Toughening epoxy resin composition

A technology of tough epoxy resin and halogen epoxy resin, applied in the field of toughened epoxy resin composition for copper clad laminates, can solve the problems of difficulty in taking into account the heat resistance and performance degradation of epoxy resin, and achieve convenient large-scale industrialization The effect of production, low dielectric constant, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific embodiments.

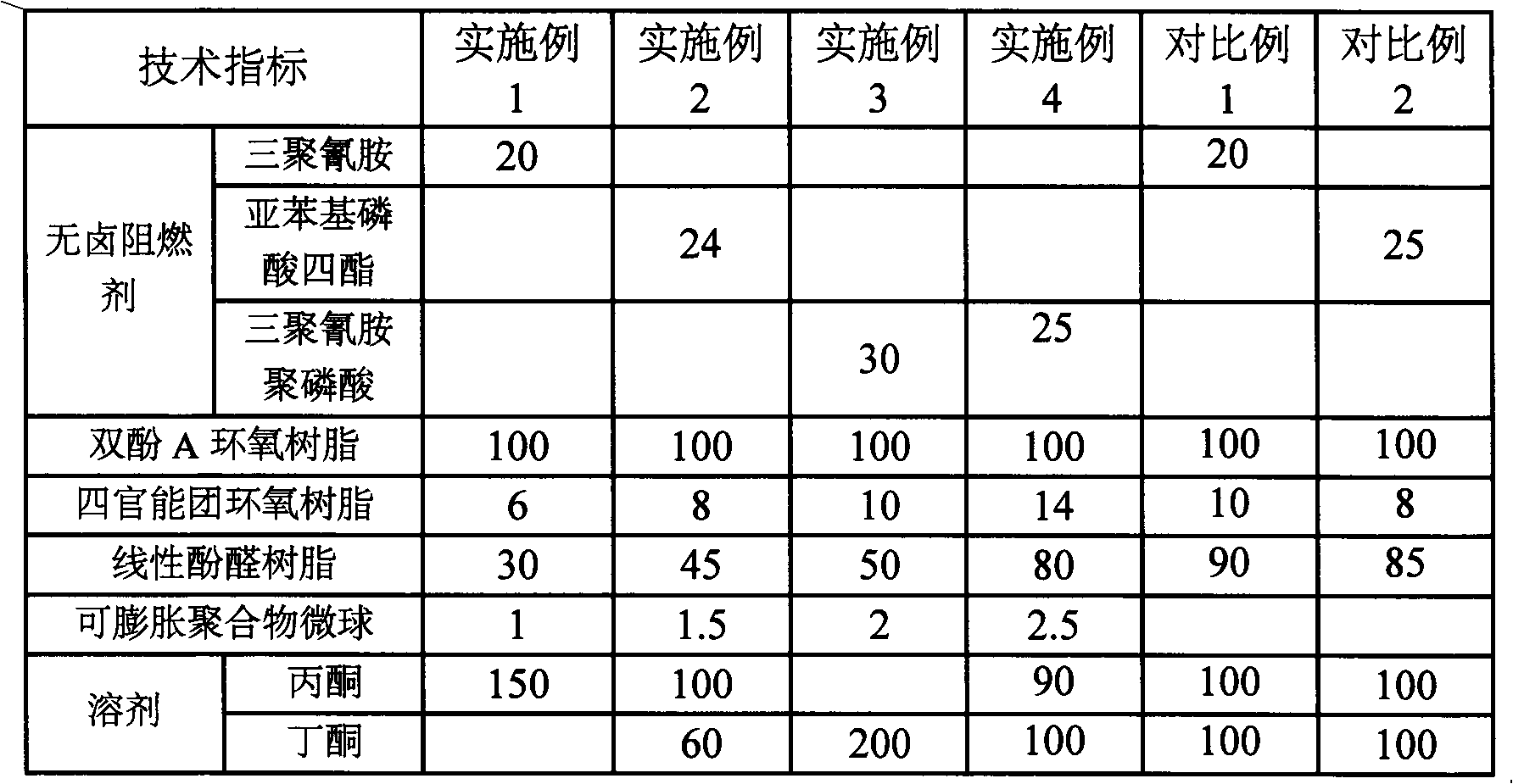

[0025] The formula of the epoxy resin composition of embodiment 1~4 and comparative example 1~2 is shown in table 1

[0026] Epoxy resin composition formula in the embodiment of table 1

[0027]

[0028] Follow the steps below to prepare a copper clad laminate

[0029] (1) Prepare the glue solution according to the formula in Table 1: add epoxy resin, phenolic resin, polymer microspheres, flame retardant, solvent to the container, start stirring, and get the epoxy resin composition glue solution in 2 hours;

[0030] (2) Preparation of prepreg: cut flat and clean glass cloth six pieces of 50cm×50cm, evenly coat the glue solution of the above-mentioned examples 1 to 4 and comparative examples 1 to 2 on both sides of each glass cloth, the glue content is 50% , baked in an oven at 170° C. for 2 minutes to prepare a prepreg.

