Self-contained interior wall decoration environmental protection composite coating material and its preparation method and application

A technology for coating materials and interior walls, applied in the direction of adhesives, etc., can solve the problems of no research work, low life and efficiency of photocatalytic materials, low photocatalytic efficiency, etc., and achieve excellent self-consumption, excellent adsorption and organic permeation The effect of pollutants on the performance of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

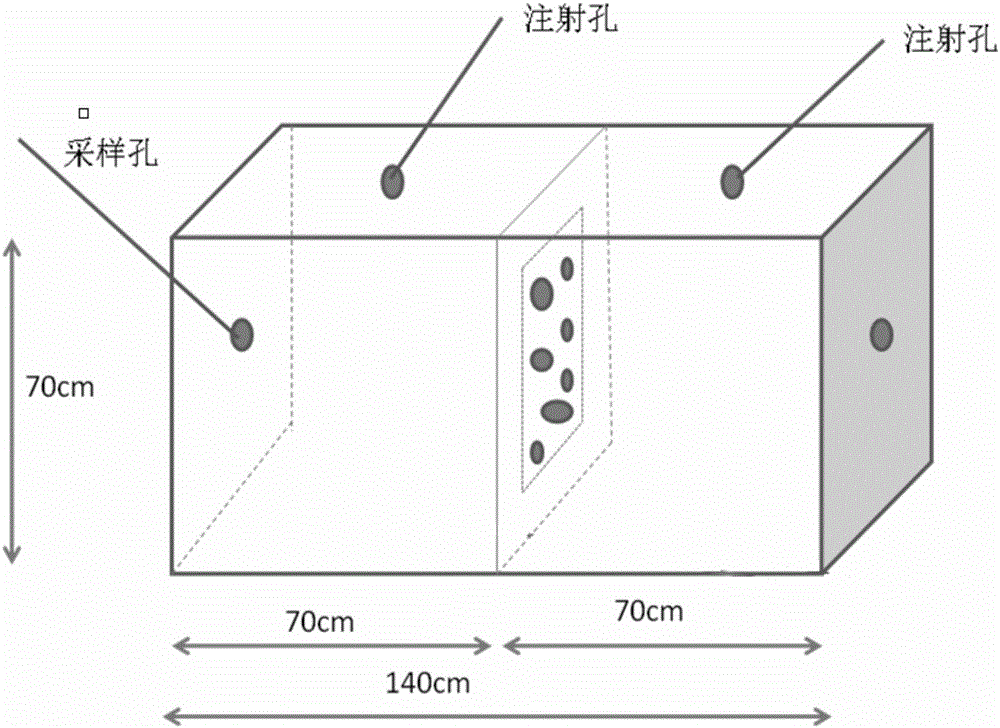

Image

Examples

preparation example Construction

[0060] 3. Preparation and application of composite coating materials

[0061] The present invention also provides a method for preparing the above-mentioned self-contained interior wall decoration and environmental protection composite coating material.

[0062] The preparation method provided by the present invention may comprise the following steps:

[0063] 1) Mineral material pretreatment: According to the characteristics of the material, acid treatment or heat treatment is used to activate the pore structure of the mineral material and remove impurities:

[0064] Acid treatment method: Weigh a certain amount of water and mineral materials (the mass ratio of water: mineral materials is 0.5-5:1), stir evenly, and add a certain amount of concentrated sulfuric acid or concentrated hydrochloric acid (the mass ratio of acid: mineral materials is 0.5-5:1), fully mixed and stirred for a certain period of time (10min-6h) after the mineral material is filtered, washed and dried. ...

Embodiment 1-5

[0074] Example 1-5, Preparation of self-contained interior wall decoration composite environmental protection coating material

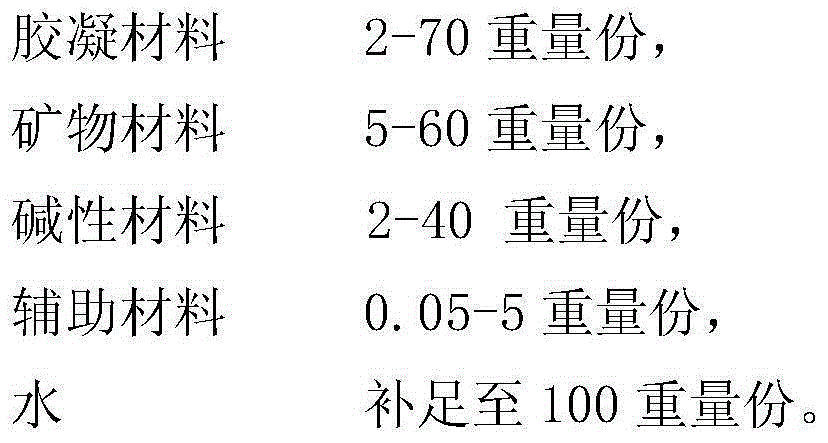

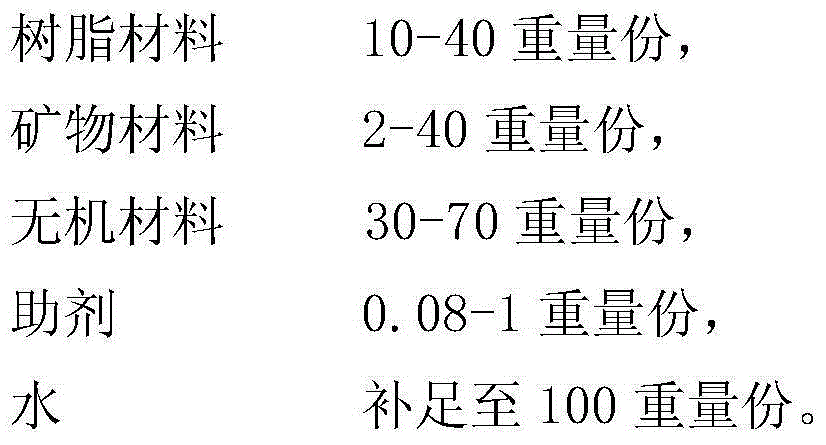

[0075] Embodiment 1-5 of the present invention self-consumption interior wall decoration compound environmental protection coating material and the raw material formula of comparative example are as shown in table 1:

[0076] The raw material formula (unit: part) of table 1 embodiment 1-5 and comparative example

[0077]

[0078]

[0079] The preparation of Examples 1-5 self-contained interior wall decoration composite environmental protection coating materials and comparative examples of the present invention is carried out according to the aforementioned steps 1)-step 3).

[0080] The prepared bottom layer coating material and surface layer coating material are stored separately, and the bottom layer and the surface layer are applied in combination for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com