Hot-rolled steel plate flocking and embossing process and special equipment for same

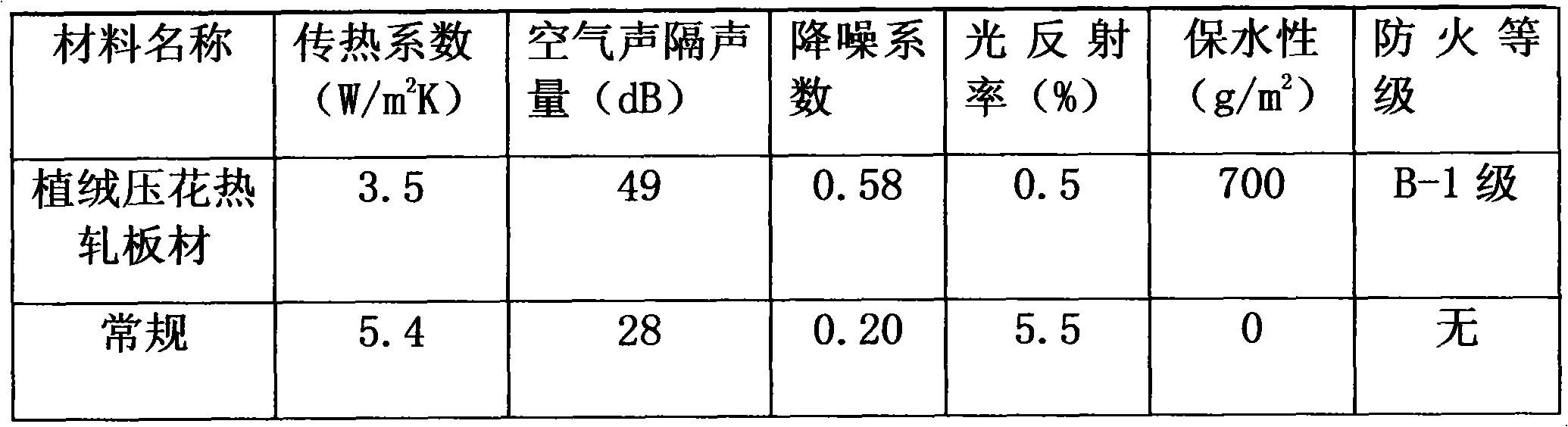

A technology of hot-rolled steel sheet and special equipment, which is applied in the field of hot-rolled steel sheet flocking and embossing process and its special equipment, can solve the problem that the flocked hot-rolled sheet cannot achieve the effect of light diffuse reflection, the color is monotonous, and the sense of velvet is not strong. and other problems, to achieve the effect of excellent light diffuse reflection effect, reliable product quality and strong velvet feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

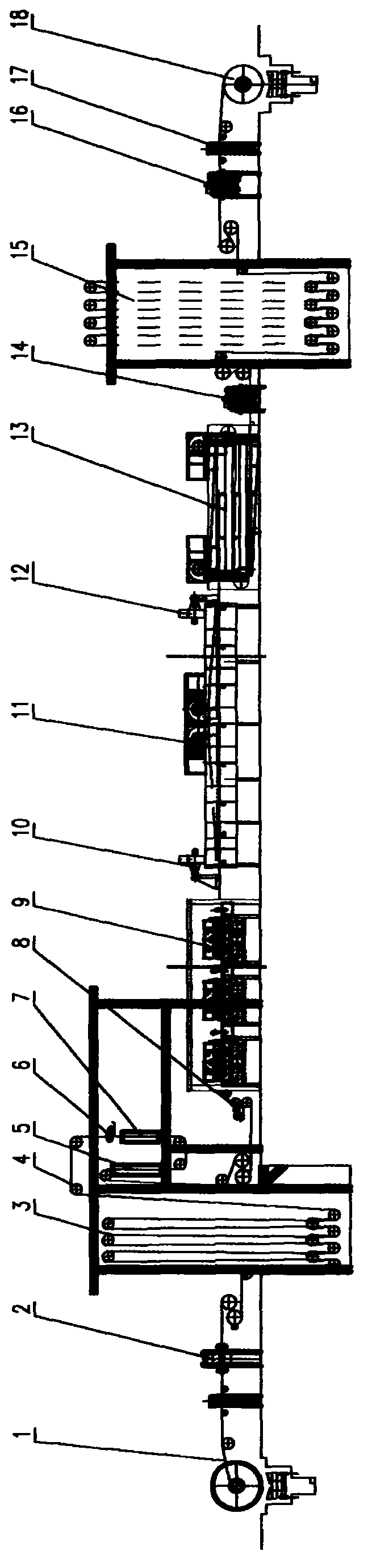

[0021] The hot-rolled steel plate flocking embossing process of the present invention comprises the following steps:

[0022] (1), unwinding: unwind and flatten the coil of the steel plate;

[0023] (2) Front storage and deviation correction: the uncoiled steel plate enters the front storage device for storage, and then enters the deviation correction device for deviation correction;

[0024] (3) Material pretreatment: Passivate the surface of the steel plate, then dry and cool it;

[0025] (4), glue coating: coat a layer of flocking glue on the surface of the steel plate;

[0026] (5) Flocking: the steel plate after gluing is moved to the flocking station for flocking;

[0027] (6) Fluff absorption: absorb the unglued fluff on the surface of the steel plate;

[0028] (7), drying: drying the steel plate after flocking and embossing;

[0029] (8) Fluff recovery: suck the excess fluff on the surface of the fabric to the designated recycling site for recycling, improve the ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com