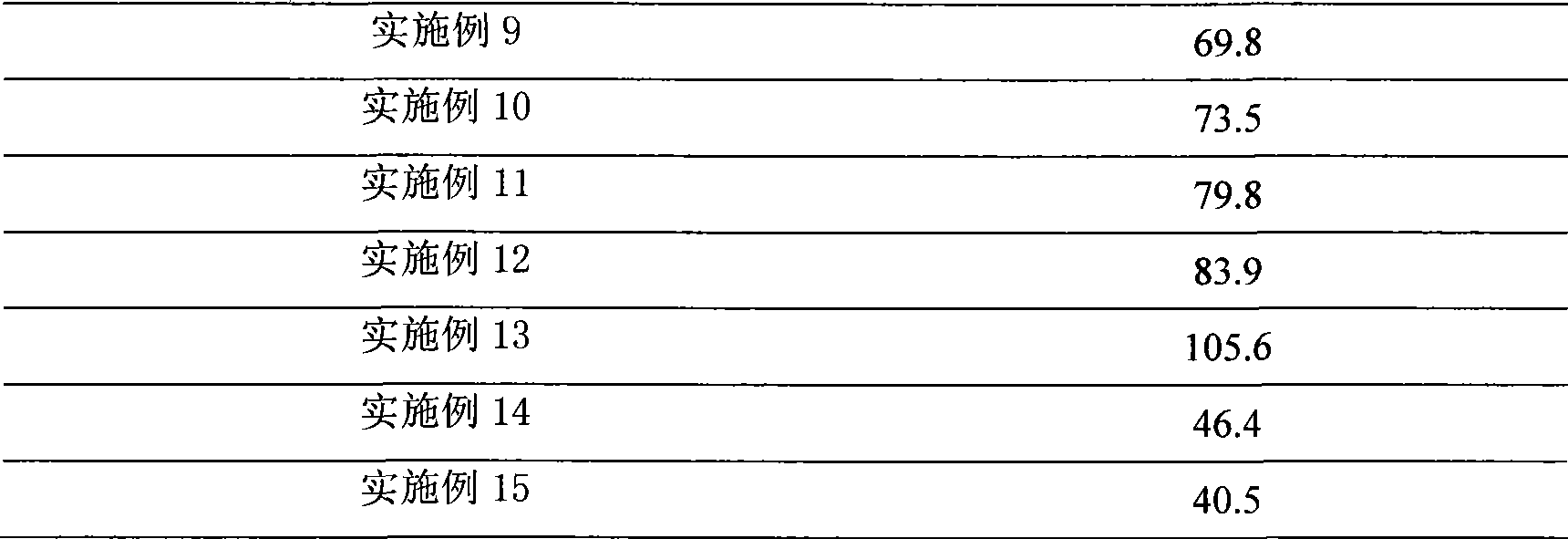

Process for producing cassia twig tuckahoe formulation

The invention discloses a preparation method for a Guizhi Fuling preparation, which belongs to the technical field of Chinese traditional medicine. In order to retrace the essence of the traditional medicine for curing the diseases, the invention provides the guiding ideology for the Guizhi Fuling classical formula in ancient way, i.e. the preparation process parameter matched with the Guizhi Fuling preparation to the utmost extent and the proper adjuvant are summarized by using water to extract the medication and by combining the modern concentration and granulating process. The invention has the advantages that the invention not only preserves the experience accumulation of the traditional medicine to the utmost extent, but also can be adapted for different forms of preparations in the fast-tempo modern society such as graduals, tablets and graduals, tablets, capsules, powder, capsules, powder, dripping pills, and the like.

