Frame filling body warm preservation heat insulation board and its construction method

A technology of thermal insulation and construction method, applied in thermal insulation, roof insulation materials, insulation layers, etc., can solve the problems of high cost, hidden safety hazards, falling off, etc., achieve low cost, convenient and fast construction, and beautify the environment during construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

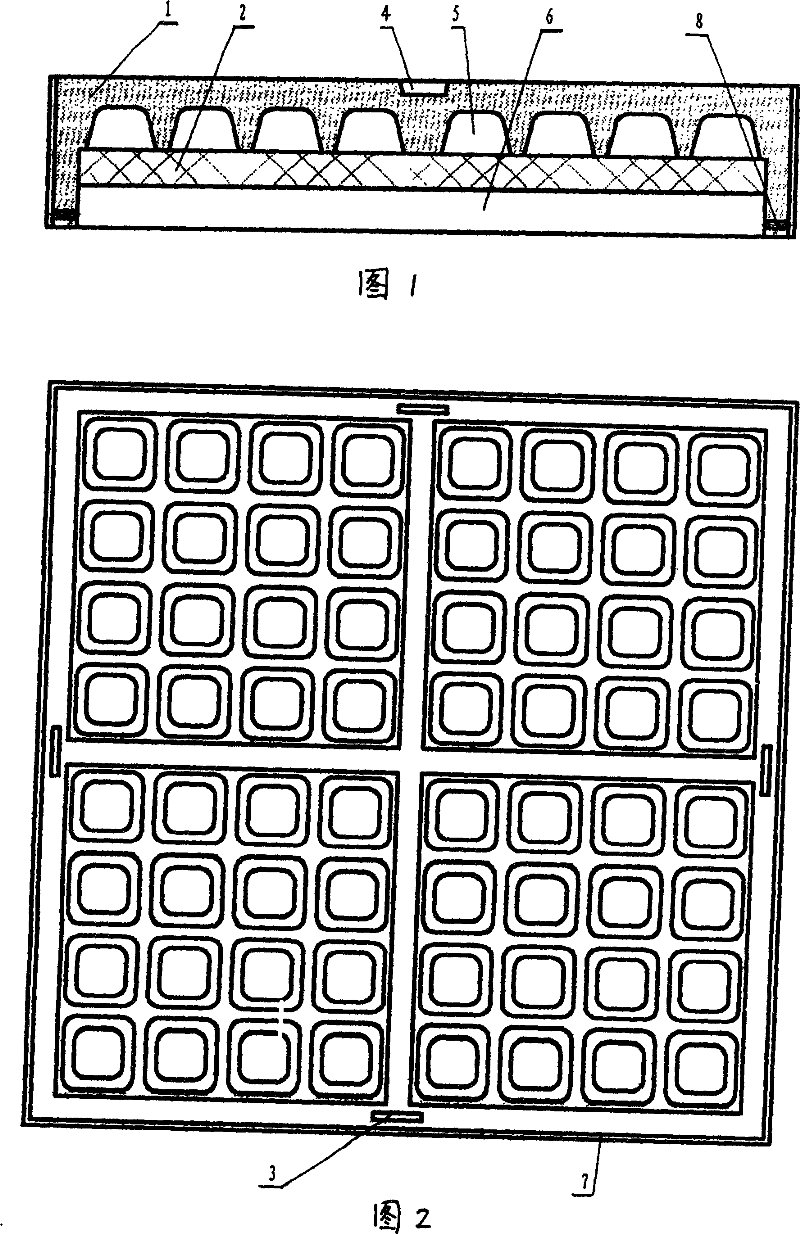

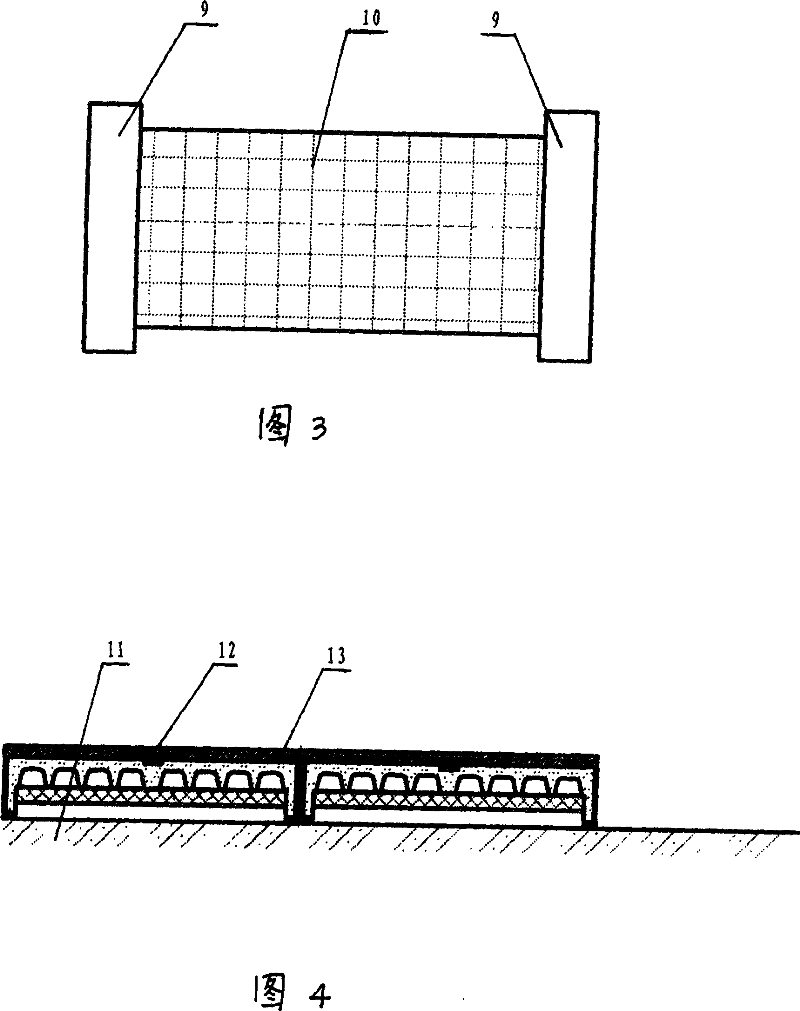

[0032] The external dimensions of the thermal insulation plate of the frame filling body are length × width × thickness = 600mm × 600mm × 80mm, and the thickness of the frame is 25mm; the thickness of the closed air interlayer is 25mm; The thickness is 30mm; the thickness of the open air interlayer is zero; the cross groove on the outer surface is 40mm wide and 15mm deep; the non-cold bridge connector is 80mm long and 40mm wide; the edge sealing material is made of non-woven felt with a thickness of 4mm.

[0033] The molding of the frame structure insulation material adopts the machine molding process, and its material formula adopts one of the following formulas:

[0034] (1)1m 3 Volume material (after pressing)

[0035] Perlite: Heap volume 1.87m 3

[0036] Cement (325 Ordinary Portland Cement): 160kg

[0037] Adhesive (107 glue): 38kg

[0038] Water: 65kg

[0039] (2)1m 3 Bulk material (industrial molding process)

