Patents

Literature

214results about How to "Meet thickness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

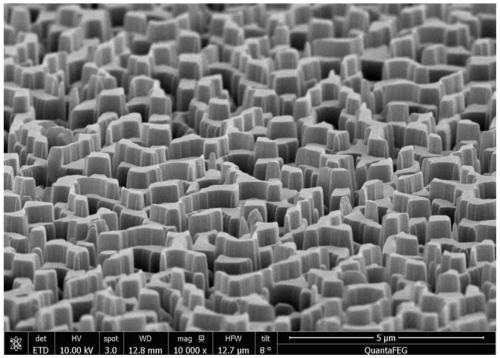

Explosive painting process of preparing heat barrier coating

InactiveCN1416964AImprove bindingFast depositionLiquid surface applicatorsMolten spray coatingHardnessAlloy

The present invention is explosive coating process of preparing heat barrier coatings. Of the coating, the connecting layer comprises MCrAlY alloy system, where M is Ni and / or Co; and the ceramic layer has the ZrO2-8Y2O3 components. The specific operations include hexahedral explosive coating controlling the base material temperature at 100-200 deg.c, coating the connecting layer and the ceramic layer successively to obtain the heat barrier coatings. The specific operation parameters for forming the connecting layer and the ceramic layer are provided. Between the connecting layer and the ceramic layer, one transition layer including two components of both connecting layer and ceramic layer may be increased. The present invention may obtain completely antioxidant coatings with high hardness and high heat insulating effect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

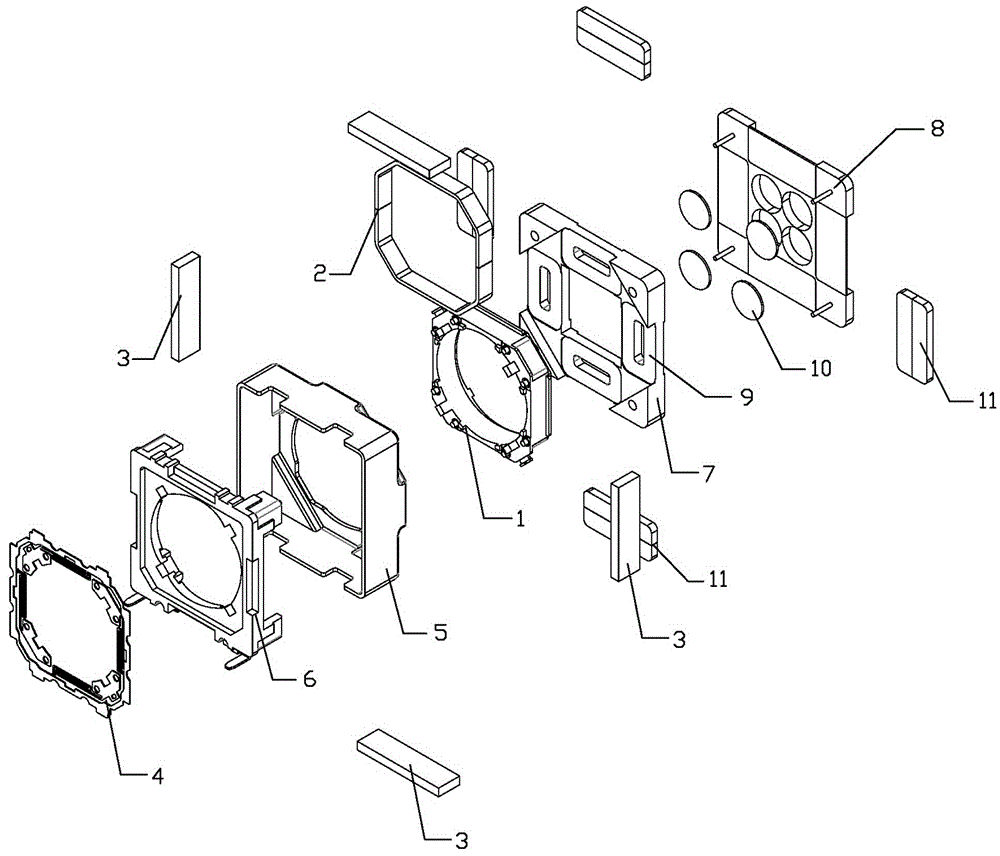

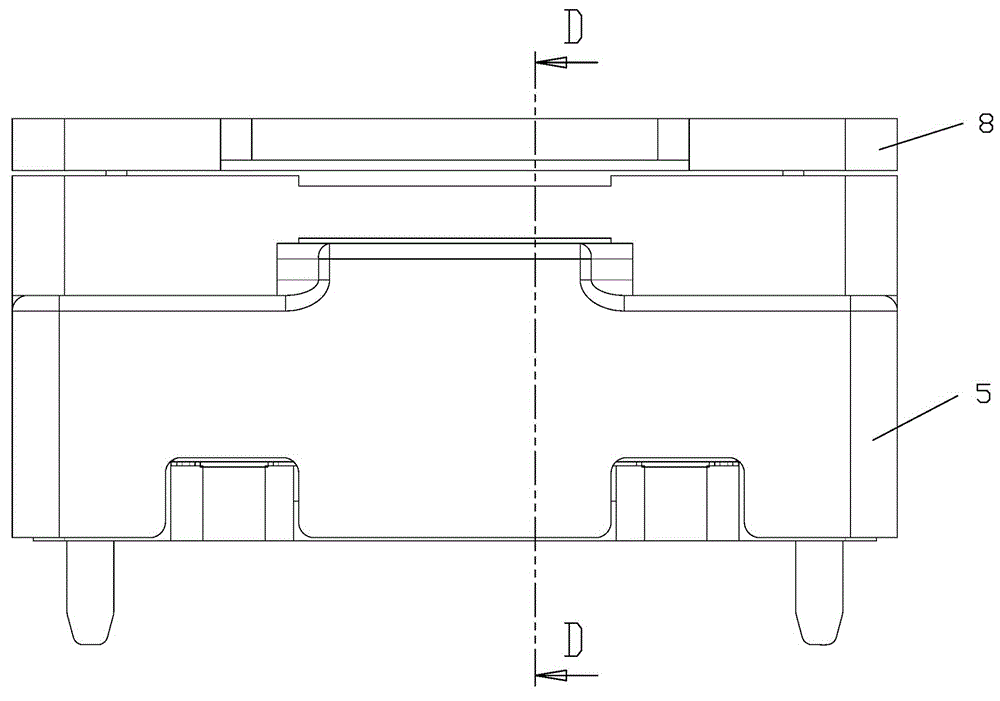

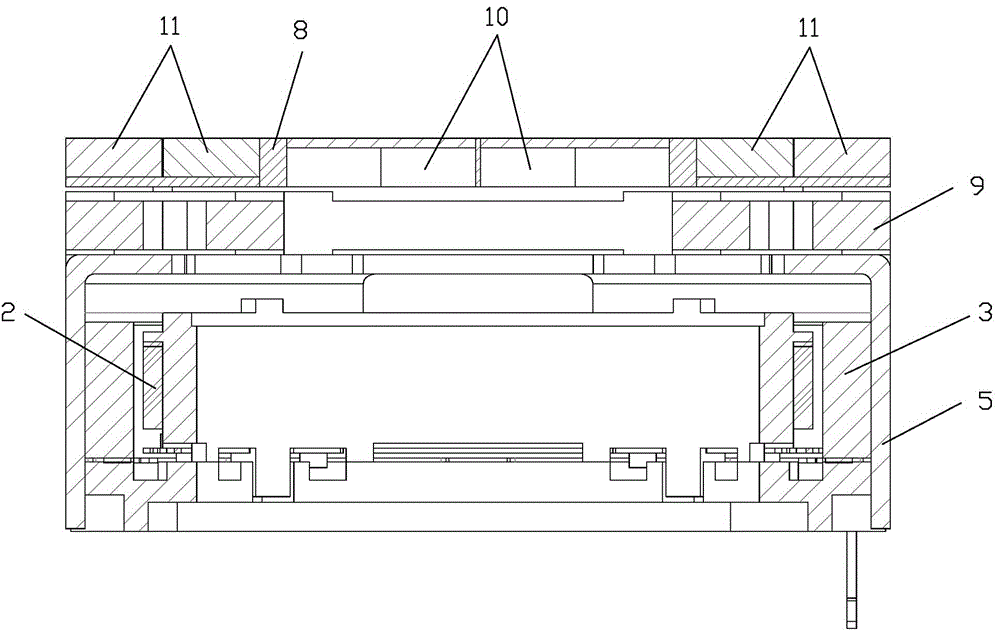

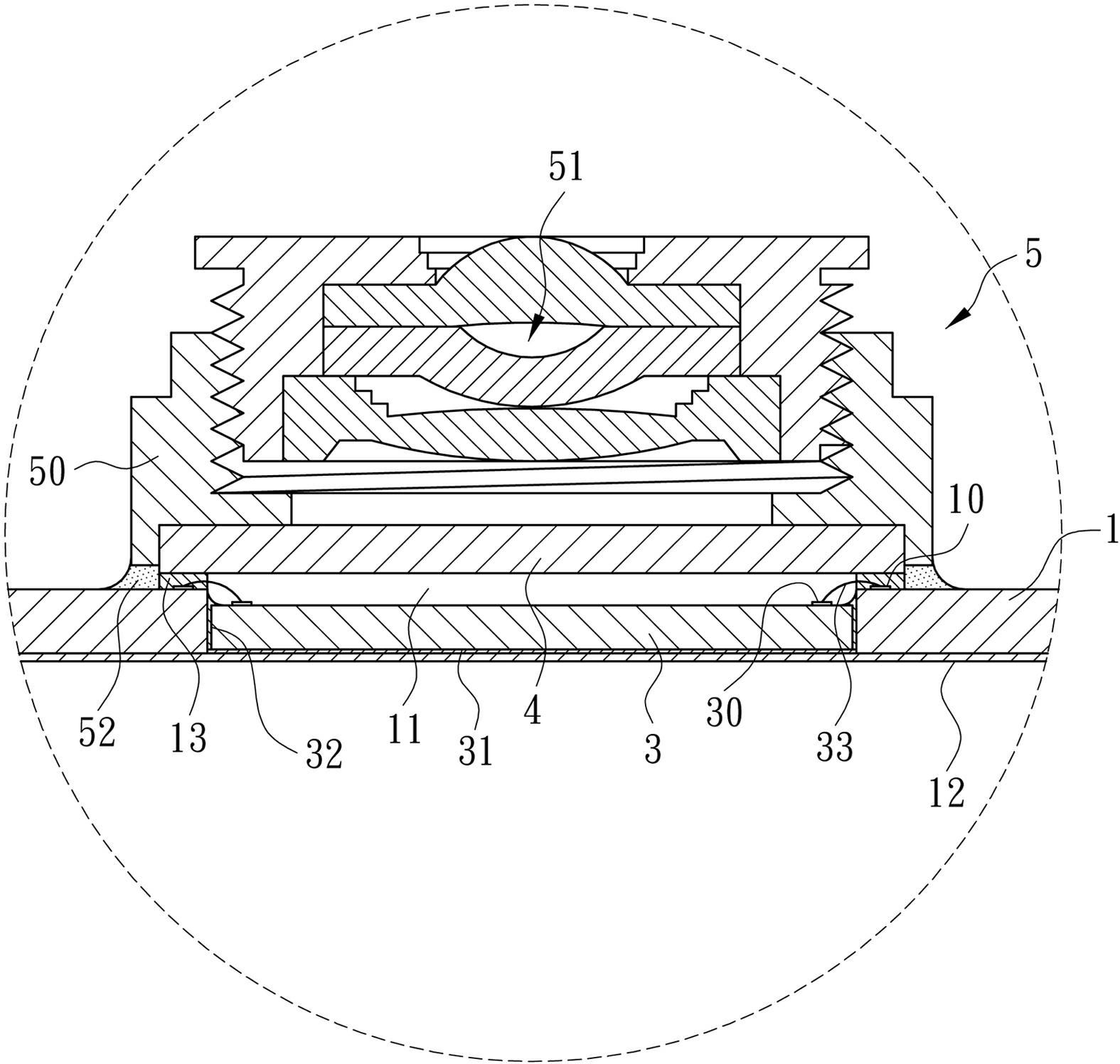

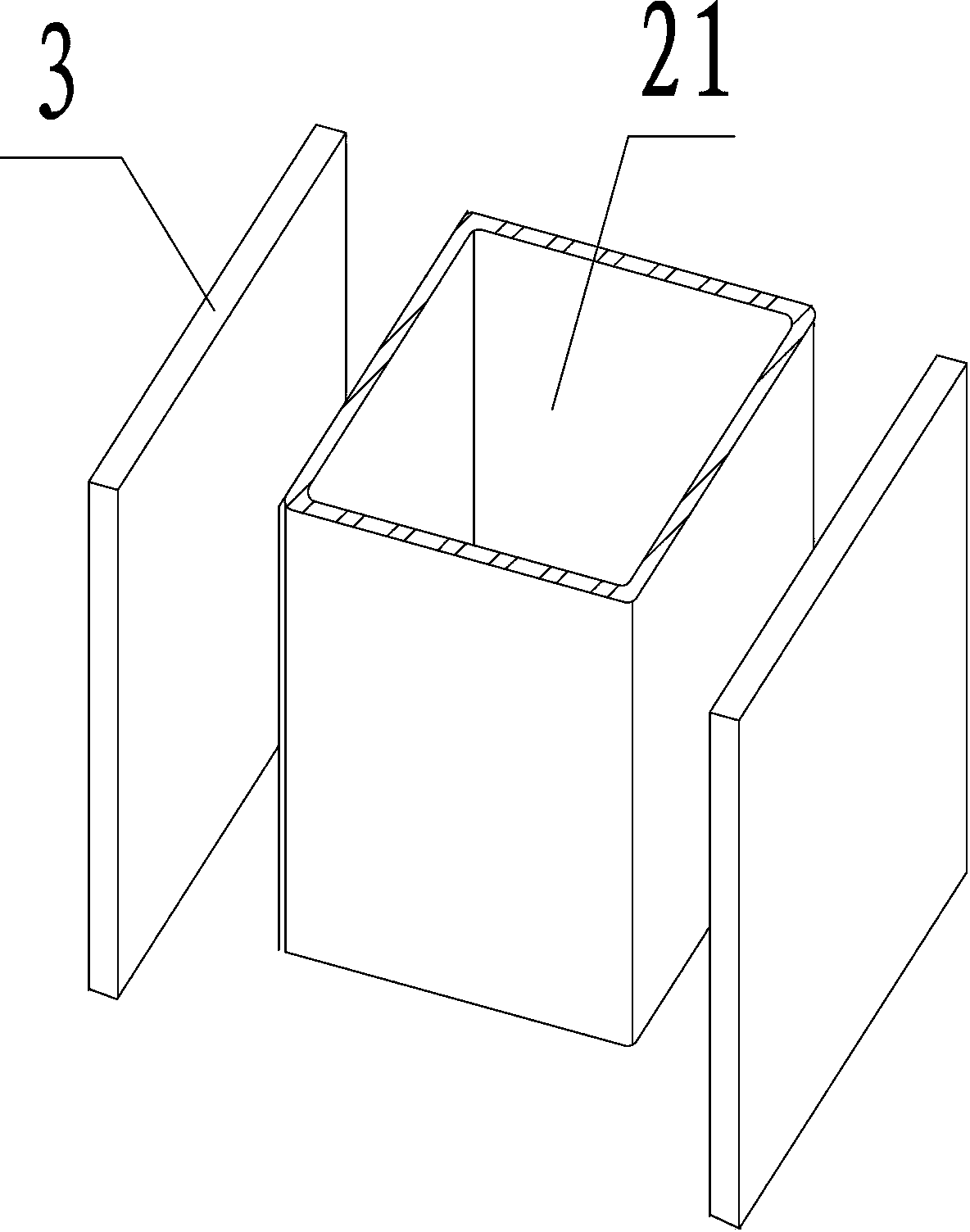

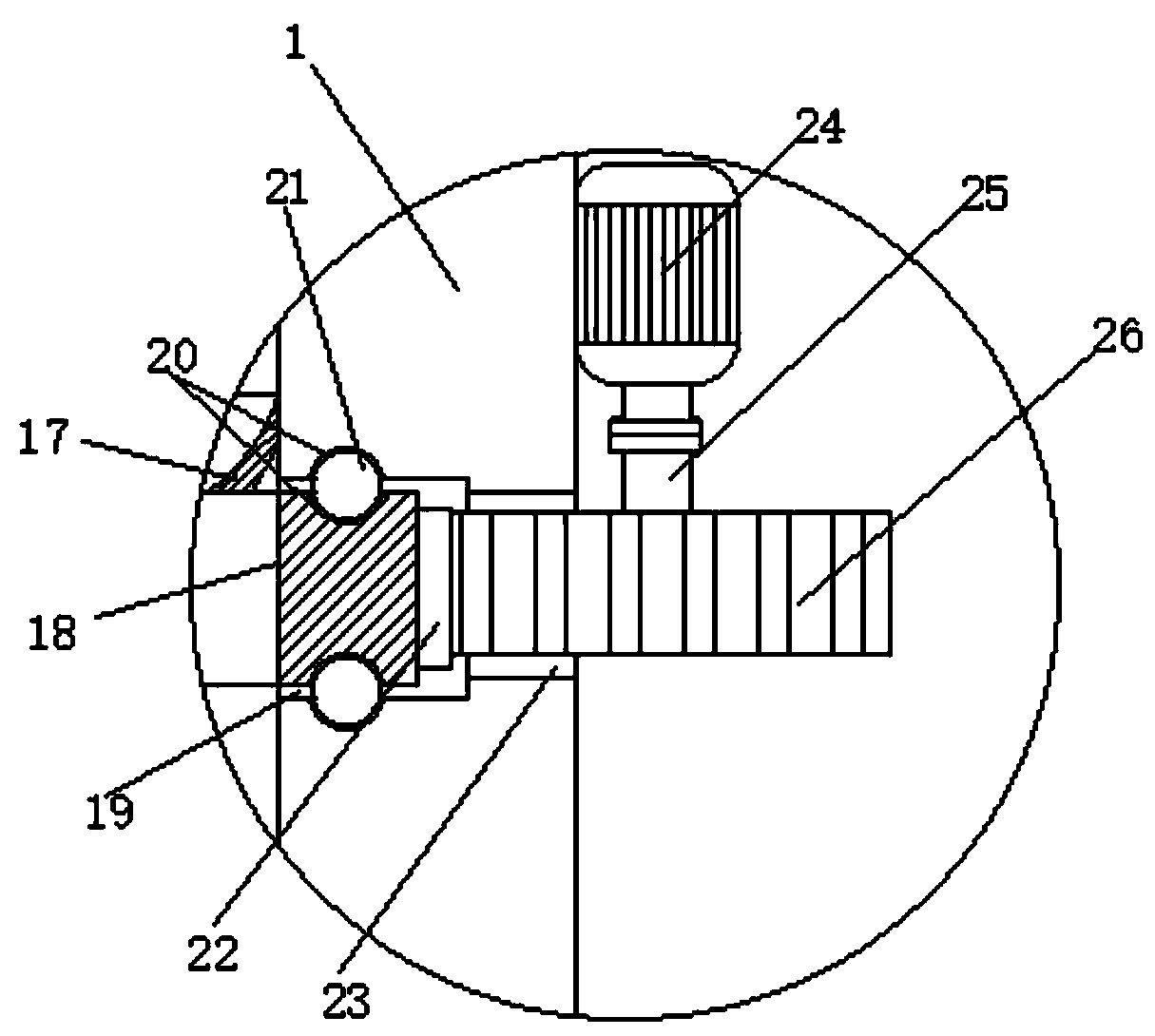

Focusing motor capable of achieving optical zooming and optical vibration prevention at the same time

ActiveCN104020546ADifferent shooting effectsMeet thickness requirementsPrintersProjectorsAutofocusMobile device

The invention discloses a focusing motor capable of achieving optical zooming and optical vibration prevention at the same time. A multi-time optical zooming device is arranged at the magnet yoke end of an automatic focusing motor body and comprises but not limited to a transversely-moving coil assembly, a support, a magnet set and a lens assembly, wherein the transversely-moving coil assembly is installed on the magnetic yoke end face, the support is movably connected with the transversely-moving coil assembly, and the magnet set and the lens assembly are fixed to the support. The transversely-moving coil assembly and the magnet set act on each other to control the support to perform multi-axial movement in a plane parallel to the transversely-moving coil assembly. The focusing motor is small in size, low in cost, good in vibration prevention effect and capable of achieving multi-time optical zooming, and can sufficiently meet demands of existing ultra-light and ultra-thin intelligent portable mobile devices.