Owner:曾雄辉

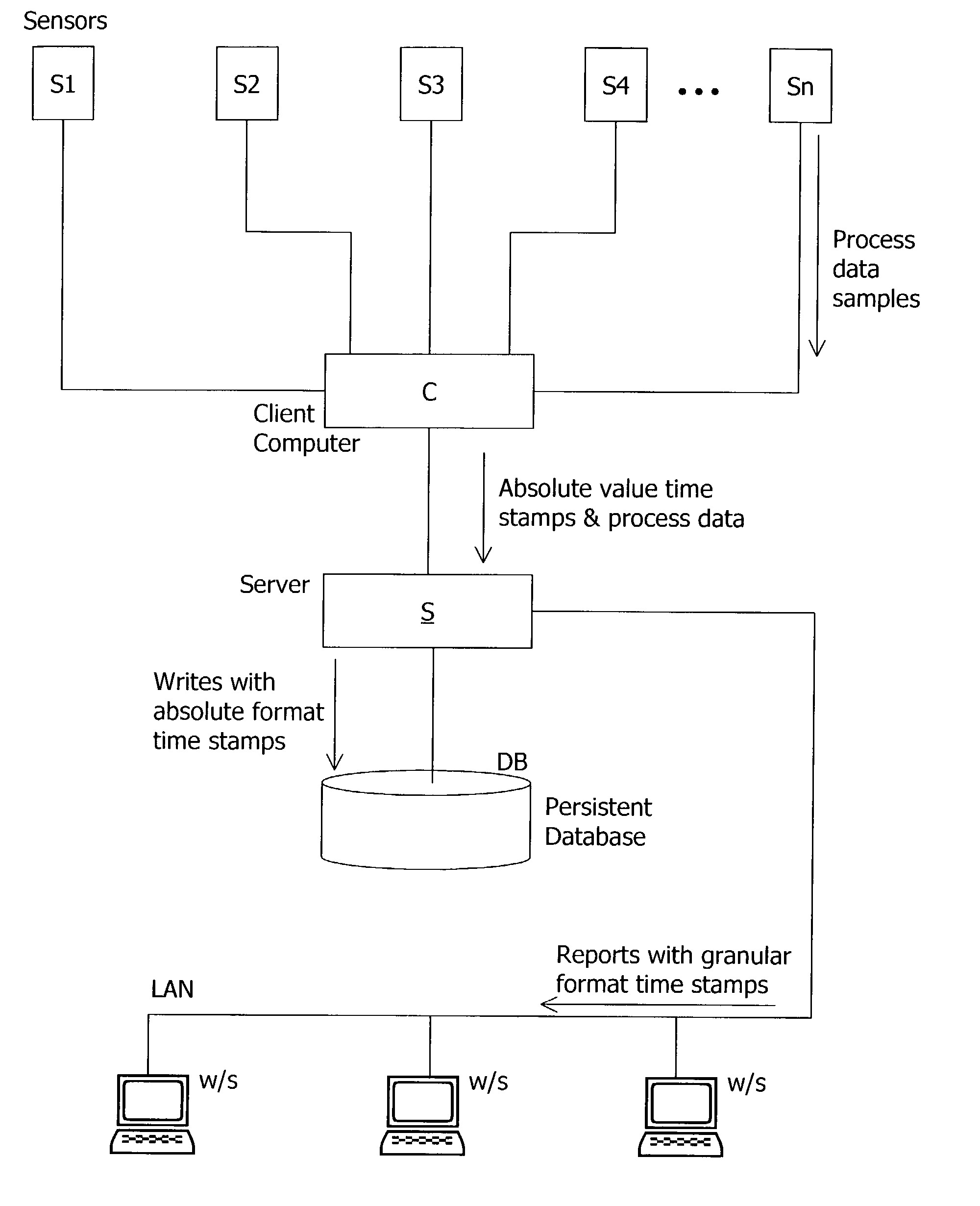

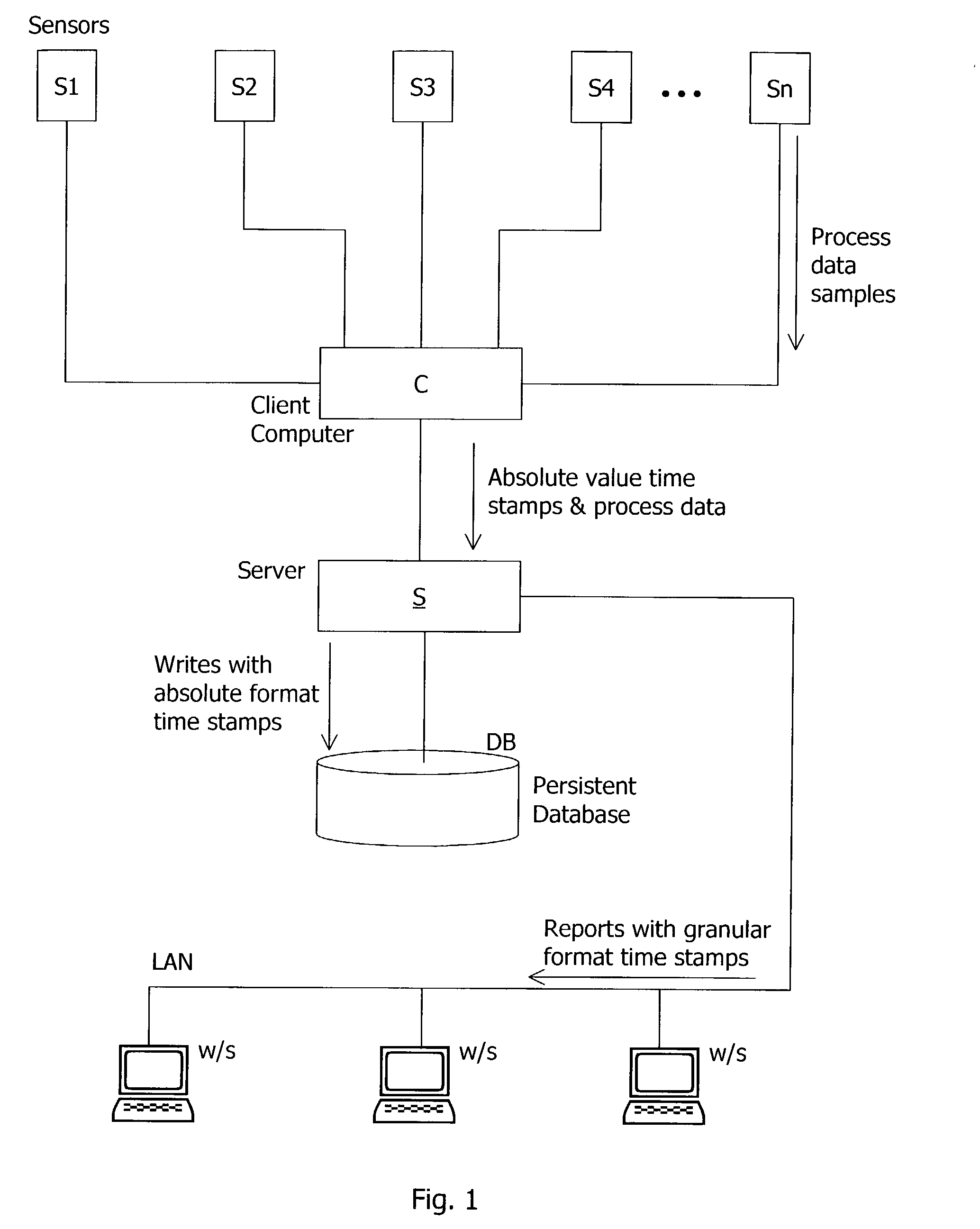

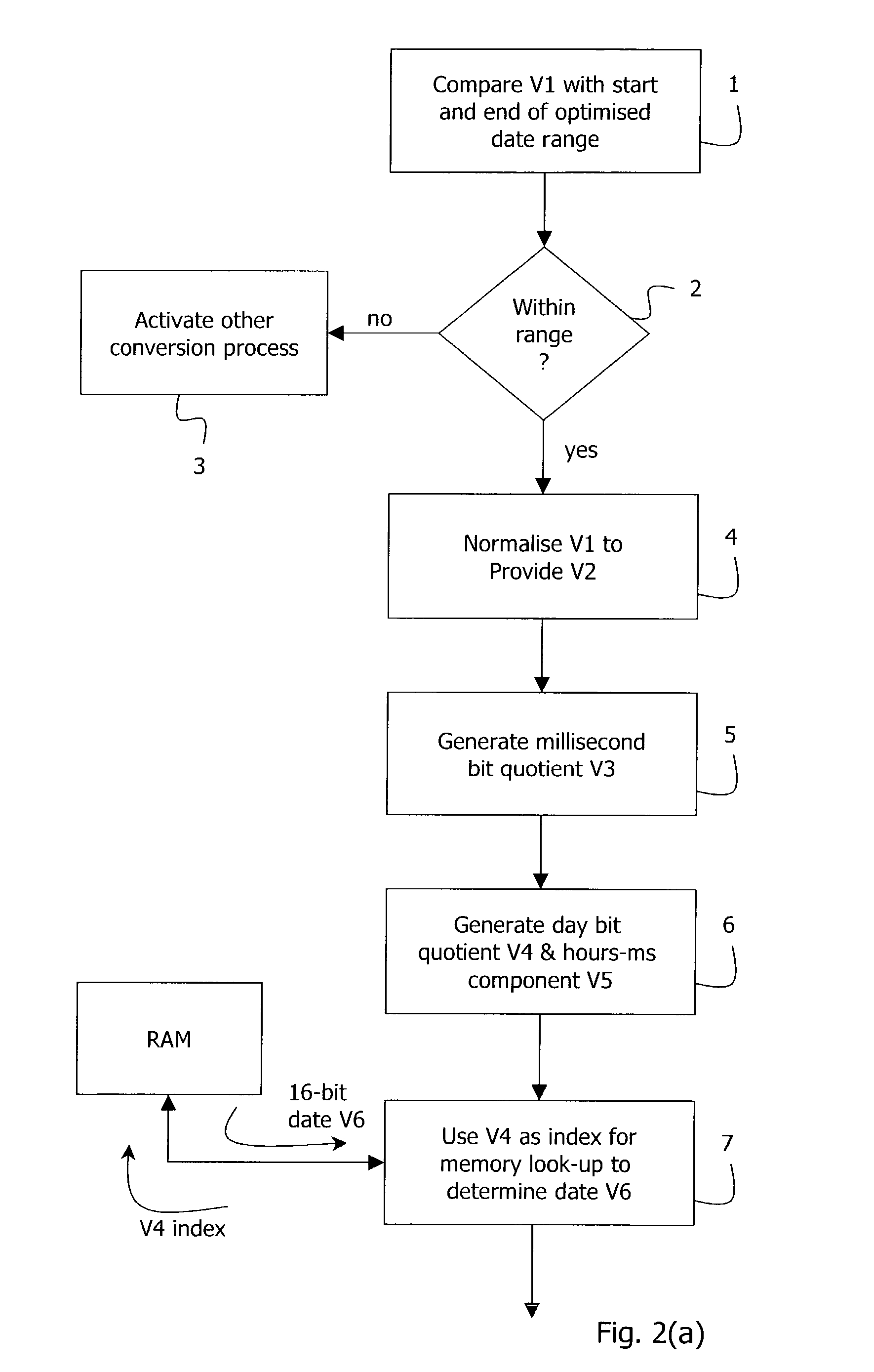

Date and time processing in computers

Owner:AUTOMSOFT R & D

Ganoderma-linearstripe rabdosia teabag and preparation method thereof

The invention relates to the field of food processing, and concretely relates to a ganoderma-linearstripe rabdosia teabag and a preparation method thereof. The ganoderma-linearstripe rabdosia teabag comprises the following components by weight fraction ratio: 20% of ganoderma, 30% of linearstripe rabdosia, 30% of hovenia dulcis thumb, and 20% of oriental waterplantain rhizome. The invention also provides a method for preparing the ganoderma-linearstripe rabdosia teabag: 1) preparing ganoderma and linearstripe rabdosia meal; 2) preparing an extract; 3) mixing meal and the extract and performing granulation; 4) drying the materials; 5) granulating the materials; 6) packaging the filter bags; 7) performing disinfection; 8) making outer package to prepare the finished product. The ganoderma-linearstripe rabdosia teabag satisfies the fast-tempo life of the consumers, provides health-preserving and health-caring functions, and can fill in the market blank.

