Patents

Literature

30results about How to "Anti-condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-insulation and heat-preservation water-based coating material with air purifying function

InactiveCN103450761ALow thermal conductivityQuality improvementFireproof paintsLignin material coatingsWater basedHazardous substance

The invention provides a heat-insulation and heat-preservation water-based coating material with an air purifying function. The water-based coating material is prepared through compounding raw materials, such as diatomite, hollow glass beads, lignocellulose, zirconium phosphate loaded sliver powder, nano zinc oxide, tourmaline powder, aluminum oxide, hydroxypropyl methylcellulose, a pure acrylic emulsion, a dispersing agent 5040, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 1,2-propanediol, Kathon, a silicone defoamer, deionized water and the like. The water-based coating material provided by the invention further has the functions of improving air quality, regulating air humidity, preventing mildew and the like through adsorbing harmful substances in air and releasing negative ions, besides an excellent heat insulation function.

Owner:深圳市宜丽环保科技有限公司

Multifunctional liquid diatom ooze coating material

The invention provides a multifunctional liquid diatom ooze coating material. The multifunctional liquid diatom ooze coating material is formed by compounding the raw materials of kieselguhr, attapulgite, silver-loaded zirconium phosphate powder, nano-zinc oxide, electrical mountain flour, aluminum oxide, hydroxypropyl methyl cellulose, pure acrylic emulsion, a dispersing agent 5040, 1,2-propylene glycol, isothiazolinones, an organic silicon defoaming agent, deionized water and the like. The multifunctional liquid diatom ooze coating material can improve air quality by absorbing hazardous substances in the air and releasing negative ions, further has the functions of regulating air humidity, preventing mildew, condensation and fire and like, and has the advantages of being free of limitations of water sources and technical requirements of constructors and the like.

Owner:中健生命科技(深圳)有限公司

Building energy-saving glass

InactiveCN102729545ALow thermal conductivityEffective throughGlass/slag layered productsFlat glassBuilding energy

The invention discloses a building energy-saving glass. The building energy-saving glass comprises two glass sheets and a seal spacer positioned between the two glass sheets, a closed cavity is formed among the seal spacer and the glass sheets, transparent heat insulation SiO2 aerogel plates are filled in the closed cavity, a transparent SiO2 aerogel aqueous rubber is used to seal the transparent heat insulation SiO2 aerogel plates, and a butyl rubber is used to seal the seal spacer and the glass sheets. Convection heat loss and condensation phenomena caused by air transmission are greatly reduced, so compared with a hollow glass and a low-irradiation hollow glass in the prior art, the energy saving glass filled with the transparent heat insulation SiO2 aerogel plates has a high heat insulation performance and simultaneously has a high light transmission rate; and the energy saving glass has a heat insulation performance near to that of a vacuum glass, and has a substantially higher service life than the vacuum glass.

Owner:CHANGSHA XINGNA AEROGEL

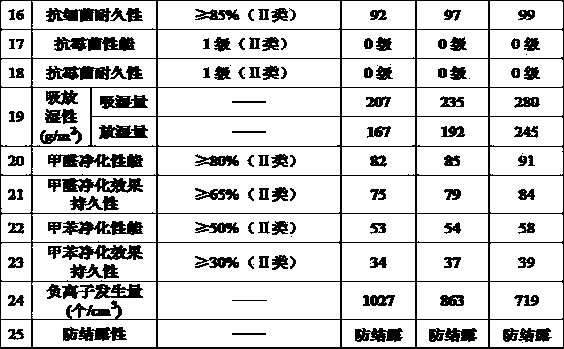

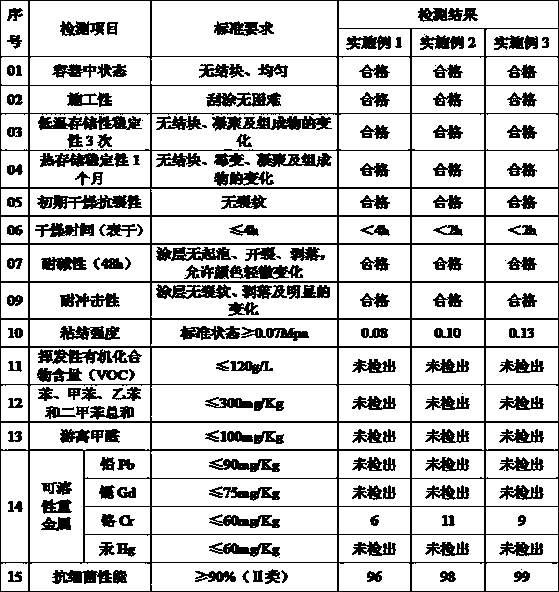

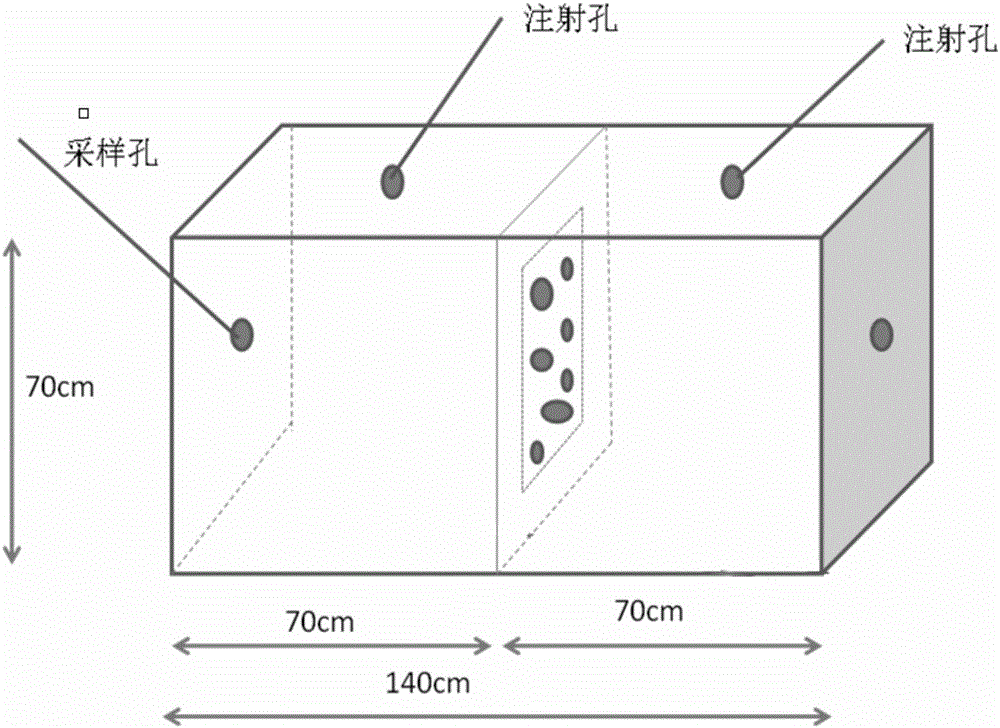

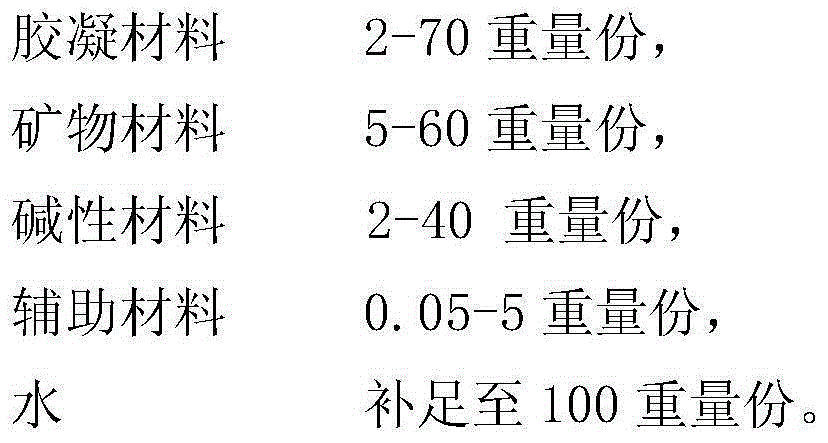

Self-adsorption interior-wall-decoration environment-friendly composite coating material as well as preparation method and application thereof

ActiveCN103664088AFull migrationEfficient and long-lasting removalAdhesivesInorganic materialsComposite coating