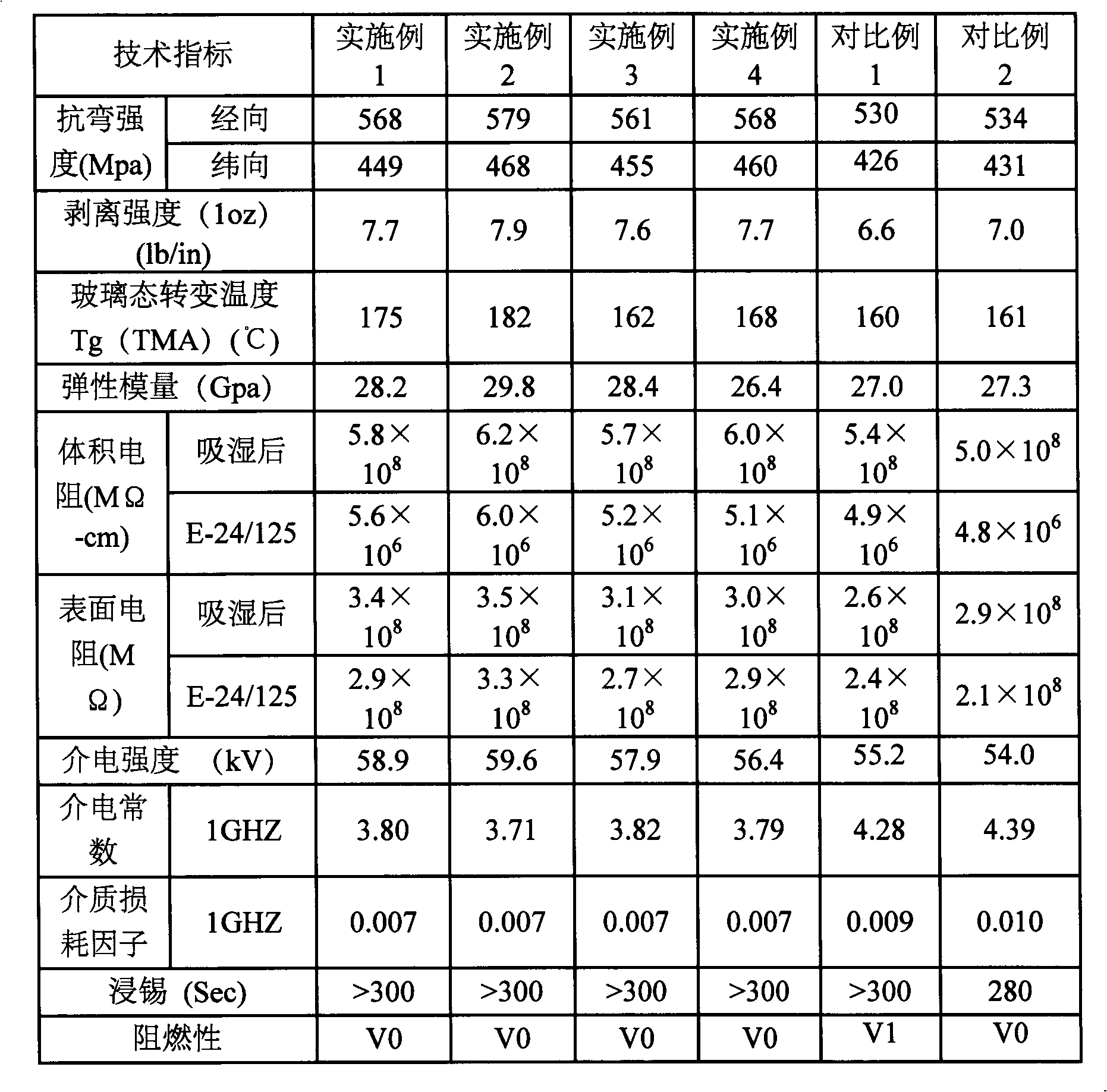

[0031] (3) Preparation of copper-cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com