Owner:成都易迅光电科技有限公司

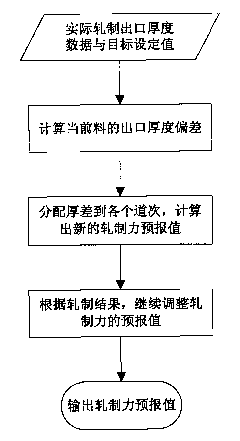

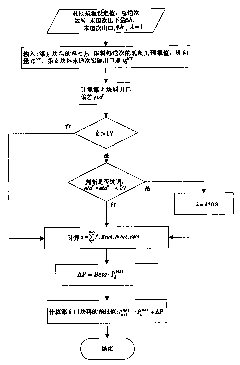

Secondary control rolling force forecasting method of hot mill

InactiveCN101797588ASolve the rolling force setting problemMeet thickness requirementsRoll force/gap control deviceWeight coefficientControl system

The invention provides a secondary control rolling force forecasting method of a hot mill, which is suitable for various objects to supply material and various regulations to roll, utilizes the historical data of the rolling process to forecast the rolling force of each pass of subsequent supplied material. For the rolling of the same material and same regulation, the forecasting method is designed on the basis of the rolling result of a previous strip, i.e. the deviate of the practical outlet thickness and the set target outlet thickness of the strip last pass. In the method, thickness difference is successively distributed on each pass according to certain group of weight coefficients, and then, the adjusting amount of the rolling force of each pass is determined; deviation is eliminated by adjusting the rolling force predicted value of all passes; after adjusted for limited times, reasonable rolling force predicted value is given. The method of the invention simply and effectively solves the problem of setting rolling force in a secondary control system under the existing rolling condition and level.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

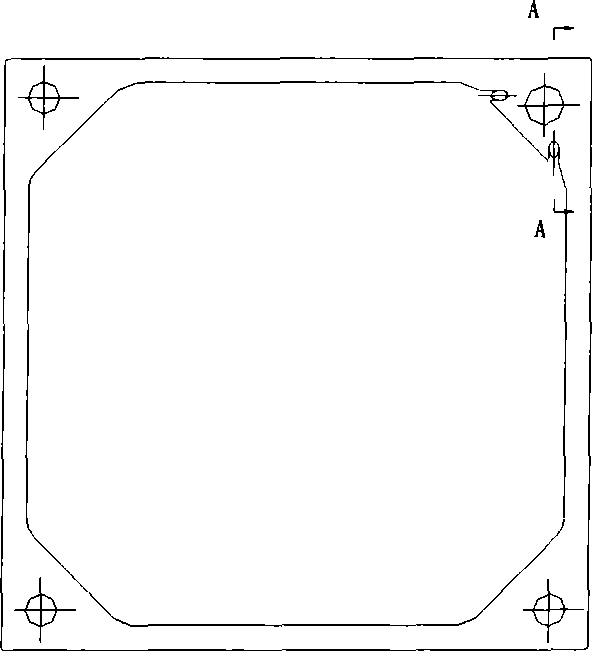

Fillet feeding diaphragm filter plate assembly constituted by flat membrane and filter board

InactiveCN101385913AFully filteredImprove cleaning rateFiltration separationBiochemical engineeringSlurry

The invention relates to a corner membrane filter plate assembly which comprises the flat membrane filter plate and the filter cloth filter plate. Both the flat membrane filter plate and the filter cloth filter plate are single-corner feeding through holes and are arranged in cross banding. The corner membrane filter plate assembly has the advantages that: 1. portholes have self-cleaning function, thus being capable of keeping the portholes smooth without obstacles; 2. rapid filter of slurry is realized; 3. a filter cake can be convenient to be washed either in a forward direction or a reverse direction, therefore, the filtering ratio of effective components in filtered slurry is greatly increased, and a feeding pump and a washing pump can share a pump; 4. by adjusting the thickness of a core board, the requirements for the thickness of the filter cake from different materials can be met; 5. a supporting lug boss can be arranged on the membrane filter plate or no supporting lug boss is arranged on the membrane filter plate; 6. no filter cloth is installed on the flat membrane filter plate.

Owner:HANGZHOU XINGYUAN FILTER TECH

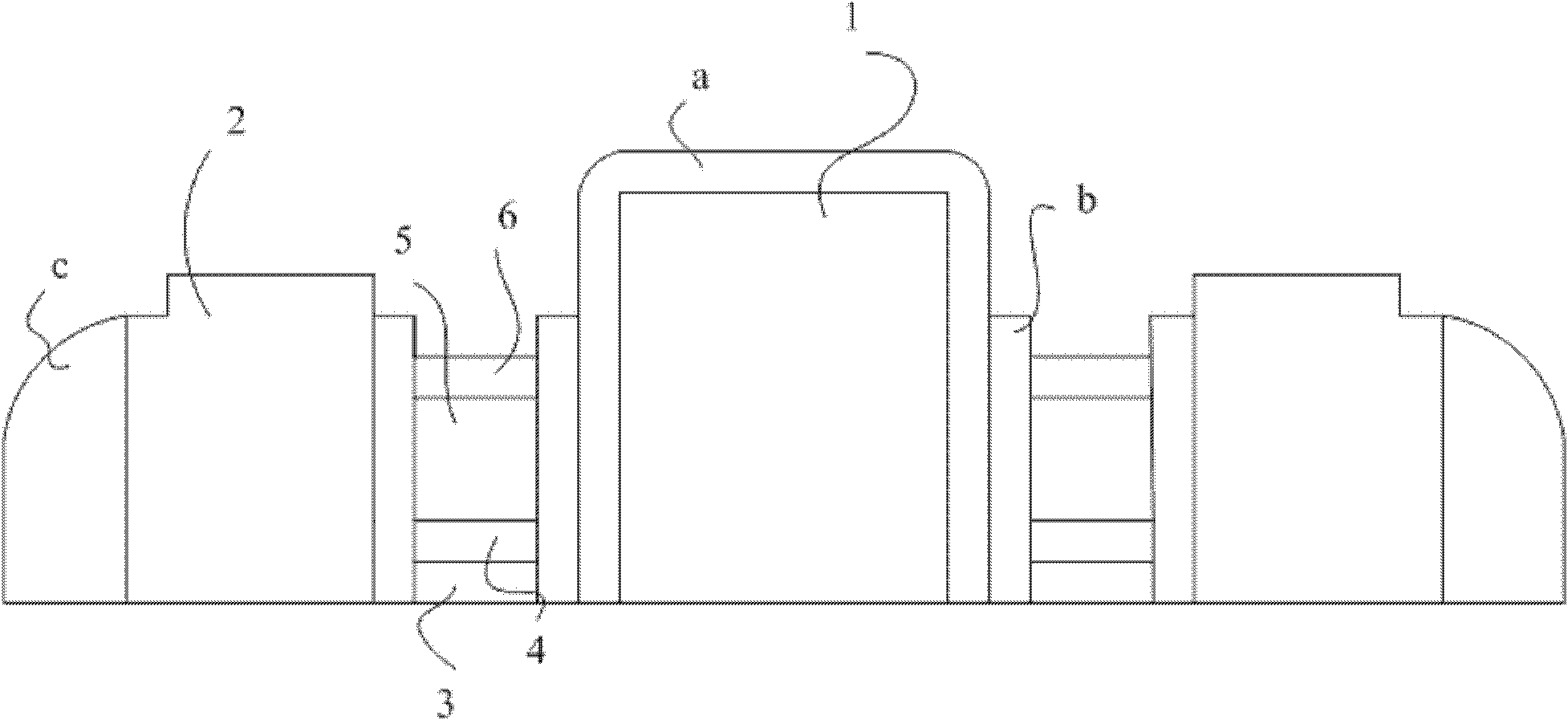

Flash memory and manufacturing method thereof as well as formation method of grids in different thicknesses

ActiveCN103021951AHigh speedHigh densitySolid-state devicesSemiconductor/solid-state device manufacturingHigh voltage transistorsMechanical milling

The invention provides a manufacturing method of a separate grid type flash memory used for an embedded logic circuit. Compared with a formation method of an individual separate grid type flash memory, the manufacturing method provided by the invention has the advantage that the separate grid type flash memory, a high voltage transistor and a logic transistor can be manufactured on one integrated circuit at the same time only by realizing formation of the grids in different thicknesses in an embedded separate grid type flash memory by virtue of chemical mechanical milling on two-layer polycrystalline silicon and oxidation of polycrystalline silicon, so that densities of the separate grid type flash memory, the high voltage transistor and the logic transistor can be increased, integration degree is high, operating speed is higher, and an integrated chip is smaller, so that cost of the whole integrated chip is reduced. The invention also provides a separate grid type flash memory used for the embedded logic circuit and a method for forming the grids in different thicknesses.

