Preparation of water-based environment-friendly coating material based on diatomite purification and titanium dioxide loading

A technology of titanium dioxide and environmentally friendly coatings, applied in the direction of fireproof coatings, coatings, chemical instruments and methods, etc., can solve problems affecting catalytic efficiency, etc., and achieve the effect of improving air quality and adjusting air humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

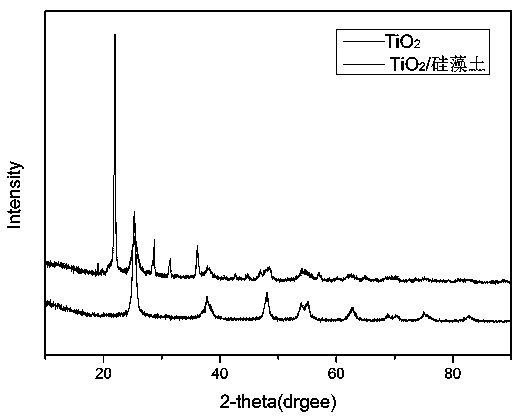

Image

Examples

Embodiment 1

[0026] Weigh 16 parts of deionized water into a container, then add 0.7 parts of dispersant 5040, 0.5 parts of 1,2-propylene glycol, 0.3 parts of Cathone and 0.3 parts of silicone defoamer for dispersion; then weigh 37 parts Untreated diatomite, 5 parts of attapulgite, 3 parts of silver-loaded zirconium phosphate powder, 2 parts of tourmaline powder and 5 parts of aluminum oxide were added to the dispersion and continued to disperse; finally weighed 30 parts of pure acrylic emulsion in Continue to disperse in the dispersion, add 0.2 parts of hydroxypropyl methylcellulose, stir evenly, fill and package the liquid, that is, Example 1.

Embodiment 2

[0028] Weigh 16 parts of deionized water into a container, then add 0.7 parts of dispersant 5040, 0.5 parts of 1,2-propylene glycol, 0.3 parts of Cathone and 0.3 parts of silicone defoamer for dispersion; then weigh 37 parts Purify diatomite, 5 parts of attapulgite, 3 parts of zirconium phosphate silver-loaded powder, 2 parts of tourmaline powder and 5 parts of aluminum oxide, and add them to the dispersion to continue dispersing; finally weigh 30 parts of pure acrylic emulsion in the dispersion Continue to disperse in the liquid, add 0.2 parts of hydroxypropyl methylcellulose, and after stirring evenly, the liquid is filled and packaged, which is Example 2.

Embodiment 3

[0030]Weigh 16 parts of deionized water into a container, then add 0.7 parts of dispersant 5040, 0.5 parts of 1,2-propylene glycol, 0.3 parts of Cathone and 0.3 parts of silicone defoamer for dispersion; then weigh 37 parts After purification, diatomite loaded with titanium dioxide, 5 parts of attapulgite, 3 parts of silver-loaded zirconium phosphate powder, 2 parts of tourmaline powder and 5 parts of aluminum oxide were added to the dispersion and continued to disperse; finally weighed 30 parts of pure acrylic acid The emulsion continued to disperse in the dispersion liquid, and 0.2 parts of hydroxypropyl methylcellulose was added, and after stirring evenly, the liquid was filled and packaged, namely Example 3.

[0031] In order to verify whether the product of the present invention complies with the standard requirements of GB18582-2009 "Synthetic Resin Emulsion Interior Wall Coating" and GB18582-2008 "Limits of Harmful Substances in Interior Decoration Materials and Interior...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com