Special tool for cleaning special-shaped spinneret orifice

A special tool and spinneret technology, applied in spinneret assemblies, textiles and papermaking, etc., can solve the problems of small aperture or pores, difficult to clean, etc., and achieve the effect of meeting the requirements of toughness and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

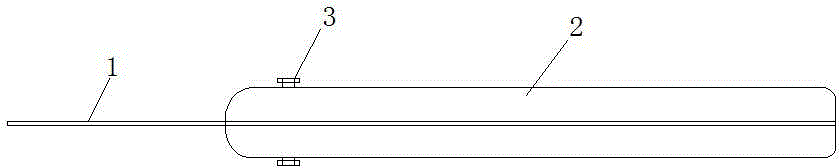

[0011] like figure 1 As shown, a special tool for cleaning special-shaped spinneret holes is characterized in that it includes a through needle 1 and an operating rod 2, and one end of the through needle 1 extends into the end of the operating rod 2 and is fixed by a screw. There are 2 screw holes at one end of the operating rod, and there is a gap in the middle of the screw holes, and the micro-through needle is placed in the middle of the gap and fixed with screws.

[0012] The thickness of the through needle 1 is 0.06mm, the width of the through needle is 0.12mm, and the length of the through needle is 25mm, so that it can be easily inserted into the spinneret hole.

[0013] The through needle 1 is a silver needle, and the miniature through needle is made of silver, which meets the toughness and thickness requirements.

[0014] The length of the operating rod 2 is 70 mm, which satisfies the operability of the operator.

[0015] Using this special tool, turn the spinneret’...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com