Owner:SEMICON MFG INT (SHANGHAI) CORP

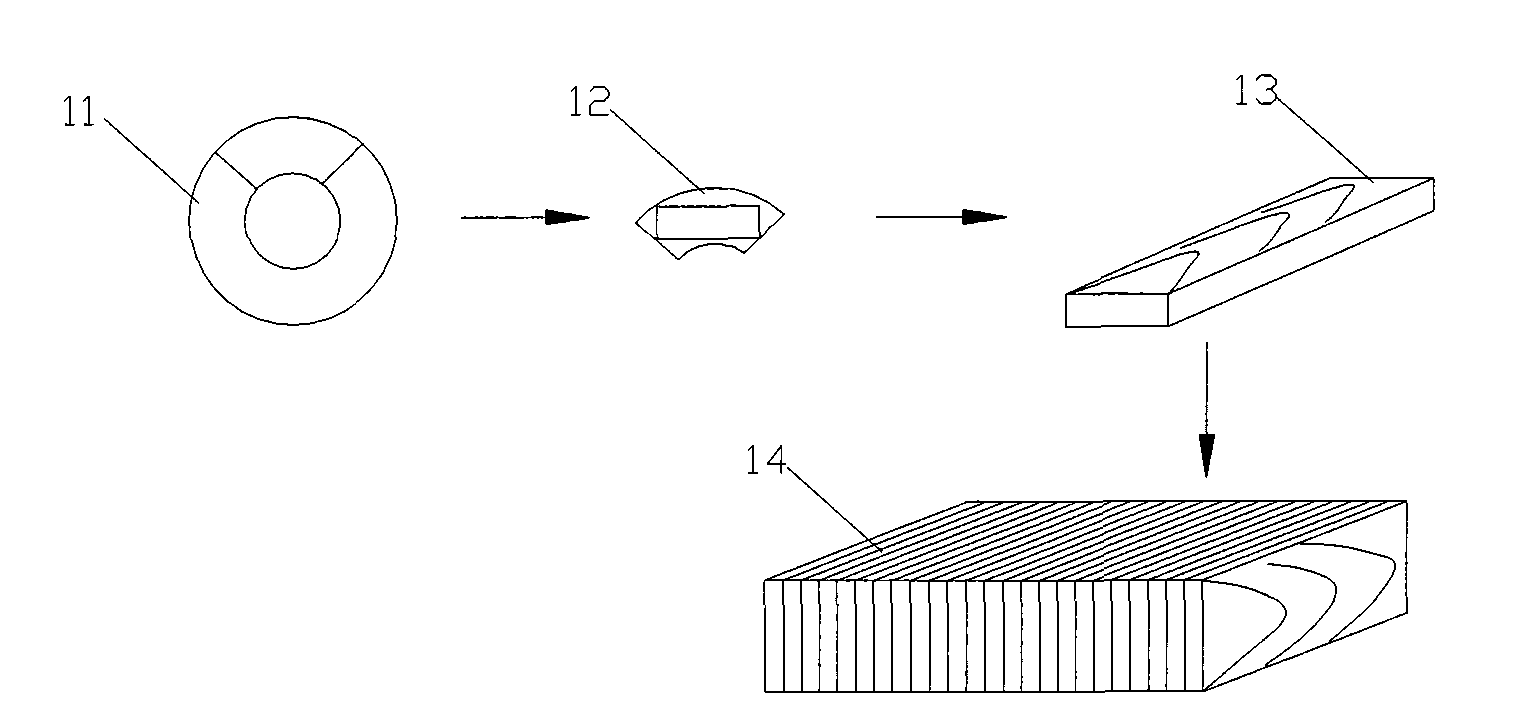

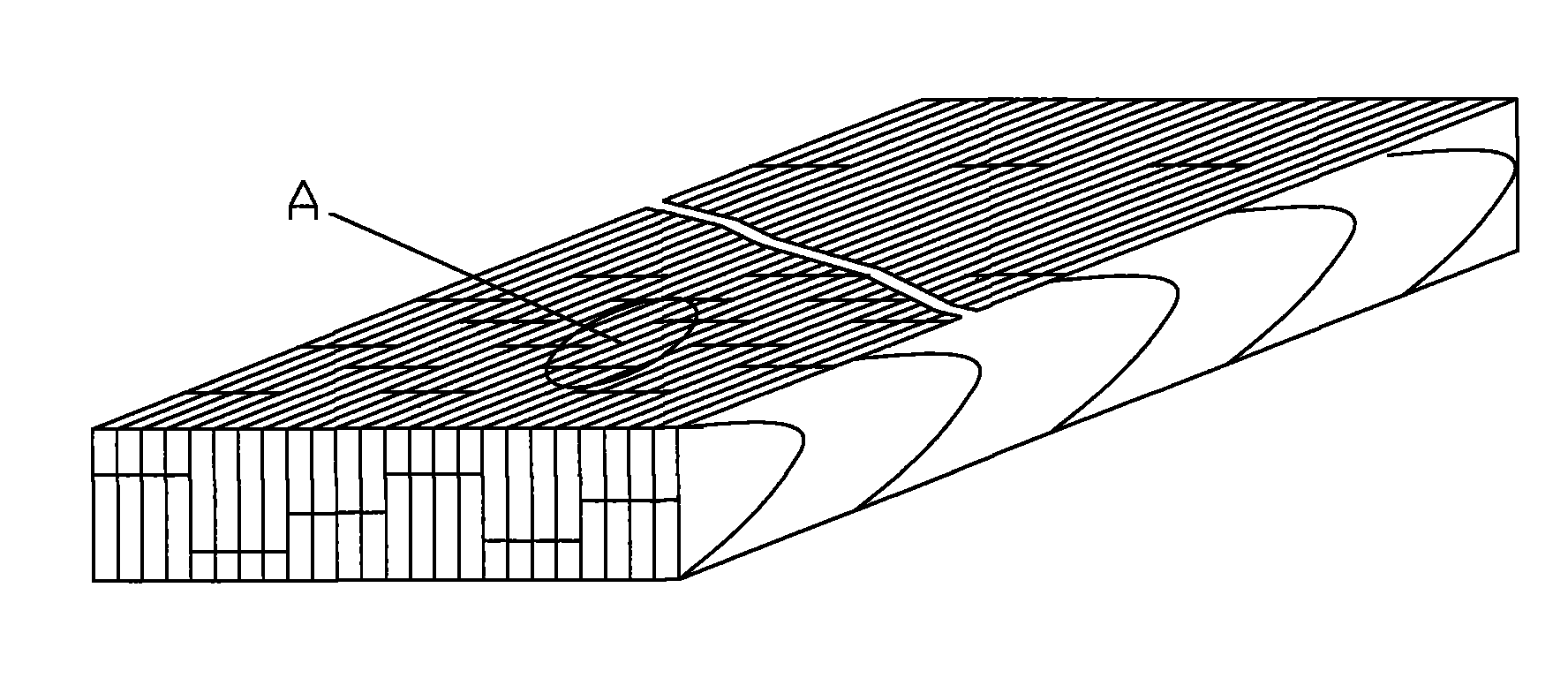

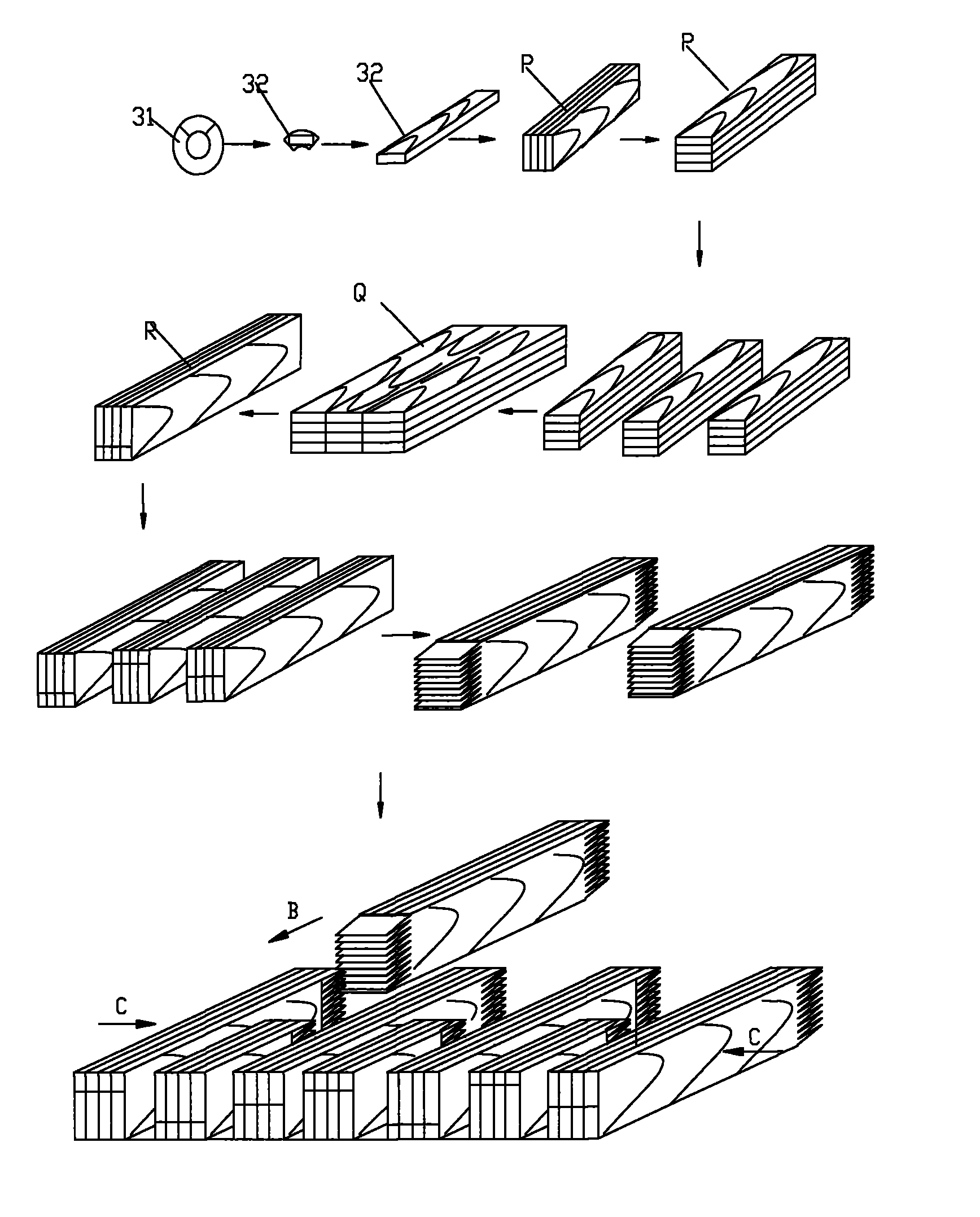

Glued laminated bamboo floor and manufacturing method thereof

ActiveCN101891047AReduce consumptionMeet the use requirementsBio-packagingLarge containersEngineeringBamboo floor

The invention discloses a method for manufacturing glued laminated bamboo floors. The bamboo is applied to containers, so the consumption of wood resources in inland container floors is reduced, the use requirement of the container floors is better met, and the manufacturing cost of the container floors is reduced; meanwhile, an intermittent continuous production method is adopted, so the method for manufacturing the glued laminated bamboo floors can produce various specifications of inland container floors, and better meets the requirements on the strength and fatigue resistance of the inland container floors.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

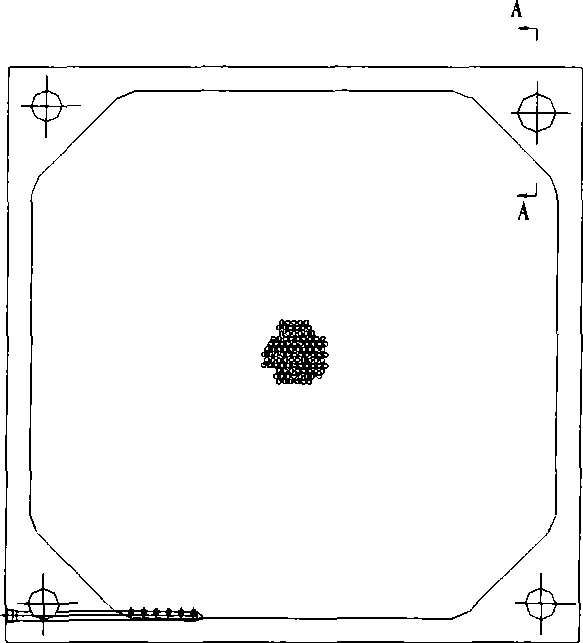

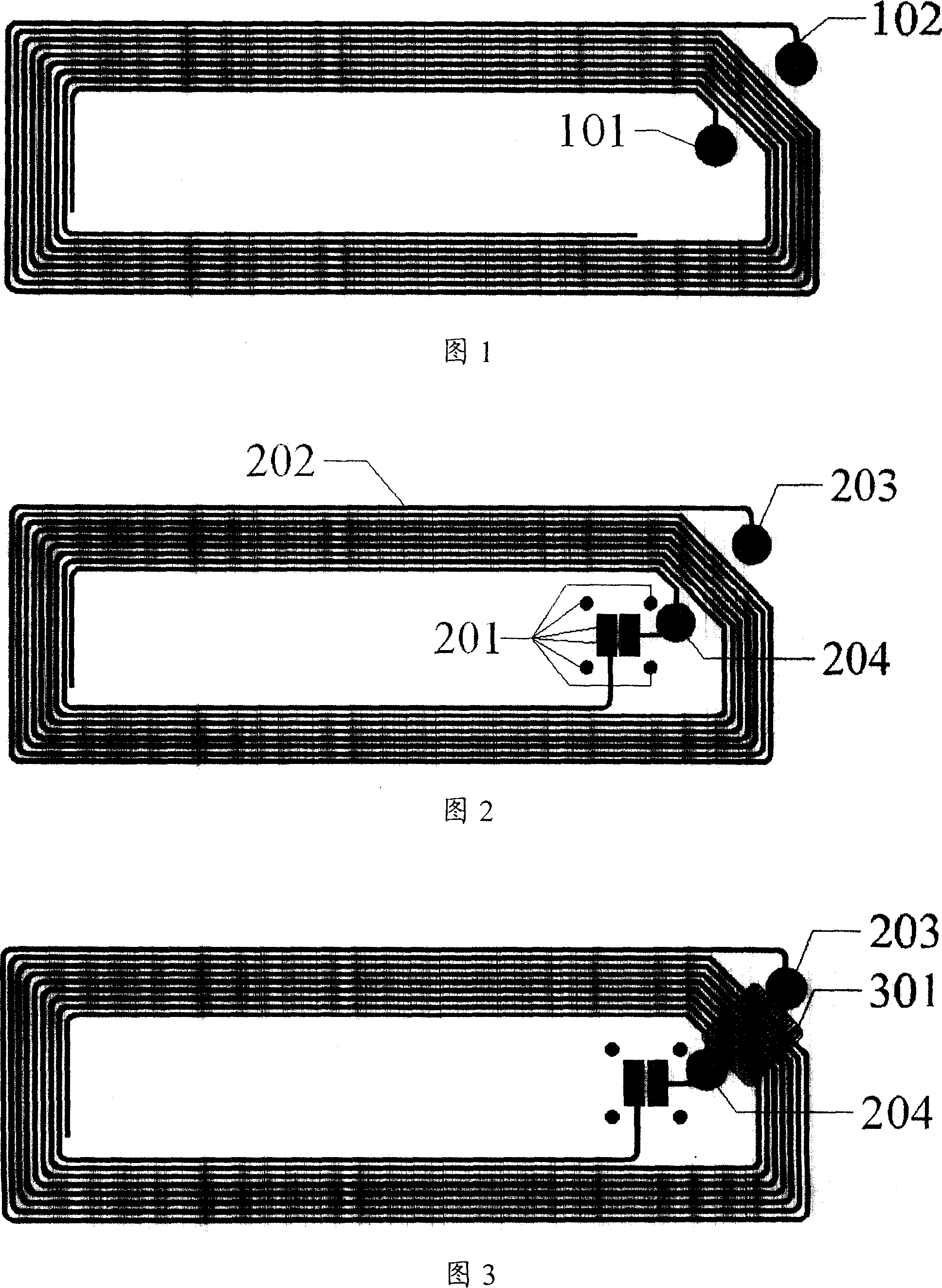

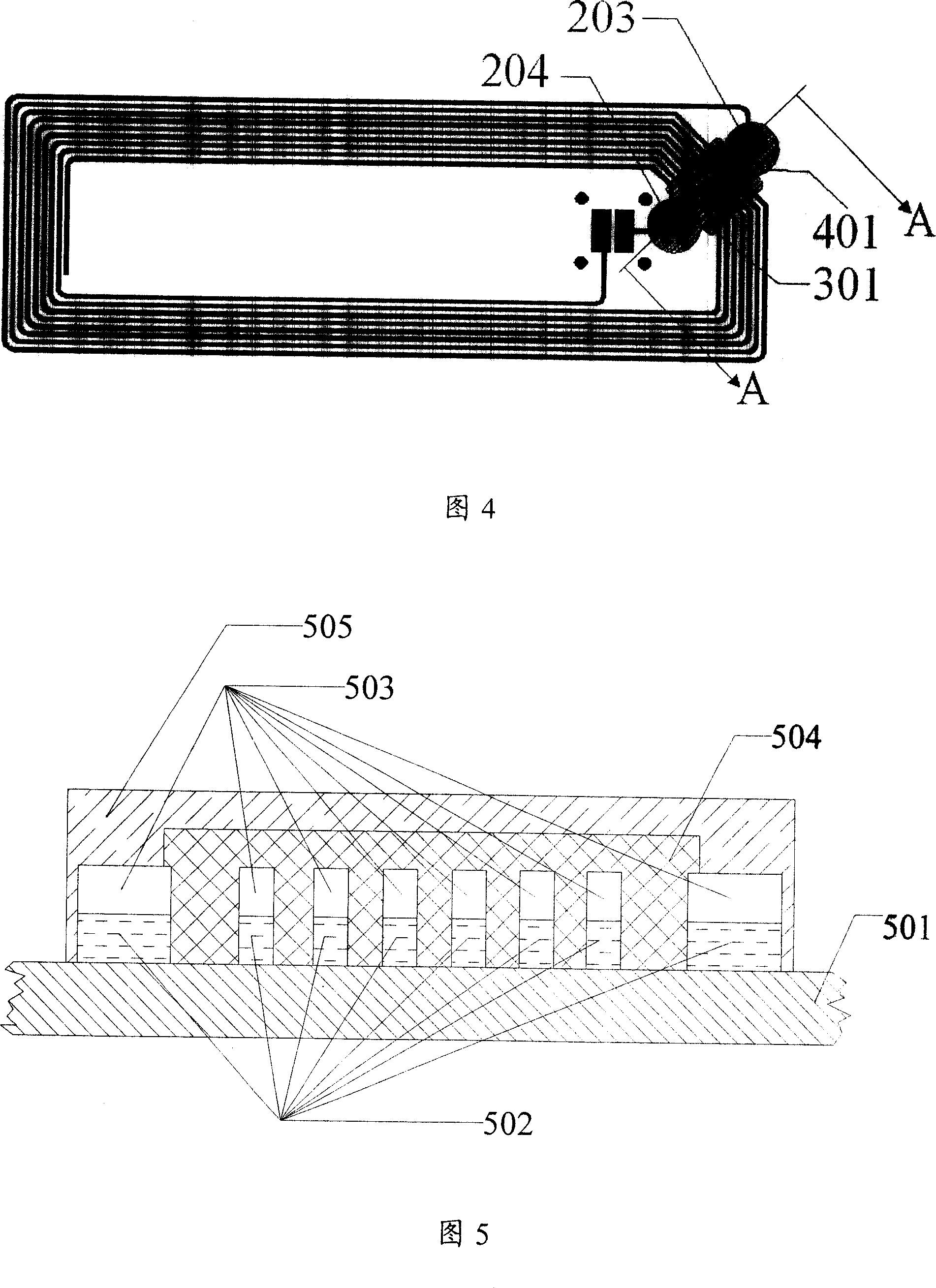

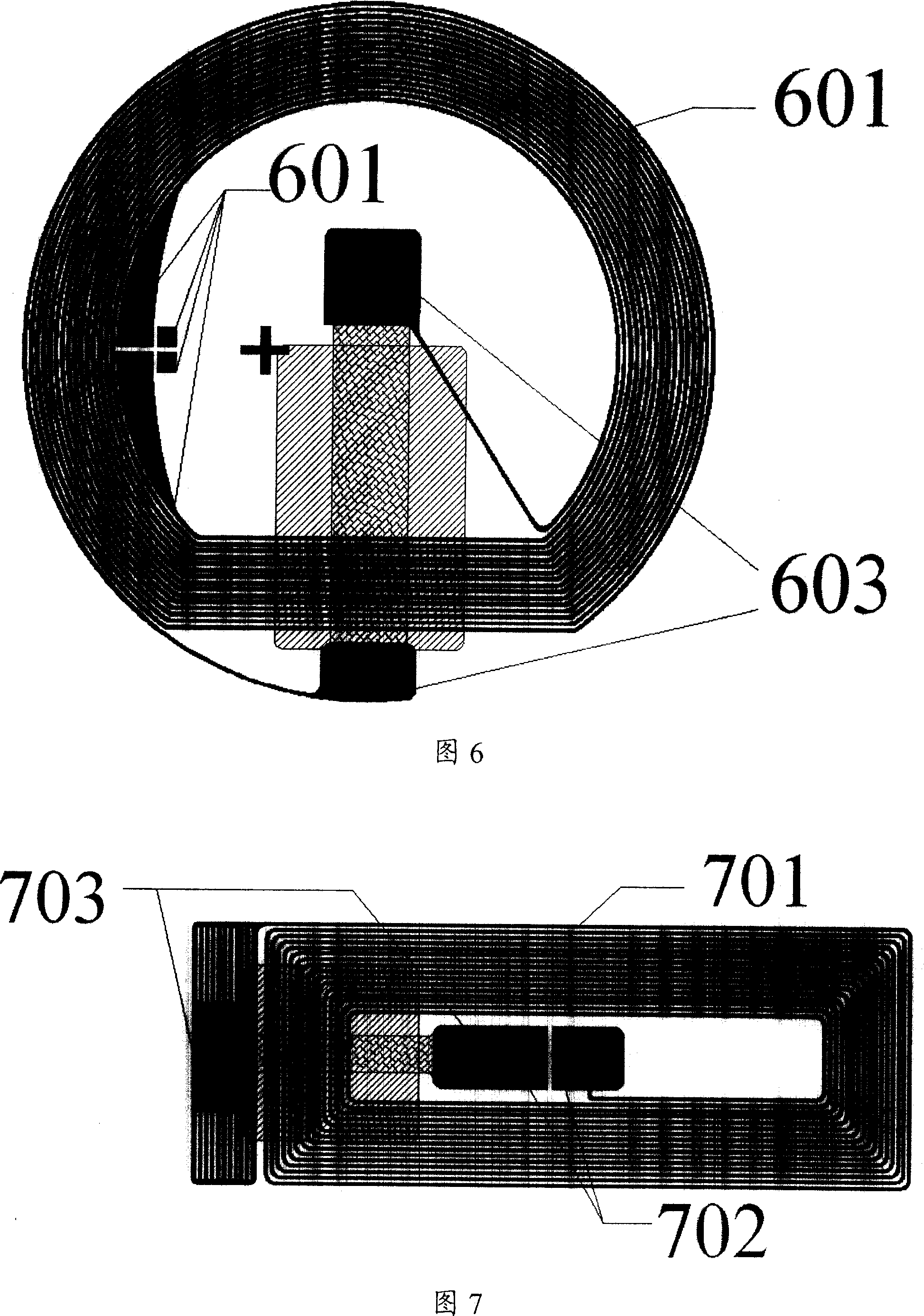

RF antenna, electronic label and method for making RF antenna

InactiveCN101087038AReduce thicknessFirmly connectedRadiating elements structural formsConductive pattern formationRadio frequencyElectron

The invention discloses a method of producing radio-frequency antenna which includes: etching loop and position for integrated circuit which is connected with loop; producing gap bridge of said antenna to accomplish production of radio-frequency antenna. The invention also discloses a radio-frequency antenna which includes loop, Gap Bridge, insulating layer, and position for integrated circuit, said position for integrated circuit is connected with loop. The invention also discloses an electronic mark which adopts said radio-frequency antenna. By adopting the invention, thickness of electronic mark can be decreased effectively; reliability of integrated circuit chip, Gap Bridge and antenna connection can be increased.

