High-weather-resistance light-color halogen-free flame-retardant PC/ASA alloy material and preparation method thereof

An alloy material and weather-resistant technology, which is applied in the field of high-weather-resistant light-colored halogen-free flame-retardant PC/ASA alloy materials and its preparation, can solve the problems of poor long-term weather resistance, improve weather resistance, avoid light energy damage, and flame-retardant The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

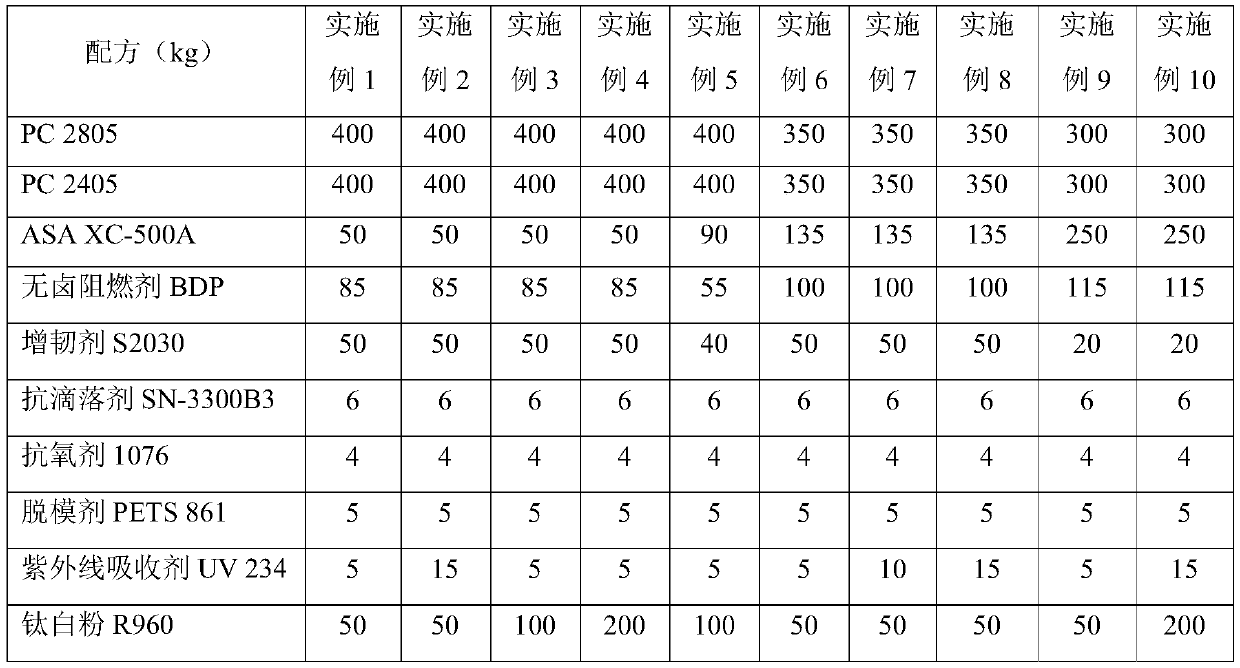

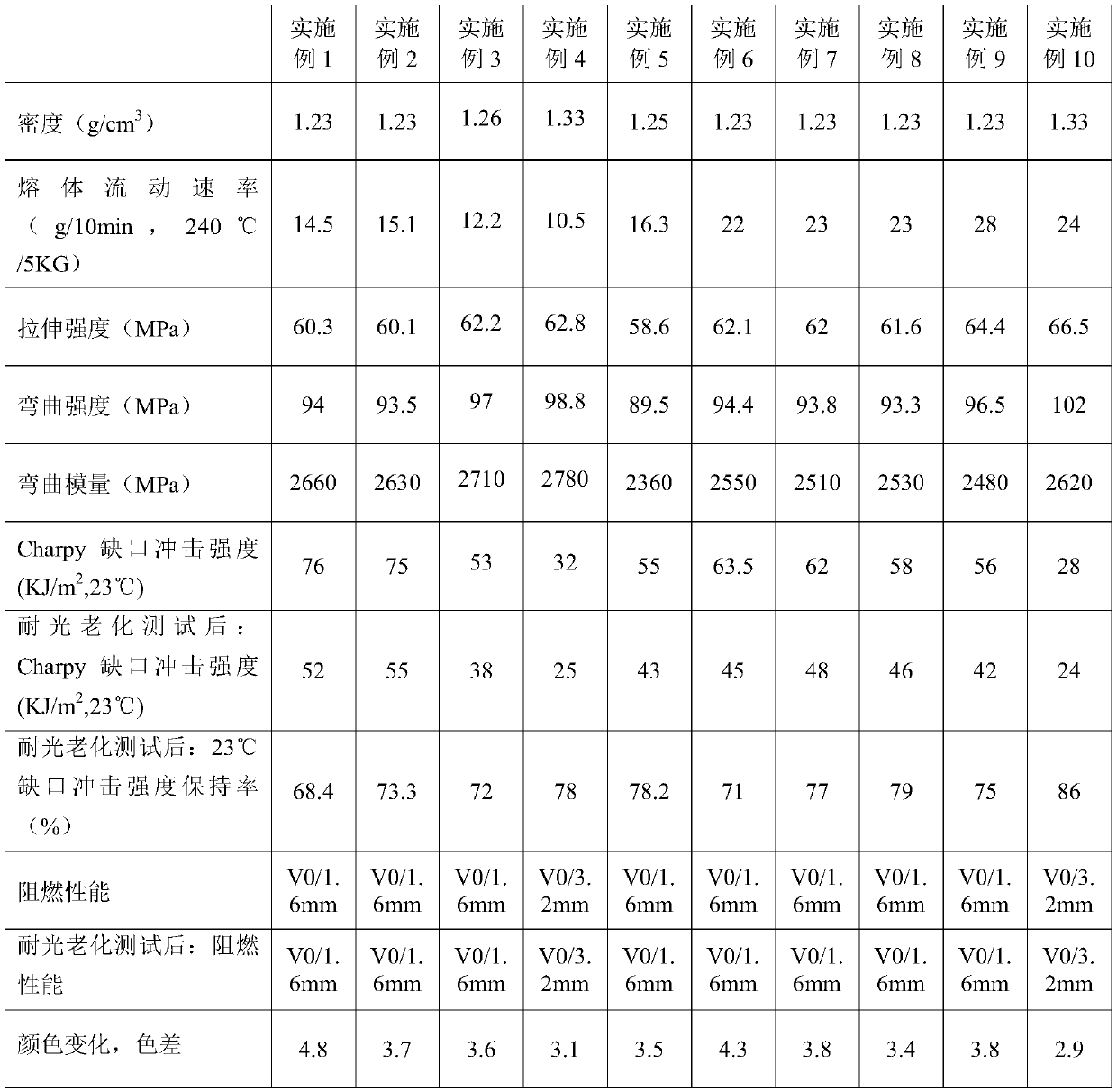

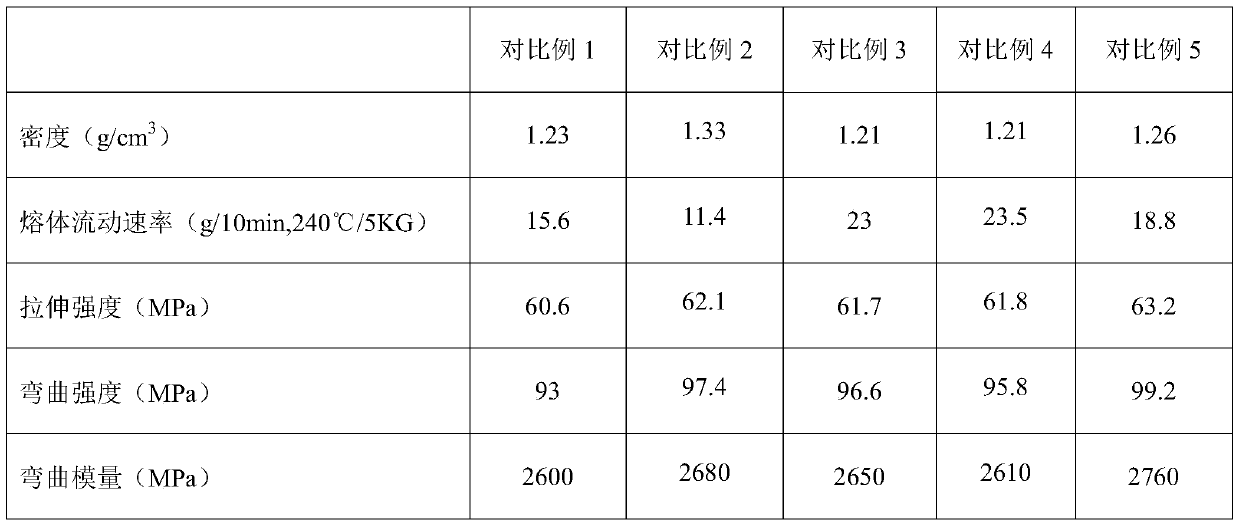

[0054] The composition and dosage of high weather resistance light color halogen-free flame retardant PC / ASA alloy material are shown in Table 1:

[0055] According to the ratio in Table 1, each raw material component was prepared according to the following preparation method to obtain a high-weather-resistant light-colored halogen-free flame-retardant PC / ASA alloy material.

[0056] Step 1: Grind the first part of PC into 80-100 mesh PC powder;

[0057] The second step: PC powder accounting for 10% by weight of the total weight (PC powder is used to dilute the auxiliary agent, so that the dilution concentration is between 1:5 and 1:50, because the additive ratio is different, use a fixed The proportion of PC powder added to ensure the dilution concentration.), and titanium dioxide, toughening agent, flame retardant anti-dripping agent, antioxidant, mold release agent, anti-ultraviolet agent are added to the high-speed disperser at one time for ultra-high-speed mixing 10 to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com