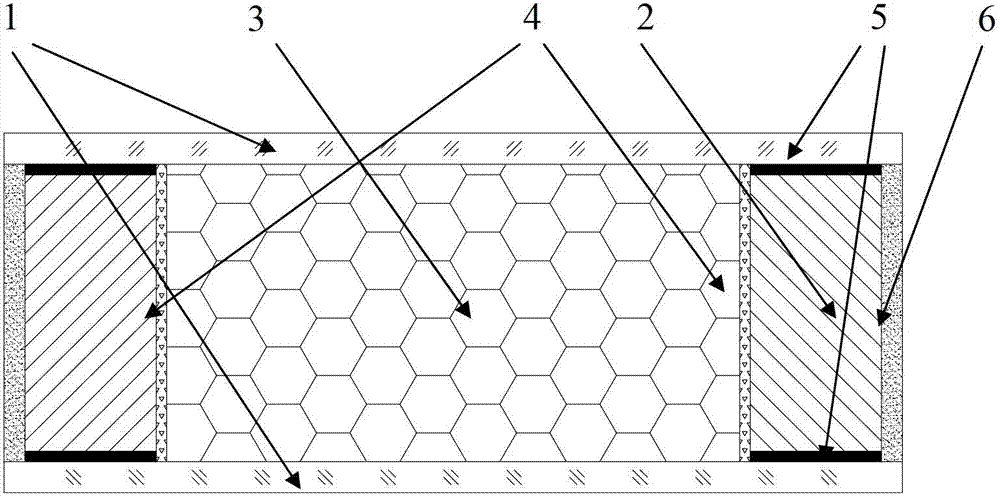

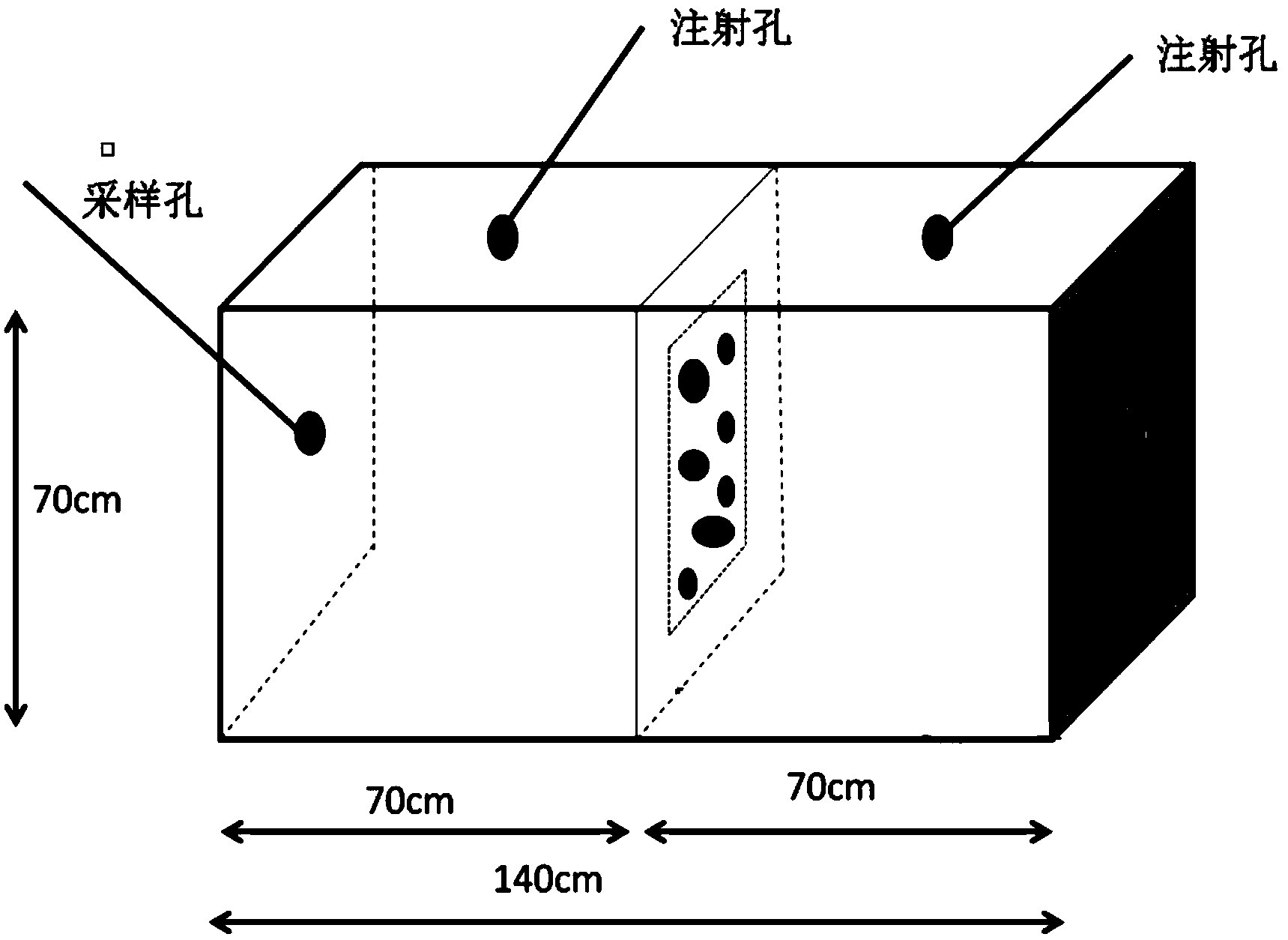

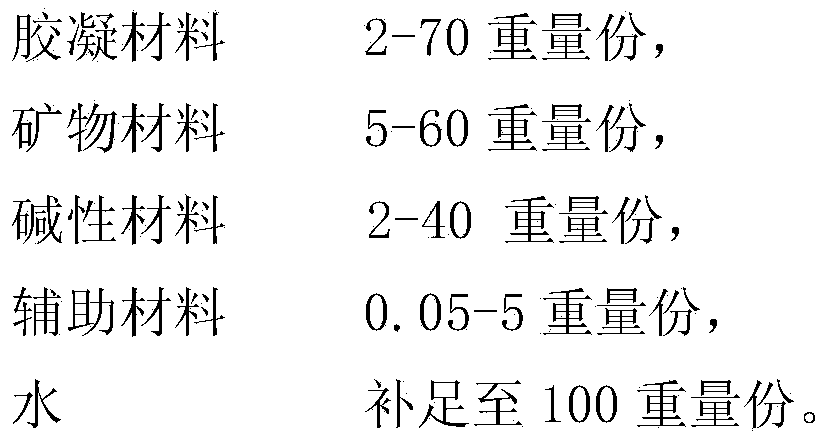

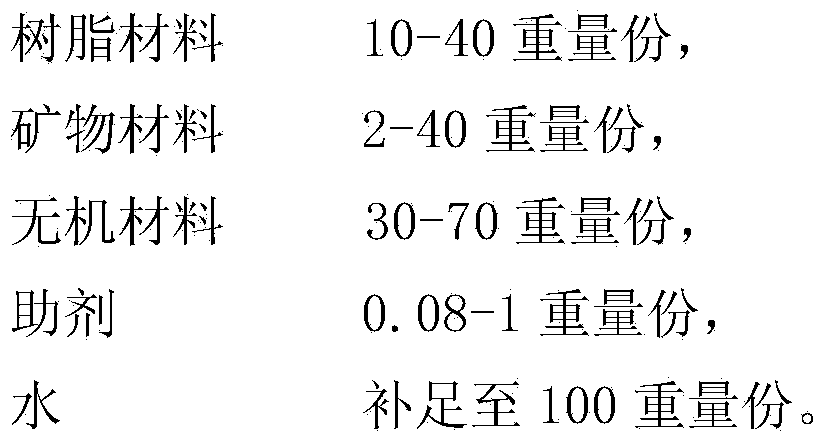

The invention discloses a self-adsorption interior-wall-decoration environment-friendly composite coating material as well as a preparation method and an application thereof. The coating material is a multiple-layer coating material and consists of a bottom-layer coating material and a surface-layer coating material, wherein the bottom-layer coating material consists of a cementing material, a mineral material, a basic material and necessary auxiliary materials which react with one another so as to form an interlaced network structure; the surface-layer coating material consists of a resin material, a mineral material, an inorganic material and an additive which react with one another so as to form a loose network structure full of tiny holes. According to detection, the composite coating material, which is a novel self-adsorption interior-wall-decoration environment-friendly composite coating material for environment-friendly building interiors, is efficient, long-acting and environment-friendly and integrates functions of purification, permeation, diffusion and the like.

Owner:CHINA BUILDING MATERIALS ACAD

Production process for polytetrafluoroethylene (PTFE) aqua tex composite high-temperature tail gas filter material

InactiveCN102527156AGood chemical resistanceImprove performanceSynthetic resin layered productsGlass/slag layered productsGlass fiberFiber

The invention relates to a production process for a polytetrafluoroethylene (PTFE) aqua tex composite high-temperature tail gas filter material, which belongs to the technical field of spinning filter materials. Polytetrafluoroethylene fibers and glass fiber base fabrics are adopted as raw materials. Firstly, the polytetrafluoroethylene fibers are detected and weighted, then sequentially fed into a long curtain, a horizontal opener, a large-cabinet and a fine opener, combed by a combing machine 1 and a combing machine 2 in layering mode, and respectively fed into a cross lapping machine 1 and a cross lapping machine 2 to be lapped. The glass fiber base fabrics are laminated between the raw materials sent out of the cross lapping machine 1 and the cross lapping machine 2 to be coincided and then sequentially is processed by a prewetting process, an aqua tex process, a dewatering process, a drying process and a coiling process. The PTFE aqua tex composite high-temperature tail gas filter material is strong in mechanical performance, filter performance, high temperature resistance and chemical corrosion resistance and stable in size.

Owner:ZHEJIANG HEZHONG NONWOVEN

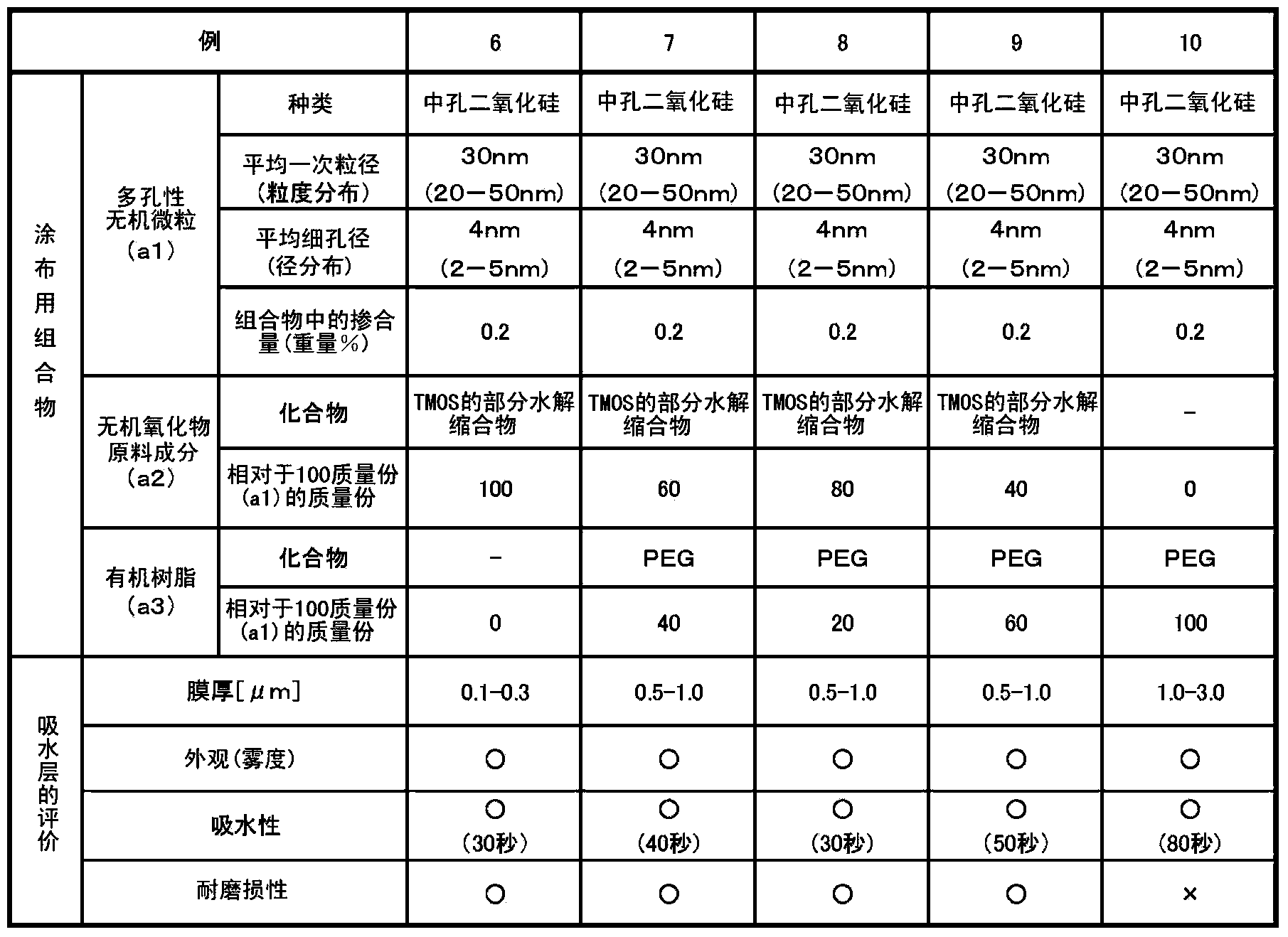

Functional article, article for transport equipment, article for construction, and composition for coating

InactiveCN103459139AAnti-condensationWith humidity controlOther chemical processesLayered productsPartial hydrolysisEnvironmental engineering

Provided is a functional article having a water absorption layer having wear resistance as well as a water absorption function involved in condensation prevention, humidity control, fouling prevention, fogging prevention, icing prevention, and the like; also provided are an article for transport equipment and an article for construction provided with the same. Further provided is a composition for coating making it possible to form a water-absorbent coating having a water absorption function involved in condensation prevention, humidity control, fouling prevention, fogging prevention, icing prevention, and the like, and also having wear resistance. This functional article having a substrate as well as a water absorption layer provided to at least one surface of the substrate is characterized in that the water absorption layer contains a porous inorganic particulate and also an inorganic oxide serving as a binder component. This composition for coating contains a porous inorganic particulate having a mean primary particle diameter of 5-100 nm and a mean pore diameter of 1-50 nm, a metal alkoxide and / or a partial hydrolysis condensation product thereof, and a solvent.

Owner:AGC INC

Manufacturing method of aluminum alloy coated plates

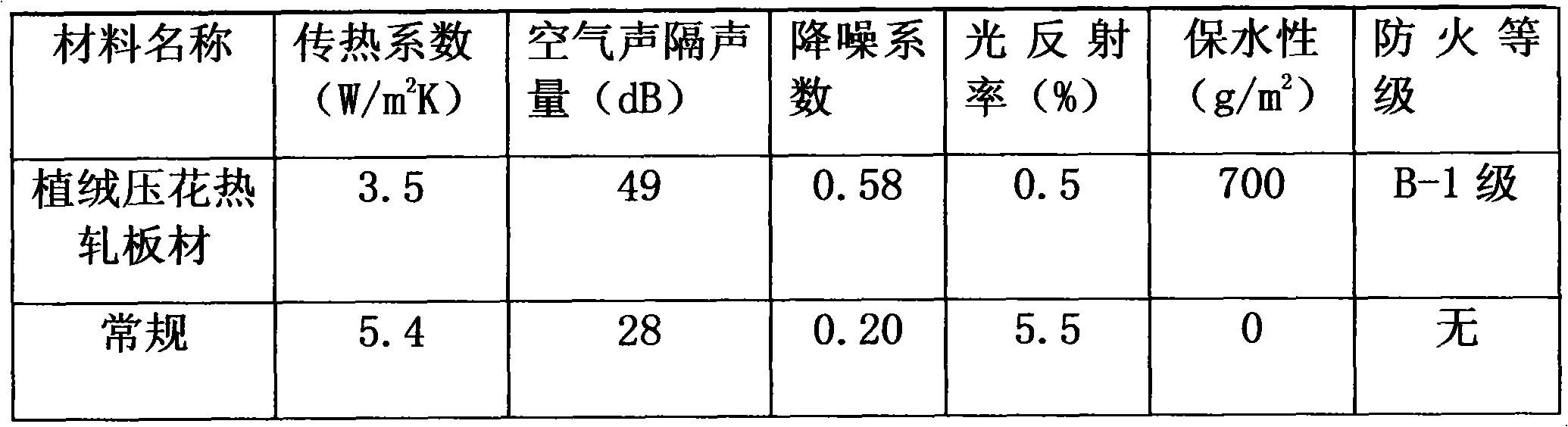

InactiveCN103790317AHigh transparencyHigh glossCovering/liningsLamination ancillary operationsAcoustic absorptionThermal insulation

The invention relates to a manufacturing method of building plates, in particular to a manufacturing method of aluminum alloy coated plates. The building plates are resistant to corrosion and weather proof, prevent dew dropping, and have certain insulation performance. The manufacturing method includes the steps of selecting materials, preprocessing surfaces of plates, drying, coating with glue, laminating, drying, hot-pressing, and checking for storage. The product manufactured by the method has good fire resistance; detections show that the product is approved by the level B-1 of fire rating for national building materials, is fully environment friendly and pollution free, also passes environmental certification, and has the advantages of long service life, environment friendliness, fire proofing, dew prevention, corrosion resistance, acoustic absorption, light absorption, thermal insulation, high transparency, high glossiness, low haze, excellent UV barrier property, laser security, and bright decoration.

Owner:WUXI XINDAZHONG STEEL SHEET

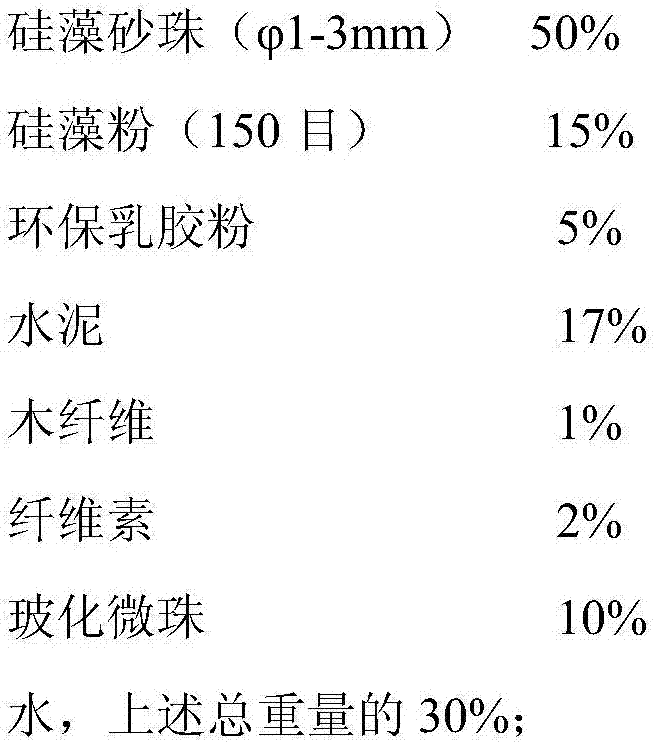

Diatom sand beads and high-strength, environment-friendly and thermal-insulation mortar containing same

The invention relates to diatom sand beads and high-strength, environment-friendly and thermal-insulation mortar containing the same. The diatom sand beads are prepared from second-class and third-class diatomite used as a raw material through four steps including drying, purification, granulation and roasting. The diatom sand beads are light in weight, environment-friendly and high in adsorbability and have the advantages of damp prevention, fire prevention, purification, thermal insulation and the like. The thermal-insulation mortar is prepared from 50%-60% of the diatom sand beads, 10%-20% of diatom powder, 5%-8% of environment-friendly latex powder, 10%-20% of cement, 1% of wood fiber, 2% of cellulose, 0-10% of glass beads and water. The thermal-insulation mortar can replace cement mortar to be directly applied to building wall brick surfaces, when the thermal-insulation mortar is used for an exterior wall, other decoration processes can be performed directly on the thermal-insulation mortar, and when the thermal-insulation mortar is used for an interior wall, the thermal-insulation mortar can well adsorb indoor formaldehyde produced during decoration, is environment-friendly and can purify indoor air; the thermal-insulation mortar has the advantages of being light in weight, low in heat conductivity coefficient, environment-friendly, thermal-insulation, high-temperature-resistant, fireproof, low-temperature-resistant, noise-reducing, damp-proof, mildew-proof, anti-condensation, free of radioactive substances, stable in physical and chemical property and the like.

