Steering drive shaft connection structure

A technology of steering transmission shaft and connecting structure, which is applied in steering column, steering control mounted on the vehicle, etc., can solve the problems affecting the driver's operating comfort, and achieve the effects of improving operating comfort, convenient assembly and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

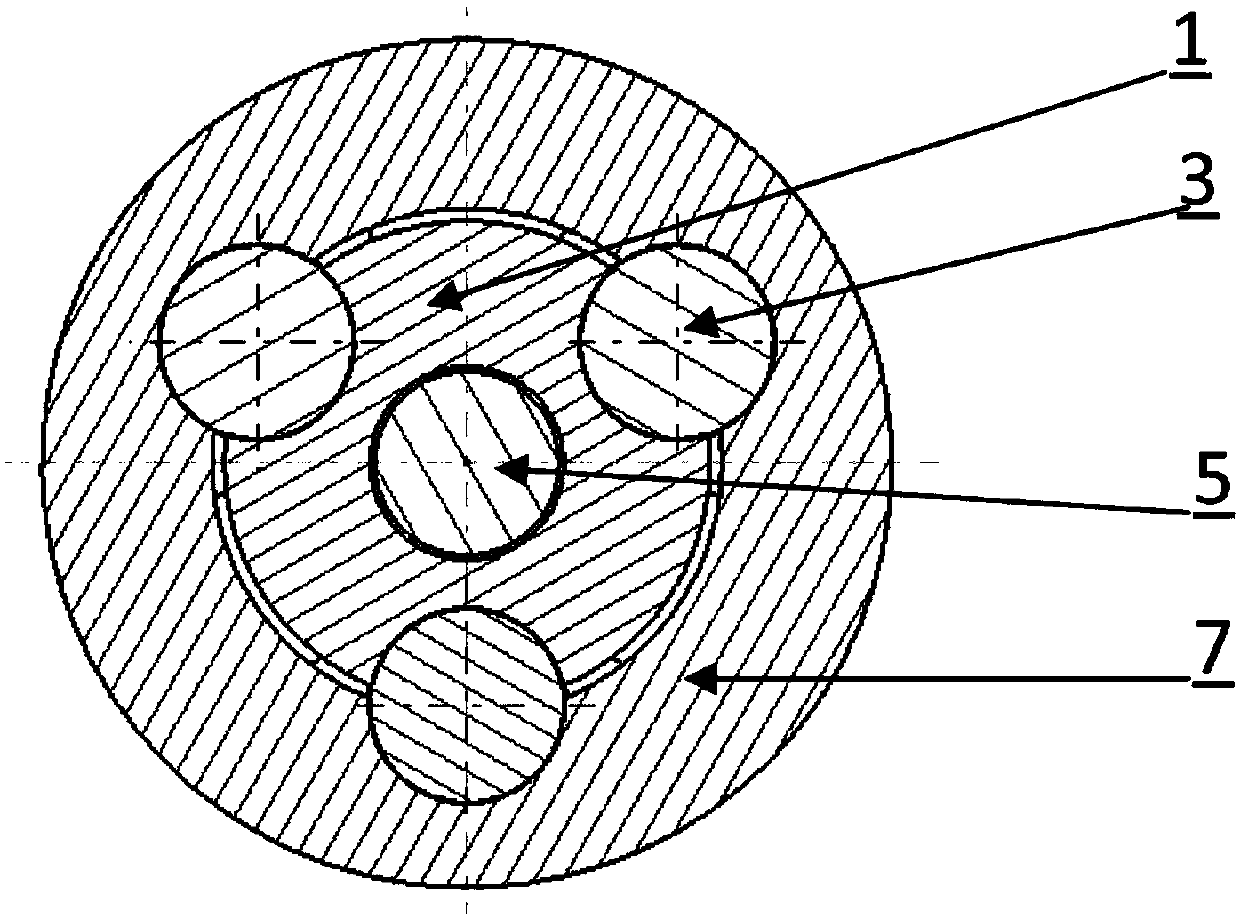

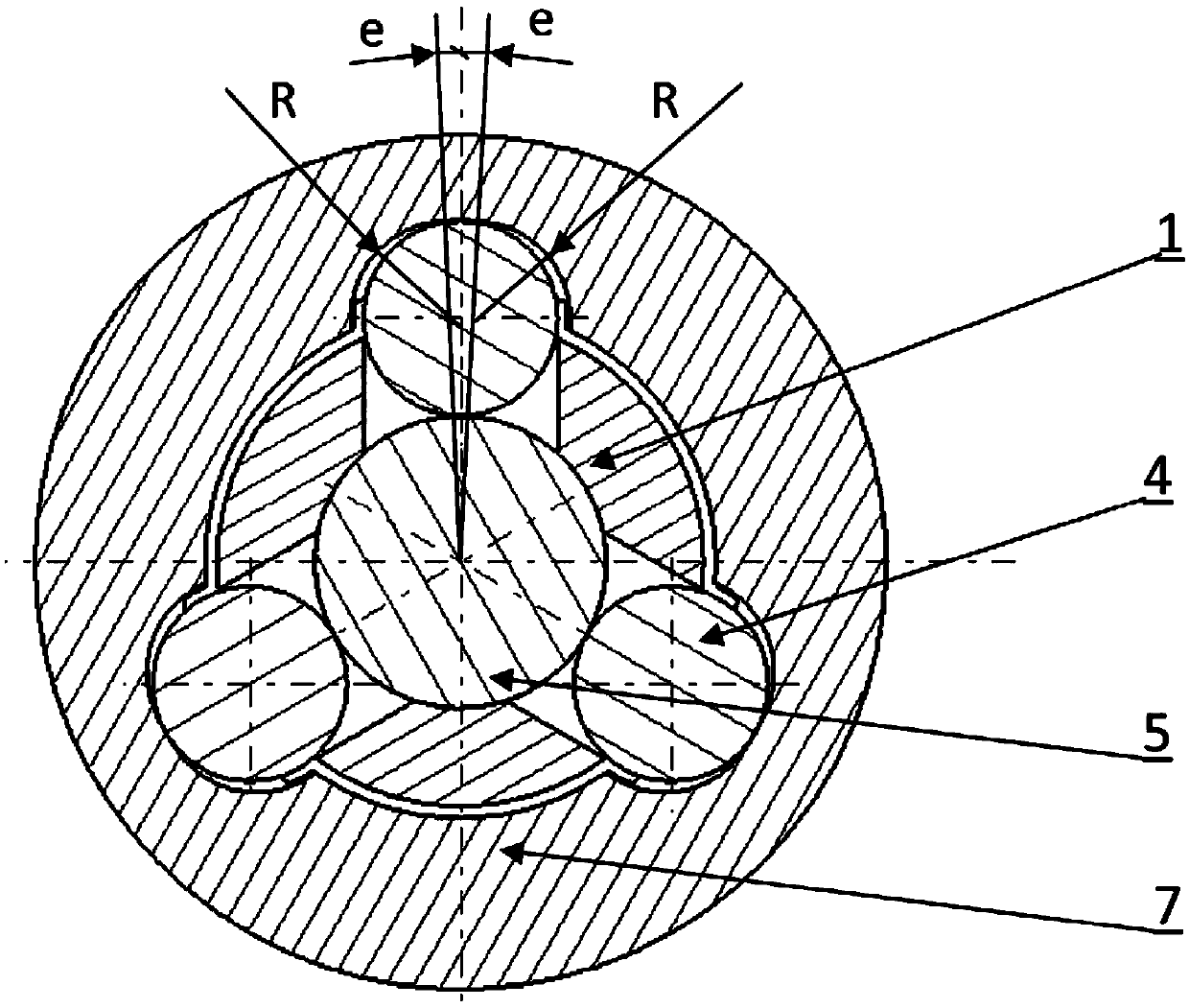

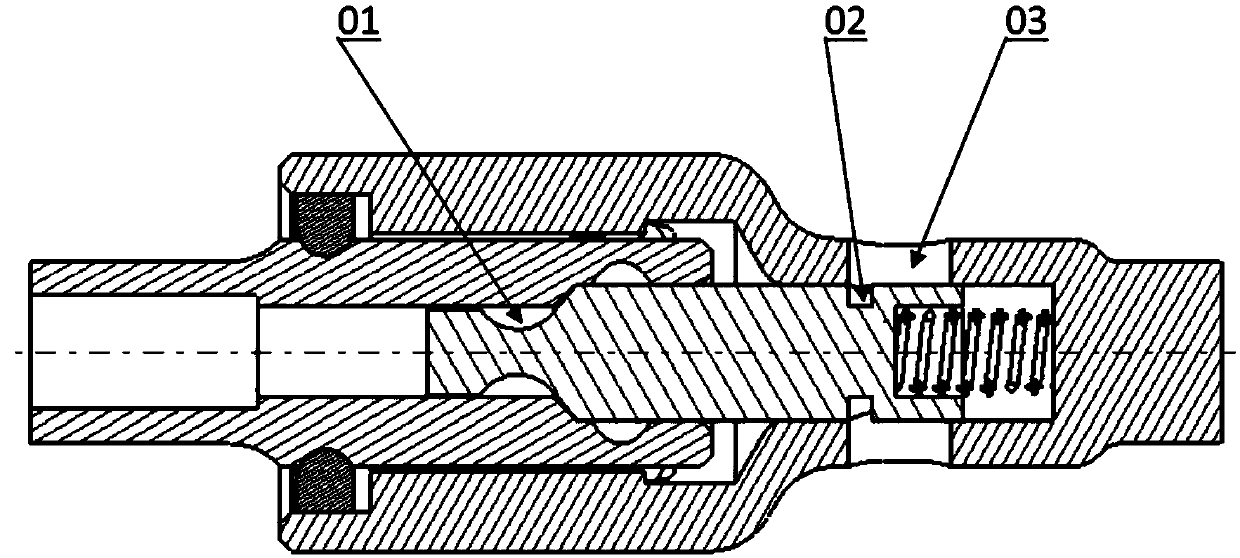

[0022] see Figure 1 to Figure 4 As shown, it is a steering transmission shaft connection structure provided by the embodiment of the present invention, and its purpose is to flexibly connect the upper and lower two transmission shafts. Wherein, the lower transmission shaft 1 is connected to the steering gear through a universal joint, and the upper transmission shaft 7 is connected to the steering wheel through a universal joint.

[0023] Specifically, it includes: a self-locking pin 5 , the self-locking pin 5 is provided with a plurality of circular grooves 01 in the circumferential direction, and the circular grooves 01 are used to accommodate the self-locking steel ball 4 .

[0024] The upper transmission shaft 7 has a connecting sleeve at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com