Injection device of cold-chamber die casting machine

A cold-chamber die-casting and pressure technology, applied in the field of cold-chamber die-casting machine injection devices, can solve the problems of insufficient speed of injection, unqualified die-casting products, poor fluidity, etc., so as to shorten the construction time and save energy. The cost of machining, the effect of simplifying the hydraulic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

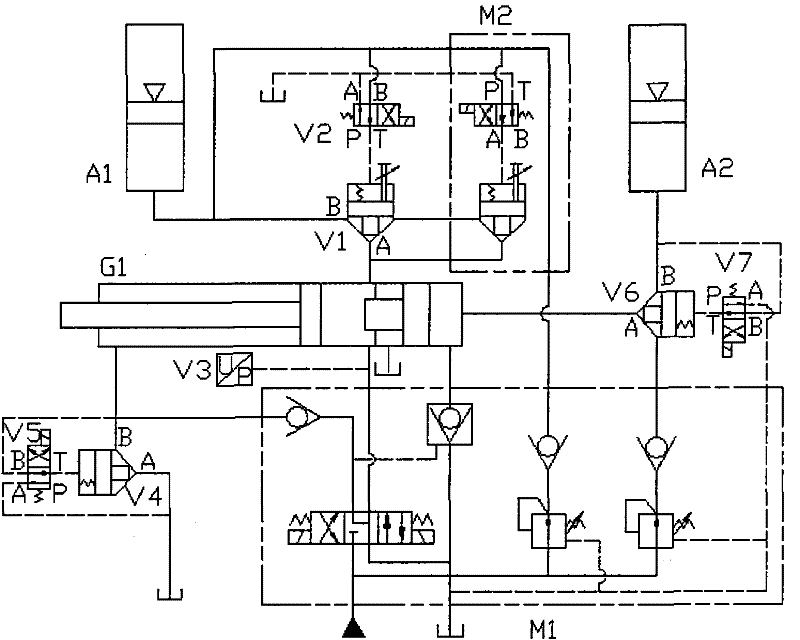

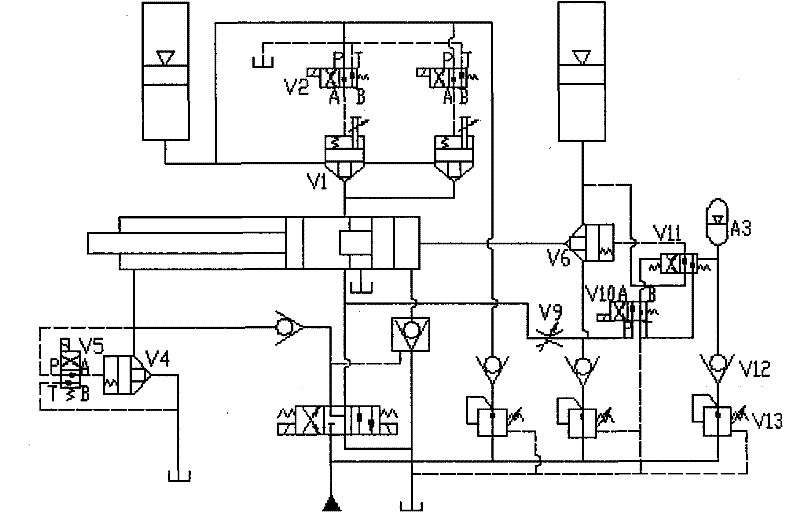

[0012] The patent of the present invention will be described in detail below in conjunction with the above-mentioned drawings. This embodiment takes the standard configuration of a domestic cold chamber die-casting machine 800T as an example, and its hydraulic principle is as attached figure 1 shown.

[0013] When the injection system changes from slow speed to fast injection, the directional valves V2 and V5 are energized, the oil in the spring chamber of the cartridge valve V1 drains oil through the T port of V2 to the A port, the cartridge valve V2 is opened, and the accumulator passes through The cartridge valve V1 quickly fills the rodless chamber of the injection cylinder with oil, and at the same time, the oil in the spring chamber of the cartridge valve V4 drains oil to the A port through the T port of V5, and the cartridge valve V4 opens to realize rapid injection. But in this process, in the originally designed hydraulic system, the directional valve V2 drains oil fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com