A method of preparing high-strength oil and gas fracturing proppant by using ceramsite waste

A high-strength, oil-pneumatic technology, applied in the production of ceramic materials, chemical instruments and methods, applications, etc., can solve the problems of increasing oil and gas production, small deformation coefficient, low strength, etc., to promote reuse, reduce product density, The effect of improving product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

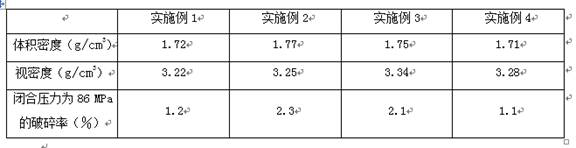

Examples

Embodiment 1

[0019] A method for preparing a high-strength oil-gas fracturing proppant by utilizing ceramsite waste, comprising the following steps:

[0020] After the ceramic waste is pulverized, ceramic fine powder is obtained; the ceramic fine powder, graphite powder, and magnesium powder are mixed uniformly, fired at 600-700°C for 2 hours with protective gas, and fired at 950-1100°C for 1 hour h, take it out after cooling, and pulverize again to obtain secondary powder; mix the secondary powder with sodium tripolyphosphate, tuff, and mineralizer, spray, mix, granulate, and polish to obtain ceramic primary particles, which are passed into protective gas and preheated. The ceramic primary particles are fired at 1150-1210°C for 0.5 h, and then continue to heat up to 1250-1350°C for 1 h. Among them, in terms of mass percentage, the ratio of the above raw materials is as follows: ceramic fine powder 70%, graphite powder 6%-11%, magnesium powder 6%-11%, sodium tripolyphosphate 0.2%-1.2%, tuf...

Embodiment 2

[0023] A method for preparing a high-strength oil-gas fracturing proppant by utilizing ceramsite waste, comprising the following steps:

[0024] After the ceramic waste is pulverized, ceramic fine powder is obtained; the ceramic fine powder, graphite powder, and magnesium powder are mixed uniformly, fired at 600-700°C for 2 hours with protective gas, and fired at 950-1100°C for 2 hours. h, take it out after cooling, and pulverize again to obtain secondary powder; mix the secondary powder with sodium tripolyphosphate, tuff, and mineralizer, spray, mix, granulate, and polish to obtain ceramic primary particles, which are passed into protective gas and preheated. The ceramic primary particles are fired at 1150-1210°C for 1 hour, and then continue to heat up to 1250-1350°C for 2 hours. Among them, in terms of mass percentage, the ratio of the above raw materials is as follows: ceramic fine powder 65%, graphite powder 6%, magnesium powder 6%, sodium tripolyphosphate 0.5%, tuff 9%, ...

Embodiment 3

[0027] A method for preparing a high-strength oil-gas fracturing proppant by utilizing ceramsite waste, comprising the following steps:

[0028] After the ceramic waste is pulverized, ceramic fine powder is obtained; the ceramic fine powder, graphite powder, and magnesium powder are mixed uniformly, fired at 600-700°C for 1.2 h with protective gas, and fired at 950-1100°C for 1.8 h. h, take it out after cooling, and pulverize again to obtain secondary powder; mix the secondary powder with sodium tripolyphosphate, tuff, and mineralizer, spray, mix, granulate, and polish to obtain ceramic primary particles, which are passed into protective gas and preheated. The ceramic primary particles were fired at 1150-1210°C for 0.8 h, and then continued to heat up to 1250-1350°C for 1.5 h. Among them, in terms of mass percentage, the ratio of the above raw materials is as follows: ceramic fine powder 75%, graphite powder 6%, magnesium powder 6%, sodium tripolyphosphate 0.2%, tuff 6%, miner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com