Owner:长白朝鲜族自治县玉鑫硅藻土有限公司

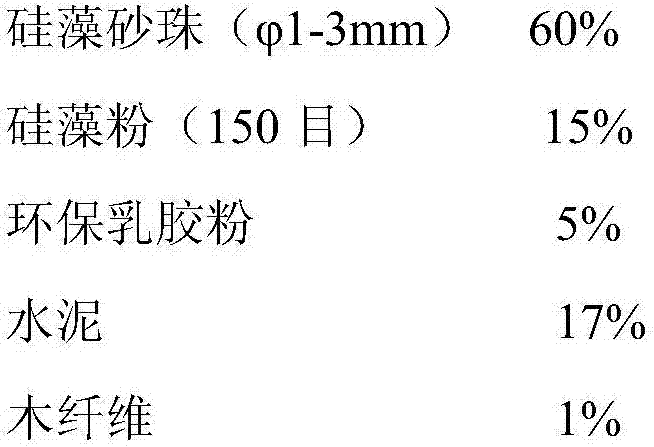

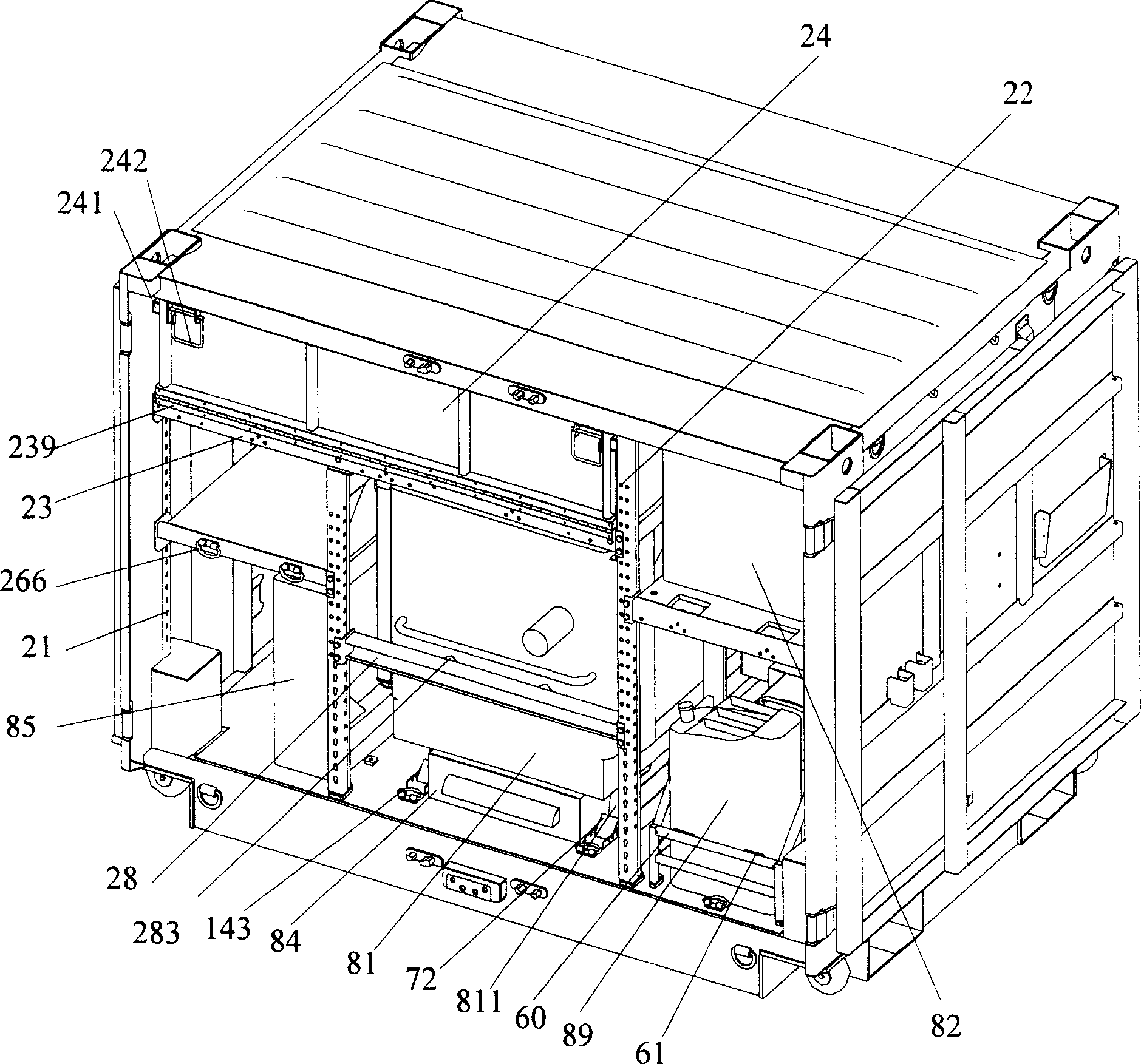

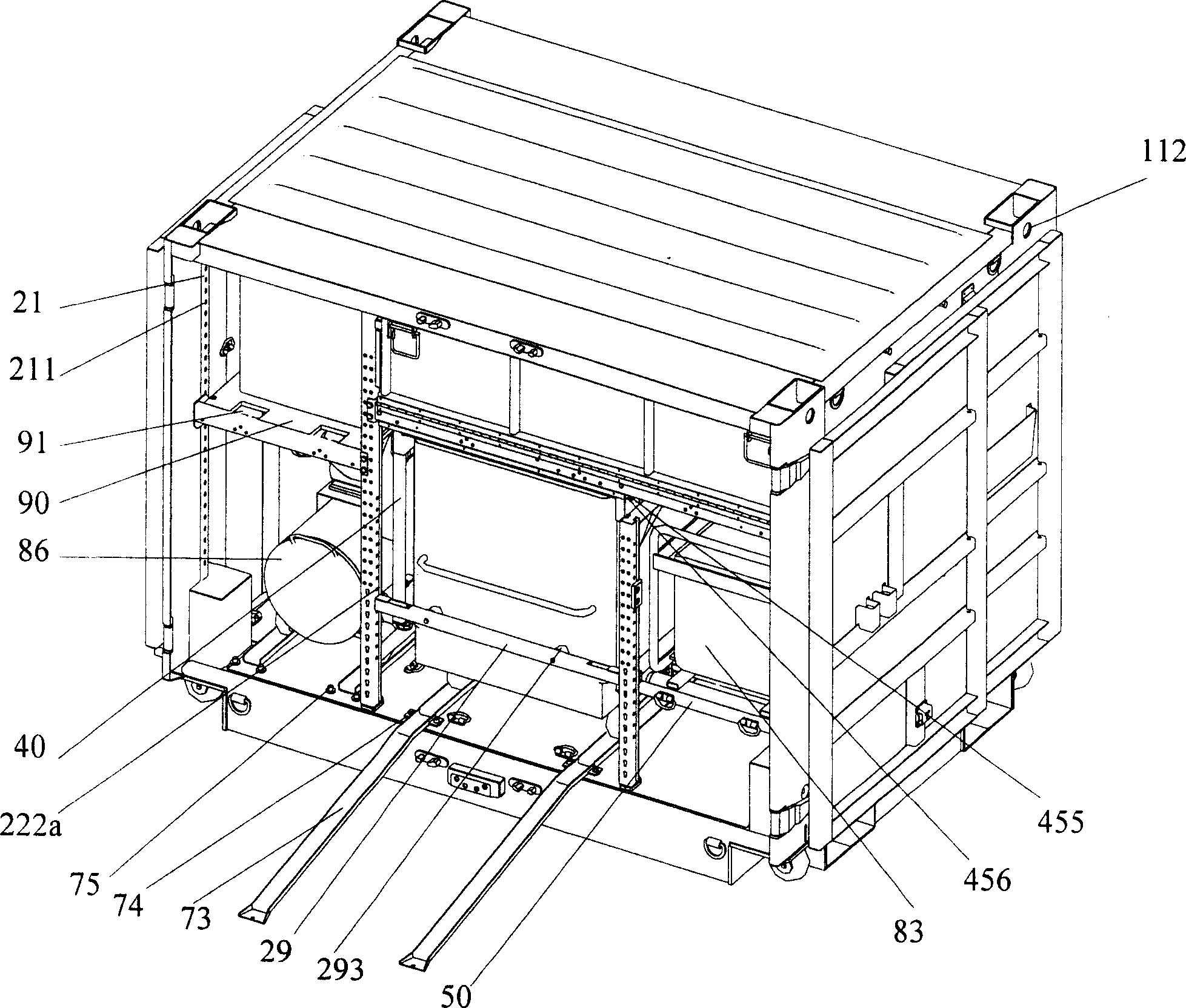

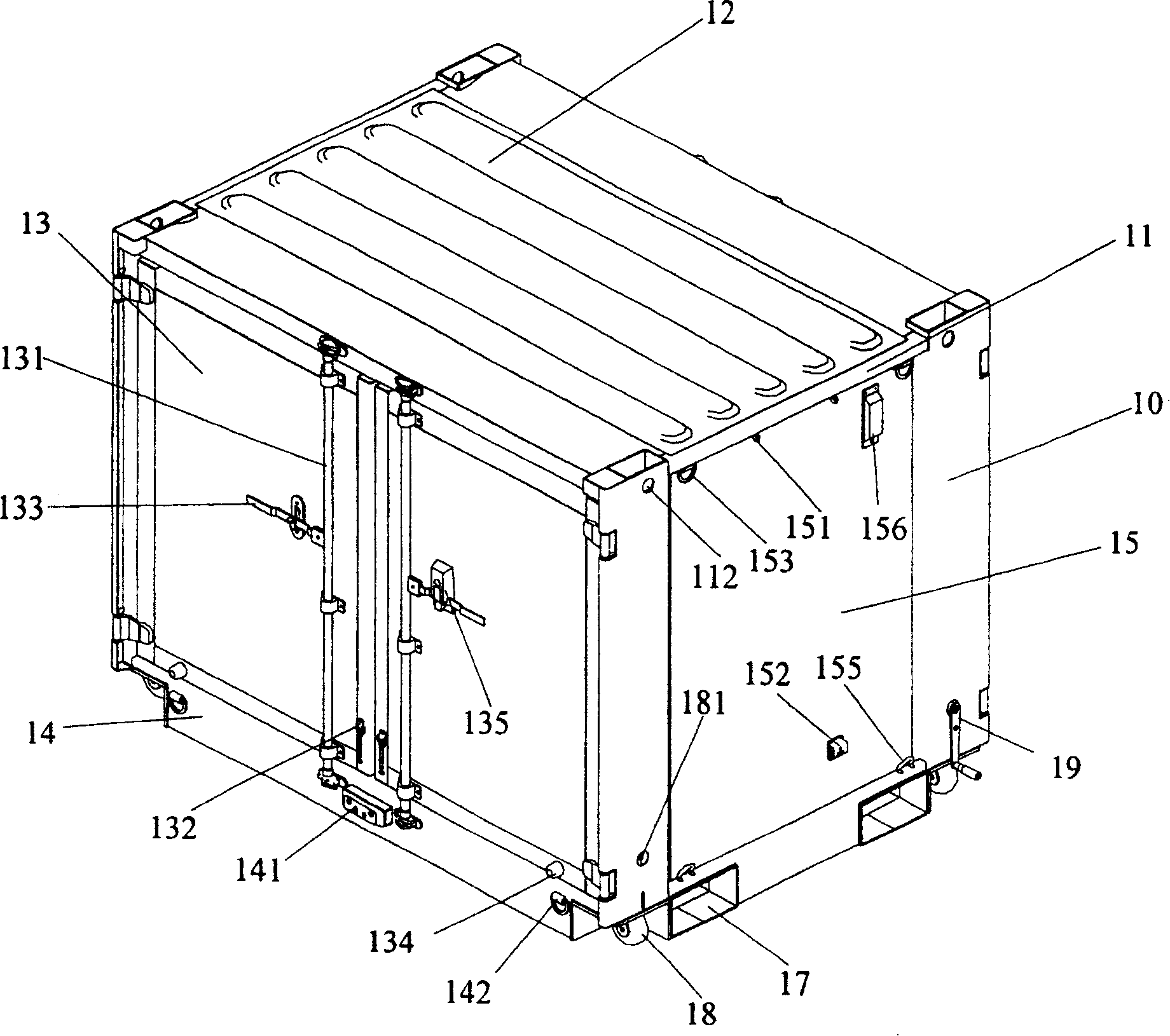

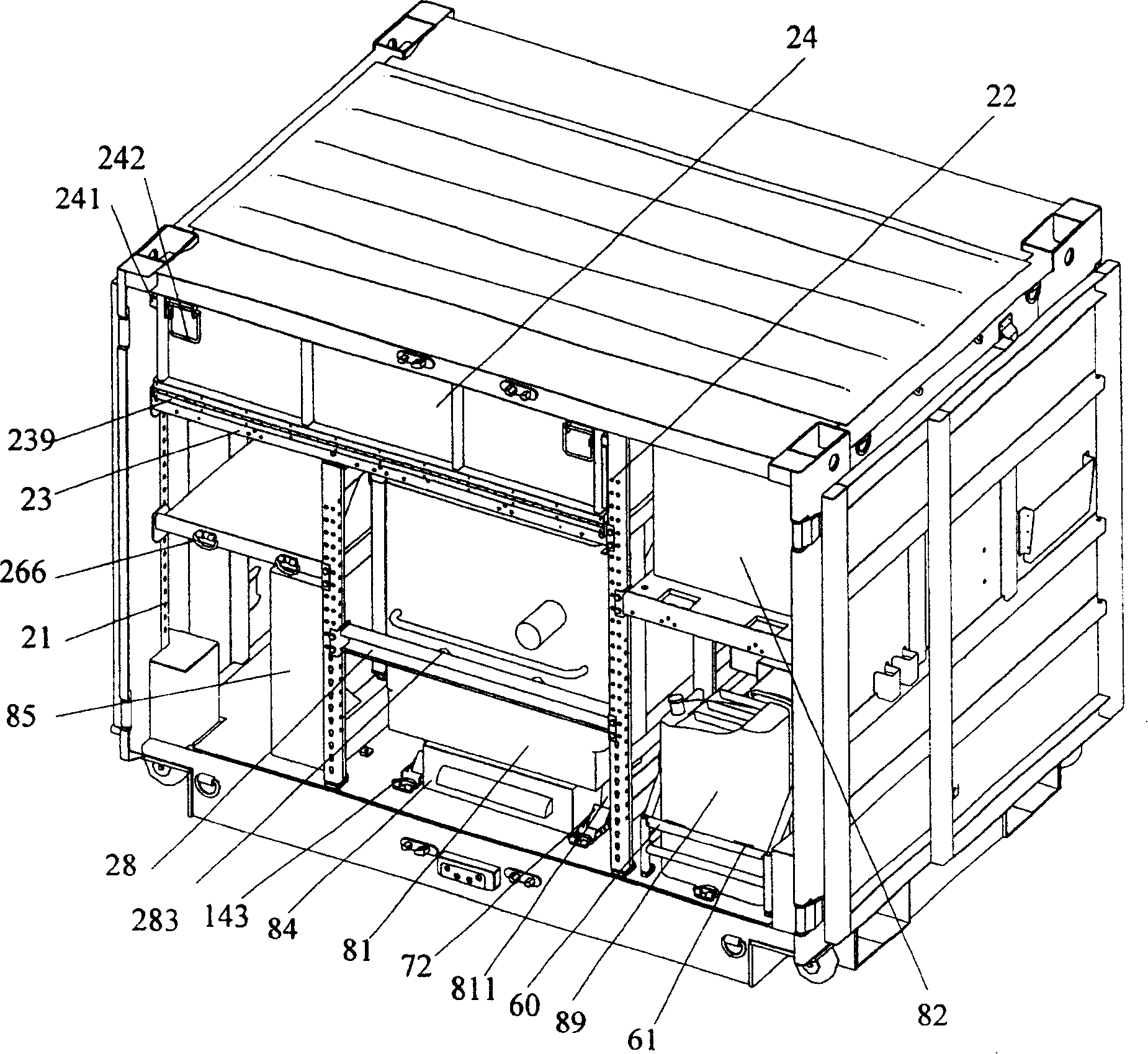

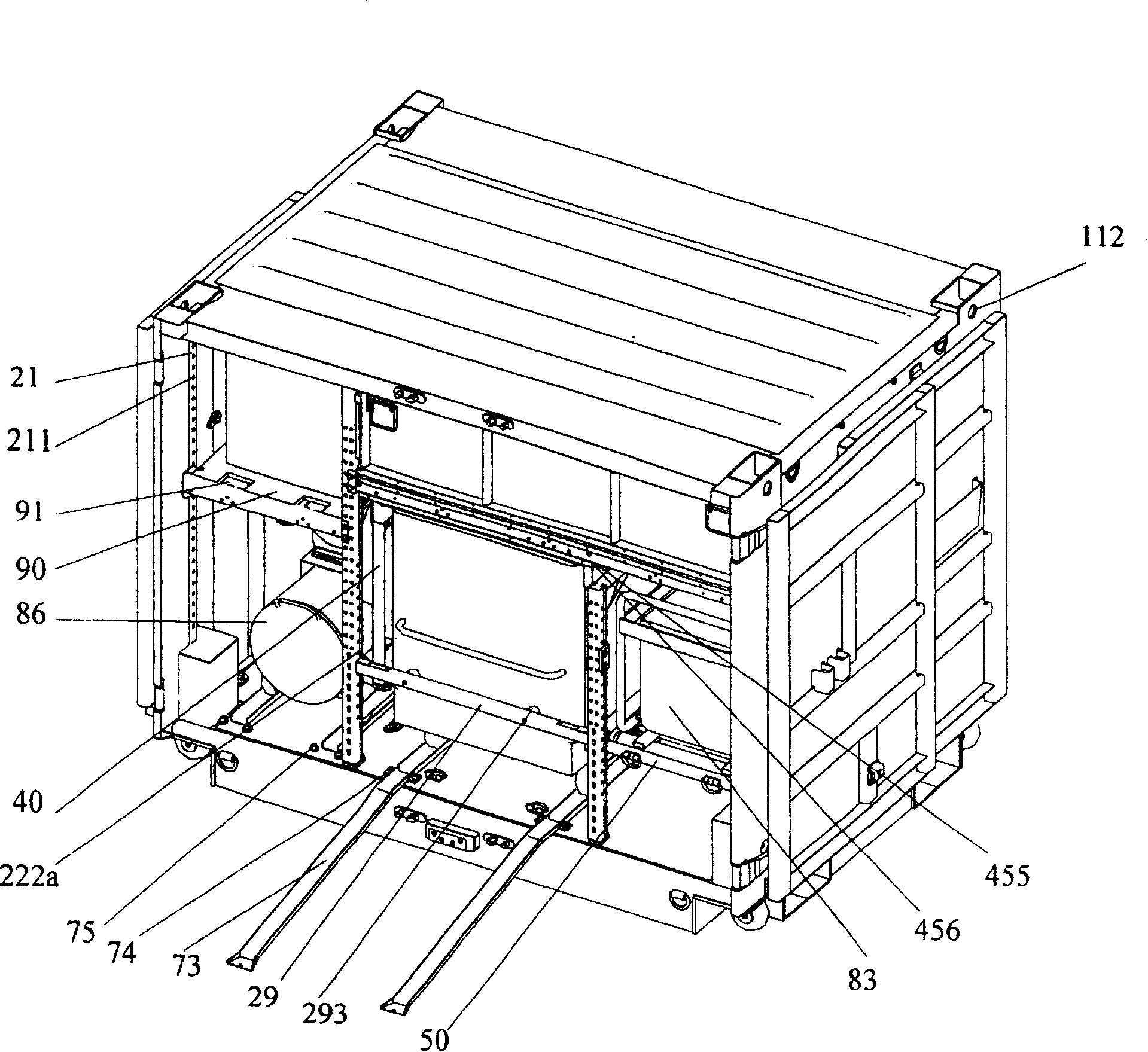

Mechanical first aid repair square cabin

A movable square cabin for emergency repair is composed of a cabin body consisting of frame, top plate, side plates, door, chassis, and 4 telescopic casters, and a storage unit comprising regulatable frame, partitioned storage spaces and the apparatus and materials used for emergency repair.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

Manufacturing method of hot-dip galvanized coated plates

InactiveCN103790309AExtended service lifeEnvironmentally friendlyLamination ancillary operationsCovering/liningsAcoustic absorptionThermal insulation

The invention relates to a manufacturing method of building plates, in particular to a manufacturing method of hot-dip galvanized coated plates. The building plates are resistant to corrosion and weather, prevent dropping of dews, and have certain thermal insulating property. The manufacturing method includes the steps of selecting materials, preprocessing the surfaces, drying, coating with glue, laminating, drying, hot-pressing, and checking for storage. Products manufactured by method are well fireproof; detections show that the products are approved by the level B-1 of national building materials fire rating, are fully environment friendly and free of pollution, also pass environmental certification, and have the effects of long service life, environment friendliness, fire proofing, dew prevention, corrosion resistance, acoustic absorption, light absorption, thermal insulation, high transparency, high glossiness, low haze, excellent UV barrier property, laser security, and bright decoration.