Owner:陈栋栋

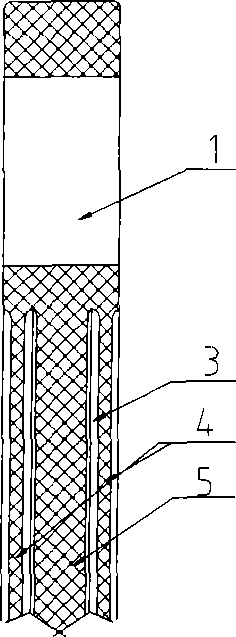

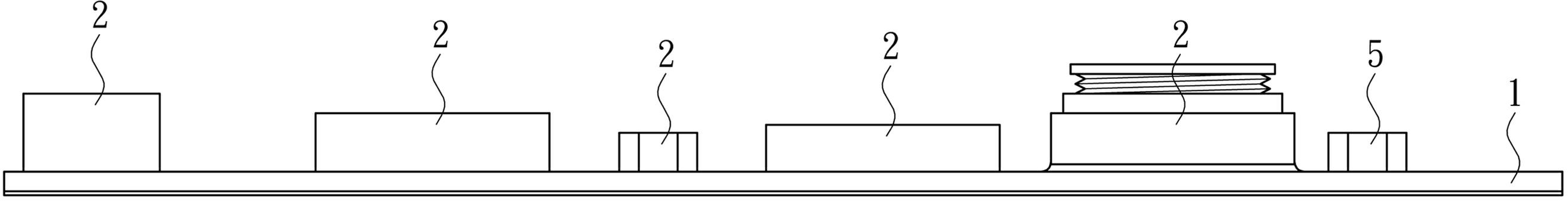

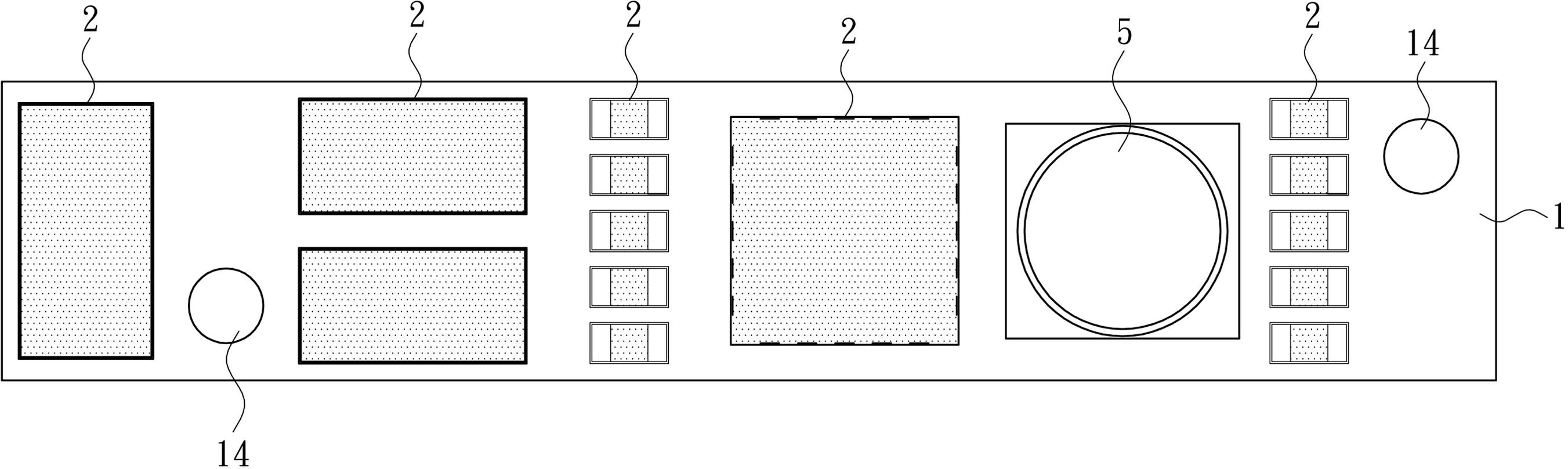

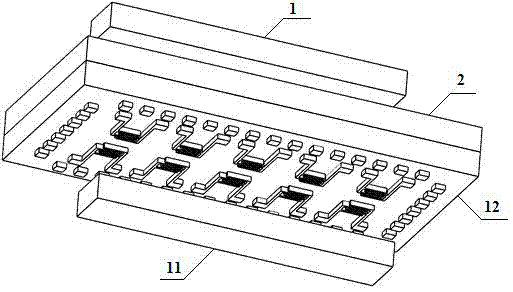

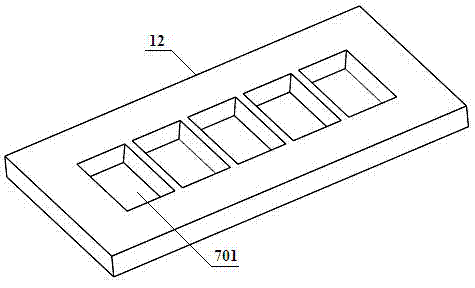

Thinned image capture module and manufacturing method thereof

InactiveCN102593116AThe overall thickness is thinMeet the thickness requirementsTelevision system detailsSolid-state devicesLight sensingElectrical connection

The invention relates to a thinned image capture module and a manufacturing method of the thinned image capture module. The structure comprises a printed circuit board which is provided with a plurality of electronic components; a light-sensing component is packaged on the printed circuit board; a lens is arranged on the light-sensing component to capture an image. The manufacturing method comprises the steps of manufacturing the printed circuit board, tapping a hole on the printed circuit board, adhering a metal film, packaging the light-sensing component and packaging an electronic surface. The manufacturing method specifically comprises the following steps of: manufacturing the printed circuit board and then tapping the hole; adhering the metal film at the back side to cover the hole; packaging the light-sensing component; and packaging the plurality of electronic components on the electronic surface. The overall thickness of the whole image capture module is reduced so as to meet the thickness demand of a thin type notebook computer shell, and the light-sensing component can be stably combined to the printed circuit board so as to prevent from breaking a gold wire in electrical connection due to displacement of the light-sensing component.

Owner:陈淑姿

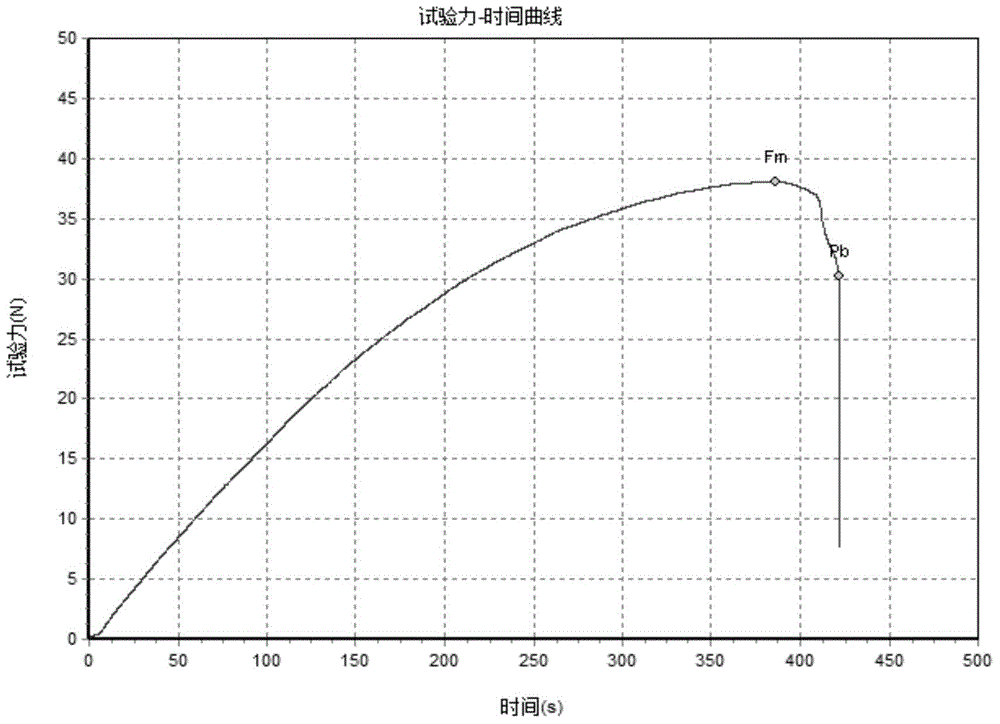

Steel rolling method and steel obtained through method

ActiveCN105855299AReduce thicknessMeet thickness requirementsTemperature control deviceWork treatment devicesMicrometerMetallurgy

