Functional article, article for transport equipment, article for construction, and composition for coating

A functional and compositional technology, applied in the direction of transportation and packaging, coating, layered products, etc., which can solve the problem of insufficient wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

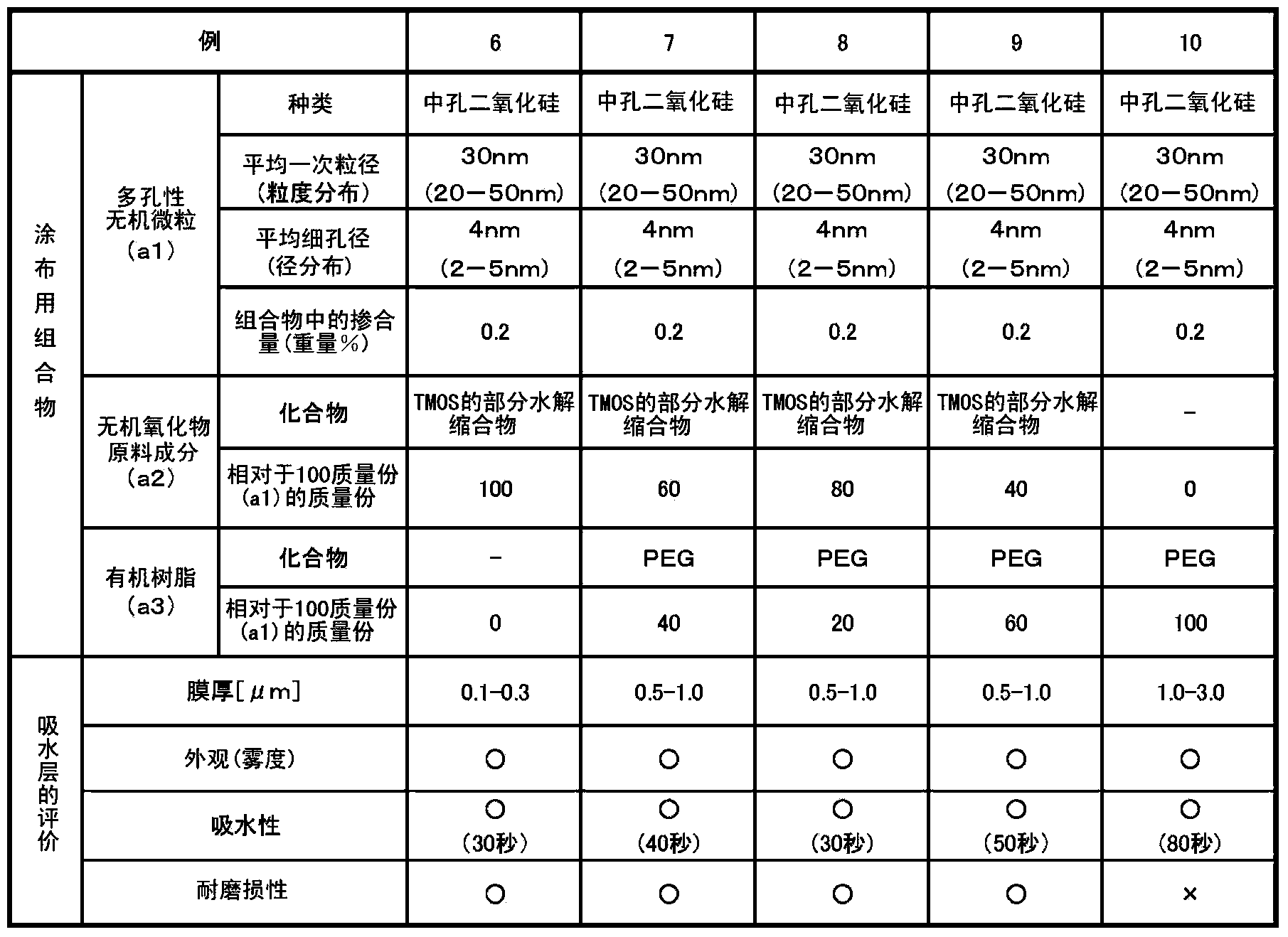

[0158] Hereinafter, the present invention will be specifically described with reference to examples, but the present invention is not limited to these examples. In addition, Examples 1-4 and 6-9 are examples, and Example 5 and Example 10 are comparative examples.

[0159] The porous inorganic fine particles used in Examples and Comparative Examples, and the functional articles obtained in Examples and Comparative Examples were evaluated as follows.

[0160] [Porous inorganic fine particles]

[0161] The average primary particle diameter is to randomly extract 200 particles from the image obtained by shooting the porous inorganic fine particle sol with a transmission electron microscope: JEM-1230 (JEOL Ltd.), measure the particle diameter of each particle, and then divide 200 The particle diameter of the particles was calculated as an average value. In addition, the average pore diameter was computed using the image analysis program of said JEM-1230 (JEOL Ltd.).

[0162] [fi...

manufacture example 1

[0176] Distilled water (240 g, manufactured by Wako Pure Chemical Industries, Ltd.), triethanolamine (0.42 g, manufactured by Junsei Chemical Co., Ltd.), cetyltrimethylammonium bromide (2.00 g , Tokyo Chemical Industry Co., Ltd.), and stirred at 80° C. for 30 minutes. Next, tetramethoxysilane (2.29 g, manufactured by Junsei Chemical Co., Ltd.) was added, and after stirring at 80° C. for 2 hours, ultrafiltration (cut molecular weight: 12,000 to 14000), performing ultrafiltration (cut molecular weight: 12000-14000) using water once as an acid removal step. Filtration with a filter (0.5 μm) was carried out again to obtain mesoporous silica (0.4 mass %, average primary particle diameter 30 nm (particle size distribution: 20-50 nm), average pore diameter 4 nm (diameter distribution: 2 nm) as porous inorganic fine particles. -5 nm)) of dispersion A.

manufacture example 2

[0178] Add mixed alcohol (ethanol:isopropanol:n-propanol=88:4:8 (mass ratio), 237.51g, NEO Ethanol PIP (trade name, Neoetanol) while stirring in a glass container equipped with a stirrer and a thermometer. IPM), manufactured by Daishin Chemical Co., Ltd.), tetramer (1.96 g, M Silicate51 (trade name, Msilicate 51) of tetramethoxysilane (hereinafter, referred to as "TMOS" if necessary), manufactured by Tama Chemical Co., Ltd. ), hydrochloric acid (6.94 g, special grade, manufactured by Junsei Chemical Co., Ltd.), distilled water (3.60 g, manufactured by Wako Pure Chemical Industries, Ltd.), and stirred at 25°C for 3 hours to obtain partial hydrolysis of TMOS containing inorganic oxide raw material components Solution B of the condensate (0.4% by mass).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com