Aligning and leveling method for main machine guide rails of sizing and reducing machine

A technology of sizing and reducing diameters and guide rails, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of not meeting production requirements, taking a long time, wasting manpower, etc., shortening operation time, improving product quality, and improving assembly. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

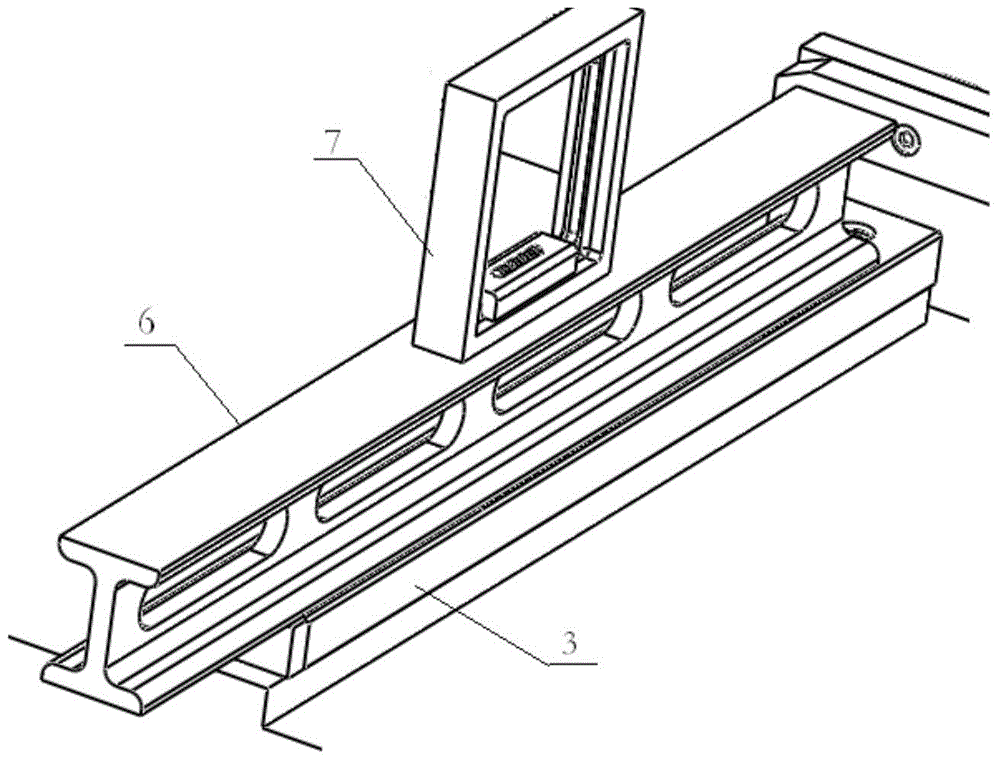

[0044] The present invention will be further described below in conjunction with the drawings.

[0045] The alignment and leveling method of the present invention for 15 guide rails 3 in the C-type seat of the main body of the sizing and reducing machine is as follows:

[0046] 1. Preliminary preparation:

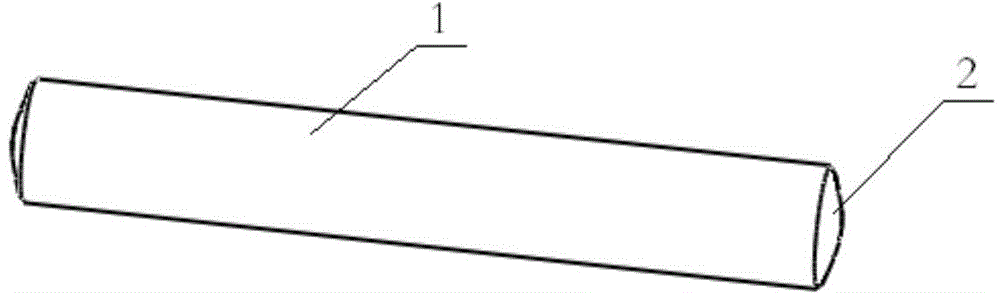

[0047] Making measuring column 1: Measuring column 1 is a cylinder with hemispheres 2 at both ends. The distance between the end points of the two hemispheres 2 is 270.3±0.02mm, which is the same as the distance between two adjacent guide rails 3 ( see figure 1 ).

[0048] Make two gauge blocks 10 with a thickness of 1mm, and several spacers with a thickness of 0.05mm, 0.1mm, and 0.2mm.

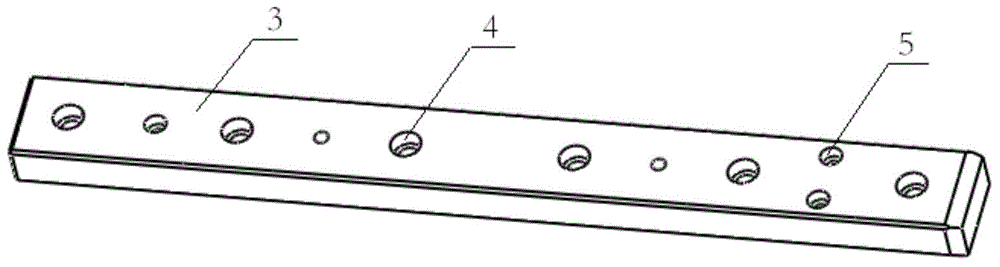

[0049] Three M12 top thread holes 5 are machined on the new guide rail 3 to be used, one of which is on one side, and two are machined in parallel on the other side. And on each bolt hole position of the guide rail 3, a counterbore 4 with a diameter of 26mm and a depth of 18mm is concentrically ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com