Owner:SUZHOU SUXIN SPECIAL STEEL +2

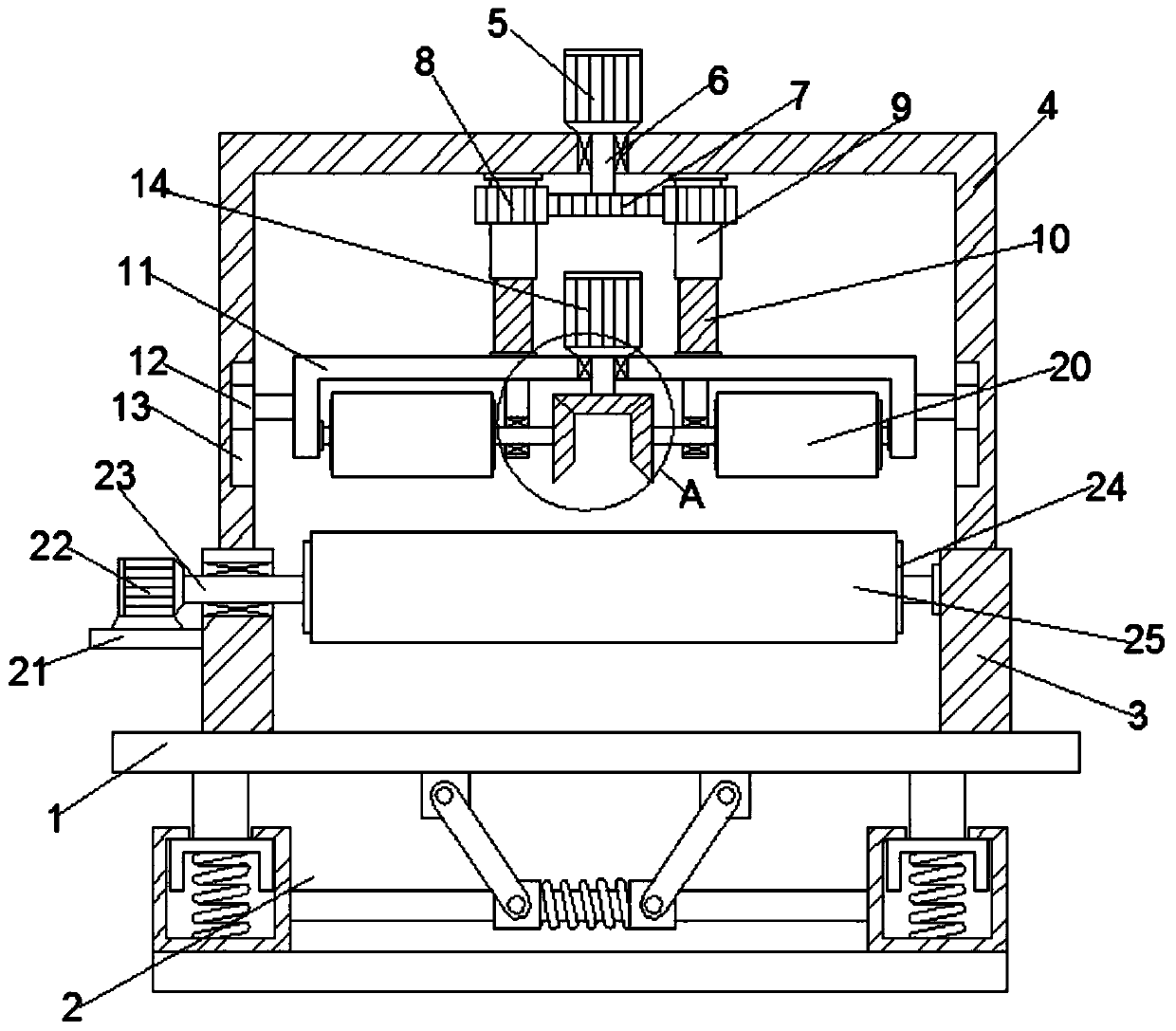

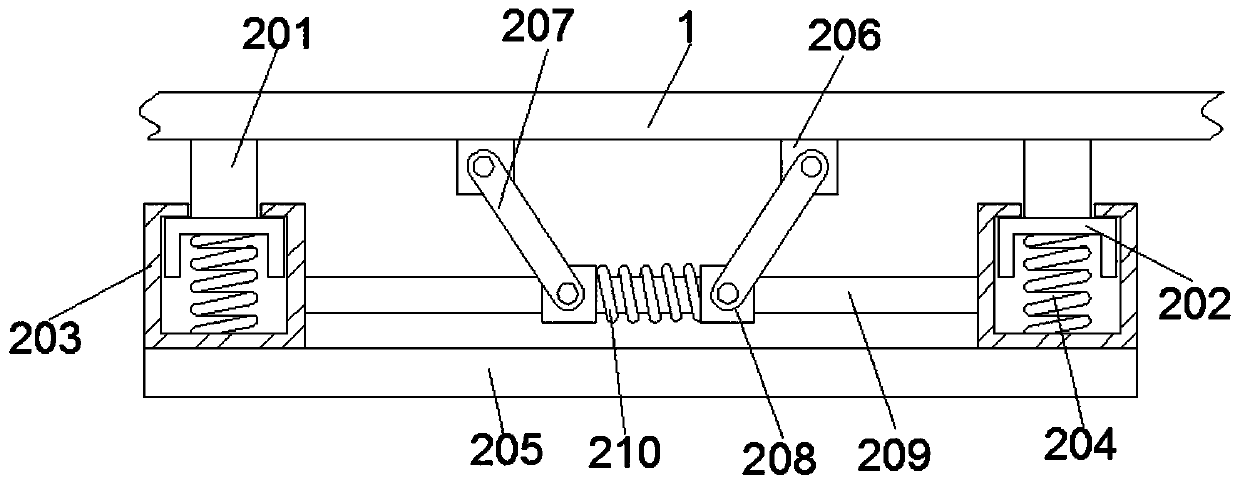

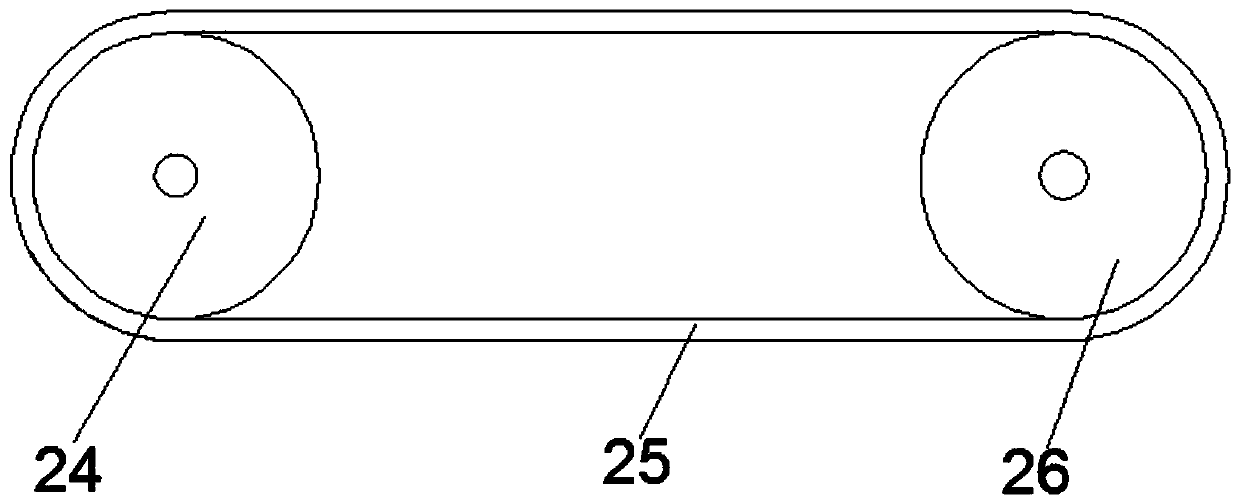

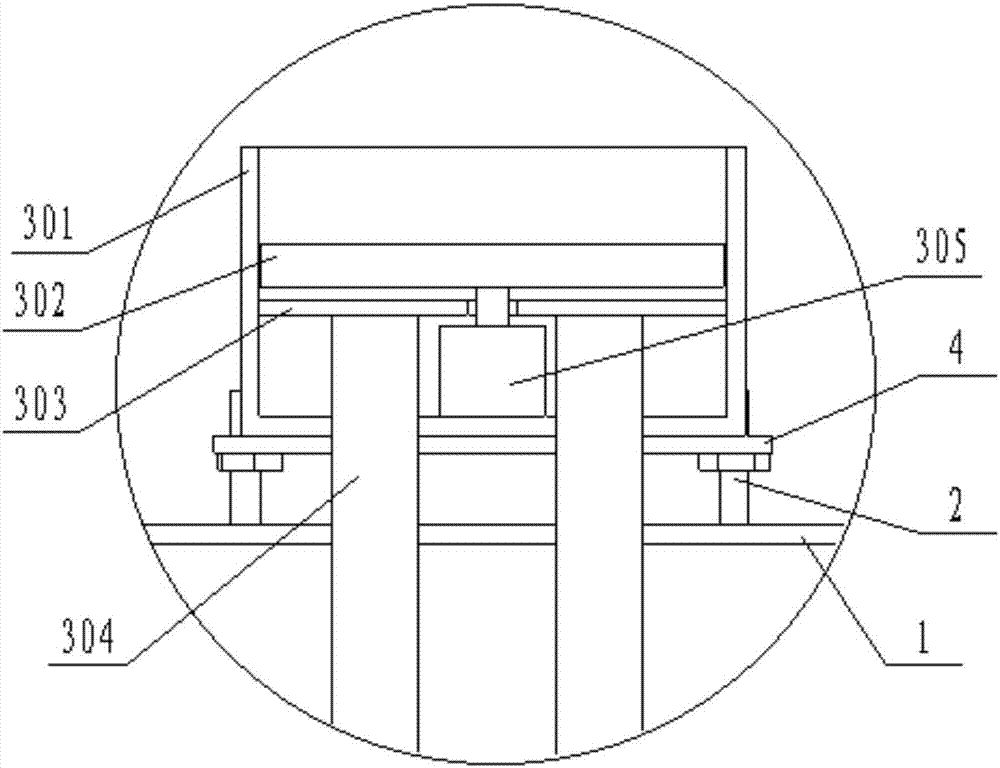

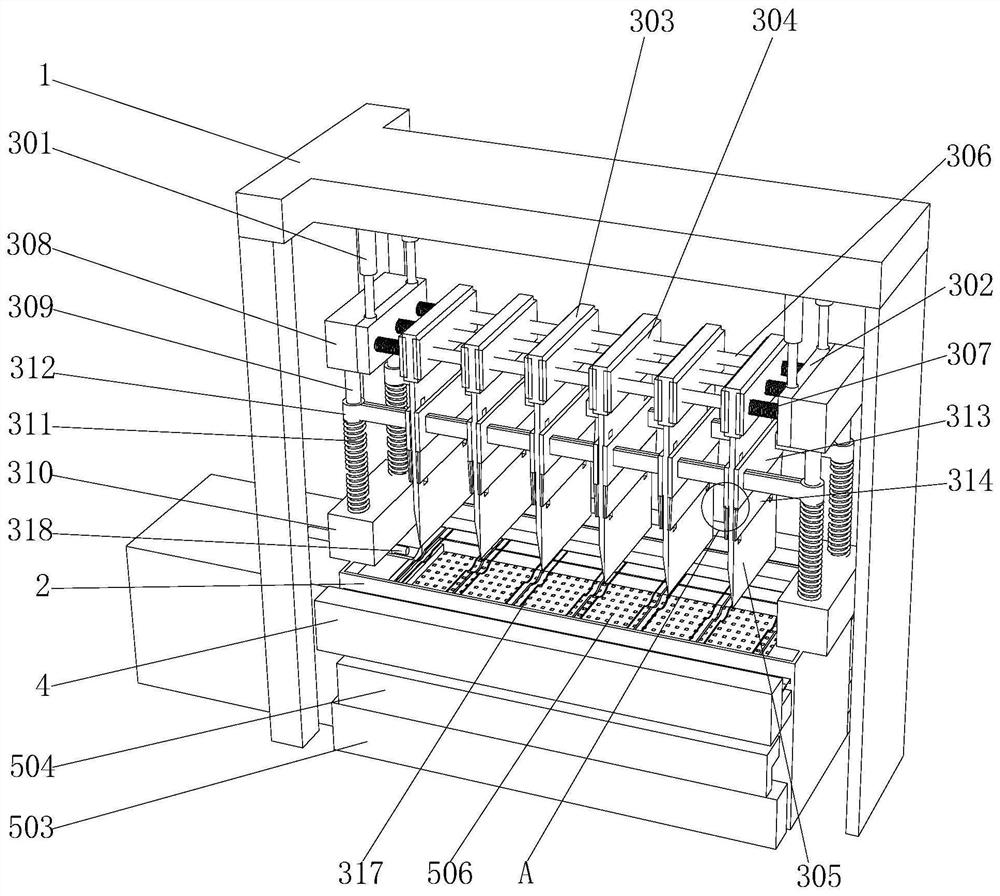

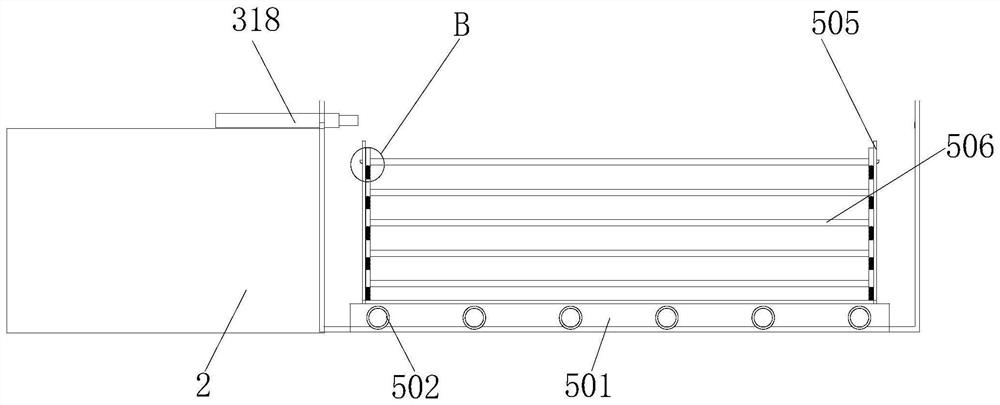

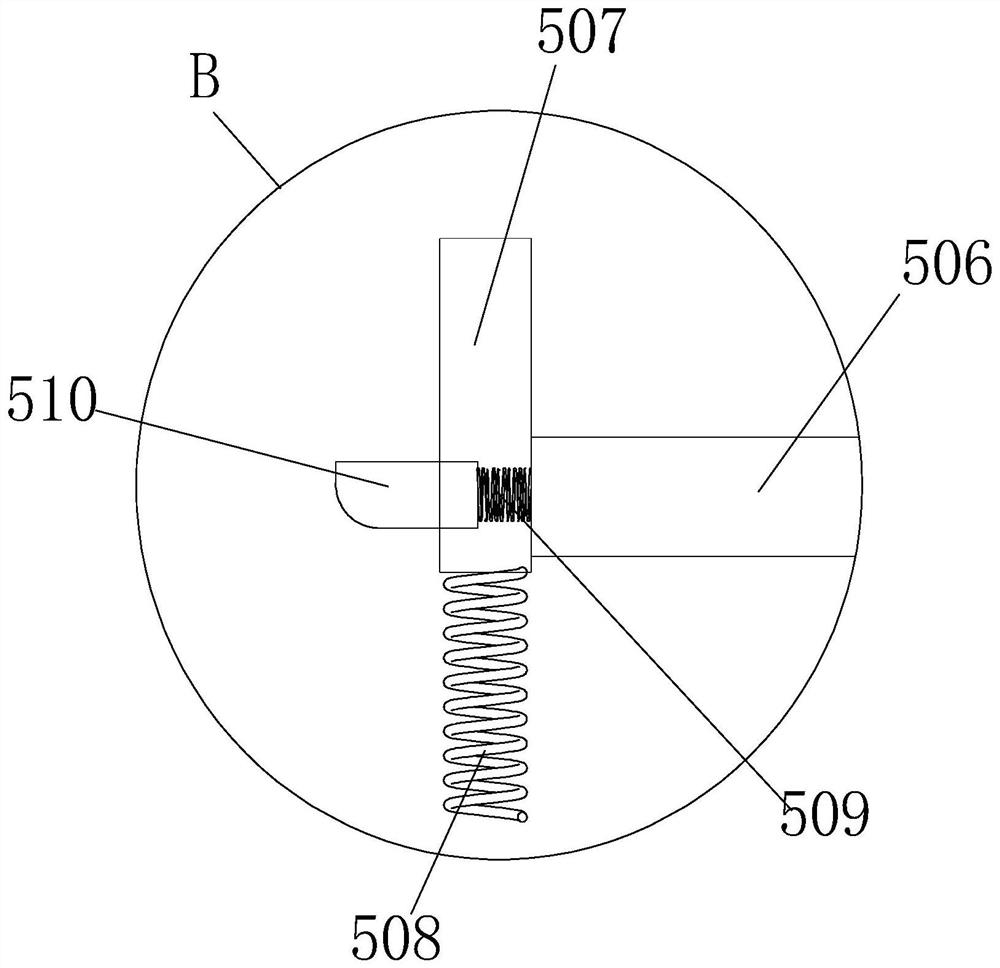

Dual-roller flattening machine with supporting structure

InactiveCN110239149AImprove work efficiencyMeet thickness requirementsMechanical working/deformationGear wheelFixed frame

The invention relates to the technical field of flattening machines, in particular to a dual-roller flattening machine with a supporting structure. The machine comprises a base, a supporting mechanism is arranged on the bottom of the base, fixed plates are symmetrically mounted on the two sides of the top of the base, a fixed frame is arranged between the tops of the fixed plates, a first driving motor is arranged in the middle of the top wall of the fixed frame, the output end of the first driving motor is provided with a first rotating shaft, and the first rotating shaft penetrates through the middle of the top wall of the fixed frame to be connected with a first gear. According to the dual-roller flattening machine with the supporting structure, the flattening thickness of the flattening machine is adjusted, thickness needs of different products can be met, under cooperation of a pressing roller and a conveying belt, the products can be flattened, the flattening treatment effect is better, two sets of products are flattened, the work efficiency of the flattening machine is improved, meanwhile, through the effect of a first damping spring and a second damping spring, damage of vibration to equipment is reduced, and the service life of the equipment is prolonged.

Owner:安徽文博纸品印刷有限公司

Thick film phosphating method

InactiveCN102534591AHigh film thicknessSmooth surfaceMetallic material coating processesTitaniumPhosphate

The invention discloses a thick film phosphating method. The method comprises the following steps of: removing oil stain on the surface of a workpiece and washing with water; washing the surface subjected to oil stain removal by using acid; washing the workpiece with water; carrying out surface conditioning on the workpiece by using a titanium salt; putting the workpiece subjected to surface conditioning in a phosphating solution for phosphating processing; and washing the workpiece. The workpiece provided by using the thick film phosphating method has higher film forming thickness, smooth and fine surface and no rust after a salt spray test; meanwhile the thick film phosphating method disclosed by the invention has the advantages of short reaction time and strong corrosion resistance, can meet the thickness requirements of different phosphate films, and is suitable for the phosphating requirements of the workpiece with high corrosion and high hardness; and the workpiece can meet the process requirements in a small-scale test and an intermediate-scale test.