Owner:GUANGDONG HAOSHUANG NATURAL HEALTH FOOD

Seafood seasoning flavor

The invention discloses a seafood seasoning flavor, comprising the following ingredients: 5-15 weight portions of seafood powder reactant, 8-12 weight portions of salt, 4-10 weight portions of monosodium glutamate, 50-80 weight portions of starch, 1-2 weight portions of seafood incense base, 0.05-0.1 weight portions of potassium sorbate, and 3-4 weight portions of drying agent. The seafood seasoning flavor has pure color, stable quality, strong frangrance, full palate, and abundant nutrition, and is suitable for people who live in modern fast-tempo life and have different life habits.

Owner:TIANJIN LANSHI SEASONING

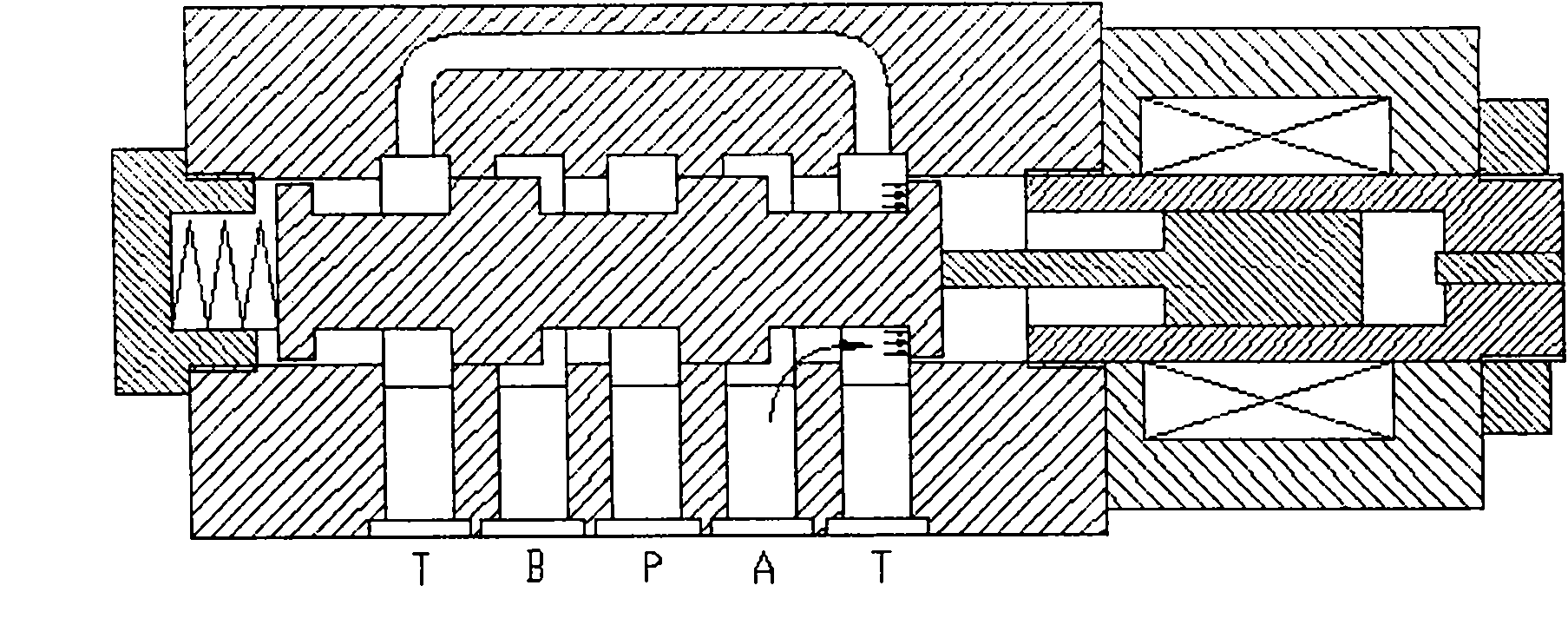

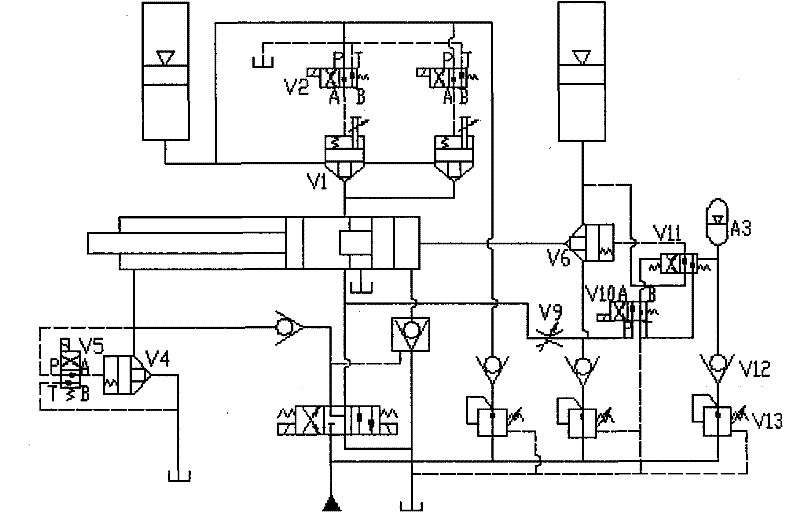

Injection device of cold-chamber die casting machine

The invention discloses an injection device of a cold-chamber die casting machine. Improvement is made based on the conventional injection device of the homemade cold-chamber die casting machine, and the time for conversion from a low speed to a high speed in an injection process can be shortened and simultaneously the pressure building-up time for pressurizing injection also can be shortened only by adopting a usual hydraulic valve to execute control, so the key performance of the cold-chamber die casting machine in terms of an injection system is improved and the application range of the cold-chamber die casting machine is expanded. The injection device has good effect for cast products requiring high speed and short injection time, such as magnesium alloy die castings, thin-walled die castings, die-castings of complex shapes and the like.

