Building energy-saving glass

A building energy-saving and glass technology, applied in glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problems of inability to fill the contact part, reduce the thermal insulation properties of glass, aerogel damage, etc. The effect of solving the problem of condensation phenomenon, improving the practicability of the project and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but the scope of protection is not limited by these embodiments.

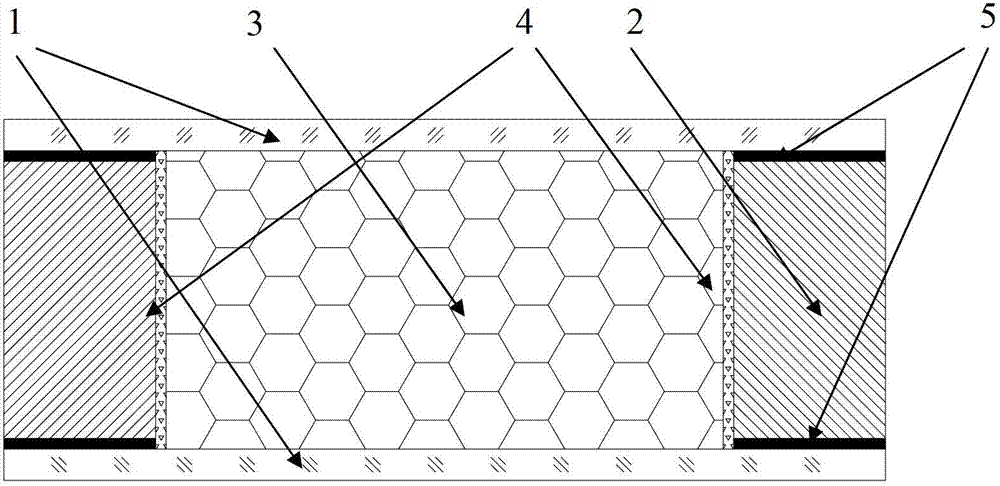

[0032] Please refer to figure 1 , which is Embodiment 1 of the present invention, the building energy-saving glass includes two sheets of flat glass 1 and a solid sealing spacer 2 between the two sheets of glass, and the space between the solid sealing spacer 2 and the flat glass 1 A sealed cavity is formed, and the sealed compartment is filled with transparent and insulating SiO 2 Airgel sheet 3. In a solid hermetic spacer 2 with transparent insulating SiO 2 Between the airgel panels 3, by using transparent insulating SiO 2 Airgel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com