High-speed mute miniature precision bearing

A precision bearing and bearing technology, applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of bearing movement and increased noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0030] This embodiment is an embodiment of a high-speed and silent miniature precision bearing.

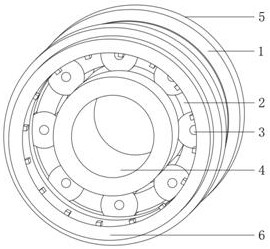

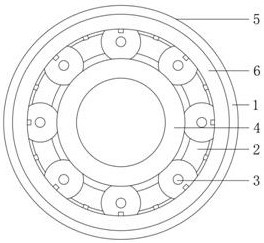

[0031] Such as Figure 1-7 As shown, a high-speed and quiet miniature precision bearing includes a bearing outer ring 1. The deep groove ball bearing of a deep groove ball bearing of Chinese Patent No. CN202022430434.9 is cited as the prior art. The inner wall of the bearing outer ring 1 is front and rear Two groups of bearing cages 2 are detachably connected at the end, and the inner walls of the two groups of bearing cages 2 are movably connected with eight groups of bearing rolling elements 3, and the inner walls of the bearing cage 2 and the bearing rolling elements 3 are detachably connected with the bearing inner ring 4 and the bearing outer ring The outer surfaces of the front and rear ends of 1 can be detachably connected to the bearing spacer mechanism 6, and the bearing outer ring 1, bearing cage 2, bearing rolling element 3, bearing inner ring 4 and the outer walls of t...

specific Embodiment 2

[0035] This embodiment is an embodiment of a bearing outer ring used on a high-speed and quiet miniature precision bearing.

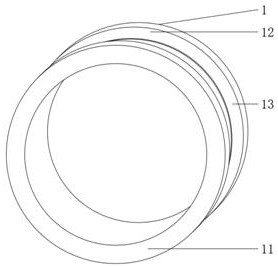

[0036] Such as Figure 1-4 As shown, a bearing outer ring 1 used on a high-speed and silent miniature precision bearing, the bearing outer ring 1 includes a No. 1 outer ring main body 11, a No. 2 outer ring main body 12 and a V-shaped groove 13. On the outer surface of the front end of the No. 2 outer ring main body 12, the V-shaped groove 13 is located at the junction of the No. 1 outer ring main body 11 and the No. 2 outer ring main body 12. The No. 1 outer ring main body 11 and the No. 2 outer ring main body 12 are integrally formed. The groove 13 is provided in the middle part of the outer wall between the No. 1 outer ring main body 11 and the No. 2 outer ring main body 12 .

specific Embodiment 3

[0038] This embodiment is an embodiment of a bearing outer protective coating used on a high-speed and quiet miniature precision bearing.

[0039] Such as Figure 1-2 , Figure 5 As shown, a bearing outer protective coating 5 used on a high-speed and quiet miniature precision bearing, a group of bearing outer protective coatings 5 include a Teflon anti-corrosion coating 51, a sound-absorbing coating 52 and a tough coating 53, The sound-absorbing coating 52 is positioned on the inner wall of the Teflon anti-corrosion coating 51, the tough coating 53 is positioned on the inner wall of the sound-absorbing coating 52, the tough coating 53 is applied on the outer walls of each component, and the sound-absorbing coating 52 is applied on For the outer wall, the Teflon anti-corrosion coating 51 is applied to the outer wall of the sound-absorbing coating 52 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com