Owner:卢志刚

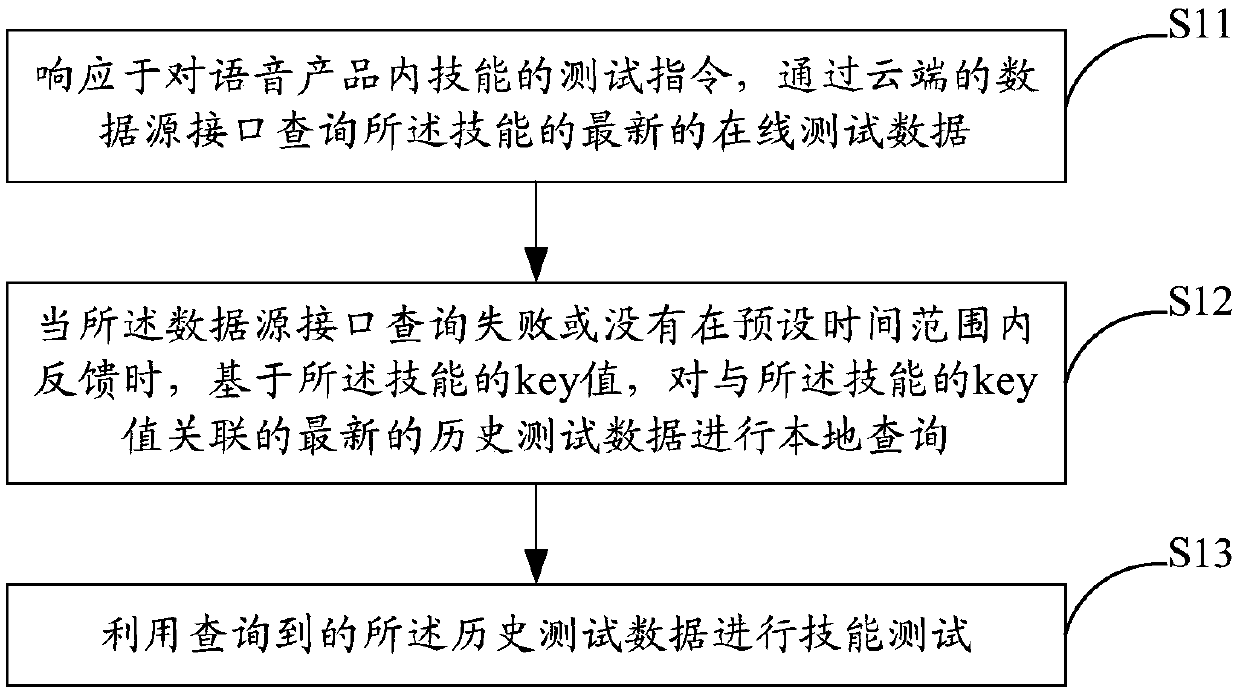

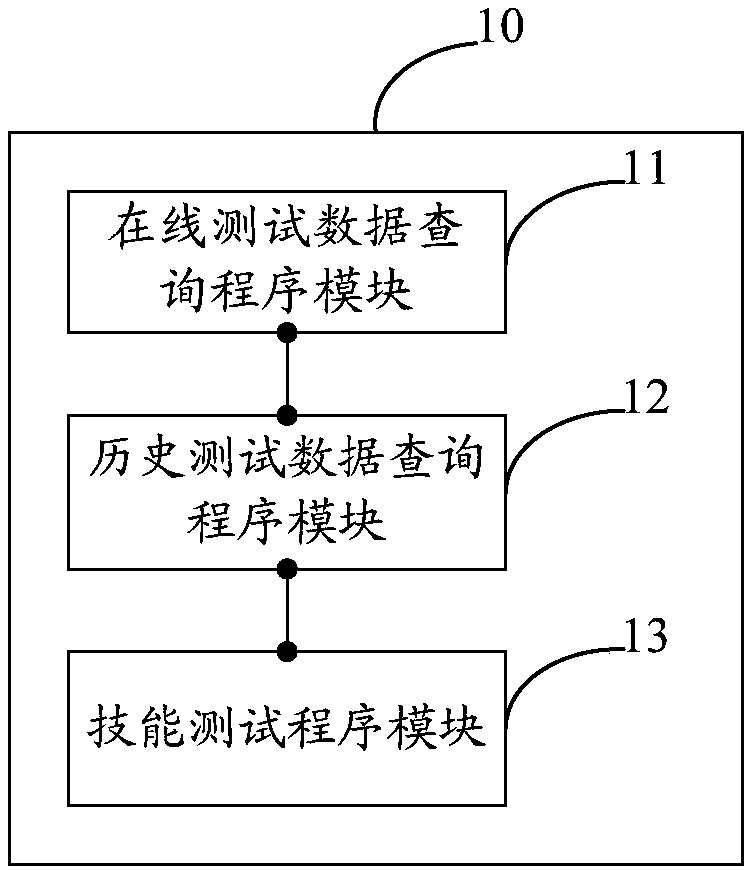

A skill testing method and system for a voice product in a voice dialogue platform

ActiveCN109670016AThe test result is accurateImprove experienceDatabase management systemsTransmissionComputer hardwareTime range

The embodiment of the invention provides a skill testing method for a voice product in a voice dialogue platform. The method comprises the following steps of in response to a test instruction for skills in a voice product, querying latest online test data of the skills through a data source interface of a cloud; when the query of the data source interface fails or is not fed back within a preset time range, performing local query on the latest historical test data associated with the key value of the skill based on the key value of the skill; and performing skill testing by using the queried historical test data. The embodiment of the invention also provides a skill testing system for the voice product in the voice conversation platform. According to the embodiment of the invention, the test data of the voice skills are stored locally, and when the data source is invalid or the data source response is overtime, the data for testing the voice skills are obtained from the memory of the user, so that the user can obtain a relatively accurate test result within a rapid time, and the user experience is improved.

Owner:AISPEECH CO LTD

A UV-heat dual curing optical adhesive containing epoxidized polybutadiene resin

ActiveCN104449419BImprove bindingUniform responseOrganic non-macromolecular adhesivePolyolefinAdhesive

Owner:信泰永合(烟台)新材料有限公司

Aligning and leveling method for main machine guide rails of sizing and reducing machine

InactiveCN105881000AImprove assembly accuracyImprove product qualityMetal working apparatusFast tempoEngineering