Owner:WUXI XINDAZHONG STEEL SHEET

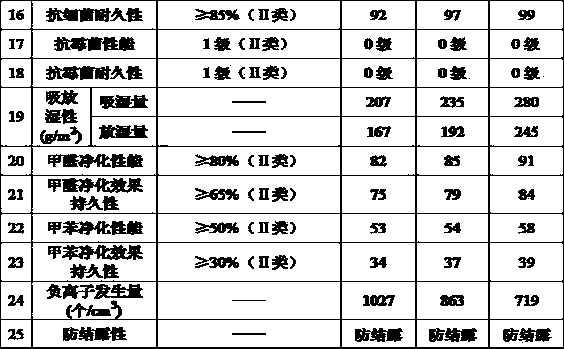

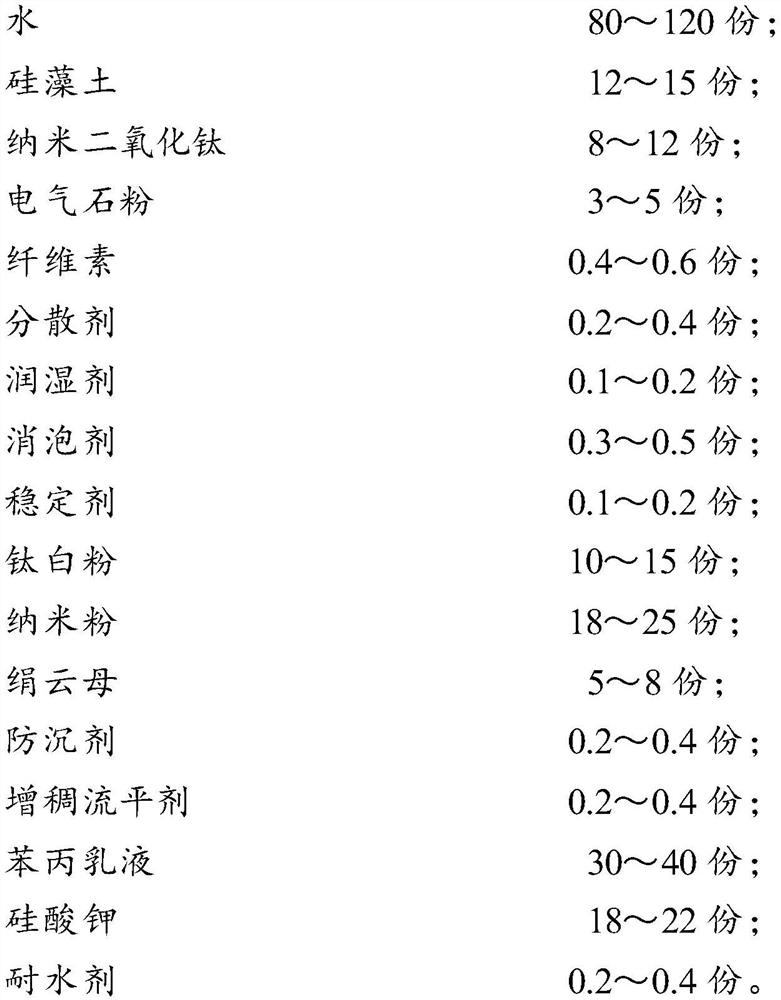

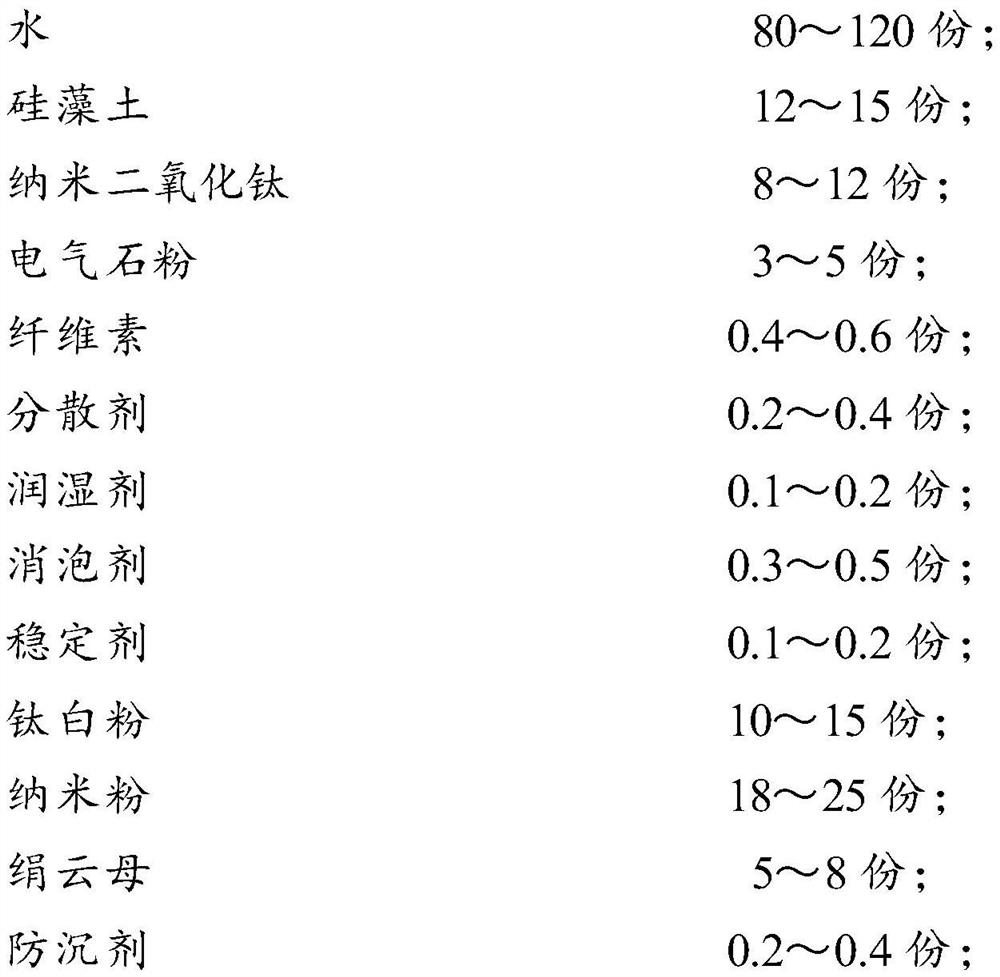

Diatomite-modified inorganic water-based paint and preparation method thereof

InactiveCN113122030AWith purifying formaldehydeAnti-condensationAntifouling/underwater paintsAlkali metal silicate coatingsCelluloseEmulsion

The invention provides diatomite-modified inorganic water-based paint. The diatomite-modified inorganic water-based paint comprises the following raw materials in parts by weight: 80 to 120 parts of water, 12 to 15 parts of diatomite, 8 to 12 parts of nanometer titanium dioxide, 3 to 5 parts of tourmaline powder, 0.4 to 0.6 part of cellulose, 0.2 to 0.4 part of a dispersant, 0.1 to 0.2 part of a wetting agent, 0.3 to 0.5 part of a defoaming agent, 0.1 to 0.2 part of a stabilizing agent, 10 to 15 parts of titanium dioxide, 18 to 25 parts of nano-powder, 5 to 8 parts of sericite, 0.2 to 0.4 part of an anti-settling agent, 0.2 to 0.4 part of a thickening leveling agent, 30 to 40 parts of a styrene-acrylic emulsion, 18 to 22 parts of potassium silicate and 0.2 to 0.4 part of a water-resistant agent. According to the invention, the diatomite, the nanometer titanium dioxide and other components are added into the paint, so the paint can purify formaldehyde and resist mildew, and does not contain any VOC, benzene series and soluble heavy metals.