[0040] Expanded polystyrene particles: 0.9m 3heap...

Embodiment 2

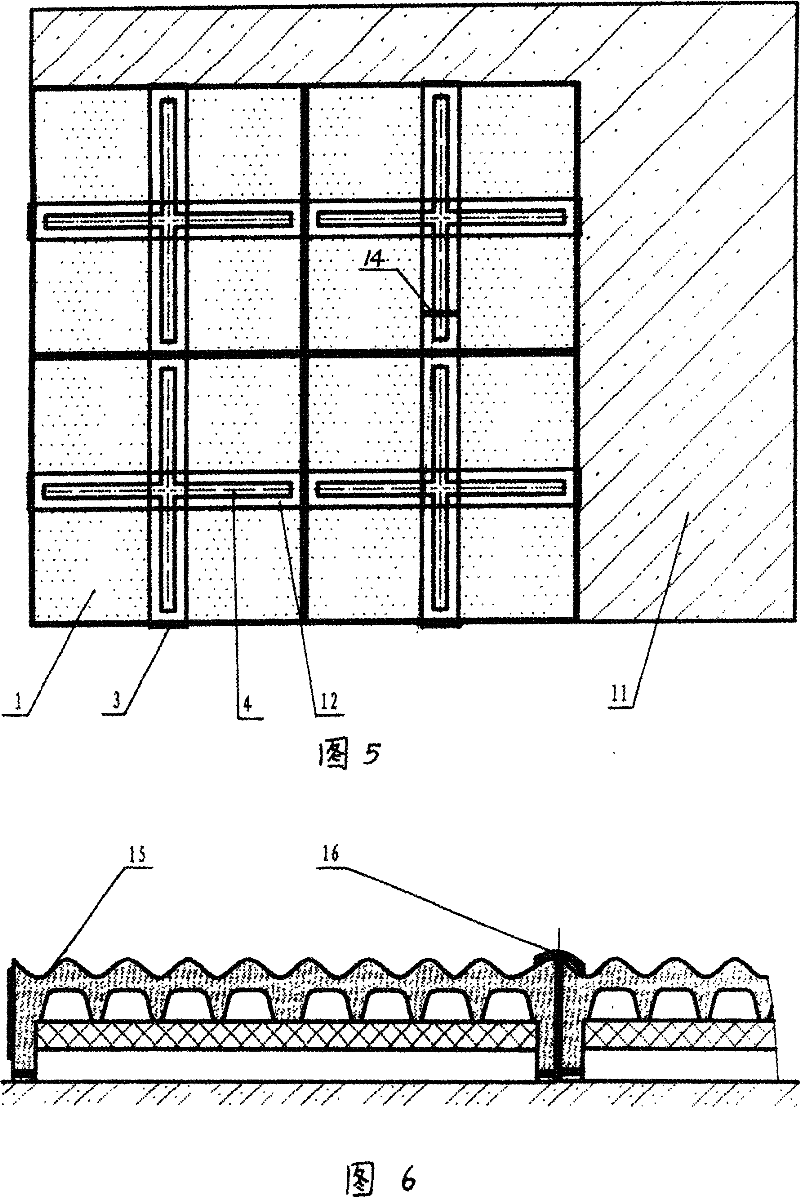

[0049] As shown in Figures 4 and 5, from the corner of the wall body 11, each frame-fill body thermal insulation board is continuously fixed on the wall surface, the method is to use the strapping belt 12 to connect the non-cold bridge connectors in the vertical and horizontal directions respectively. 3. One end of the lock 9 is locked, and the other end of the lock 9 is fixed on the wall with expansion wall nails, and the strapping belt 12 is formed into a large square grid covering the entire wall. Finally, the outer surface of the slab is plastered with concrete mortar to form a grid-like concrete rib—the outer cover surface structural protection layer 13 .

Embodiment 3

[0051] As shown in Figures 4 and 5, from the corner of the wall body 11, each frame-fill body thermal insulation panel is continuously fixed on the wall surface by locking each The thermal insulation panels of the frame filling body are sequentially fixed on the wall, and then the other end lock 9 of the non-cold bridge connector 3 is connected to the other end of the non-cold bridge connector 3 by the strap 12 in two directions, and the strap 12 is formed into a large area covering the entire wall. The square mesh, and finally the cover decorative panel is installed through the external connecting piece 14 on the strapping belt 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com