Owner:ANHUI QIMING SURFACE TECH

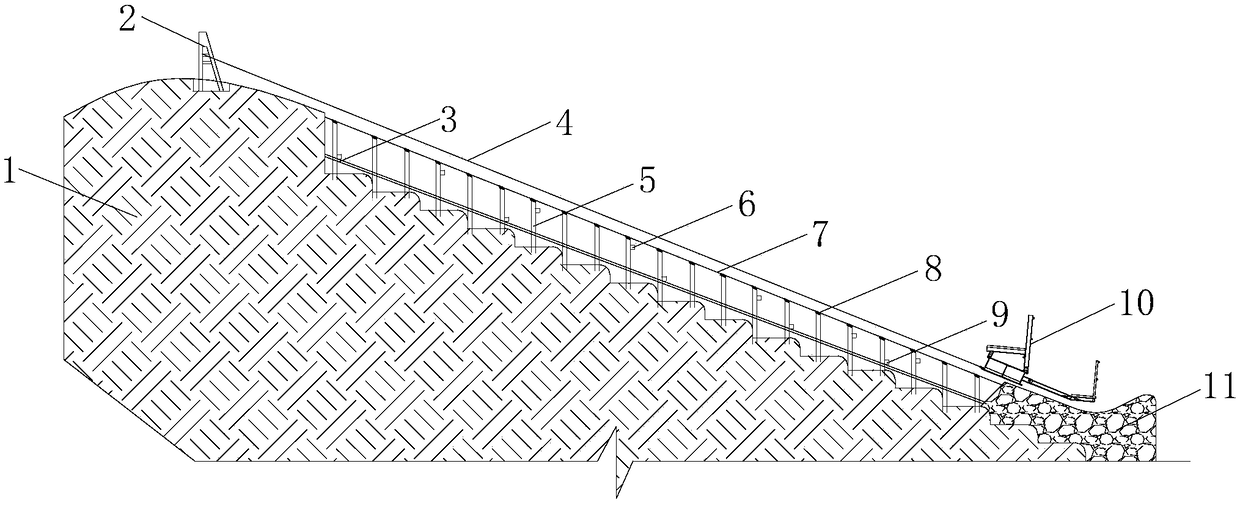

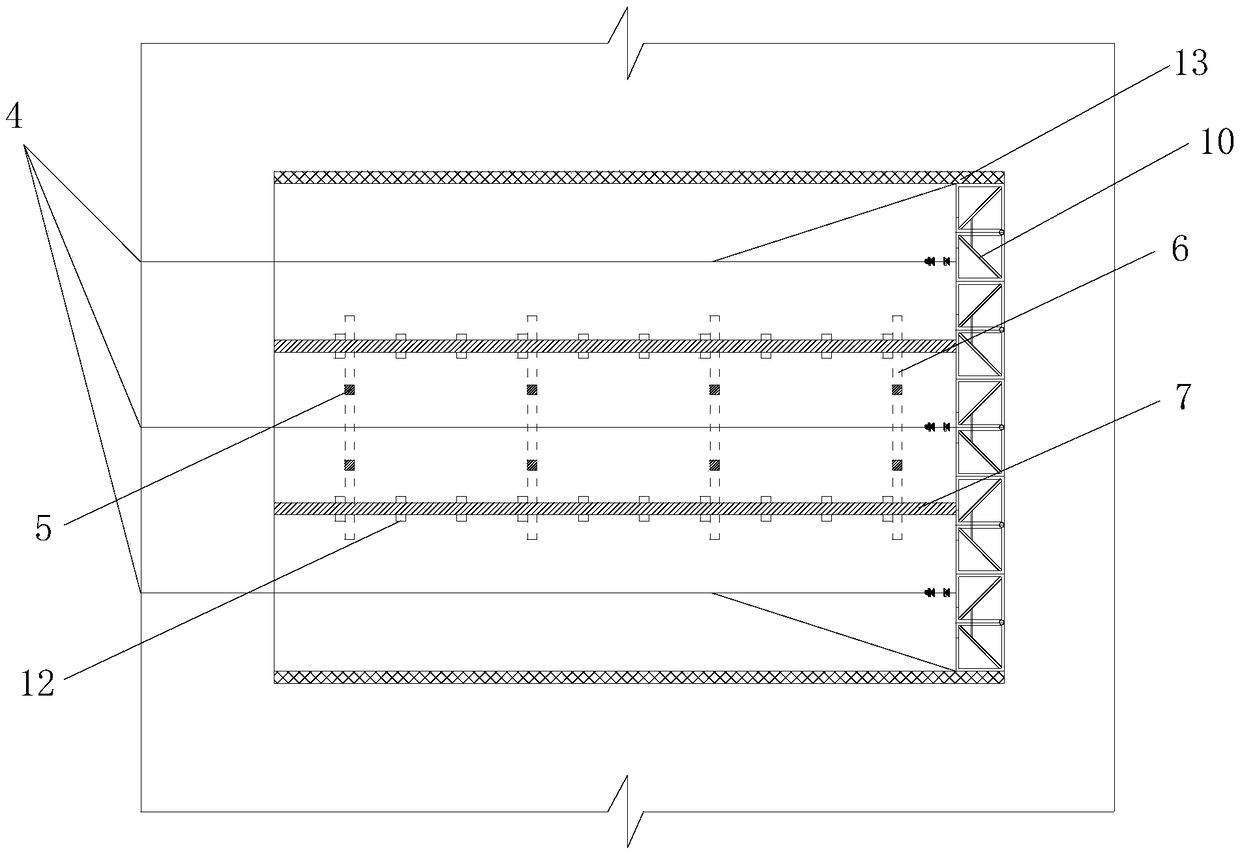

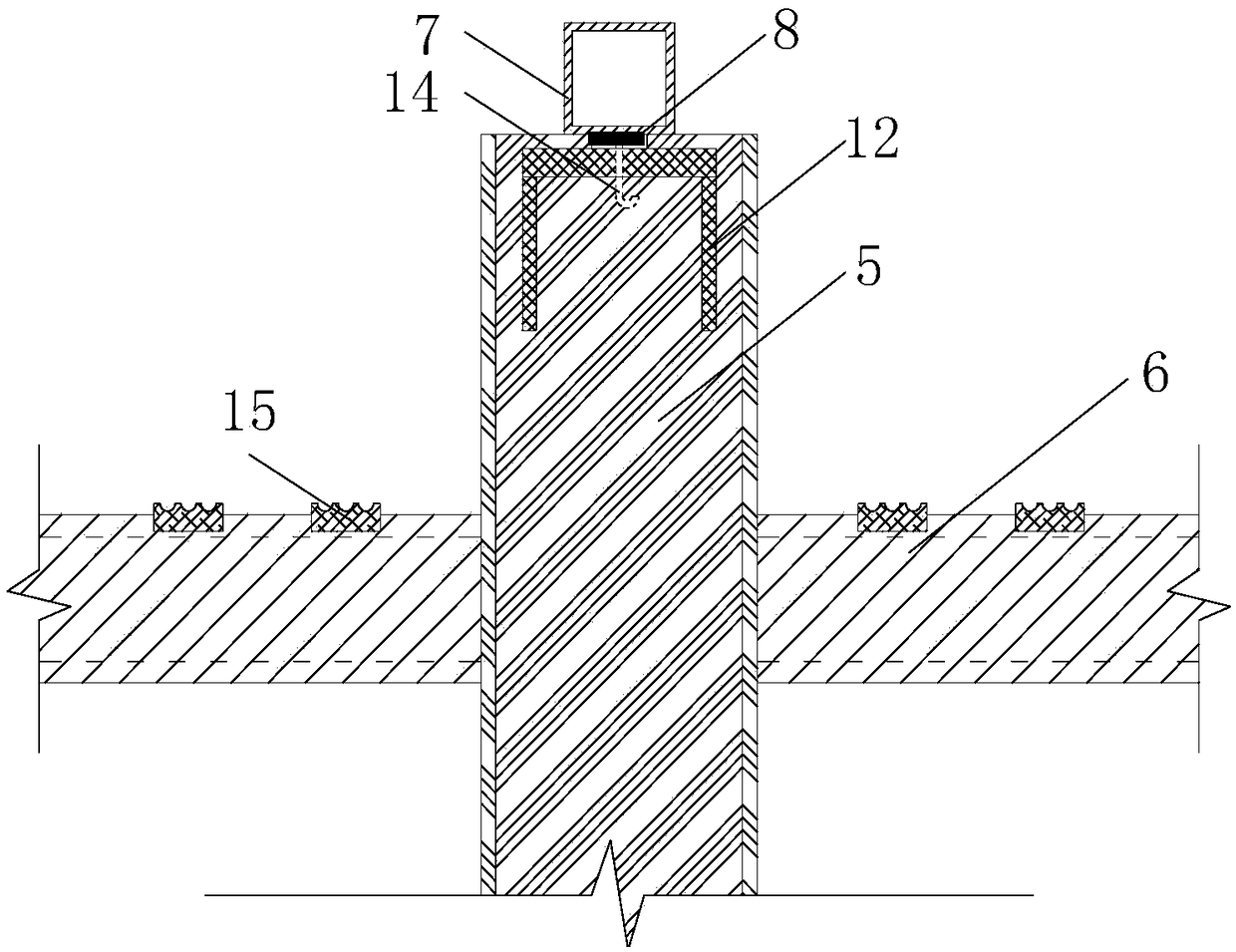

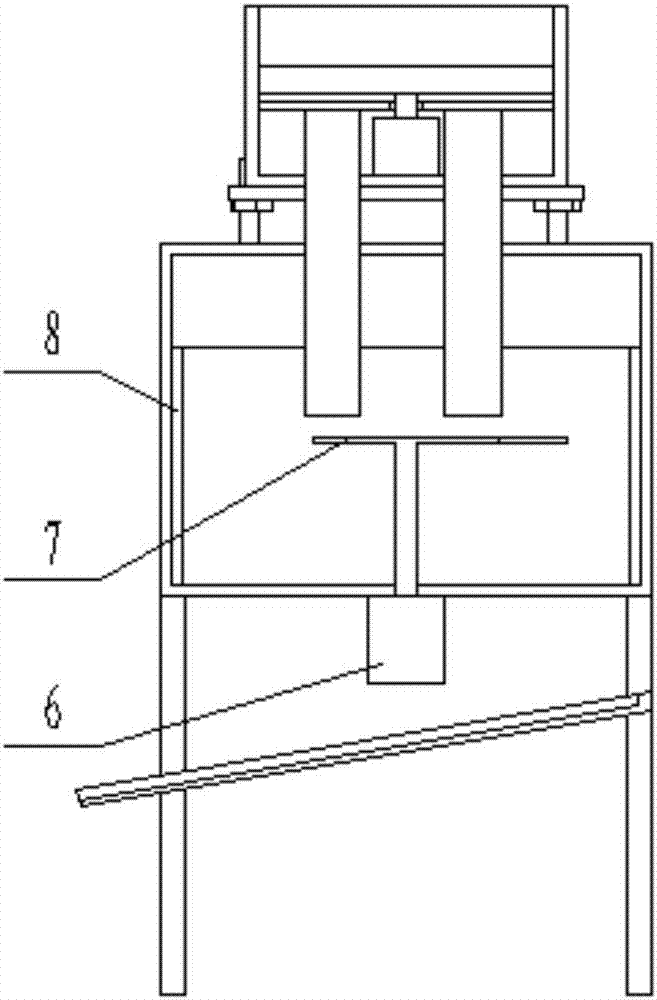

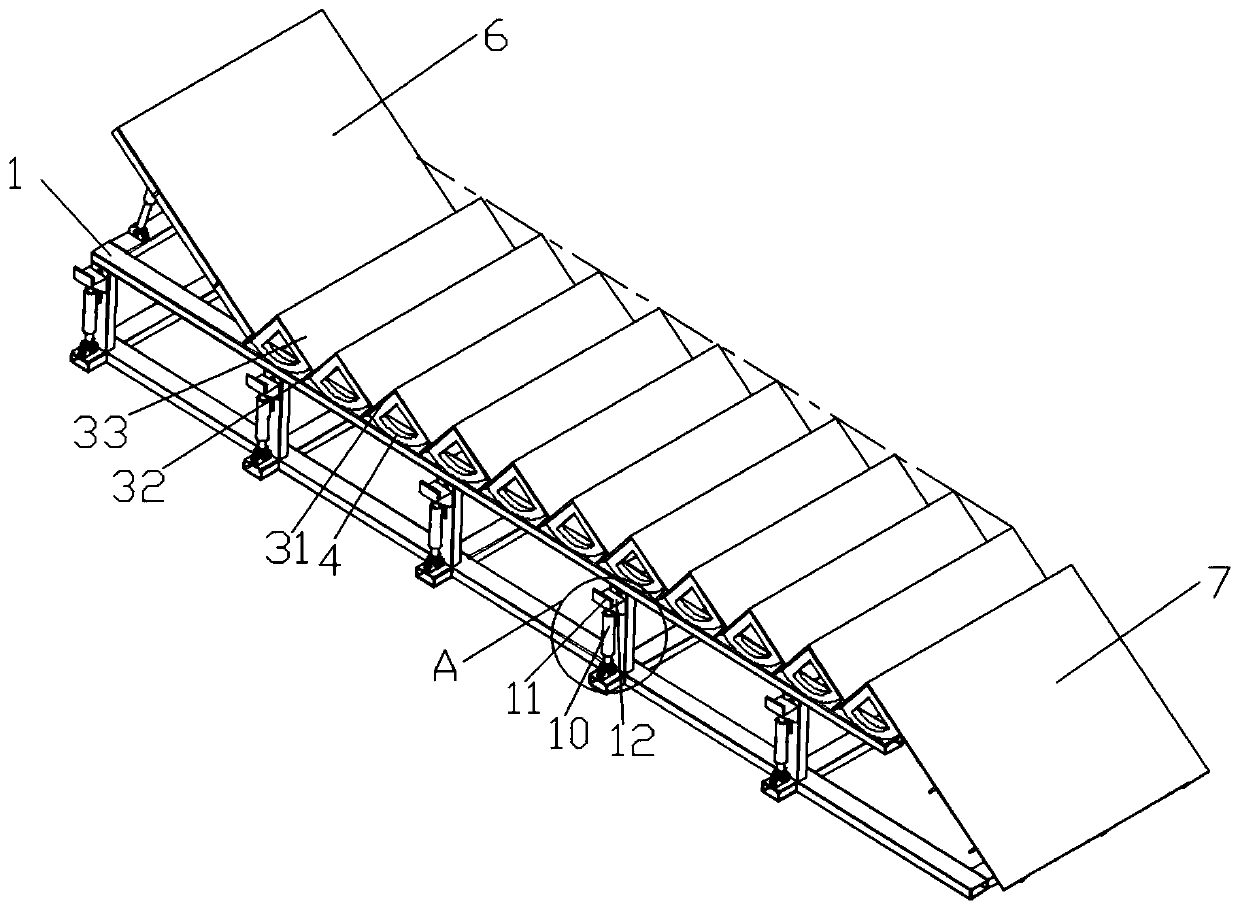

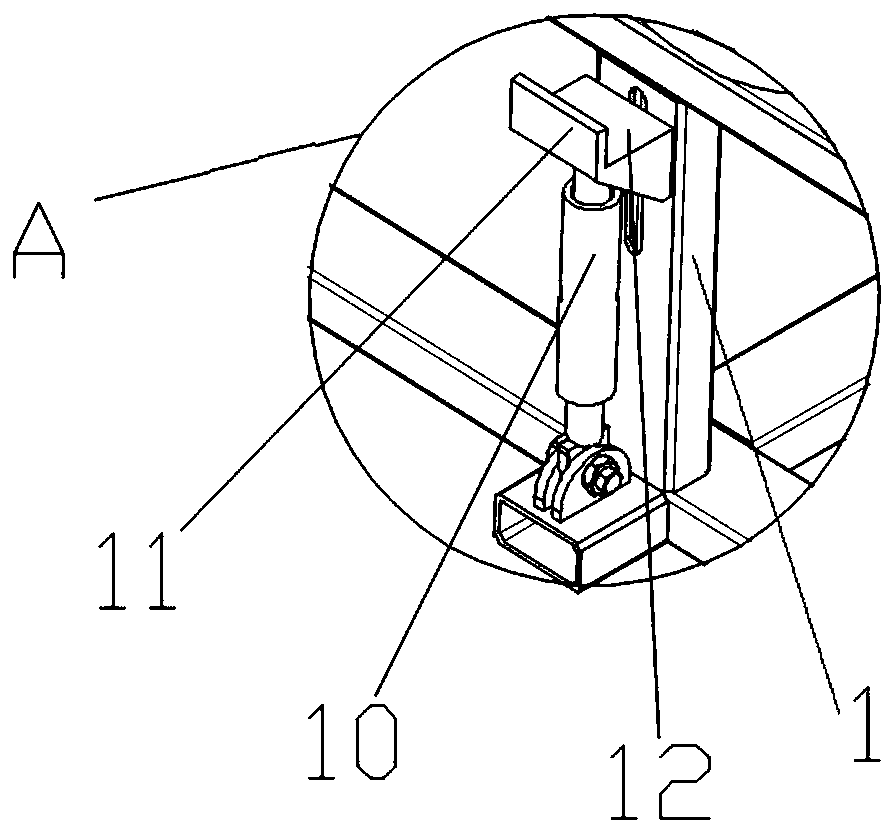

Large-area slope concrete hidden-rail slip form structure and construction method

InactiveCN108330980AImprove pouring qualityImprove installation accuracyBarrages/weirsFoundation engineeringEngineeringRebar

The invention relates to a large-area slope concrete hidden-rail slip form structure. The structure comprises a slope top support pillar, vertical support columns, top connecting cross beams, bottom connecting cross beams, slip rails, combined side forms and pull forms. The vertical support columns are longitudinally and transversely arranged on an original slope at equal intervals, the top connecting cross beams and the bottom connecting cross beams are arranged at upper and lower ends of the vertical support columns respectively, and rebar positioning tooth plates are arranged on top surfaces of connecting beams; bracket plates are symmetrically arranged at the top of the rail support columns in the slope direction, rail pads are arranged on the bracket plates, and the slip rails are erected on the bracket plates; the combined side forms are mounted on two sides of the slope, and slip rails are also arranged in the combined side forms. The structure has the benefits as follows: an inner form body of a slip form system is divided into cavities uniformly at equal intervals, adjustable sand partition boards are arranged in the cavities to form limiting counterweight frames, and bagsbetween partition boards are filled with sand to realize area ballasting; flat plate vibrating tampers and vibrating leveling beams are arranged on lower panels of the slip forms, and the slope concrete pouring quality is further improved.

