Grease composition and preparation method for standard assembly of tower cranes

A technology of tower crane and grease composition, applied in the field of grease, can solve problems such as difficulty in disassembling pin shafts, and achieve the effects of improving anti-corrosion and anti-corrosion ability, excellent heat resistance, and improving adhesion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

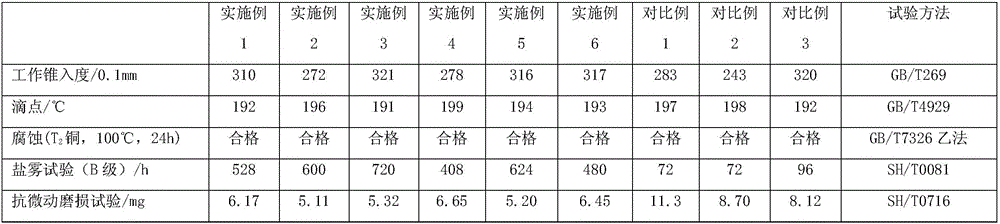

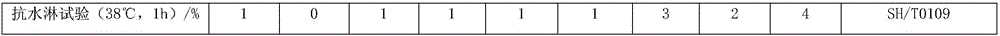

Examples

Embodiment 1

[0038] The special grease composition for the standard section assembly of tower cranes, the components and mass percentages are as follows:

[0039] (1) No. 2 general lithium grease 90.6%;

[0040] (2) Diphenylamine 0.4%;

[0041] (3) Flake graphite 1.3%;

[0042] (4) Light calcium carbonate 2.7%;

[0043] (5) Sorbitan monooleate 1.2%

[0044] (6) Phenolic resin 1.0%

[0045] (7) Barium dinonylnaphthalene sulfonate 2.3%

[0046] (8) Polyisobutylene 0.5%

[0047]Put 906g of No. 2 general-purpose lithium-based grease (working penetration 287, unit 0.1mm) into the refining kettle, stir and heat up. When the temperature rose to 125°C, the heating was stopped. Add 10 g of phenolic resin and 23 g of barium dinonylnaphthalene sulfonate, and keep stirring at the temperature for 21 min. Cool the material. When the temperature reached 105°C, 4g of diphenylamine, 13g of flake graphite, 27g of light calcium carbonate (45μm sieve residue less than 0.4%), 12g of sorbitan monooleat...

Embodiment 2

[0049] The special grease composition for the standard section assembly of tower cranes, the components and mass percentages are as follows:

[0050] (1) No. 3 general lithium grease 85.5%;

[0051] (2) N-phenyl-α-naphthylamine 0.3%;

[0052] (3) Colloidal graphite 2.7%;

[0053] (4) Light calcium carbonate 3.6%;

[0054] (5) Sorbitan monooleate 1.5%

[0055] (6) Phenolic resin 1.9%

[0056] (7) Barium dinonylnaphthalene sulfonate 3.7%

[0057] (8) Polyisobutylene 0.8%

[0058] Put 855 g of No. 3 general-purpose lithium-based grease (working penetration 245, unit 0.1 mm) into the kettle, and stir to raise the temperature. When the temperature rose to 130°C, the heating was stopped. Add 19 g of phenolic resin and 37 g of barium dinonylnaphthalene sulfonate, and keep stirring at the temperature for 22 minutes. Cool the material. When the temperature reached 99°C, 3g of N-phenyl-α-naphthylamine, 27g of colloidal graphite, 36g of light calcium carbonate (45μm sieve residu...

Embodiment 3

[0060] The special grease composition for the standard section assembly of tower cranes, the components and mass percentages are as follows:

[0061] (1) No. 2 general lithium grease 78.8%;

[0062] (2) N-phenyl-α-naphthylamine 0.8%

[0063] (3) Colloidal graphite 3.2%;

[0064] (4) Light calcium carbonate 4.5%;

[0065] (5) Sorbitan monooleate 3.0%

[0066] (6) Phenolic resin 2.2%

[0067] (7) Barium petroleum sulfonate 6.0%

[0068] (8) Polyisobutylene 1.5%

[0069] Put 788g of No. 2 general-purpose lithium-based grease (working penetration 287, unit 0.1mm) into the kettle, stir and heat up. When the temperature rose to 135°C, the heating was stopped. Add 22g of phenolic resin and 60g of barium petroleum sulfonate, keep the temperature and stir for 30min. Cool the material. When the temperature reaches 110°C, add 8 g of N-phenyl-α-naphthylamine, 32 g of colloidal graphite (particle size less than 30 μm), 45 g of light calcium carbonate (45 μm sieve residue is less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com