Sintering process of petroleum fracturing propping agent

A technology of fracturing proppant and oil, which is applied in the direction of drilling composition, production fluid, application, etc. It can solve the problems of increasing oil and gas production and low strength, so as to reduce the broken rate, reduce the product density and improve the product strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

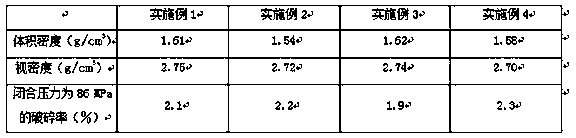

Examples

Embodiment 1

[0019] A kind of sintering process of oil fracturing proppant, it comprises the following steps:

[0020] After removing impurities, drying and pulverizing the potassium feldspar, the potassium feldspar fine powder is obtained; the potassium feldspar fine powder, graphite powder, and magnesium powder are mixed evenly, and fired at 600-700°C for 1 h with protective gas , heated to 950-1100°C and fired for 2 h, cooled, taken out, and pulverized again to obtain secondary powder; mixed with light-burned clay, sodium tripolyphosphate, and tuff, sprayed, mixed, granulated, and polished to obtain ceramic primary powder. The granules are fed with protective gas, and the ceramic primary granules are sintered at 1150-1210°C for 0.8 h, and then continue to heat up to 1250-1350°C for 2 h to obtain the petroleum fracturing proppant.

[0021] Include in described light burnt clay: SiO 2 32%-38%, Al 2 o 3 42%-50%, and the particle size is less than 50 μm. The potassium feldspar mainly ...

Embodiment 2

[0024] A kind of sintering process of oil fracturing proppant, it comprises the following steps:

[0025] After removing impurities, drying and pulverizing the potassium feldspar, the potassium feldspar fine powder is obtained; the potassium feldspar fine powder, graphite powder, and magnesium powder are mixed evenly, and fired at 600-700°C for 2 hours with protective gas , heated to 950-1100°C and fired for 1-2 h, cooled, taken out, and pulverized again to obtain secondary powder; mixed the secondary powder with light-burned clay, sodium tripolyphosphate, and tuff, sprayed, mixed, granulated, and polished to obtain The ceramic primary particles are fed with protective gas, and the ceramic primary particles are sintered at 1150-1210°C for 0.5 h, and then heated up to 1250-1350°C for 2 h to obtain the petroleum fracturing proppant.

[0026] The particle size of the primary ceramic particles is 20 mesh-40 mesh; the lightly fired clay includes: SiO 2 32%-38%, Al 2 o 3 42%-50%...

Embodiment 3

[0029] A kind of sintering process of oil fracturing proppant, it comprises the following steps:

[0030]Potassium feldspar is cleaned of impurities, dried, and pulverized to obtain potassium feldspar fine powder; the potassium feldspar fine powder, graphite powder, and magnesium powder are mixed evenly, and fired at 600-700°C for 1.5 h with protective gas , heated to 950-1100°C and fired for 2 hours, cooled, taken out, and pulverized again to obtain secondary powder; mixed the secondary powder with light-fired clay, sodium tripolyphosphate, and tuff, sprayed, mixed, granulated, and polished to obtain ceramic primary granules , pass through protective gas, sinter the ceramic primary particles at 1150-1210°C for 0.8 h, and then continue to heat up to 1250-1350°C for 1.6 h to obtain the petroleum fracturing proppant.

[0031] The particle size of the primary ceramic particles is 20 mesh-40 mesh; the lightly fired clay includes: SiO 2 32%-38%, Al 2 o 3 42%-50%, and the partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com