Owner:HANGZHOU JIANGRUN TECH LIMITED

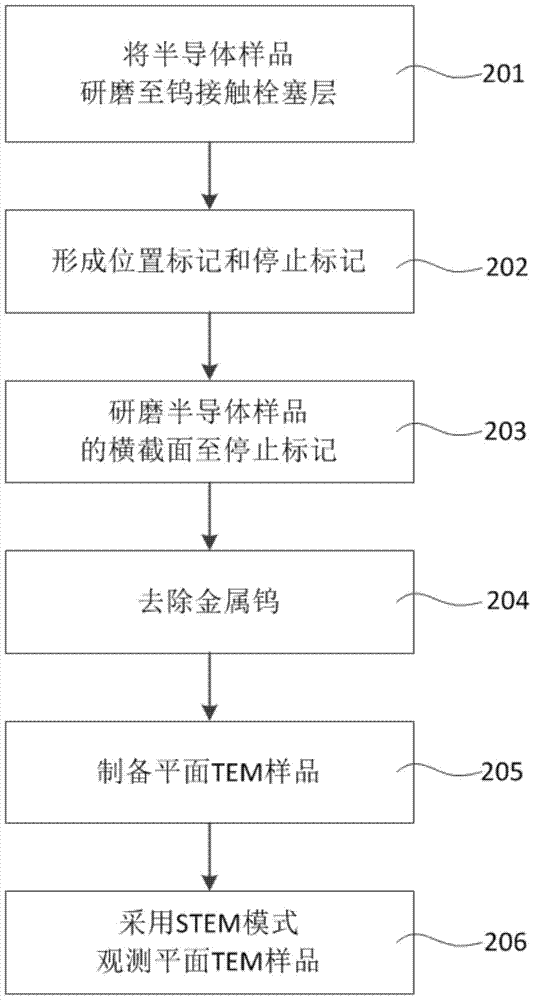

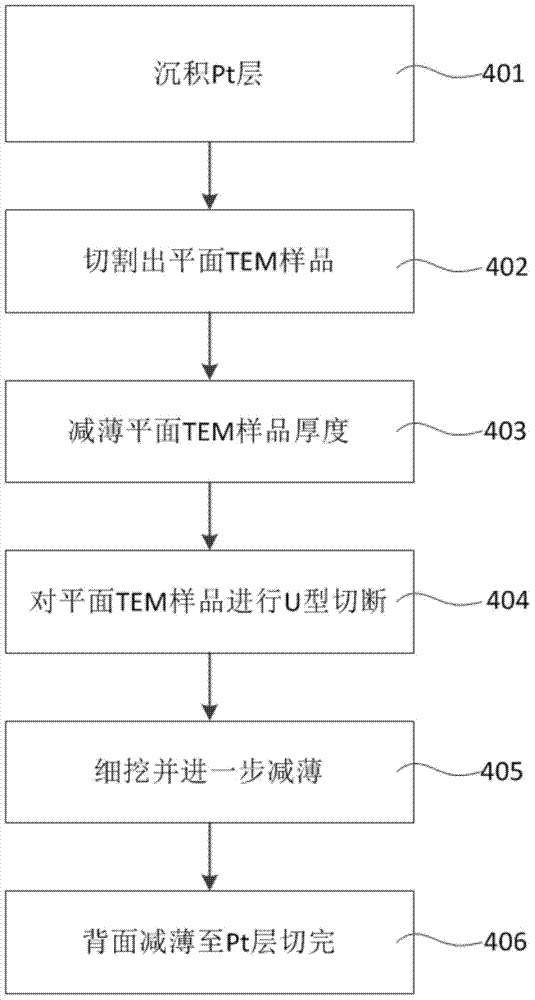

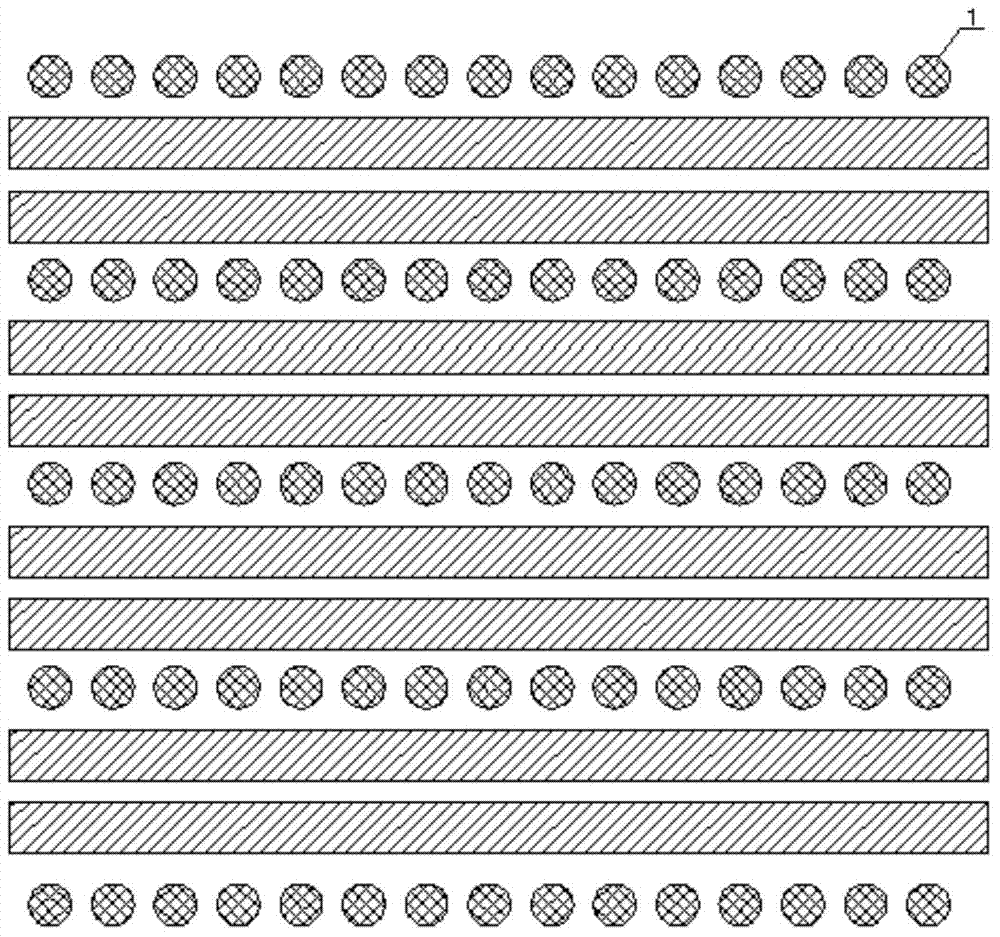

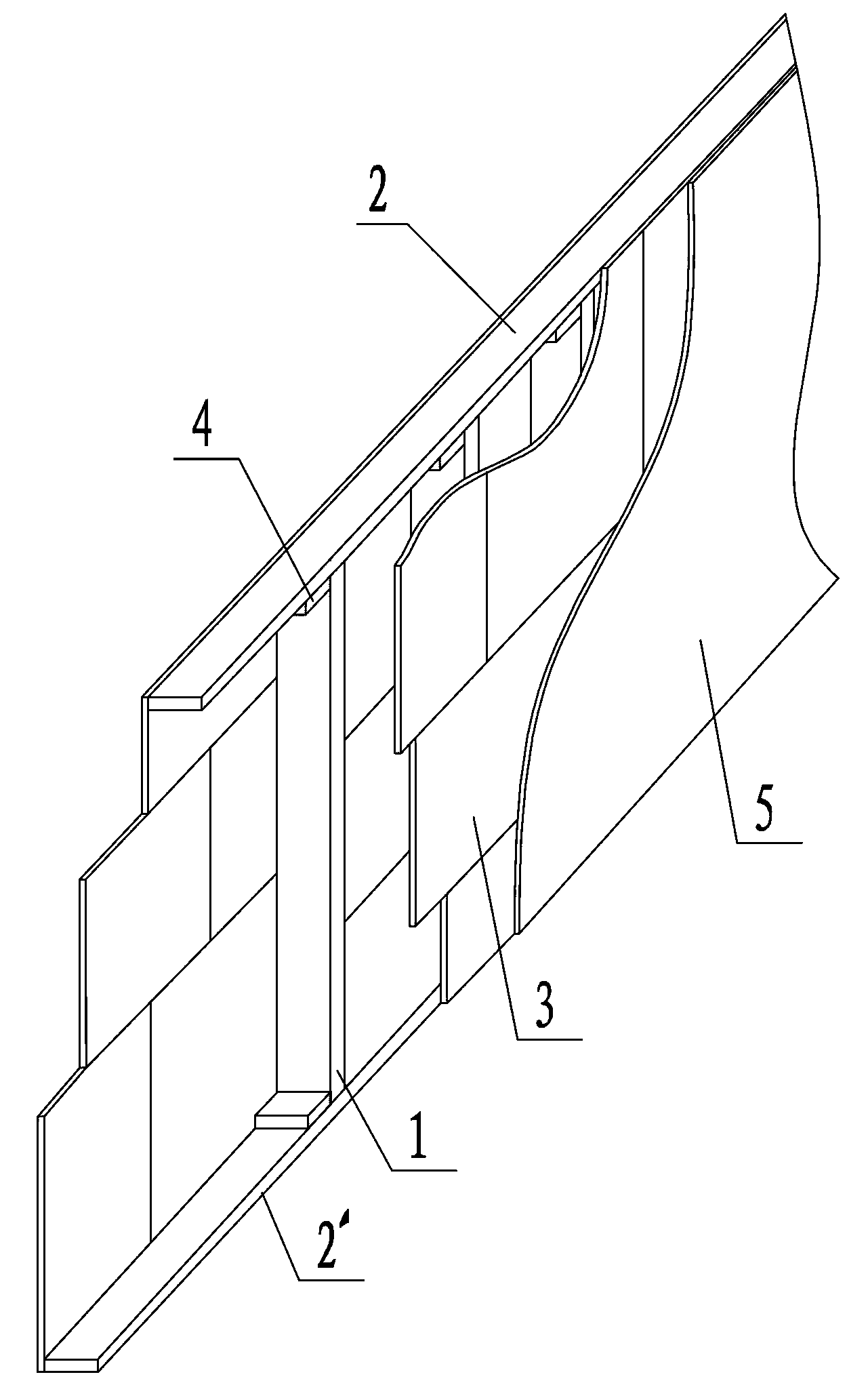

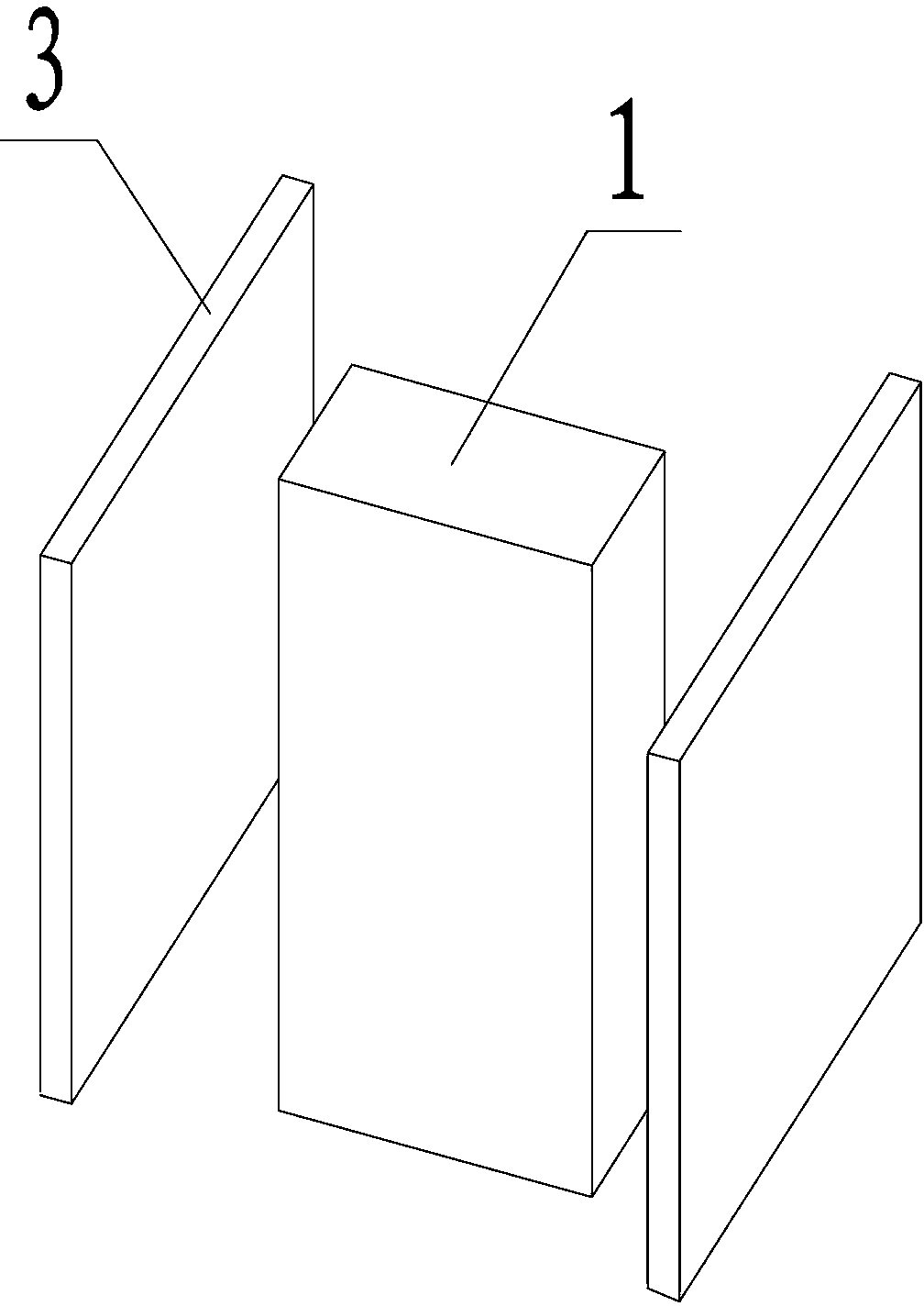

Detection method of high resistance of tungsten contact plug

ActiveCN103700603APromote formationClearly reflect the structureMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementHigh resistanceContact layer

The invention relates to a detection method of high resistance of a tungsten contact plug. The detection method comprises the following steps of grinding a semiconductor sample to a tungsten plug contact layer; forming two location tags used for determining a fail address in an area to be observed of the semiconductor sample, and forming a stop flag on a position, which is close to the fail address; grinding a cross section of the semiconductor sample to the stop flag; digesting the semiconductor sample in boiled hydrogen peroxide until metal tungsten is removed and a cobalt silicide layer is exposed; preparing a planar TEM (Transmission Electron Microscopy) sample; observing the planar TEM sample by adopting STEM (Scan Transmission Electron Microscopy). According to the technical scheme of the invention, the metal tungsten is firstly removed, and then the growth morphology and the quality of the cobalt silicide are observed through a STEM mode, so that the reason for the high resistance of the tungsten contact plug can be quickly found, an improvement direction of a technology is indicated, and the detection method has a very important function of improving formation of the high resistance of the tungsten contact plug.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Assembly type wallboard and installation method thereof

The invention relates to an assembly type wallboard and an installation method of the assembly type wallboard. The assembly type wallboard comprises an edgewise locating plate, a plurality of keels, face plates and decorative surface layers, wherein the edgewise locating plate is arranged perpendicular to the horizontal installation datum of the wallboard; the keels are arranged in a vertical state according to a basic array pitch modulus with the edgewise locating plate as the datum relative to the horizontal installation datum of the wallboard, and the upper ends and the lower ends of all the keels are fixed; the face plates are installed on the two sides of the keels in a fastening mode through row nails, and gaps are reserved between the face plates on each side; the decorative surface layers are arranged outside the face plates arranged on the two sides, and the gaps are filled with expansible joint materials, and anti-cracking bands adhere to the gaps. As a result, the assembly type wallboard is easy and convenient to install and locate, high in strength and resistant to water.

Owner:BAOTOU JIANQIANG LIGHT-WEIGHT SLAB CO LTD

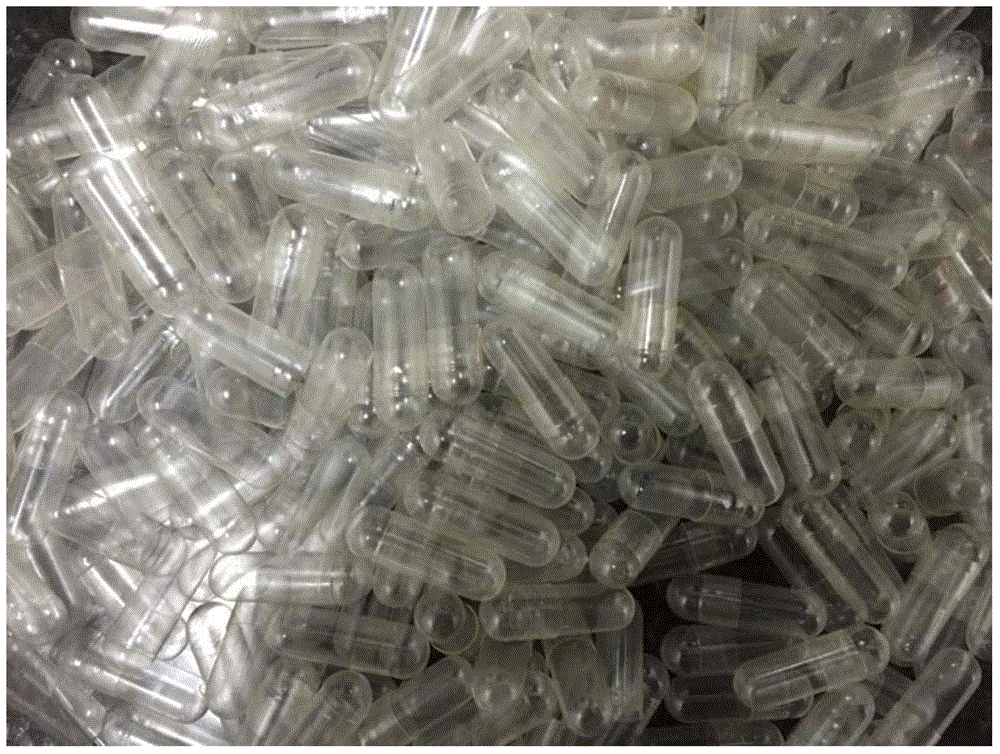

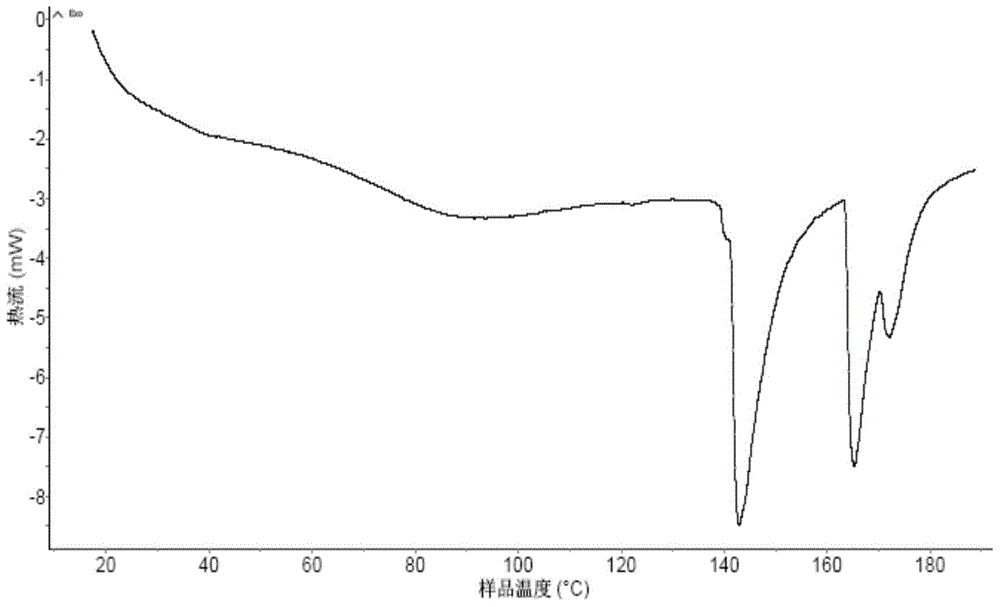

Special glue for composite starch and preparation method of empty capsule of special glue

InactiveCN104873977ALow gelatinization temperatureImprove stabilityPharmaceutical non-active ingredientsCapsule deliveryMoistureAccelerant

The invention discloses special glue for composite starch. The special glue is prepared from the following components in percentage by weight: 50 to 85% of starch, 1 to 6.5% of gel, 0.1 to 5% of coagulant aid, 2 to 15% of a plastification humectants, 0 to 15% of a disintegration accelerant, 0 to 0.5% of food coloring, and 0 to 3% of an opacifying agent. The special glue for composite starch is a plant-based empty capsule of which the main raw material is food starch, so that the biological compatibility of a human body is high. A composite starch empty capsule prepared by using the special glue for the composite starch as the raw material can subjected to one feeding, is simple to operate, small in glue maintaining and deaerating time and applicable to a gelatin empty capsule production line, and prevents an operator from dust pollution of raw material. The empty capsule prepared by using the special glue for the composite starch as the raw material contains 7 to 11% of water, difficultly absorbs moisture under normal room temperature and humidity, is difficult to crack, difficultly causes microorganism and is free of a preservative, and meets the requirement of National Formulary on pharmaceutical pharmacy index of empty capsules; the empty capsule prepared from the composite starch is true plant-based empty capsule and suitable for all people.

Owner:ZHEJIANG WANLI UNIV

Projection device based on surface emitting laser and manufacturing method thereof

The invention provides a projection device based on surface emitting laser. The device comprises a surface emitting laser which can emit a needed plane pattern, and an integrated diffractive optical element, wherein the integrated diffractive optical element is arranged at a front end of the surface emitting laser, a surface of the integrated diffractive optical element is provided with an embossed microstructure, the shape of the integrated diffractive optical element is determined by a fused phase transformation function, and the fused phase transformation function is obtained by fusing a lens function of a virtual collimating lens and a phase transformation function of an original diffractive optical element. The invention further provides a manufacturing method of the corresponding projection device based on the surface emitting laser. The device is advantaged in that an entity collimating lens can be omitted, so miniaturization of a projection module is facilitated.