Owner:JILIN CHUNZHIYUAN DIATOM OOZE CO LTD

Plastic-wood composite panel for packaging steel coils and preparation method thereof

The invention relates to a plastic-wood composite panel for packaging steel coils and a preparation method thereof. The plastic-wood composite panel is composed of a fiber baseboard and a plastic layer which is compounded by a tape casting method and a calendaring method and arranged on the surface of the fiber baseboard. The preparation method of the plastic-wood composite panel comprises the following steps: firstly fusing and plastifying a plastic material; coating the surface of a fiber baseboard with the plastic material by a tape casting method; calendering the fiber baseboard coated with the plastic material by the use of calender rolls; and cooling and shaping the calendered fiber baseboard by the use of setting rollers so as to prepare the plastic-wood composite panel. The plastic layer of the plastic-wood composite panel is very firm and will not fall off from the fiber baseboard under the action of large external force.

Owner:SHENYANG FENGHE PACKING

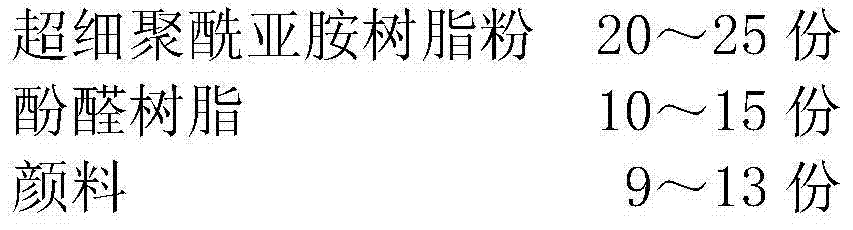

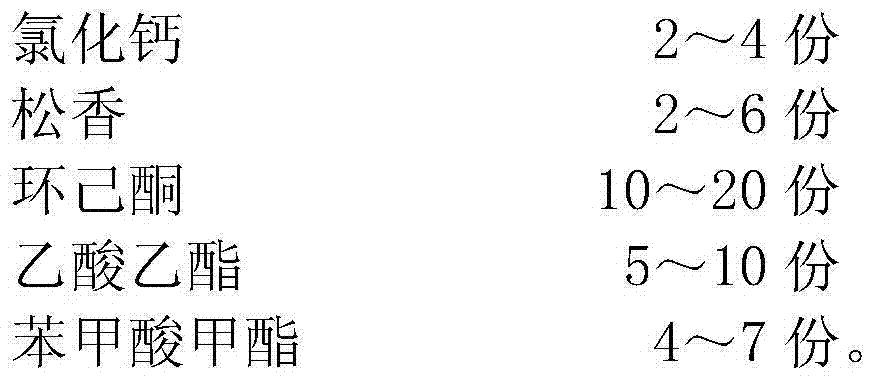

Anticorrosion and antirust coating

InactiveCN104513609AAnti-corrosion and anti-rustAnti-condensationAnti-corrosive paintsCyclohexanonePetrochemical

The invention belongs to the field of coatings and particularly relates to an anticorrosion and antirust coating. The anticorrosion and antirust coating is prepared from the following raw materials in parts by weight: 20-25 parts of ultrafine polyimide resin powder, 10-15 parts of phenolic resin, 9-13 parts of pigment, 2-4 parts of calcium chloride, 2-6 parts of rosin, 10-20 parts of cyclohexanone, 5-10 parts of ethyl acetate and 4-7 parts of methyl benzoate. The anticorrosion and antirust coating has anticorrosion, antirust, anti-condensation and anti-icing effects, has good abrasive resistance and excellent mechanical performance, can also prevent high temperature and has good adhesive force, high durability and very ideal endurance and acid and alkali resistance. The anticorrosion and antirust coating is mainly applied to ocean and offshore vessels, ship submarines, ocean engineering, drilling platforms, ports and wharfs, water conservancy facilities, petrochemical equipment, bridge buildings and other metal and concrete facilities.

Owner:于芳

A heat-insulating and heat-preserving water-based coating with the function of purifying air

InactiveCN103450761BLow thermal conductivityQuality improvementFireproof paintsLignin material coatingsWater basedHazardous substance

The invention provides a heat-insulation and heat-preservation water-based coating material with an air purifying function. The water-based coating material is prepared through compounding raw materials, such as diatomite, hollow glass beads, lignocellulose, zirconium phosphate loaded sliver powder, nano zinc oxide, tourmaline powder, aluminum oxide, hydroxypropyl methylcellulose, a pure acrylic emulsion, a dispersing agent 5040, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 1,2-propanediol, Kathon, a silicone defoamer, deionized water and the like. The water-based coating material provided by the invention further has the functions of improving air quality, regulating air humidity, preventing mildew and the like through adsorbing harmful substances in air and releasing negative ions, besides an excellent heat insulation function.

Owner:深圳市宜丽环保科技有限公司

Manufacturing method for hotly-rolled steel film coated sheet material

InactiveCN103786388AExtended service lifeEnvironmentally friendlyCovering/liningsLaminationAdhesiveUltraviolet lights

The invention relates to a manufacturing method for a building sheet material which has corrosion-resisting and weather-resisting performances, can prevent dew from dripping off and has a certain heat-preservation performance, and particularly relates to a manufacturing method for a hotly-rolled steel film coated sheet material. The manufacturing method comprises the following steps: selecting materials, pre-treating a sheet surface, carrying out drying treatment, coating an adhesive, coating a film, carrying out a drying procedure, hotly pressing, checking and storing. According to the method, an obtained product has a very good fireproof performance; as being detected, the hotly-rolled steel film coated sheet material obtains the national building material fireproof B-1-grade authentication, is completely environmentally-friendly and has no pollution; the hotly-rolled steel film coated sheet material also obtains the environment-friendly authentication, has the long service life, is environmentally-friendly, has the fireproof, anti-dewing and corrosion-resisting effects, and has the effects of sound absorption, light absorption, heat preservation, high transparency, high glossiness, low haze, excellent ultraviolet light barrier property, laser anti-counterfeiting property and bright decoration effect.

Owner:WUXI XINDAZHONG STEEL SHEET

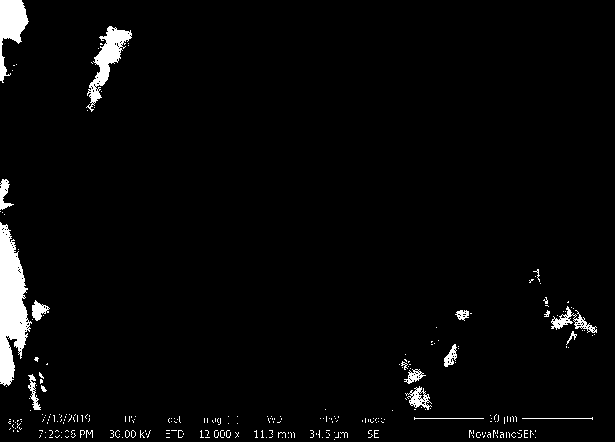

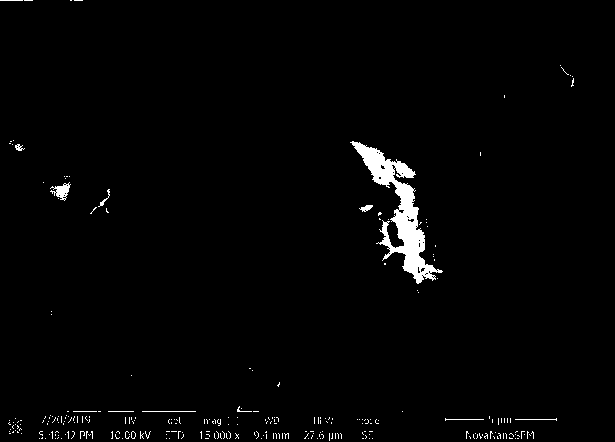

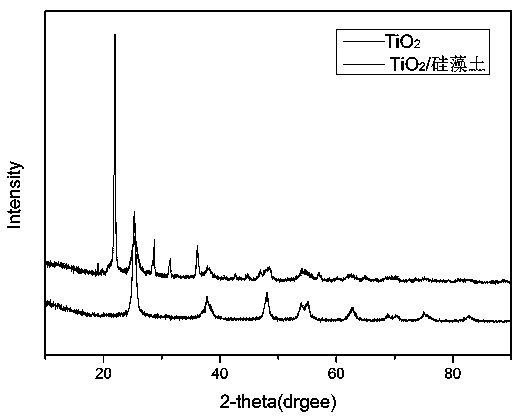

Preparation of water-based environment-friendly coating material based on diatomite purification and titanium dioxide loading

InactiveCN111004539AQuality improvementRegulate humidityFireproof paintsGas treatmentDiffractometerElectron microscope

The invention provides a water-based environment-friendly coating material based on diatomite purification and titanium dioxide loading. According to the invention, diatomite is economically and effectively purified, and the purified diatomite loads nano titanium dioxide; by carrying out electron microscope standard on the diatomite before and after loading, the results show that the purity of diatomite is greatly improved; comparing the diatomite before and after loading by using an X-ray diffractometer (XRD), the results show that the nano titanium dioxide is already loaded in the pores of the diatomite; and the water-based coating material product prepared by purified diatomite loading the nano titanium dioxide can obviously improve the purification performance durability of toluene, and also has antibacterial function, mildew-proof function, anti-condensation function and other functions.

Owner:深圳市宜丽家生态建材有限公司

Production method for electrogalvanizing laminated boards

InactiveCN103790308AExtended service lifeEnvironmentally friendlyCovering/liningsLamination ancillary operationsFireproofingUltraviolet lights

The invention relates to a production method for anti-corrosive, weather-proof and dew-dripping preventive building boards with a certain heat insulation performance, in particular to a production method for electrogalvanizing laminated boards. The production method includes the steps of material selecting, board surface pre-processing, drying treatment, adhesive coating, laminating, drying, hot pressing, inspecting and storing. Products produced by the production method have good fireproofing performance, pass the national building material fireproofing grade certification B-1 according to tests, is completely environment friendly and pollution-free, pass the environmental protection certification, and have the advantages of long service life, environment protection, fireproofing, condensation and corrosion resistance, sound and light absorption, heat insulation, high transparency, high glossiness, low haze, excellent ultraviolet-light isolation property, laser anti-fake property and bright decorative effect.

Owner:WUXI XINDAZHONG STEEL SHEET

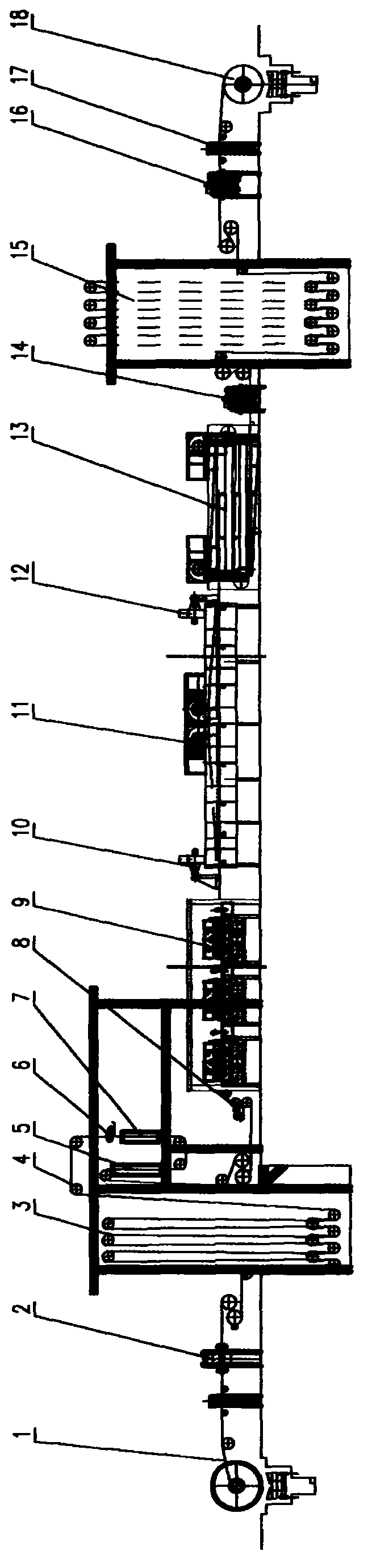

Hot-rolled steel plate flocking and embossing process and special equipment for same

InactiveCN103538345AImprove utilization efficiencyQuality improvementLamination ancillary operationsLaminationSheet steelHigh volume manufacturing

The invention relates to a hot-rolled steel plate flocking and embossing process and special equipment for the same. The process comprises the following steps: unreeling; front storage and deviation correction; material pretreatment; glue spreading; flocking; fluff absorption; drying; fluff recovery; cooling and brushing; back storage; embossing; reeling. The special equipment provided by the invention comprises an unreeling device, a front storage device, a double-roller deviation correcting device, a cooling tank, a passivating device, a passivating and drying device, a roller glue spreader, an electrostatic flocking machine, a fluff absorbing device, a drying room, a fluff recovery device, an air cooling room, a first brushing box, a back storage device, a second brushing box, an embossing device and a reeling device which are connected in sequence. By using the process and special equipment provided by the invention, hot-rolled flocked and embossed plates can be continuously produced in a large scale, the production efficiency is high, and the product quality is reliable. A product produced by using the special equipment provided by the invention is strong in upright pile feeling, attractive and bright in color, soft in touch, environment-friendly, fireproof, anti-sweat, capable of absorbing sound and light, and favorable in ray diffuse reflection effect.

