355MPa-grade maritime work steel plate for polar region and preparation method of 355MPa-grade maritime work steel plate

A steel plate and grade technology, applied in the field of 355MPa polar marine steel plate and its preparation, to achieve fine and uniform grain, improve low temperature toughness, ensure welding performance and welding crack sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

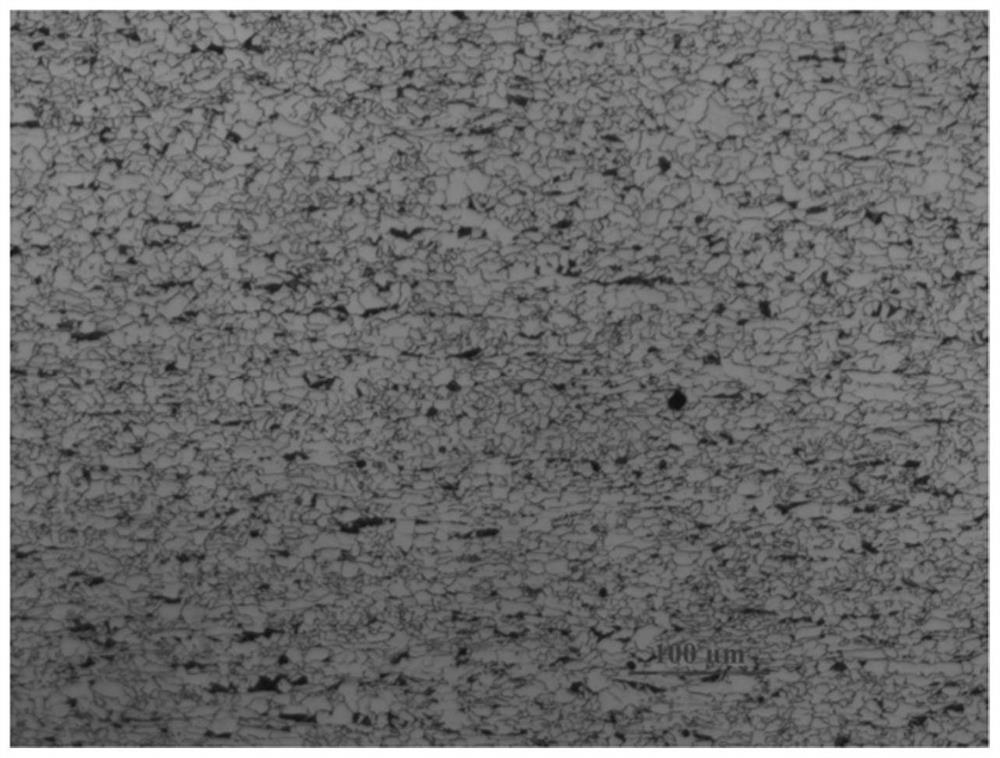

Image

Examples

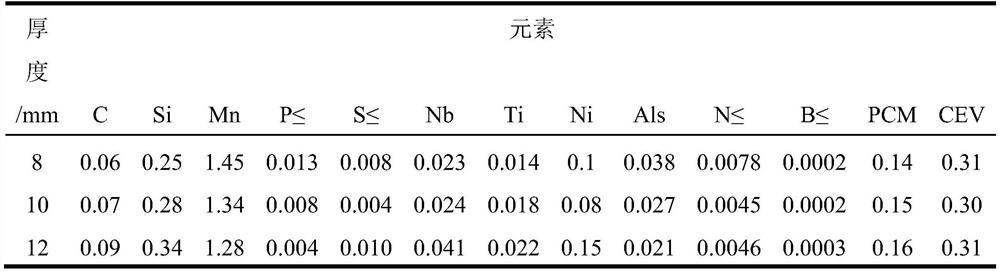

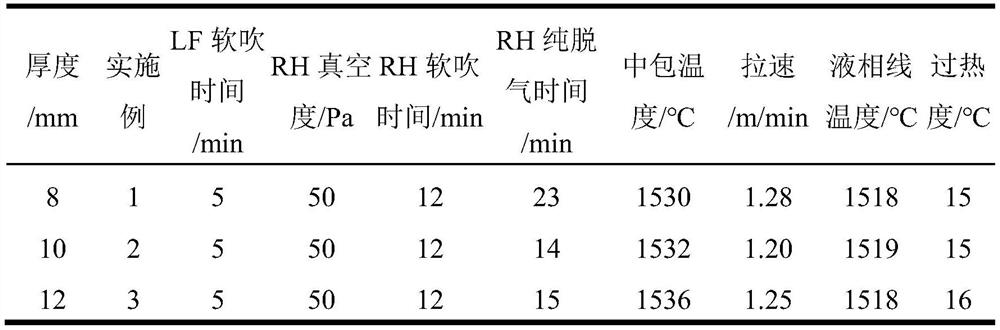

Embodiment 1-3

[0054] The invention provides a 355MPa grade polar marine steel plate and a preparation method thereof;

[0055] The production process is as follows:

[0056] Blast furnace molten iron—hot metal pretreatment (desulfurization)—converter or electric furnace primary refining—LF refining—RH refining—slab continuous casting—slab slow cooling—slab cleaning—slab reheating—high-pressure water descaling—rolling (coarse) Rolling under high pressure of rolling mill, temperature-controlled rolling of finishing mill) - air cooling - slow cooling of steel plate stacking - flaw detection - sampling and inspection - storage

[0057] 1) Smelting

[0058] KR pretreatment is used to pretreat and desulfurize molten iron into the furnace, and the slag on the surface of molten iron is removed after desulfurization; high-quality scrap steel is used, and the amount of scrap steel added does not exceed 8% of the total charge; the obtained molten iron and scrap steel are re-blown at the top and botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com