Cable three-dimensional forming method and cable three-dimensional forming device

A three-dimensional forming and cable technology, which is applied to cable installation devices, cable installation, equipment for connecting/terminating cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

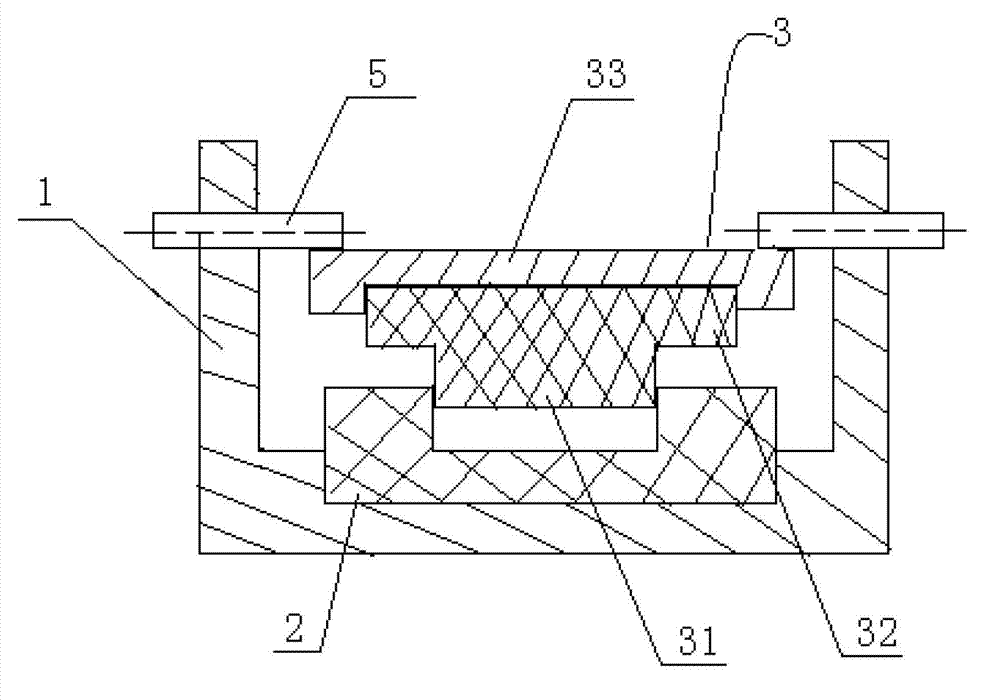

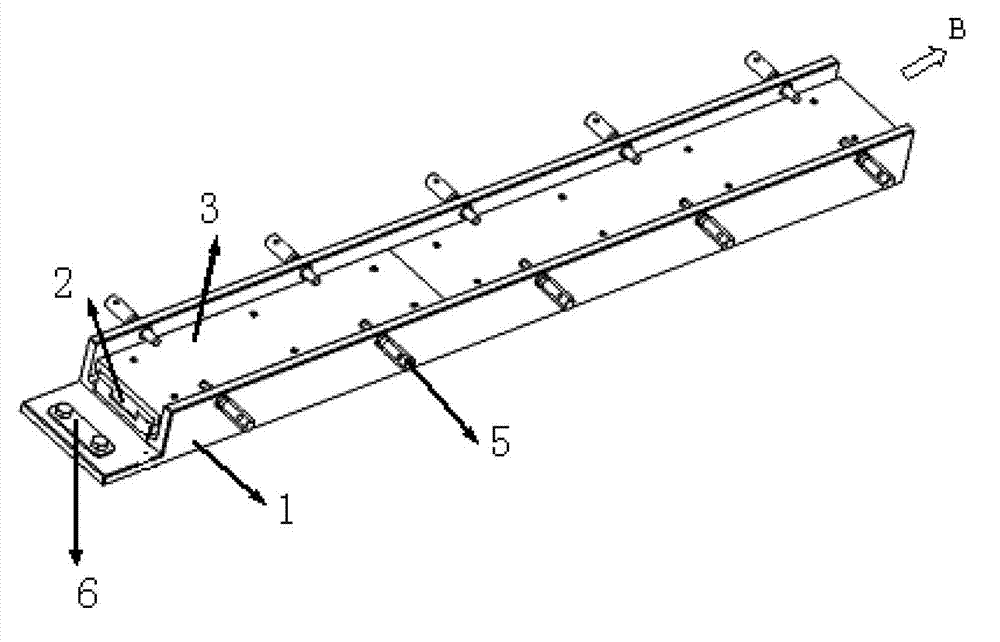

[0047] The cable three-dimensional forming device of the present invention is used for three-dimensional forming of cables. The selected cables are as follows: the cable diameter is between 2 and 3.2 mm: HF46P-2 0.2, HF46 P-2 0.3, HF46P-2 2X0.2, HF46 P- 2 0.5 four types of shielded wires and twisted pair shielded wires.

[0048] Specific steps are as follows:

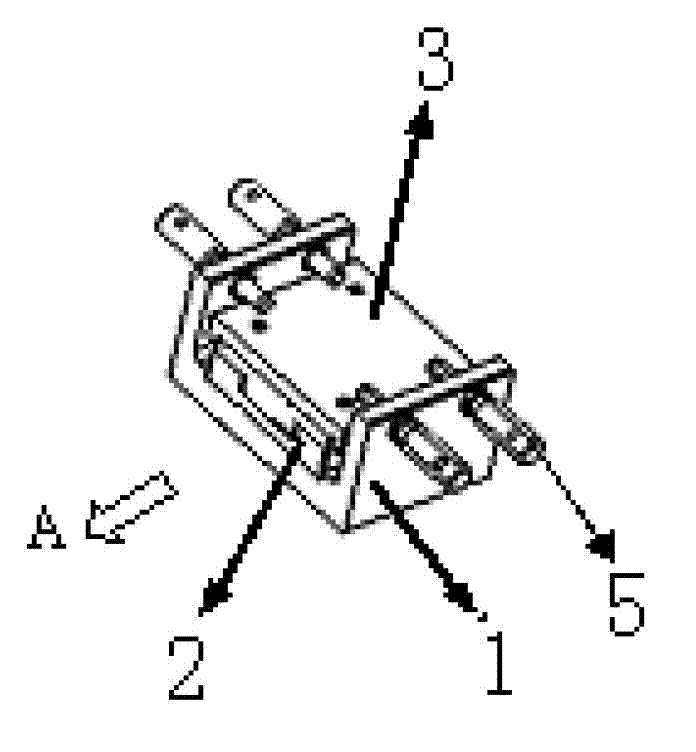

[0049] Step 1: Place the wire harness ends side by side on the figure 2 In the positioning groove 2 of the shown three-dimensional cable forming device, since the end of the wire bundle is fixed, the forming device can be used as figure 2 Shown are short fixtures for easy handling. Apply polyurethane glue evenly on the end of the wire bundle, put the pressure plate 3 on the wire bundle and push it into the positioning groove 2 along the direction of arrow A, after the excess glue is discharged, the pressure plate 3 will not move anymore, and then Insert the positioning pin 5 into the positioning hole 4 of the base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com