Owner:无锡市鹏程植绒机械有限公司

Mechanical first aid repair square cabin

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

Multifunctional liquid diatom ooze coating material

The invention provides a multifunctional liquid diatom ooze coating material. The multifunctional liquid diatom ooze coating material is formed by compounding the raw materials of kieselguhr, attapulgite, silver-loaded zirconium phosphate powder, nano-zinc oxide, electrical mountain flour, aluminum oxide, hydroxypropyl methyl cellulose, pure acrylic emulsion, a dispersing agent 5040, 1,2-propylene glycol, isothiazolinones, an organic silicon defoaming agent, deionized water and the like. The multifunctional liquid diatom ooze coating material can improve air quality by absorbing hazardous substances in the air and releasing negative ions, further has the functions of regulating air humidity, preventing mildew, condensation and fire and like, and has the advantages of being free of limitations of water sources and technical requirements of constructors and the like.

Owner:中健生命科技(深圳)有限公司

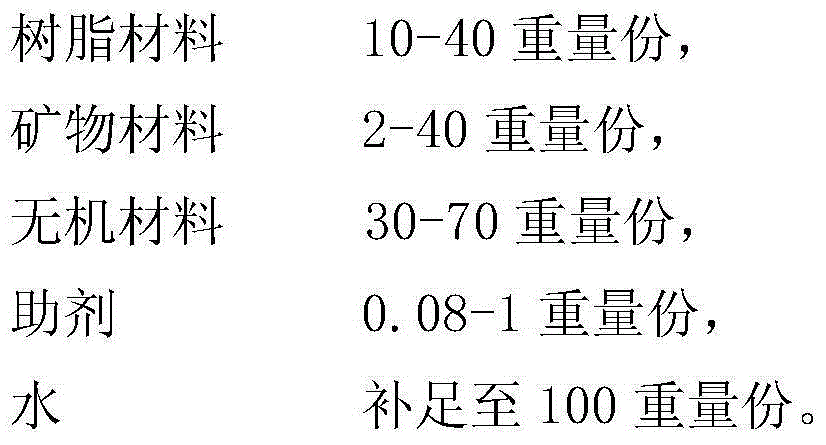

Self-contained interior wall decoration environmental protection composite coating material and its preparation method and application

ActiveCN103664088BFull migrationEfficient and long-lasting removalAdhesivesInorganic materialsComposite coating

The invention discloses a self-adsorption interior-wall-decoration environment-friendly composite coating material as well as a preparation method and an application thereof. The coating material is a multiple-layer coating material and consists of a bottom-layer coating material and a surface-layer coating material, wherein the bottom-layer coating material consists of a cementing material, a mineral material, a basic material and necessary auxiliary materials which react with one another so as to form an interlaced network structure; the surface-layer coating material consists of a resin material, a mineral material, an inorganic material and an additive which react with one another so as to form a loose network structure full of tiny holes. According to detection, the composite coating material, which is a novel self-adsorption interior-wall-decoration environment-friendly composite coating material for environment-friendly building interiors, is efficient, long-acting and environment-friendly and integrates functions of purification, permeation, diffusion and the like.

Owner:CHINA BUILDING MATERIALS ACAD

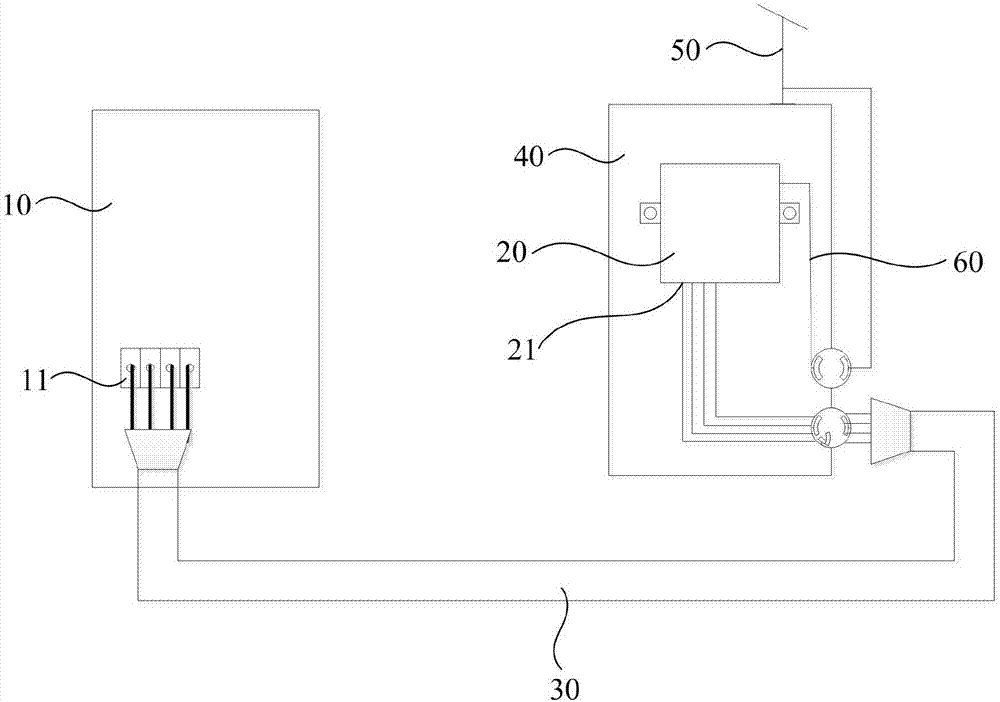

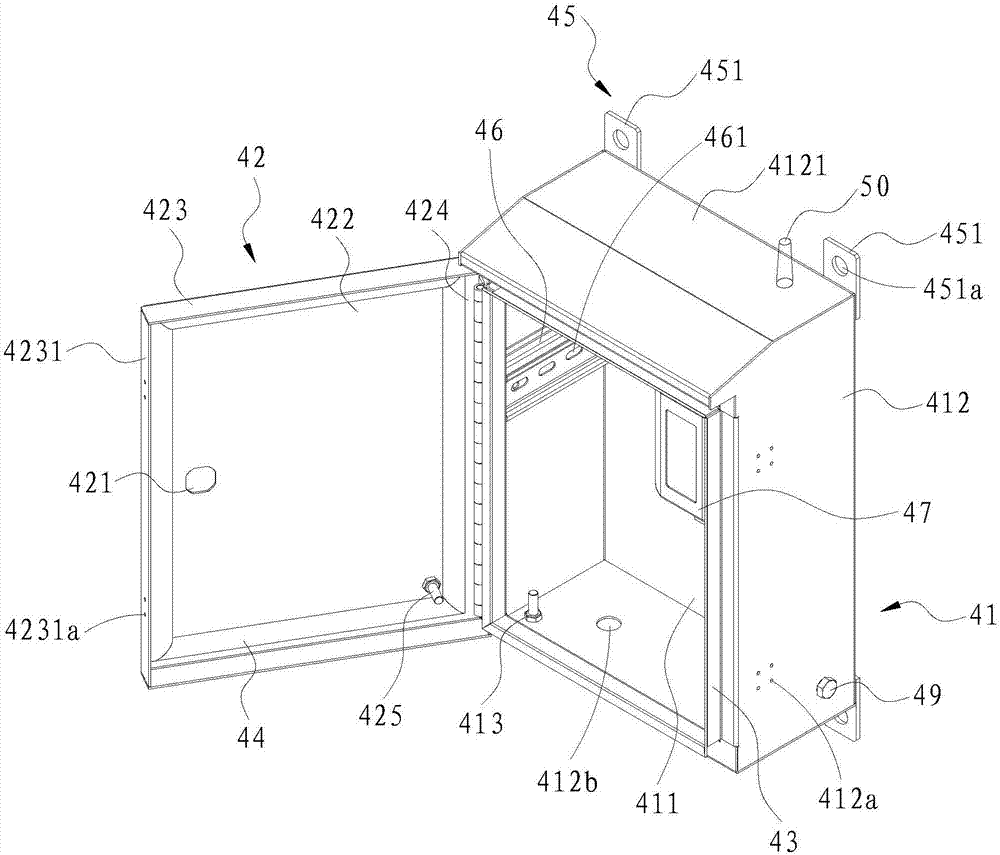

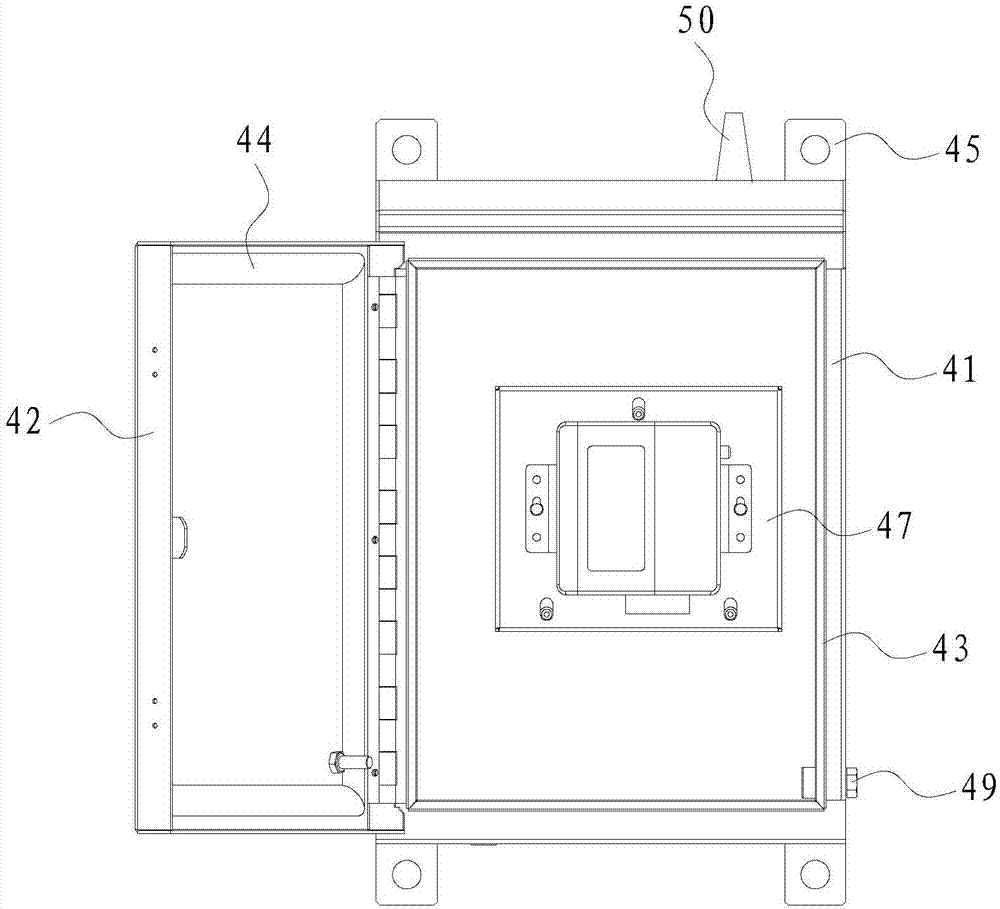

Distribution automation terminal equipment and wireless signal strength improvement method thereof

InactiveCN107425606AIncrease signal strengthImprove online rateCircuit arrangementsInformation technology support systemCommunication interfaceLine rate

The invention discloses distribution automation terminal equipment and a wireless signal strength improvement method thereof. The distribution automation terminal equipment comprises a wireless terminal device arranged in an electrical room, a wireless communication module arranged in a wireless public network signal coverage area outside the electrical room, a shielding cable and a communication module protection box, wherein the wireless terminal device is provided with a first communication interface, the wireless communication module is provided with a second communication interface, a RS-232 protocol is used for performing communication between the second communication interface and the first communication interface; two ends of the shielding cable are separately connected with the first communication interface and the second communication interface; the communication module protection box is arranged in the wireless public network signal coverage area outside the electrical room. According to the distribution automation terminal equipment and the wireless signal strength improvement method thereof, the signal strength sensed by the wireless terminal device can be effectively improved, an on-line rate of the device can be effectively improved, a transmission distance can be prolonged, and a function of protecting the wireless communication module can be achieved.

Owner:GUANGZHOU POWER SUPPLY CO LTD

Manufacturing process of nano cloth for central air-conditioning air outlets

PendingCN110846837AFireproofFlame retardantSucessive textile treatmentsFibre treatmentMaterials preparationProcess engineering

The invention discloses a manufacturing process of nano cloth for central air-conditioning air outlets. The process includes steps: material preparation, to be specific, preparing base cloth and nanosizing; pressing and immersing, to be specific, pressing air out of the base cloth to enable the nano sizing to enter the base cloth; primary drying, to be specific, subjecting the base cloth with thenano sizing to multistage drying; rolling treatment, namely rolling to make the cloth smooth; secondary drying for further reducing moisture in the cloth; cooling; rolling cutting treatment. The nanosizing is prepared from nano resin and nano calcium powder and fine in molecular particle, and excellent isolation performances including fireproof, nontoxic, anti-condensation, anti-droplet, anti-icing and anti-mildew performances, flame retardation, environmental friendliness and the like of the nano cloth can be achieved. In addition, the nano cloth which is soft joint cloth has functions of damping and silencing when being applied to the central air-conditioning air outlets.