The invention provides an aligning and leveling method for main machine guide rails of a sizing and reducing machine. The longitudinal levelness error and the transverse relative levelness error of each of the first guide rail, the eighth guide rail and the fifteenth guide rail are measured firstly, the levelness calculation value and the needed gasket thickness are calculated, and the first guide rail, the eighth guide rail and the fifteenth guide rail are leveled; then the flatness error and the transverse relative levelness error of each of the first guide rail, the second guide rail, the third guide rail, the fourth guide rail, the fifth guide rail, the sixth guide rail, the seventh guide rail, the eighth guide rail, the ninth guide rail, the tenth guide rail, the eleventh guide rail, the twelfth guide rail, the thirteenth guide rail, the fourteenth guide rail and the fifteenth guide rail are measured, the levelness calculation value and the needed gasket thickness are calculated, and the second guide rail is positioned with the first guide rail serving as the benchmark; and afterwards, the left thirteen guide rails are positioned and fastened in sequence, gaps between the top faces of all the guide rails and the bottom face of a horizontal rule are measured one by one, and it is ensured that the flatness of the top faces of the guide rails is qualified. By means of the aligning and leveling method, the working efficiency of guide rail replacing, aligning and leveling can be improved, the working time is shortened to 16 hours from the original 64 hours, the requirement for fast-tempo production is met, and the assembling precision of the guide rails of a main machine C type seat of a sizing machine and the quality of steel pipe products are improved.

