A long-life anti-seize grease composition and preparation method

A grease composition and the technology of the composition, applied in the field of grease, can solve problems such as difficulty in disassembling pins, and achieve the effects of delaying rust and wear speed, smooth assembly and disassembly, and preventing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

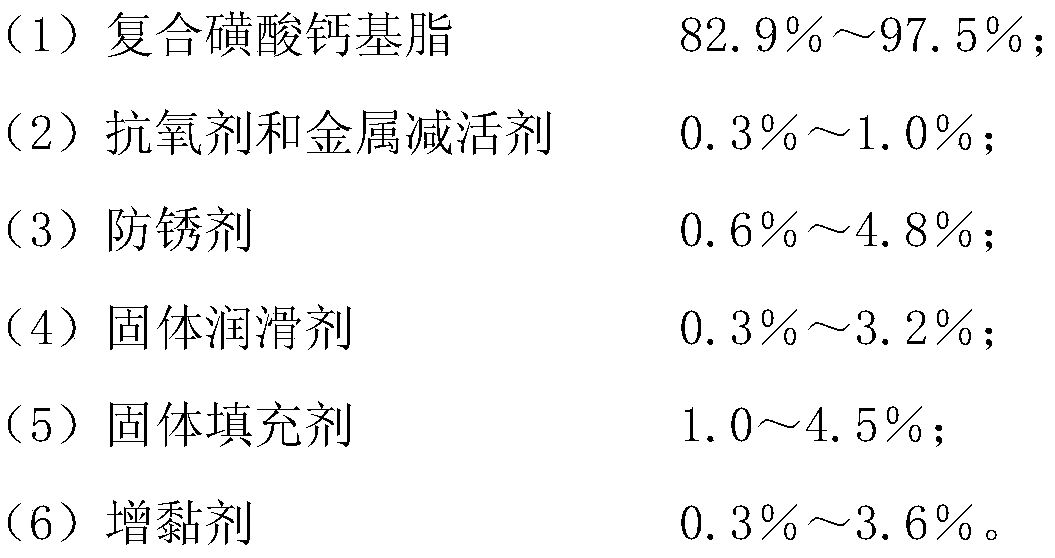

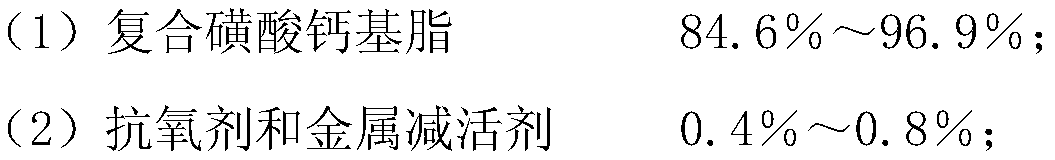

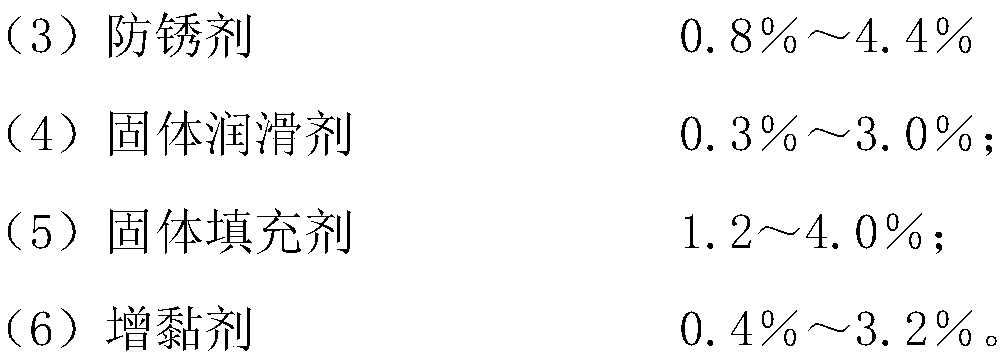

[0025] The long-life anti-seize grease composition has the following components and mass percentages:

[0026] (1) No. 2 complex calcium sulfonate base grease 92.4%;

[0027] (2) T551 0.5%;

[0028] (3) Calcium Dinonylnaphthalene Sulfonate 3.0%

[0029] (4) Molybdenum disulfide powder 0.6%;

[0030] (5) Titanium dioxide 2.7%;

[0031] (6) HSD 0.8%.

[0032] First, 924.0 g of No. 2 composite calcium sulfonate base grease (working penetration 242, unit 0.1 mm) was put into the kettle, and stirred to raise the temperature. When the temperature reaches 120°C, 5.0g of T551, 3.0g of calcium dinonylnaphthalenesulfonate, 6.0g of molybdenum disulfide powder (fineness<5μm), 2.7g of titanium dioxide (320 mesh sieve residue<0.1%), and HSD 8.0g. Stir for 21min, then get out of the kettle. Grind it three times with a three-roll machine to get the finished product.

Embodiment 2

[0034] The long-life anti-seize grease composition has the following components and mass percentages:

[0035] (1) No. 1 complex calcium sulfonate base grease 91.2%;

[0036] (2) T561 0.6%;

[0037] (3) Zinc dinonylnaphthalene sulfonate 2.8%;

[0038] (4) Tungsten disulfide 1.3%;

[0039] (5) Ceramic powder 3.4%;

[0040] (6) Ceramic powder 0.7%.

[0041] First, put 912g of No. 1 composite calcium sulfonate base grease (working penetration 331, unit 0.1mm) into the kettle, stir and heat up. When the temperature reaches 118°C, 16.0g of T56, 2.8g of zinc dinonylnaphthalenesulfonate, 1.3g of tungsten disulfide (fineness<5μm), 3.4g of ceramic micropowder (residue of 320 mesh sieve<0.1%) and ceramic Micropowder 7.0g. Stir for another 18min, then get out of the kettle. Grind it three times with a three-roll machine to get the finished product.

Embodiment 3

[0043] The long-life anti-seize grease composition has the following components and mass percentages:

[0044] (1) No. 2 complex calcium sulfonate base grease 82.9%;

[0045] (2) T551 1.0%;

[0046] (3) Calcium Dinonylnaphthalene Sulfonate 4.8%

[0047] (4) Molybdenum disulfide 3.2%;

[0048] (5) Ceramic powder 4.5%;

[0049] (6) HSD 3.6%.

[0050] First, 829.0 g of No. 2 composite calcium sulfonate base grease (working penetration 242, unit 0.1 mm) was put into the kettle, and stirred to raise the temperature. When the temperature reaches 95°C, 10.0g of T551, 48.0g of calcium dinonylnaphthalenesulfonate, 32.0g of molybdenum disulfide (fineness<10μm), 45g of ceramic micropowder (320 mesh sieve residue<0.3%) and HSD 36.0 are sequentially added. g. Stir for another 30min, then get out of the kettle. Grind it three times with a three-roll machine to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com