Owner:湖南久质新材料有限公司

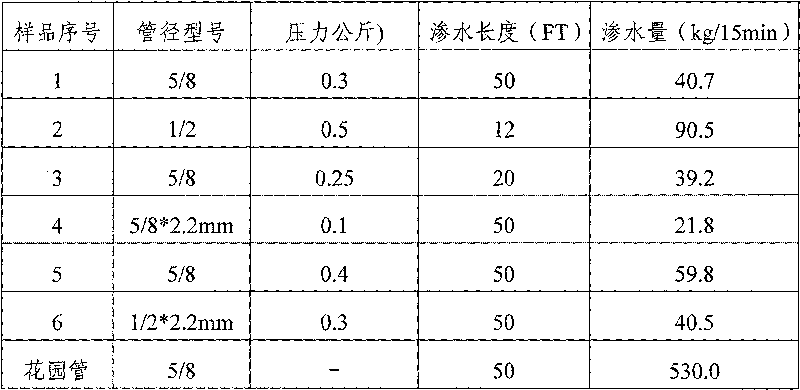

Micropore infiltrating tube manufacture method and product therefor

InactiveCN101152639BUniform water seepageAvoid easy cloggingWatering devicesSpray nozzlesFoaming agentPetroleum resin

The invention provides a microporous permeable pipe and is prepared with the following steps: (1) clean rubber and plastics is separately crushed into powder of 45 to 70mm and 55 to 75 portion of rubber and 20 to 40 portion of plastics are mixed together by weight; (2) the mixture is added with 2 to 4 portion of oil resin, 0.4 to o.6 portion of foaming agent, 0.4 to 0.6 portion of heat stabilizingagent and 0.6 to 1.4 portion of ethylene vinyl acetate copolymer by weight and then is granulated after stirring for 20 to 40min; (3) particle from the step (2) is squeezed and molded. Irregular bending Millipores are distributed on the wall of the realized Millipore soakaway trench from inward to outward. Density is 40 to 110kg / m<3>, thickness of the trench wall is 1.5 to 3mm, working pressure is 0.1 to 0.5kg, water percolating capacity is 1.4 to 4.2kg / min, and water percolating effective length is 40 to 80m. When in work, the microporous permeable pipe of the invention can coordinate the ratio of water, vapor and heat in soil and cannot lead to clotting of soil as well as water loss and soil erosion, moreover, secondary salinization of soil can be inhibited.

Owner:方晖

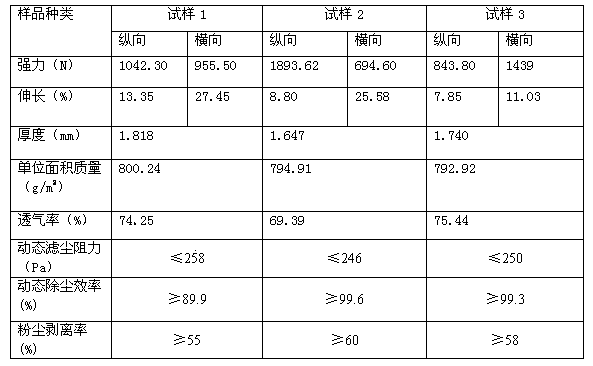

Production process for spunlace composite high temperature-resisting and corrosion-resisting filtering material

ActiveCN102580400BImprove performanceHigh strengthSynthetic resin layered productsNeedling machinesFiberFiltration

The invention relates to a production process for a spunlace composite high temperature-resisting and corrosion-resisting filtering material and belongs to the technical field of a textile filtering material. The production process comprises the following steps that: taking polyphenylene sulfide fibers and fiberglass fabrics as raw materials; checking, weighing and charging the polyphenylene sulfide fibers; charging the polyphenylene sulfide fibers into a long curtain, a horizontal opener, a big-cabin cotton blending box and a refined opener successively; and then carding by using a carding machine I and a carding machine II in a layering mode; placing into a cross lapping machine I and a cross lapping machine II to lap; clamping the fiberglass fabrics between the raw materials delivered by the cross lapping machine I and the cross lapping machine II and performing superposition; and performing the processes of pre-wetting, hydroentangling, dehydrating, drying and taking-up. The production process for the spunlace composite high temperature-resisting and corrosion-resisting filtering material provided by the invention has the advantages of excellent mechanical performance, filtration performance, high temperature-resisting performance, and chemical corrosion-resisting performance and size stability.

Owner:ZHEJIANG BAOREN NONWOVEN CO LTD

Hard polyvinyl-chloride plastic plate and producing recipe

The present invention relates to hard polyvinyl chloride plastic plate and its production process and material formulation. The plastic plate is produced through mixing pwodered material and organic solvent, molding in press through pressurizing, heating, maintaining, cooling and pressure relieving, and dischargin. The said powdered material consists of aggregate 18-30 wt%, polyvinyl chloride resin as binding material 15-28 wt%, oganic solvent 35-45 wt% and pore creating agent 12-25 wt%. The plate has the advantages of heat insulating, being fireproof, sound isolating, waterproof, non-toxic, etc. The improved formulation include great amount of aggregate and pore creating agent, and thus has reduced polyvinyl chloride resin consumption and low production cost.

Owner:林涛

Refrigerated cabinet hollow glass door

PendingCN113558438AEnsure transparencyGuaranteed aestheticsShow cabinetsDomestic cooling apparatusSilver pasteConductive coating

The invention provides a refrigerated cabinet hollow glass door which comprises a glass door body assembly and a conductive heating assembly. The glass door body assembly comprises coated glass, the white glass is arranged on one side of the coated glass, the inner side heat insulation soft rubber is arranged between the coated glass and the white glass. A hollow glass cavity is formed in the position, located on the inner side of the inner side heat insulation soft rubber, between the coated glass and the white glass, and the hollow glass cavity is filled with inert gas. The coated glass comprises a conductive coating layer arranged on the inner surface of the coated glass, and the inner side heat insulation flexible glue is located on the periphery of the inner surface of the conductive coating layer and the periphery of the inner wall surface of the white glass. A conductive silver paste belt is fixedly arranged on the inner surface, close to one side, of the conductive film coating layer, the inner side edge of the conductive silver paste belt does not exceed the inner side edge of the inner side heat insulation soft rubber, and the outer side supporting soft rubber is arranged on the outer side periphery of the inner side heat insulation soft rubber. The hollow glass can be prevented from being dewed and frosted, the leakproofness is good, the service life is long, and the glass door is transparent and attractive. The refrigerated cabinet hollow glass door can be widely applied to refrigerating cabinets.

Owner:威海蓝星特种玻璃有限公司

Hollow glass processing method

ActiveCN113565407AImprove insulation performanceImprove overall lifespanDoors/windowsClimate change adaptationSilver pasteElectrically conductive

The invention provides a hollow glass processing method. The method comprises the following steps of cutting, edging and toughening coated glass and white glass according to the required size, coating the upper and lower positions of the outer surface of a conductive coated layer of the coated glass with conductive silver paste tapes, coating the periphery of the outer side of the outer surface of the conductive coated layer of the coated glass with inner side heat insulation flexible glue with a certain thickness, pressing the coated glass and the white glass, forming a hollow glass cavity between the coated glass and the white glass, filling and coating the hollow glass cavity in the outer side of the inner side heat insulation flexible glue with outer side supporting flexible glue, realizing further combination of the coated glass and the white glass, and completely covering the conductive silver paste tapes and a power line with the outer side supporting flexible glue; and curing the coated glass and the white glass which are filled and coated with the outer side supporting flexible glue to form the hollow glass. The method disclosed by the invention can be widely applied to hollow glass processing, and is particularly suitable for processing a hollow glass door commonly used in a refrigerated cabinet.