Owner:ANGANG STEEL CO LTD

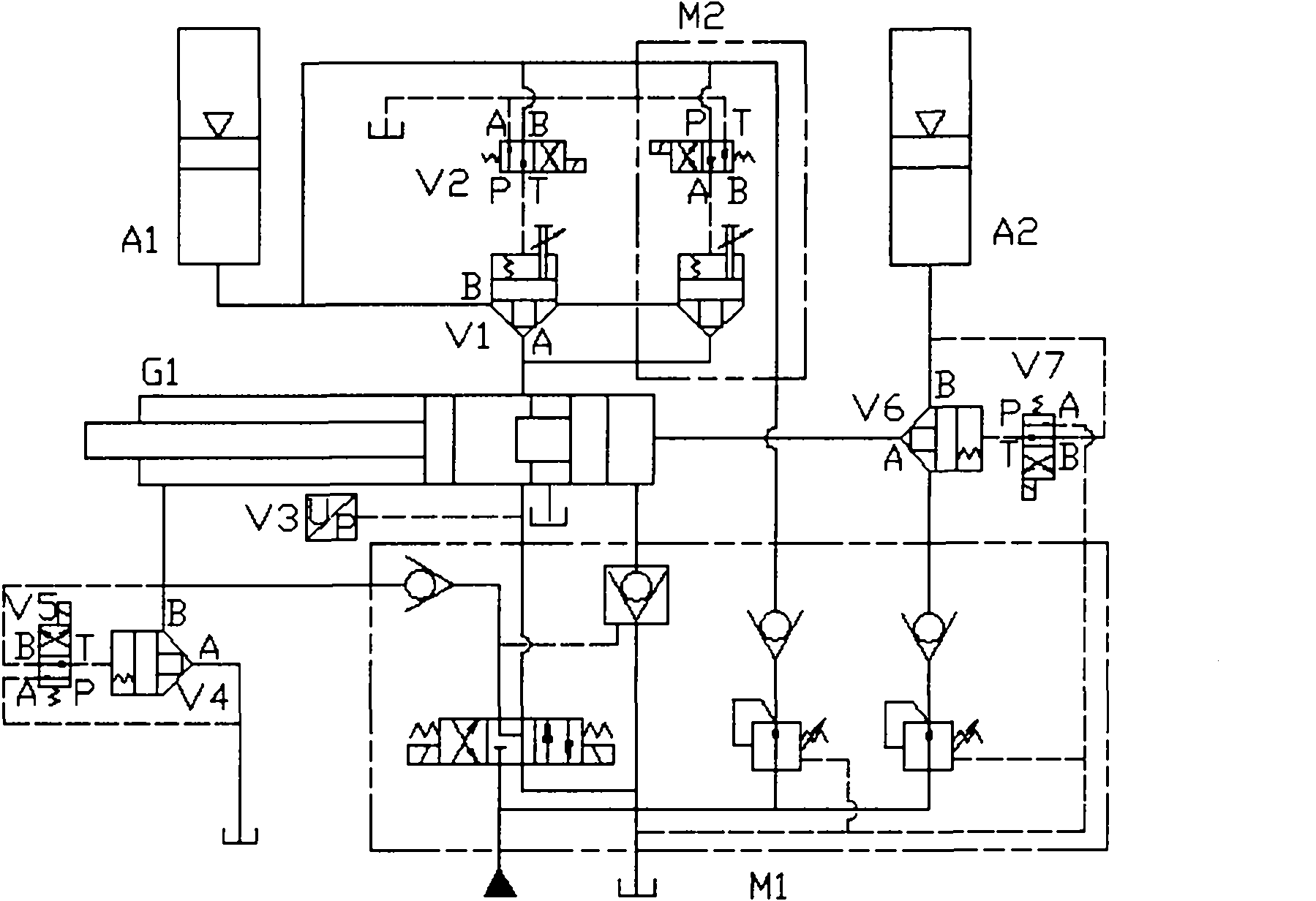

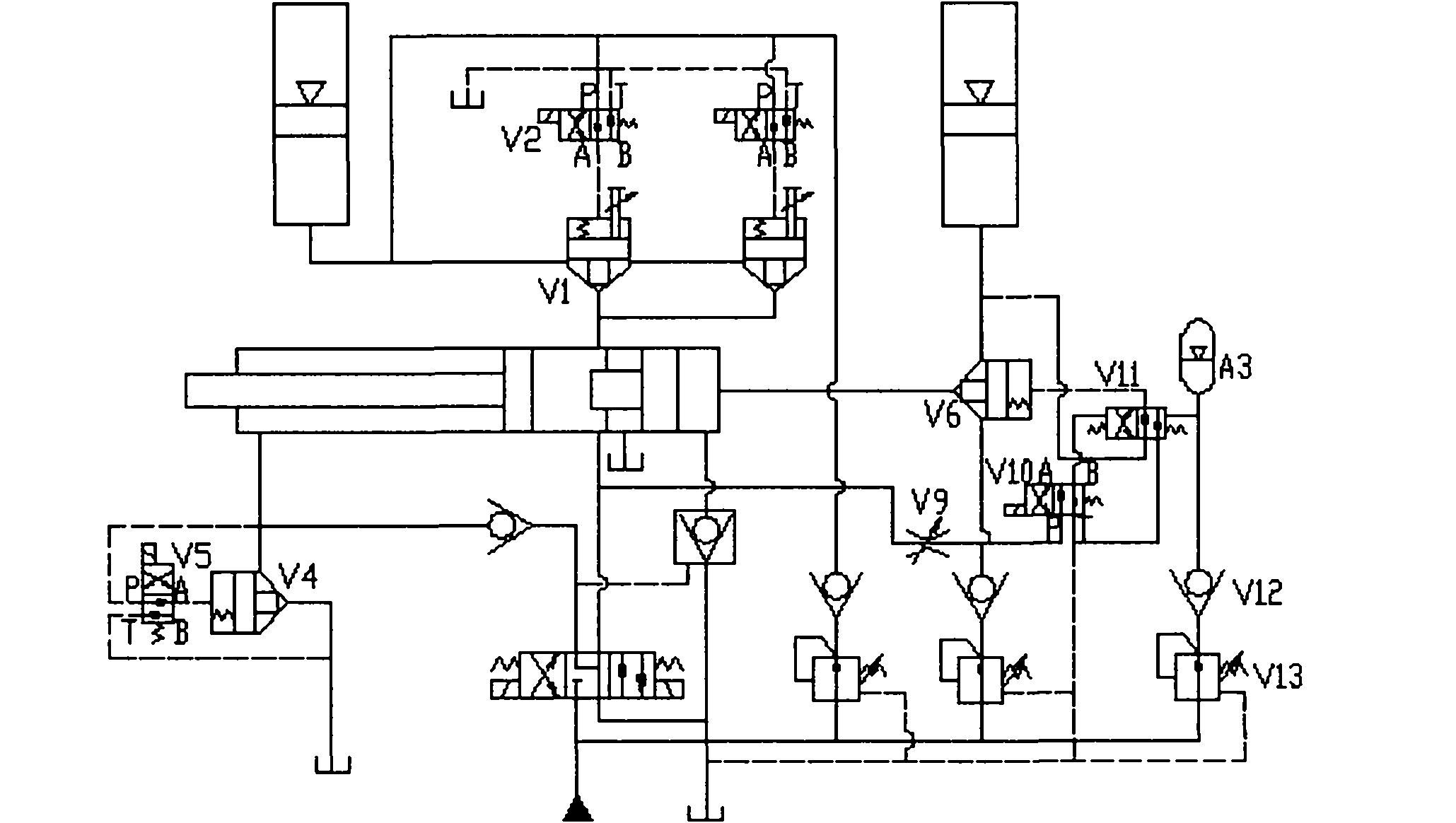

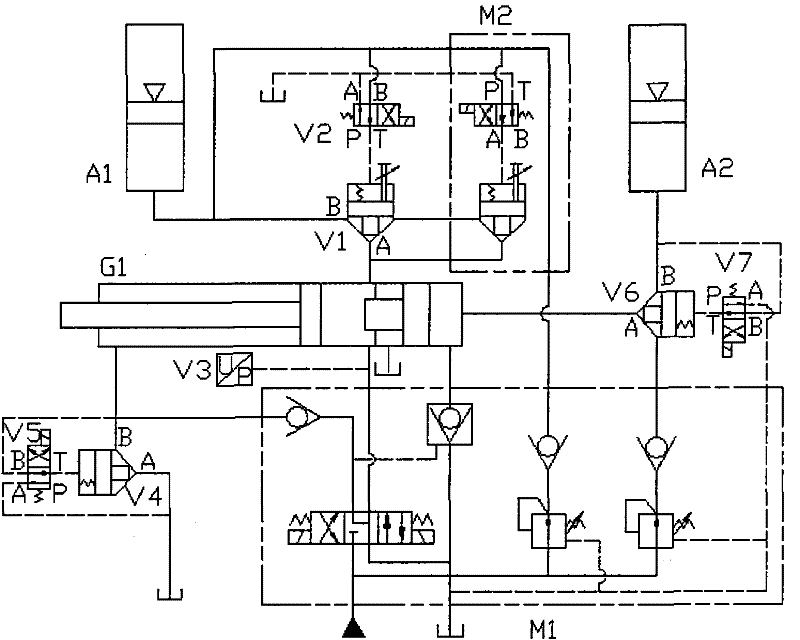

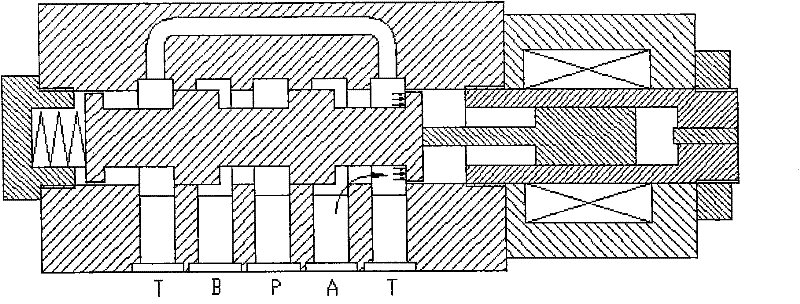

Injection device of cold-chamber die casting machine

The invention discloses a filling device of a cold-chamber die casting machine composed of direction valves V2, V5 and V7 and cartridge valves V1, V4 and V6 as well as a pressure sensor V3, wherein a spring chamber of the cartridge valve V1 is connected to a T port or a P port of the direction valve V2, the spring chamber of the cartridge valve V4 is connected to the T port or P port of the direction valve V5, the spring chamber of the cartridge valve V6 is connected to the T port or P port of the direction valve V7; when the direction valves are electrified to control the starting of the cartridge valves, an oil flowing direction of the spring chamber of the cartridge valves is in accordance with the thrust direction of an electromagnet, so that the oil passing capacity of the direction valves reaches the highest level, and can more rapidly open the cartridge valves, thereby quickening the time from a slow speed to a rapid speed during a filling process, shortening a pressure building time for increasing pressure and filling, and improving key performances of the cold-chamber die casting machine in the filling system. The invention has good effect for the die casting product requiring high speed and short injection time, such as magnesium alloy die castings, thin-walled die castings, die-castings of complex shapes and the like.

Owner:卢志刚

Method and apparatus for resource tracking and charging at end nodes

ActiveCN101300593BHigh feesCharge moreMetering/charging/biilling arrangementsAccounting/billing servicesFast tempoResource utilization

Utilization of resources used to provide a service, and / or costs associated with providing system resources for a service, are tracked in a system where the available resources vary depending on a variety of conditions including resource utilization by other users. The methods are well suited for systems such as mobile communications systems, where the amount of resources and / or costs to a system of providing a service are dynamic and can change on a relatively rapid time scale. Resource utilization is tracked on a per subscriber basis. Service charges can be determined as a function of both the amount of resources consumed and the amount of data delivered, with the amount of resources being used to deliver a fixed amount of data units varying as a function of environmental and / or other conditions. Service charges are sometimes determined as a function of the impact of providing the service to a first user on other system users.

Owner:QUALCOMM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com