Leather boot and preparation method thereof

A technology for leather boots and leather, applied to boot legs, pre-treated surfaces, fire-resistant coatings, etc., can solve problems that affect the service life of leather boots and are prone to cracks, achieve uniform toughening effects, broaden weather resistance, and improve activity effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

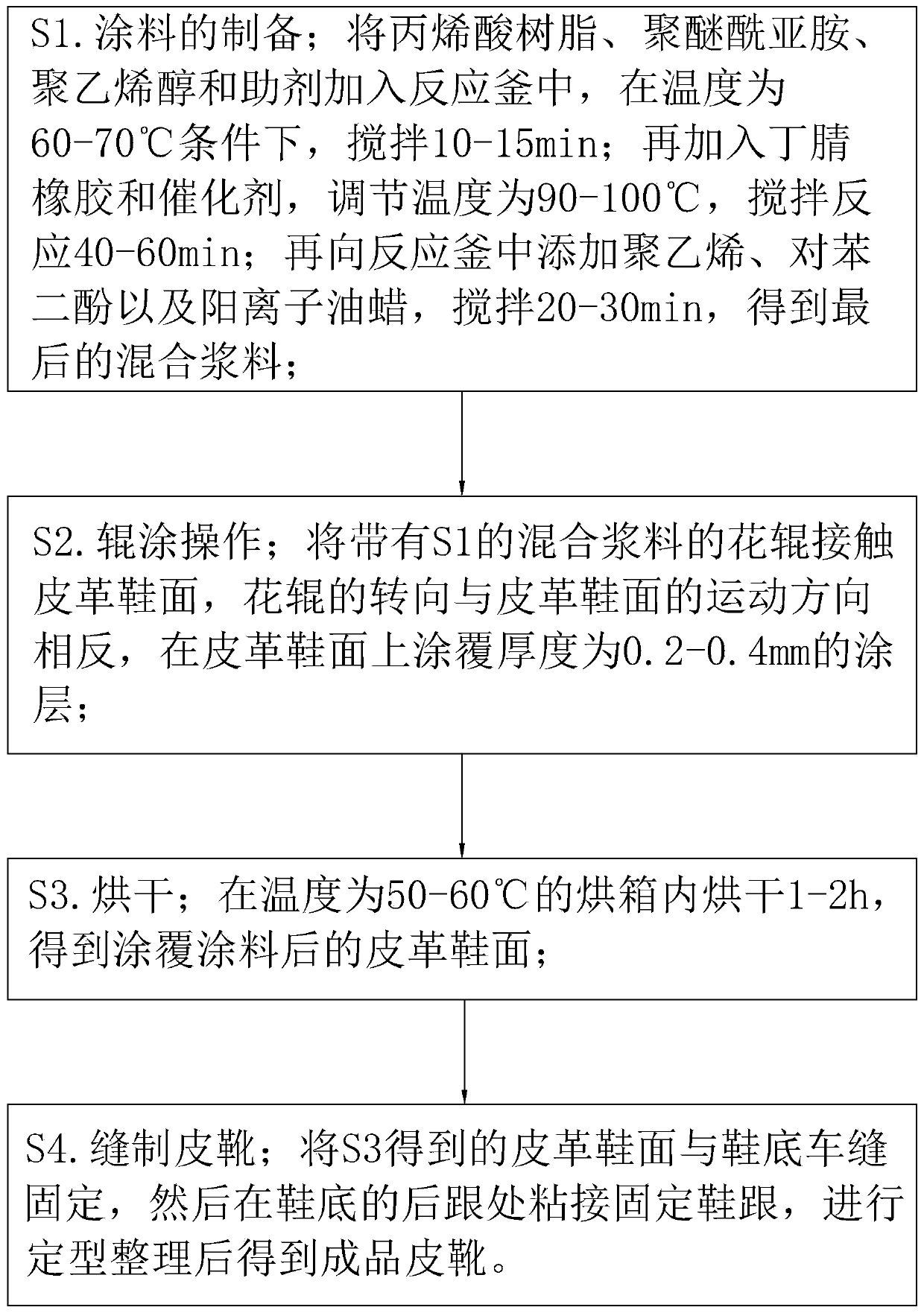

[0044] refer to figure 1 , is the preparation method of a kind of leather boot disclosed by the present invention, comprises the following steps:

[0045] S1. Preparation of paint; add acrylic resin, polyetherimide, polyvinyl alcohol and additives into the reaction kettle, and stir for 14 minutes at a temperature of 66°C; then add nitrile rubber and a catalyst, and adjust the temperature to 96°C , stirring and reacting for 55 minutes; then adding polyethylene, hydroquinone and cationic oil wax to the reactor, stirring for 27 minutes to obtain the final mixed slurry;

[0046] S2. Roller coating operation; the flower roller with the mixed slurry of S1 is contacted with the leather upper, the turning direction of the flower roller is opposite to the movement direction of the leather upper, and a coating thickness of 0.3mm is coated on the leather upper;

[0047] S3. drying; drying in an oven at a temperature of 58°C for 1.5 hours to obtain a leather upper coated with paint;

[...

Embodiment 2

[0051] refer to figure 1 , is the preparation method of a kind of leather boot disclosed by the present invention, comprises the following steps:

[0052] S1. Preparation of paint; add acrylic resin, polyetherimide, polyvinyl alcohol and additives into the reaction kettle, and stir for 10 minutes at a temperature of 60°C; then add nitrile rubber and catalyst, and adjust the temperature to 90°C , stirring and reacting for 40 minutes; then adding polyethylene, hydroquinone and cationic oil wax to the reactor, stirring for 20 minutes to obtain the final mixed slurry;

[0053] S2. Roller coating operation; contact the patterned roller with the mixed slurry of S1 to the leather upper, the turning direction of the patterned roller is opposite to the movement direction of the leather upper, and coat a coating with a thickness of 0.2mm on the leather upper;

[0054] S3. drying; drying in an oven at a temperature of 50° C. for 1 hour to obtain a leather upper coated with paint;

[00...

Embodiment 3

[0058] refer to figure 1 , is the preparation method of a kind of leather boot disclosed by the present invention, comprises the following steps:

[0059] S1. Preparation of paint; add acrylic resin, polyetherimide, polyvinyl alcohol and additives into the reaction kettle, and stir for 15 minutes at a temperature of 70°C; then add nitrile rubber and catalyst, and adjust the temperature to 100°C , stirring and reacting for 60 minutes; then adding polyethylene, hydroquinone and cationic oil wax to the reactor, and stirring for 30 minutes to obtain the final mixed slurry;

[0060] S2. Roller coating operation; contact the patterned roller with the mixed slurry of S1 to the leather upper, the turning direction of the patterned roller is opposite to the movement direction of the leather upper, and coat a coating with a thickness of 0.4mm on the leather upper;

[0061] S3. drying; drying in an oven at a temperature of 60° C. for 2 hours to obtain a leather upper coated with paint; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com