Anticorrosion and antirust coating

An anti-corrosion and anti-rust, coating technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of high brittleness, shortened coating life, and insufficient anti-corrosion and anti-rust effects, and achieve excellent mechanical properties, good wear resistance, and patience. Ideal for acid and alkali properties

Inactive Publication Date: 2015-04-15

于芳

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The main material epoxy resin used in the coating formula of the invention has high brittleness after curing, which shortens the life of the coating, and the anti-corrosion and anti-rust effect of the coating is not good enough

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

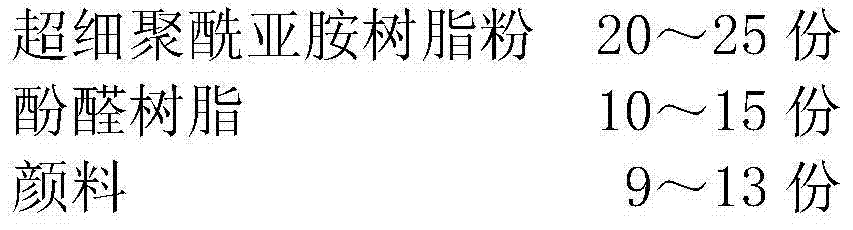

[0021] The anti-corrosion and anti-rust paint is made of the following raw materials in parts by weight:

[0022]

Embodiment 2

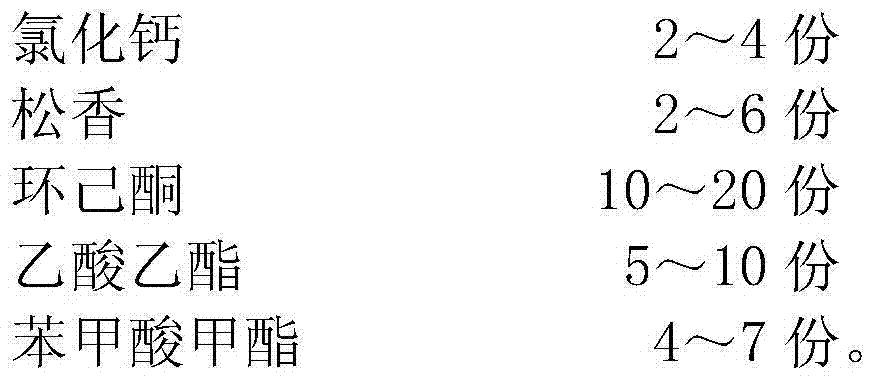

[0024] The anti-corrosion and anti-rust paint is made of the following raw materials in parts by weight:

[0025]

Embodiment 3

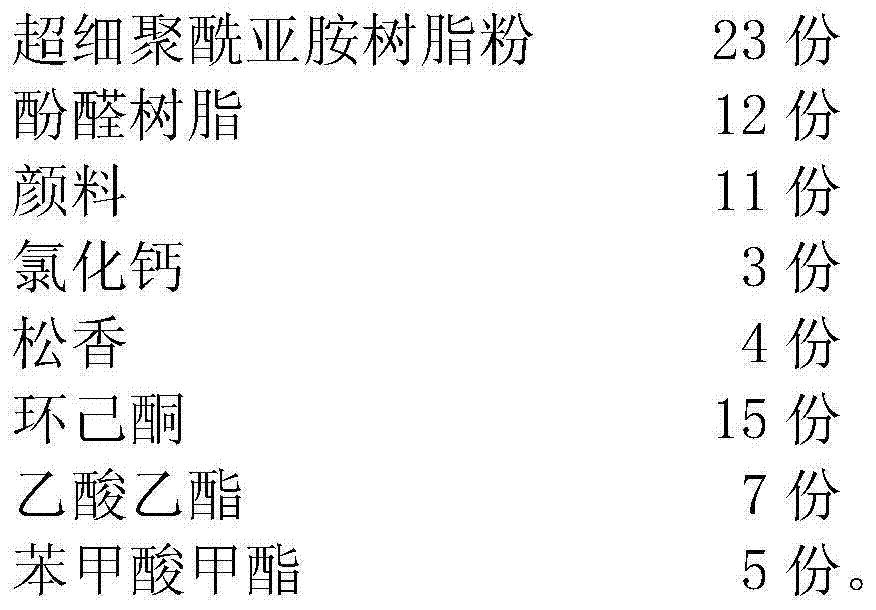

[0027] The anti-corrosion and anti-rust paint is made of the following raw materials in parts by weight:

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the field of coatings and particularly relates to an anticorrosion and antirust coating. The anticorrosion and antirust coating is prepared from the following raw materials in parts by weight: 20-25 parts of ultrafine polyimide resin powder, 10-15 parts of phenolic resin, 9-13 parts of pigment, 2-4 parts of calcium chloride, 2-6 parts of rosin, 10-20 parts of cyclohexanone, 5-10 parts of ethyl acetate and 4-7 parts of methyl benzoate. The anticorrosion and antirust coating has anticorrosion, antirust, anti-condensation and anti-icing effects, has good abrasive resistance and excellent mechanical performance, can also prevent high temperature and has good adhesive force, high durability and very ideal endurance and acid and alkali resistance. The anticorrosion and antirust coating is mainly applied to ocean and offshore vessels, ship submarines, ocean engineering, drilling platforms, ports and wharfs, water conservancy facilities, petrochemical equipment, bridge buildings and other metal and concrete facilities.

Description

technical field [0001] The invention belongs to the field of coatings, in particular to an anti-corrosion and anti-rust coating. Background technique [0002] Metal corrosion is a very common phenomenon in nature, which is very harmful to the metal components used in people's daily life and production, especially those metal components in harsh environments, such as bridges, vehicles, Ships, steel structures, chemicals, medicine, electroplating workshops and other structures, upper and lower water pipes, drainage pipes, seawater pipes, etc., are more severely corroded than metal components under normal conditions. In some cases, the annual corrosion depth of metal components It can reach 1-2 mm, and even the corrosion degree of some local parts can reach more than 3 mm per year. This is a very serious problem, so metal anti-corrosion is a problem that people have to solve all the time. [0003] At present, people use anti-corrosion coatings to realize the anti-corrosion pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D179/08C09D161/06C09D5/08C09D7/12

CPCC09D179/08C08L2205/03C09D5/08C09D7/20C09D7/61C09D7/65

Inventor 于芳

Owner 于芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com