Replacing method of strain-resistant single-hole plate insulator string

A technology of tension-resistant single-hole connecting plates and insulator strings, which is applied in the direction of overhead lines/cable equipment, etc., to achieve the effects of shortening operation time, reducing labor intensity, and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

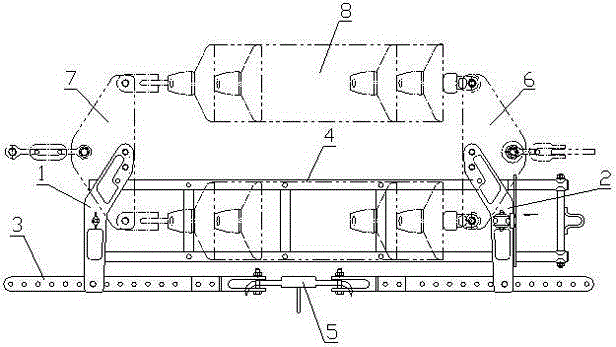

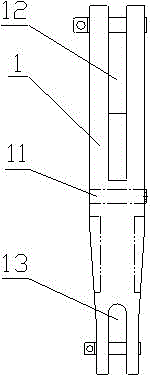

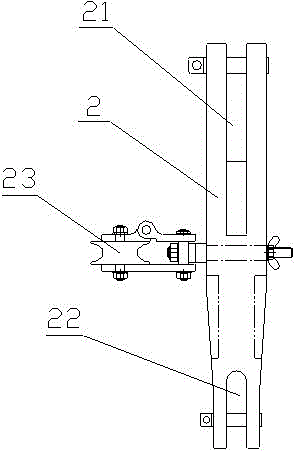

[0021] Such as Figure 1~5 As shown in the figure, a fixture for replacing a string of tension-resistant single-hole plate insulators includes a front curved plate clamp, a rear curved plate clamp, two adjustable aluminum alloy hanging rings and an aluminum alloy bottle holder. The upper part of the front curved plate clamp It is used to connect the side connecting plate of the wire. The steering block is fixed in the middle, and the lower part is connected with an adjustable aluminum alloy hanging ring. The steering block is threaded with a rope connected to the front end of the aluminum alloy bottle holder; the upper part of the rear bending plate is clamped It is used to connect the side connecting plate of the cross arm, the middle part is flexibly connected with the rear end of the aluminum alloy bottle holder, and the lower part is connected with another adjustable aluminum alloy hanging ring; The hole corresponding to the connection position of the bent plate card is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com