Fabricated flood control assembly

A prefabricated and component technology, applied in dikes, building components, water supply devices, etc., can solve the problems of difficult implementation, long preparation time, heavy weight, etc., and achieve the effects of low enclosure cost, good durability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

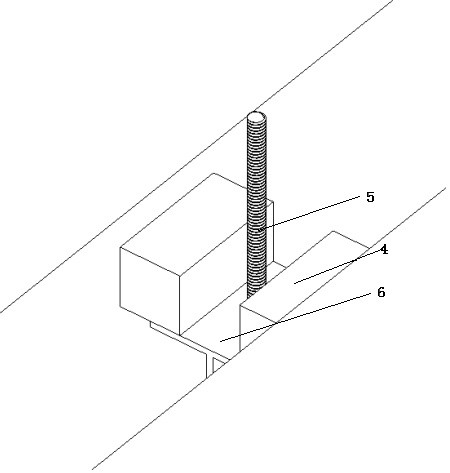

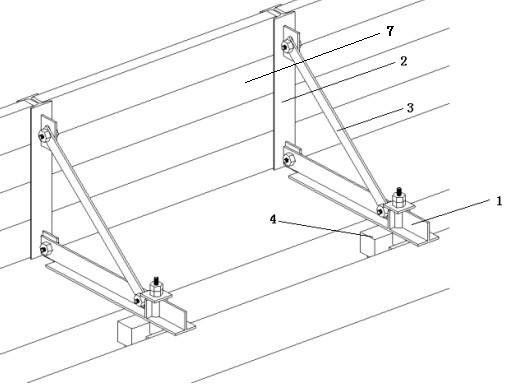

[0033] like Figure 1-2 As shown in the figure, during the later reconstruction of the entrance and exit of the underground space, pick ears 4 are left at certain intervals at the drainage ditch located in the underground space. Does not affect the drainage effect. The material of the pick ear is concrete, and steel bars are set inside it to bear the upward pull-out load. When the flood occurs, remove the grille cover above the gutter, insert the bolt 5 with the nut into the cross-shaped bottom gusset 6, and put the bottom gusset into the gutter, from the position without the pick ear Enter and move to the bottom of the pick ear, put the horizontal rod 1 into the bolt 5, adjust the position and put it into the backing plate, and fasten it with double nuts. Afterwards, the vertical bar 2, the diagonal stay bar 3 and the horizontal bar 1 are connected with bolts and fastened to form a firm triangular support device. Further, all the water retaining components are connected, a...

Embodiment 2

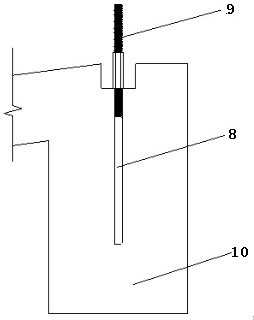

[0037] like Figure 3-5 As shown, when the basement is built or later transformed, a reinforced concrete beam or pier body 10 is buried at the entrance and exit of the car ramp, and a pre-embedded anchor bolt 8 is arranged in the beam or pier body 10, and the head of the pre-embedded anchor bolt 8 has threads. The anchor bolts cannot be exposed to the slope ground, and are placed in the notches 11 placed in advance by the beam or pier body 10. During normal use, the anchor bolts are filled with anti-corrosion and anti-rust protection materials in the notches 11, and a cover plate 12 is arranged on the notches. Make sure that it does not affect the normal use of the ramp.

[0038] When rainstorm comes, when needing to keep water, open the cover plate 12 of notch 11, utilize spanner to screw the pre-embedded anchor bolt 8 in the notch with extension anchor bolt 9, and fasten. Insert the horizontal rod 1 into the extended anchor bolt 9, adjust the position and insert it into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com