Semi-automatic screen detection machine

A semi-automatic and detection machine technology, applied in the direction of conveyors, measuring devices, mechanical conveyors, etc., can solve problems such as complexity, low detection efficiency, troublesome operation process, etc., achieve fast rhythm, high degree of automation, and improve the effect of detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

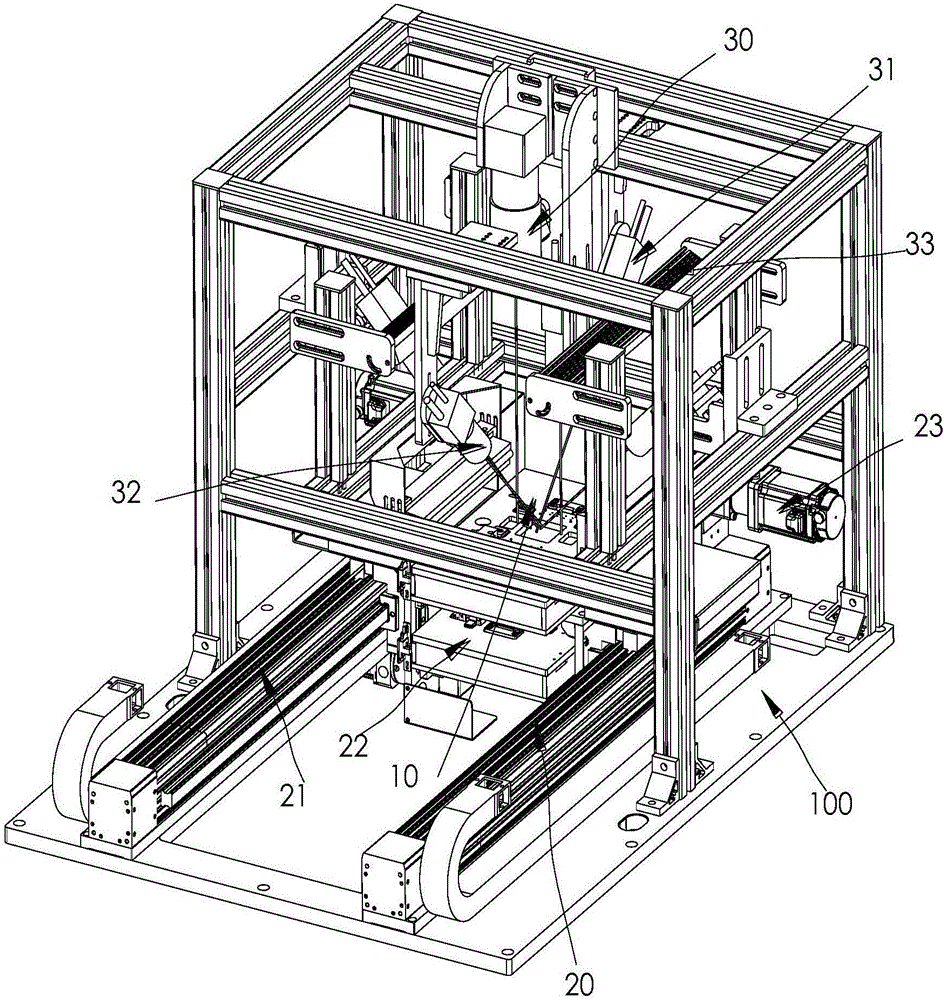

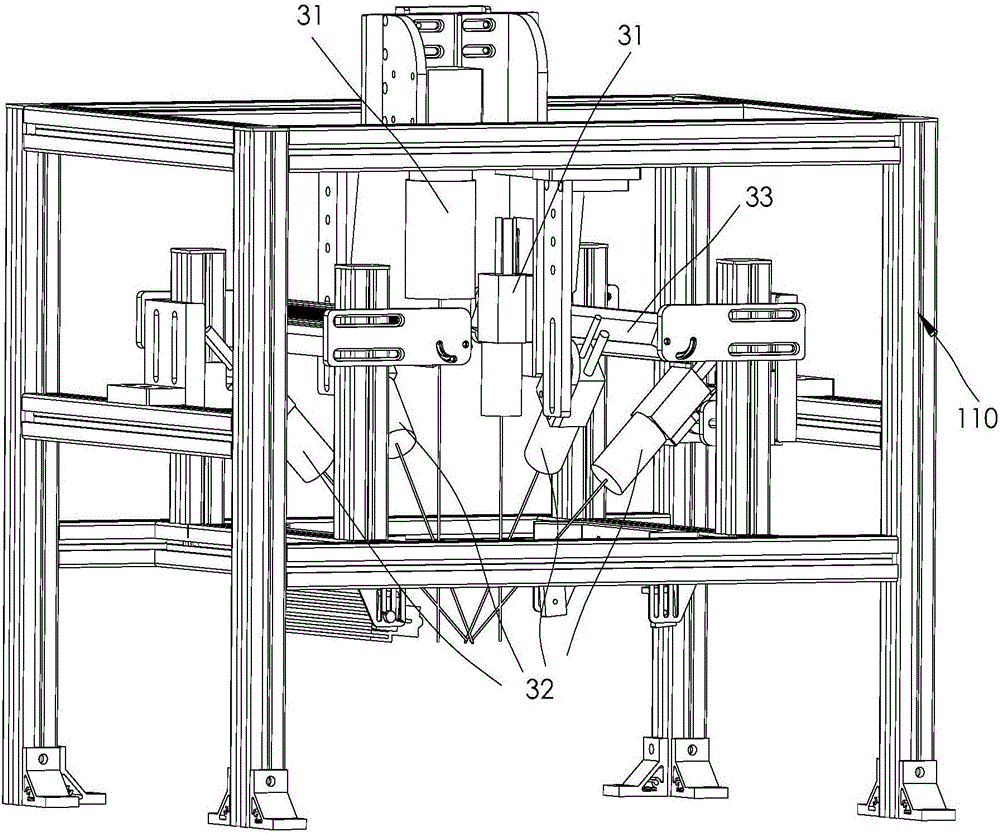

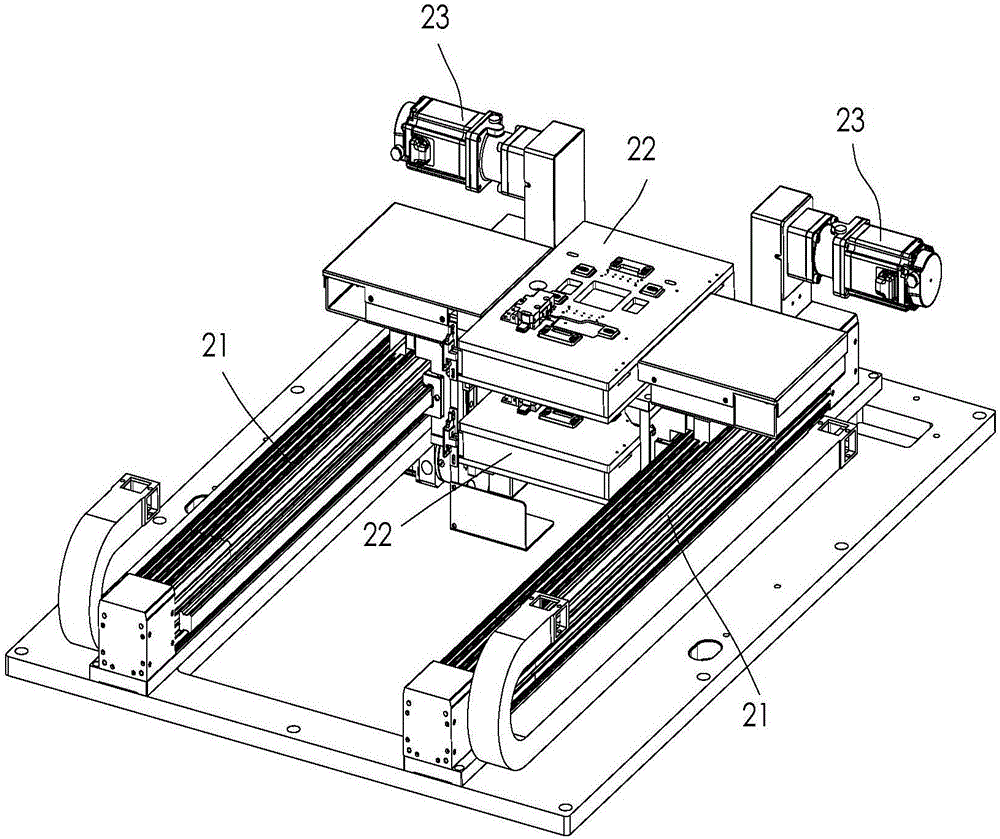

[0024] Such as figure 1 The screen semi-automatic detection machine shown includes a body 100 , a conveying mechanism 20 and a detection mechanism 30 , and both the conveying mechanism 20 and the detection mechanism 30 are installed on the body 100 . Specifically, a detection station 10 is provided on the body 100, and the conveying mechanism 20 is used to transport the external screen to be detected to the detection station 10. The above-mentioned detection mechanism 30 is installed at the detection station 10, and the detection mechanism 30 is used to detect Mechanism 20 sent into the screen to be tested. In addition, a plurality of conveying stations are formed on the conveying mechanism 20 , so that the conveying stations can pass in and out of the detected station 10 in a staggered cycle.

[0025] On the basis of the above structure, when using t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com