Owner:威海蓝星特种玻璃有限公司

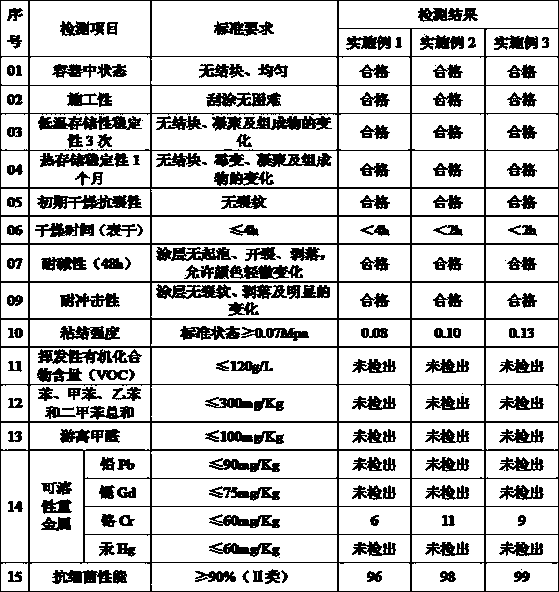

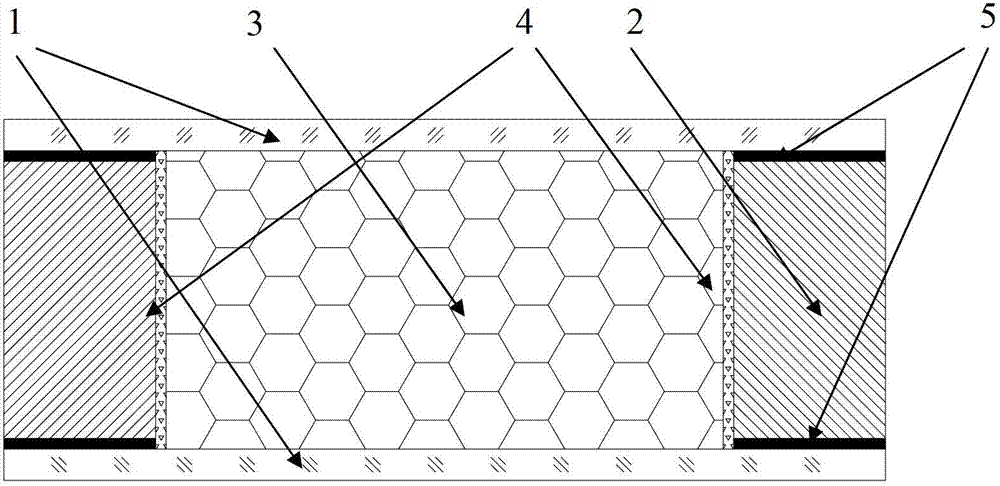

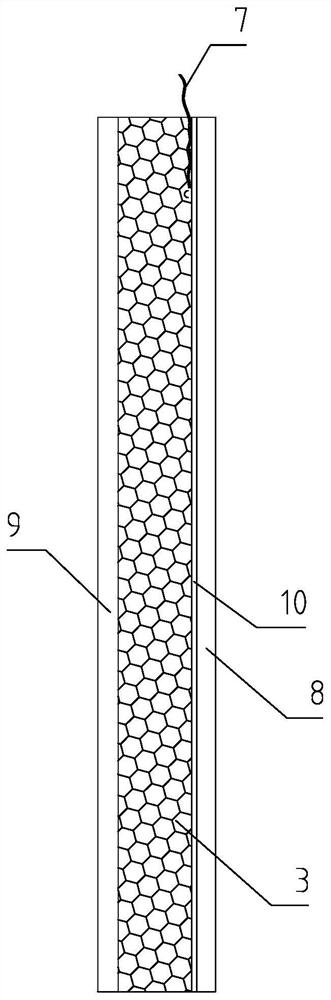

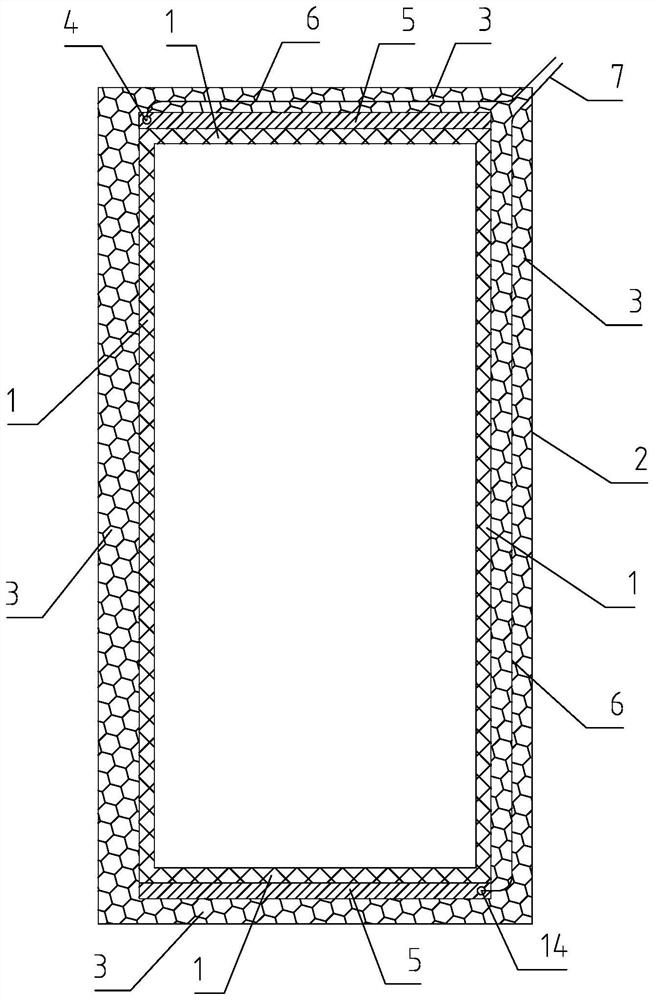

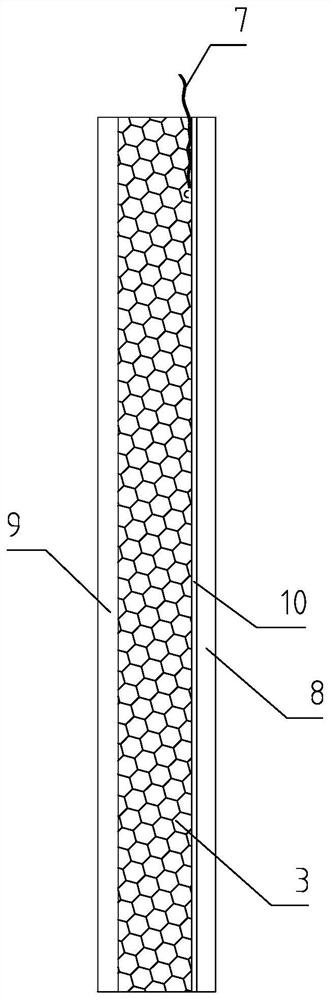

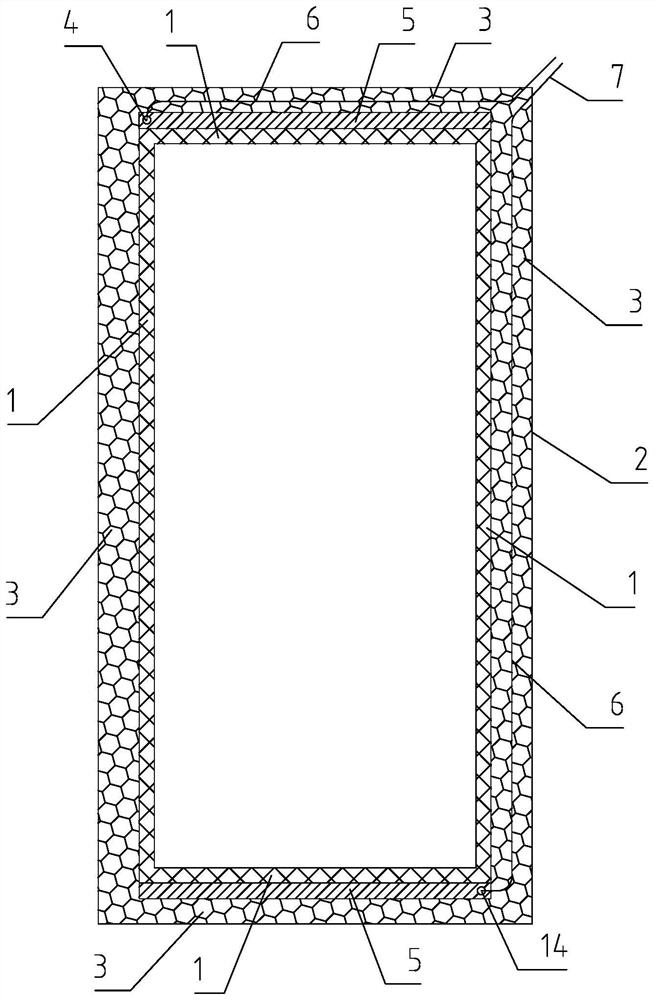

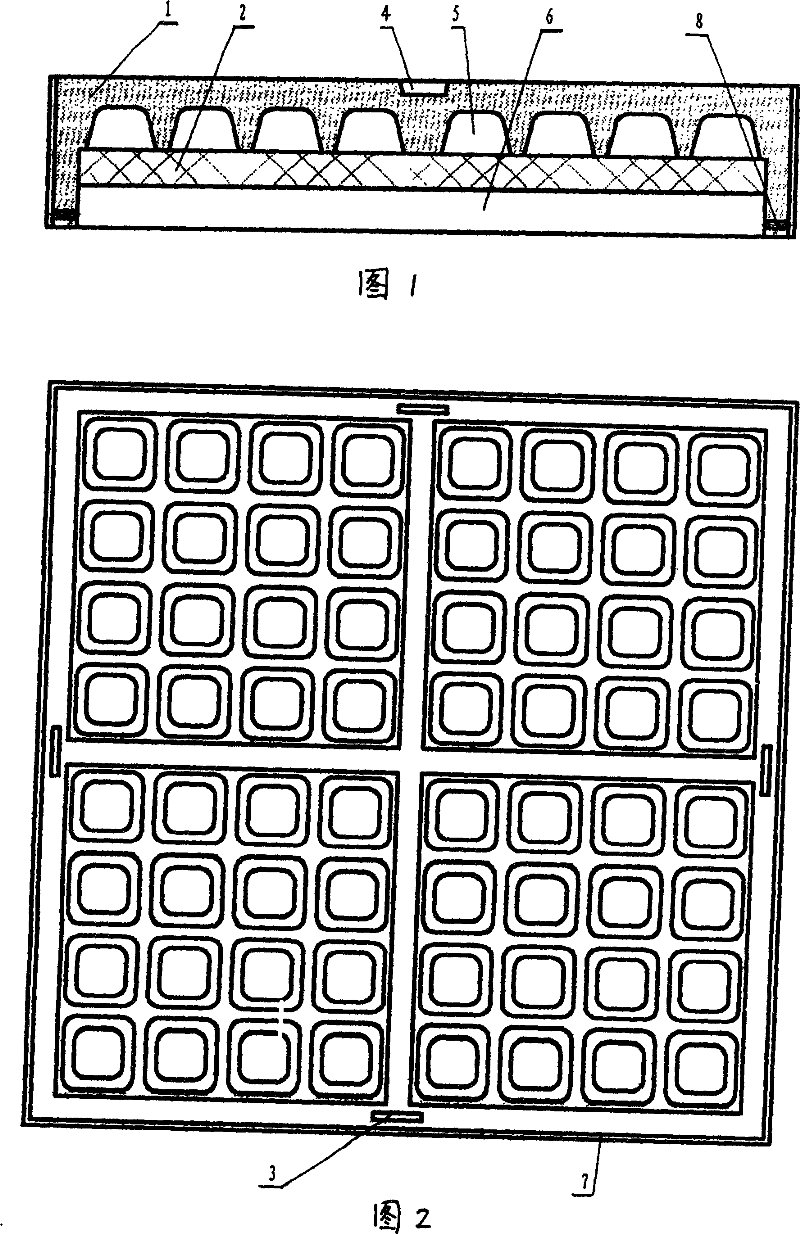

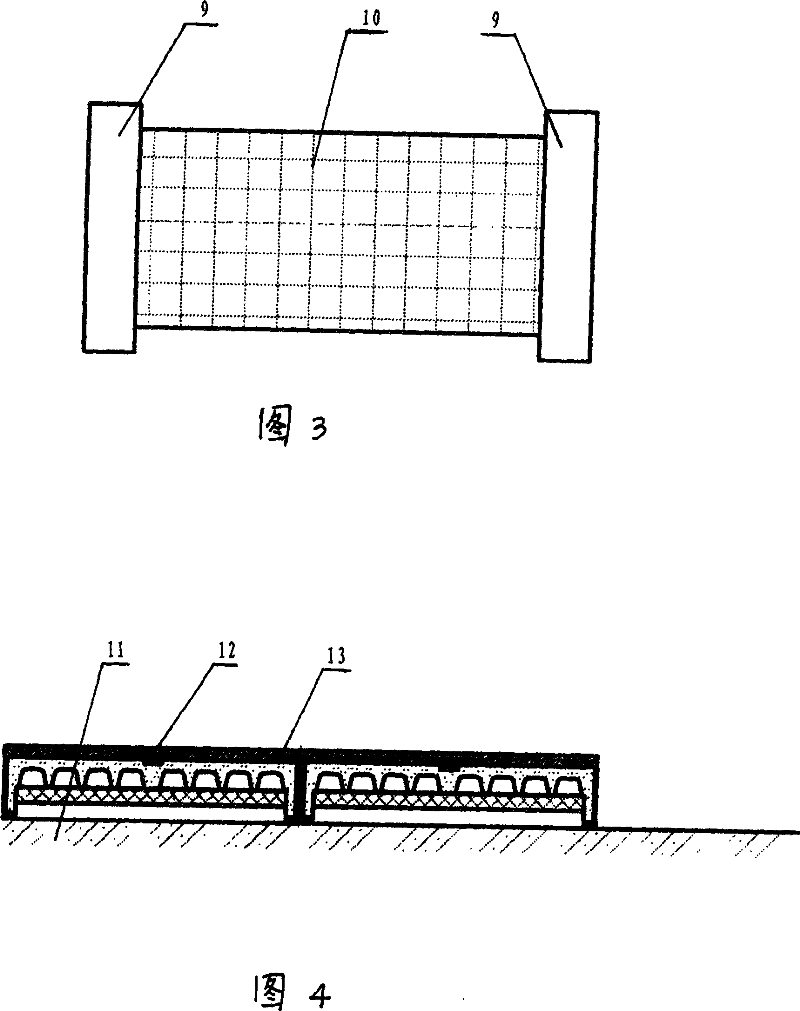

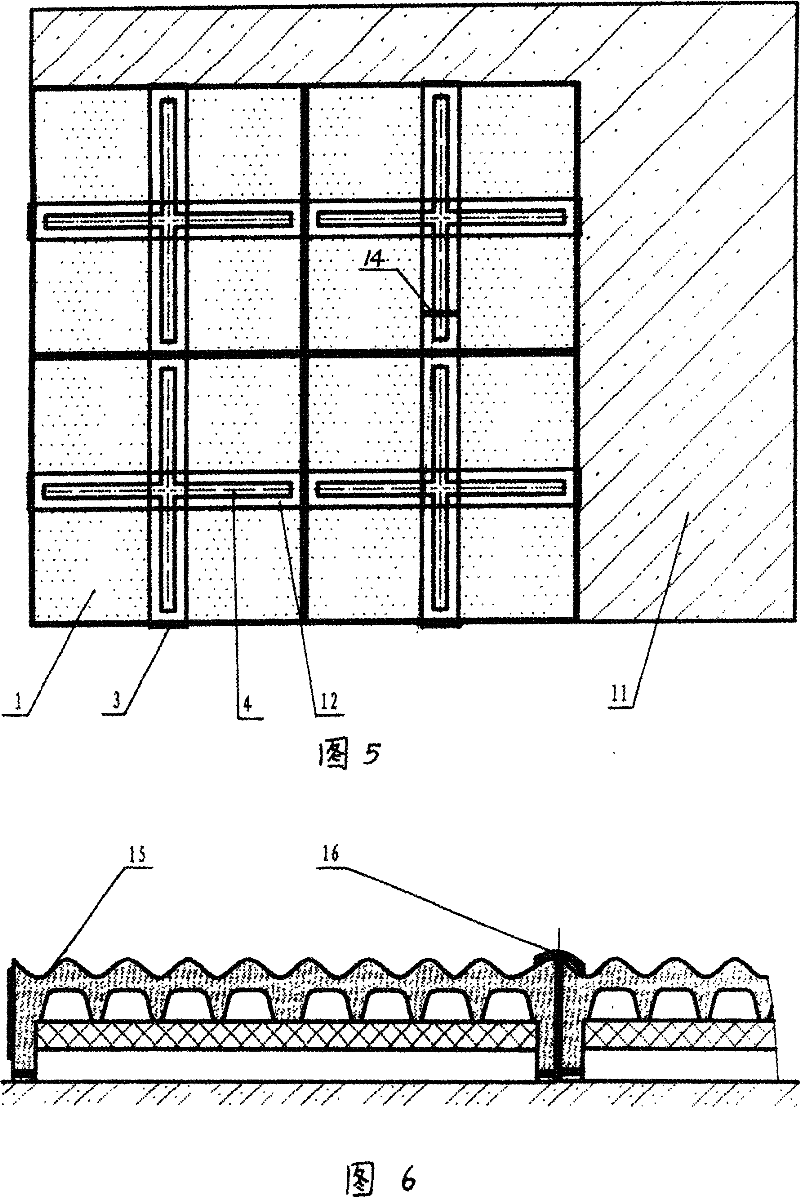

Frame filling body warm preservation heat insulation board and its construction method

The invention relates to frame filling body heat insulating board. It includes frame structure body heat insulating material, obturator heat insulating material, non cold bridge connecting piece, and edge sealing heat insulating material. The obturator heat insulating material is embedded in cavity of the frame structure body heat insulating material, and divided the cavity into enclosed type air space and open type air space. Air vent is set in open type air space and side wall of the frame structure body heat insulating material. The non cold bridge connecting piece is made up of lock catch and net band. It is set in frame structure body heat insulating material, or cross the edge sealing heat insulating material. Outer surface cross recess is set on outer surface of the frame structure body heat insulating material. The invention can apply in wall body outer heating and so on. Its advantages are light, crack resistance, sound insulation, heating, low cost, and so on. And it can satisfy country building energy conservation standard.

Owner:陈星

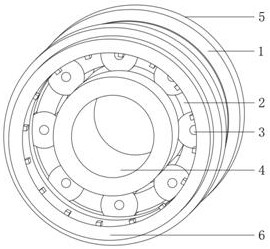

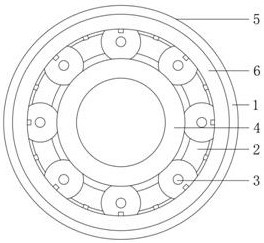

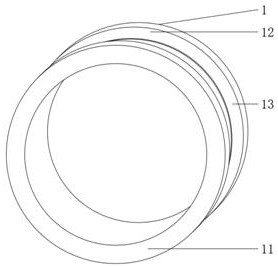

High-speed mute miniature precision bearing

The invention discloses a high-speed mute miniature precision bearing which comprises a bearing outer ring and is further provided with a bearing retainer, a bearing rolling element, a bearing inner ring, a bearing outer protective coating and a bearing spacer bush mechanism, and the bearing spacer bush mechanism is composed of a spacer bush body, a mounting ring, an embedded block and a mounting square block. According to the high-speed mute miniature precision bearing disclosed by the invention, the miniature precision bearing can be conveniently mounted on a machine to be matched with transmission use of other parts through the arranged bearing outer ring, so that the miniature precision bearing is more excellent in use; the miniature precision bearing is more durable through the coatings in the arranged bearing outer protective coatings, sound generated by operation of the miniature precision bearing is reduced, the miniature precision bearing can be protected through the arranged bearing spacer bush mechanism, and therefore the outer surfaces of the two ends of the miniature precision bearing are prevented from being abraded, and the service life of the miniature precision bearing is prolonged. And a better application prospect is brought to the technical field of miniature precision bearings.

Owner:宁波志诚轴承有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com