Owner:无锡奥普顿光电子有限公司

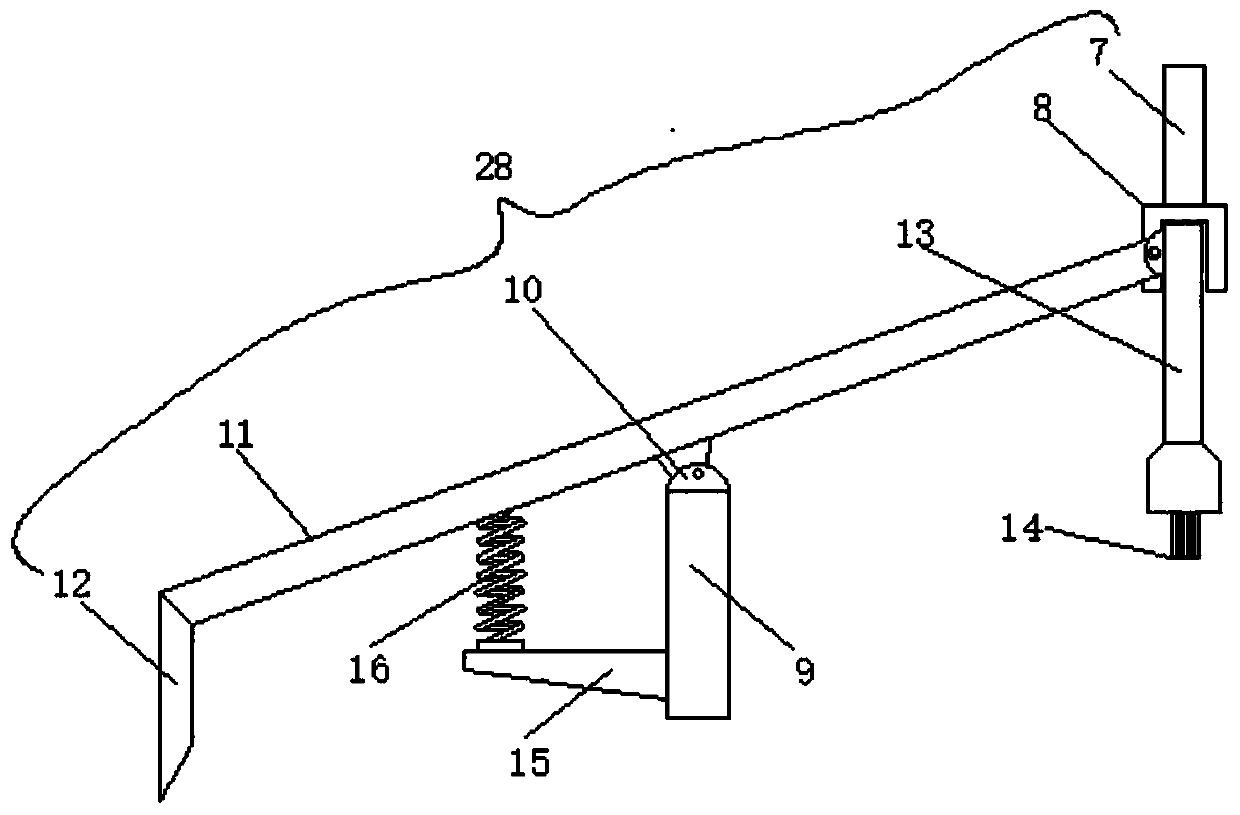

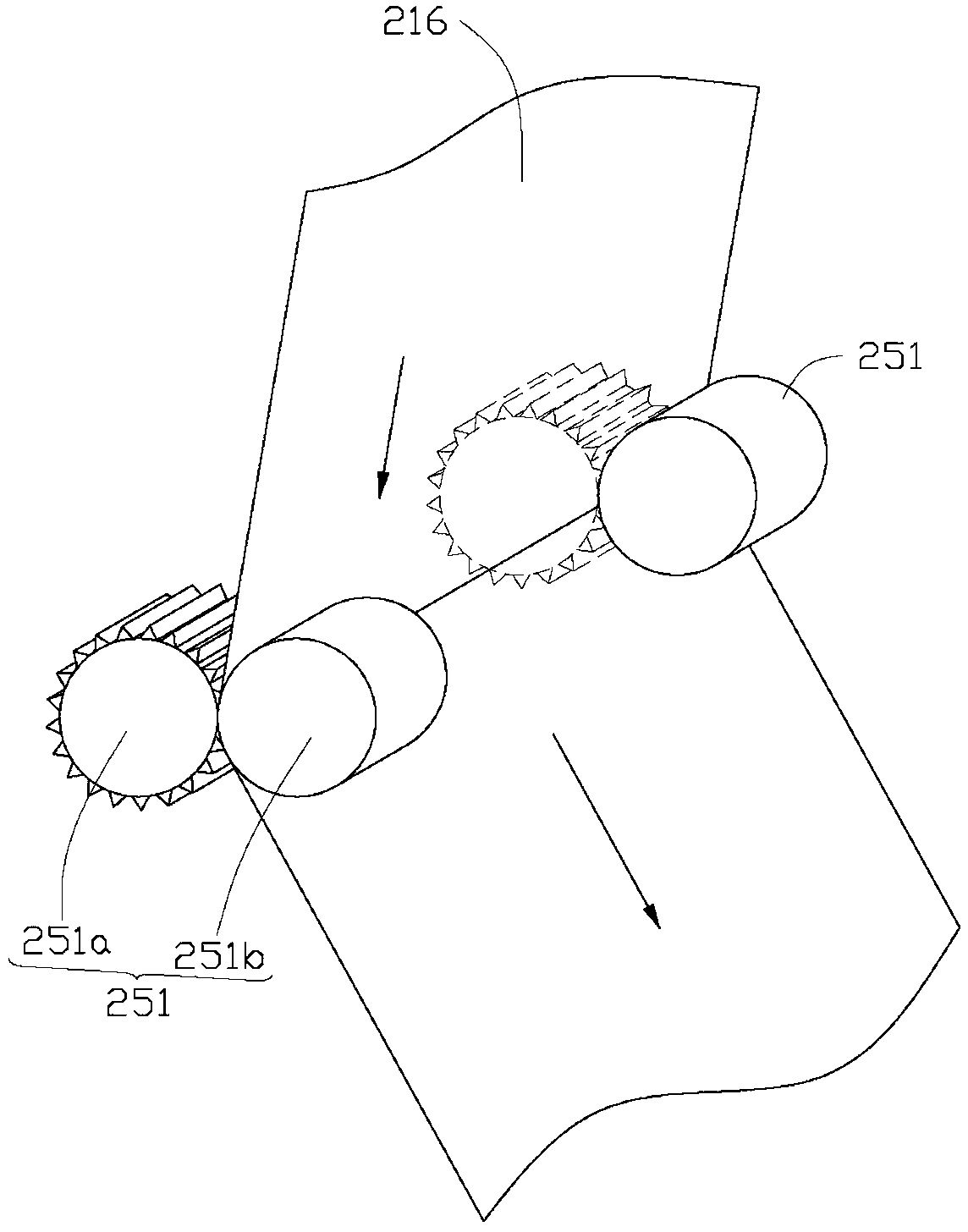

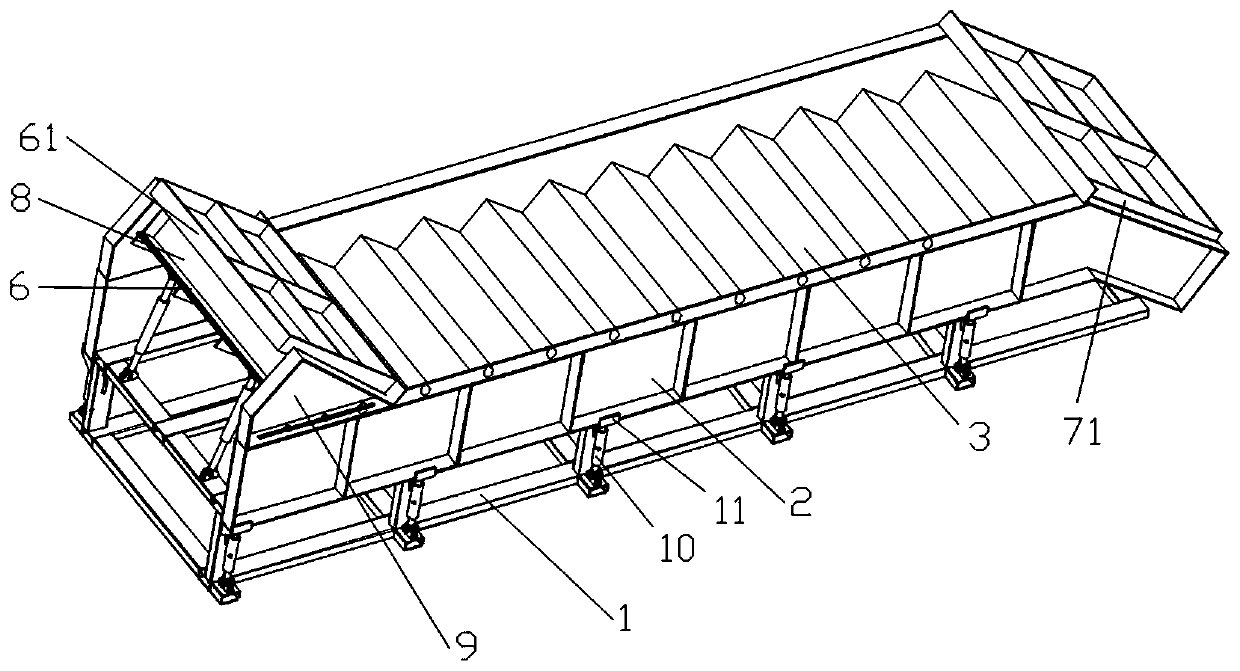

Dried sweet potato slicing and conveying integrated machine

PendingCN107457822APrevent blocking phenomenonImprove slice qualityMetal working apparatusMotor driveEngineering

The invention discloses an integrated machine for conveying dried sweet potato slices, which comprises a slicing box, a slicing motor is installed at the lower end of the slicing box, and a cutter disc is fixedly installed at the output end of the slicing box; a discharge port is arranged at the bottom of the slicing box , the outer side of the discharge port is provided with side guards; the upper end of the slicing box is fixed with a support plate through height-adjusting bolts, and a feeding device is installed at the upper end of the support plate. The beneficial effect is that: the feed motor drives the feed scraper to rotate to achieve stirring, and cooperates with the feed vibrating plate to realize the vibration, stirring and feeding of raw materials, which can prevent the phenomenon of material blocking; the raw materials enter the inside of the material guide tube under the action of vibration and stirring , to realize the adjustment of the feeding direction of the raw material, so as to ensure the consistent cutting direction and improve the cutting quality; the height of the support plate can be adjusted by adjusting the height of the bolt, so as to adjust the height of the feeding device and change the distance between the outlet of the guide tube and the cutter head. Adjust the slice thickness to meet different thickness requirements.

Owner:绍兴云疆网络科技服务有限公司

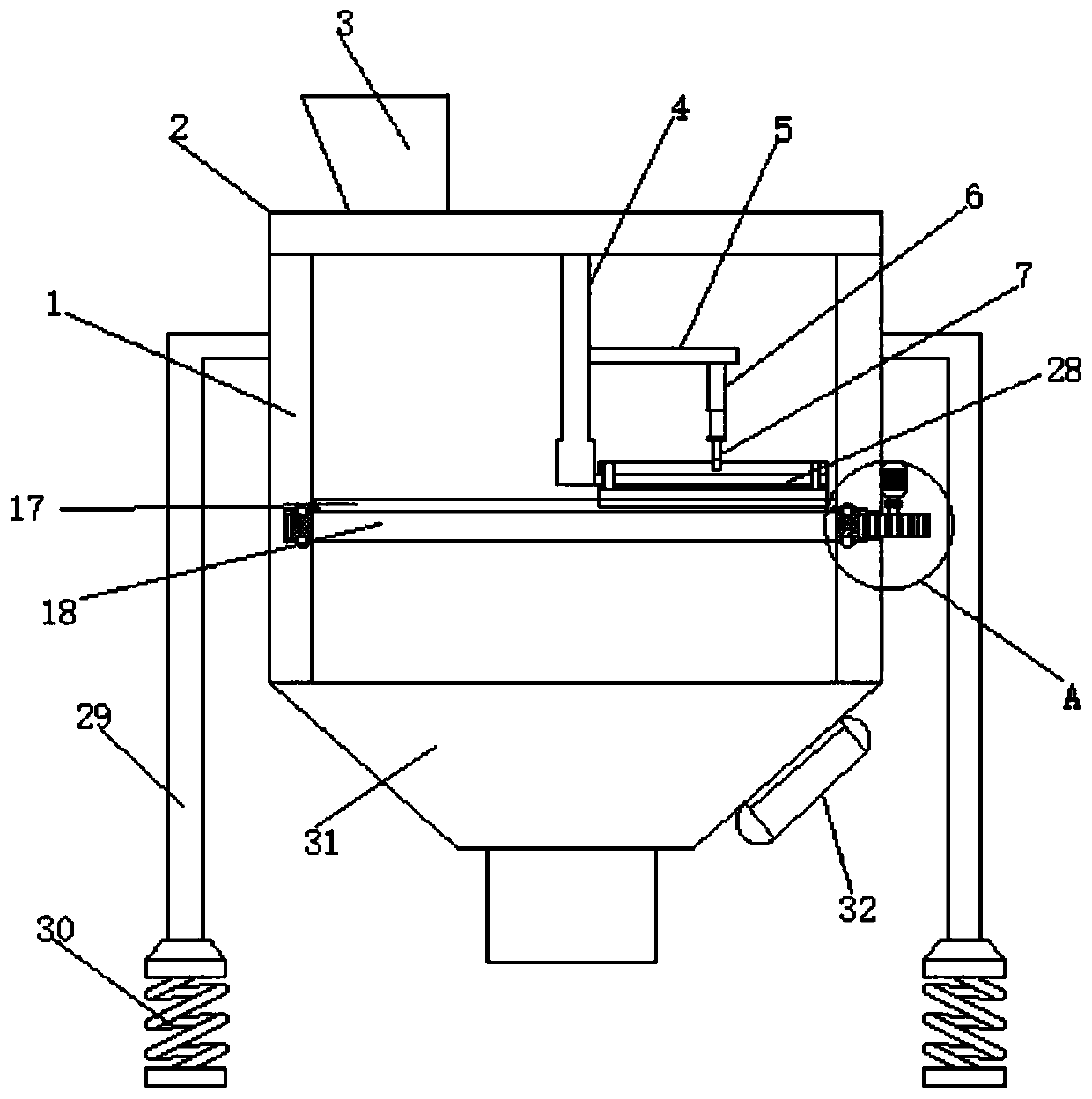

Peppermint raw material screening device for peppermint oil manufacturing

The invention relates to the technical field of peppermint oil manufacturing, in particular to a peppermint raw material screening device for peppermint oil manufacturing. The peppermint raw materialscreening device comprises a screening barrel, wherein a barrel cover is arranged at the top end of the screening barrel, a feeding hopper is arranged on one side of the top end of the barrel cover, amounting rod is arranged in the center of the bottom end of the barrel cover, a connecting plate is arranged on one side of the mounting rod, an electric push rod is arranged on one side of the bottom end of the connecting plate, a connecting rod is mounted at the output end of the electric push rod, a clamping plate is arranged at the bottom end of the connecting rod, and the clamping plate is of an inverted-concave structure. The defects in the prior art are overcome, bristles are arranged at the bottom of the vertical plate, when a screen is blocked, the vertical plate is driven by the electric push rod to be pressed downwards until the bristles make full contact with the surface of the screen, the screen rotates, the bristles can sweep the screen, and the situations that the screen isblocked and the bristles are lifted up to be separated from the screen after the screen is dredged can be effectively avoided, so that blockage of the screen is conveniently treated.

Owner:安徽华馨生物科技有限公司

Anti-oxidation adjustable Chinese yam slicing device

InactiveCN112549117AChange of repulsionThe repulsive force is changed by the size of the magnetic poles between the bar electromagnetsMetal working apparatusProcess engineeringKnife blades

The invention provides an anti-oxidation adjustable Chinese yam slicing device, and relates to the technical field of Chinese yam processing. The anti-oxidation adjustable Chinese yam slicing device comprises a support, a water tank, a slicing mechanism, telescopic boxes and a collecting mechanism, wherein the water tank is arranged below the support, and the slicing mechanism is arranged above the water tank. Chinese yams are sliced through a peel cutting mechanism, the distance between cutting blades can be adjusted, and therefore the Chinese yam slicing requirements of different thicknessesare met. The top end of the slicing mechanism is fixedly connected with the bottom end of the support. The telescopic boxes are arranged on the left side and the right side, close to the top end, ofthe water tank and fixedly connected with the two sides of the water tank. The collecting mechanism is arranged in the water tank and used for collecting sliced Chinese yams to prevent the Chinese yams from being oxidized and blackened due to long-time contact with air. The bottom end of the collecting mechanism is fixedly connected with the bottom end of the water tank. The problems that the distance between blades of an existing yam slicing device cannot be changed to meet different slicing requirements, and yams are oxidized and blackened after being sliced are solved.

Owner:李岗仁

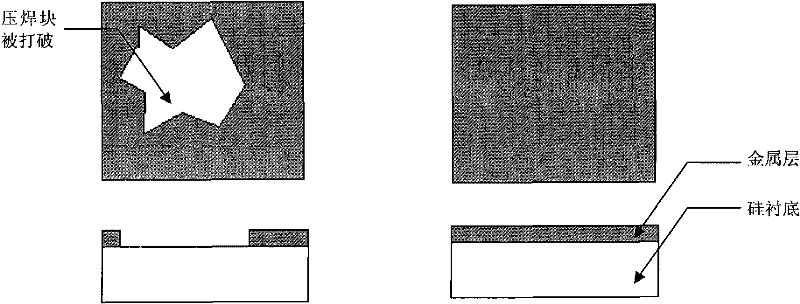

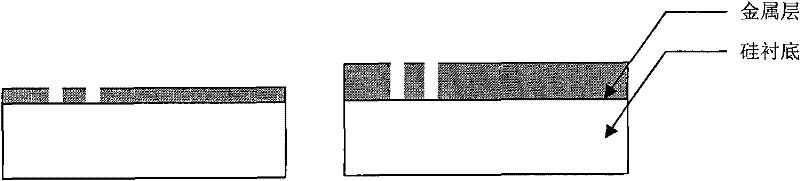

Chip with thickened metal layer of press welding block and manufacturing method for chip

InactiveCN102237327AMeet the thickness requirementsIncrease sputteringSemiconductor/solid-state device detailsSolid-state devicesCopper wireMetal

The invention discloses a chip with a thickened metal layer of a press welding block and a manufacturing method for the chip and belongs to the technical field of semiconductor chip manufacturing. The chip comprises a silicon substrate, a metal layer on the silicon substrate, a passivation layer on the metal layer and the press welding block on the metal layer, wherein the thickness of the metal layer of the press welding block is greater than that of the metal layer of a metal wire. The manufacturing method for the chip comprises the following steps of: sputtering, photoetching and etching the metal layer on the surface of the silicon substrate according to the function of the chip so as to form the metal wire and the press welding block in the chip; growing, photoetching and etching the passivation layer and etching a press welding block region; and sputtering, photoetching and etching the metal layer again on the surface of the passivation layer and retaining the metal in the press welding block region. During manufacturing of the chip, an effect of independently thickening the press welding block inside the chip is achieved and the requirement of a chip package factory on the thickness of the metal layer of the press welding block inside the chip during routing by using a copper wire is met.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

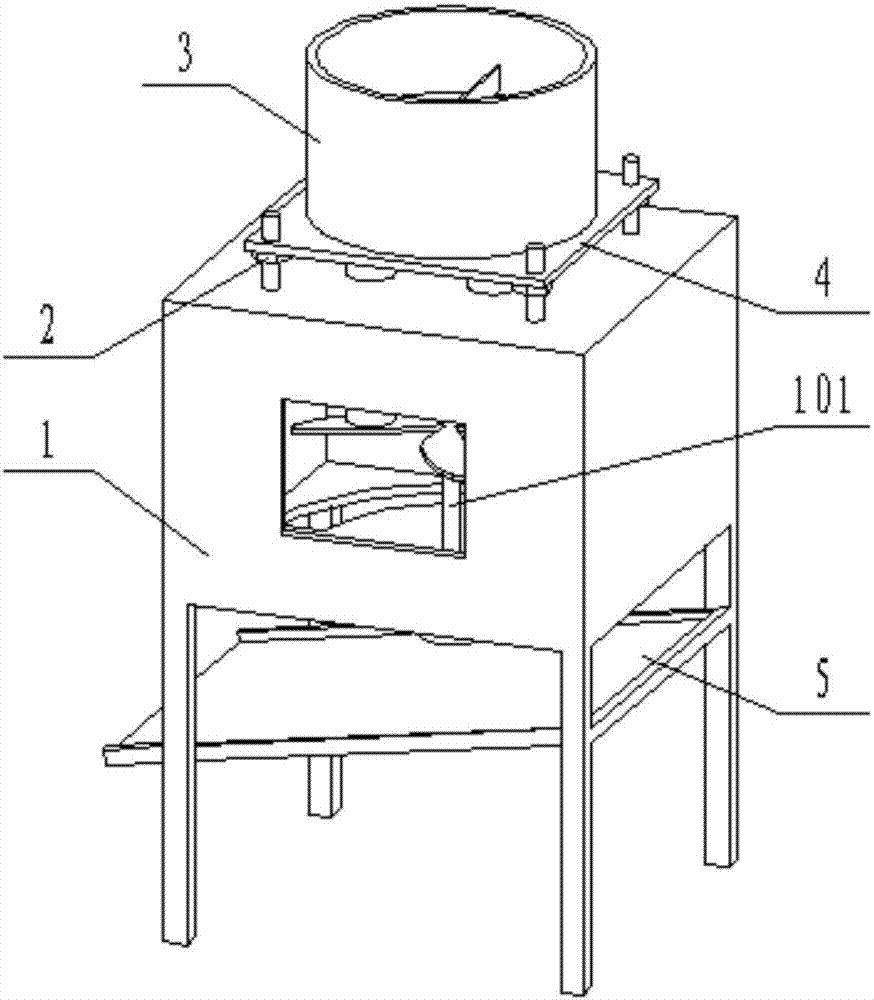

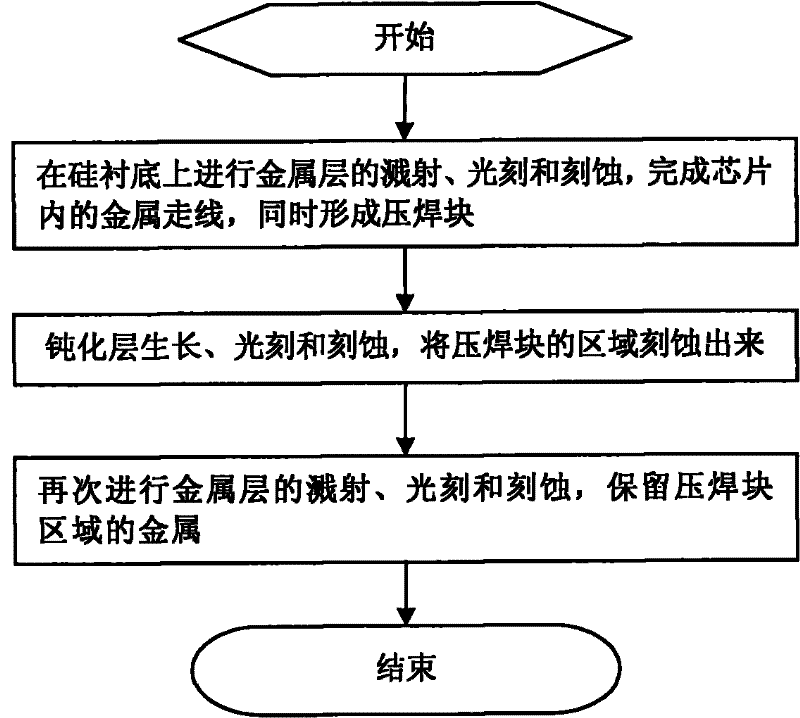

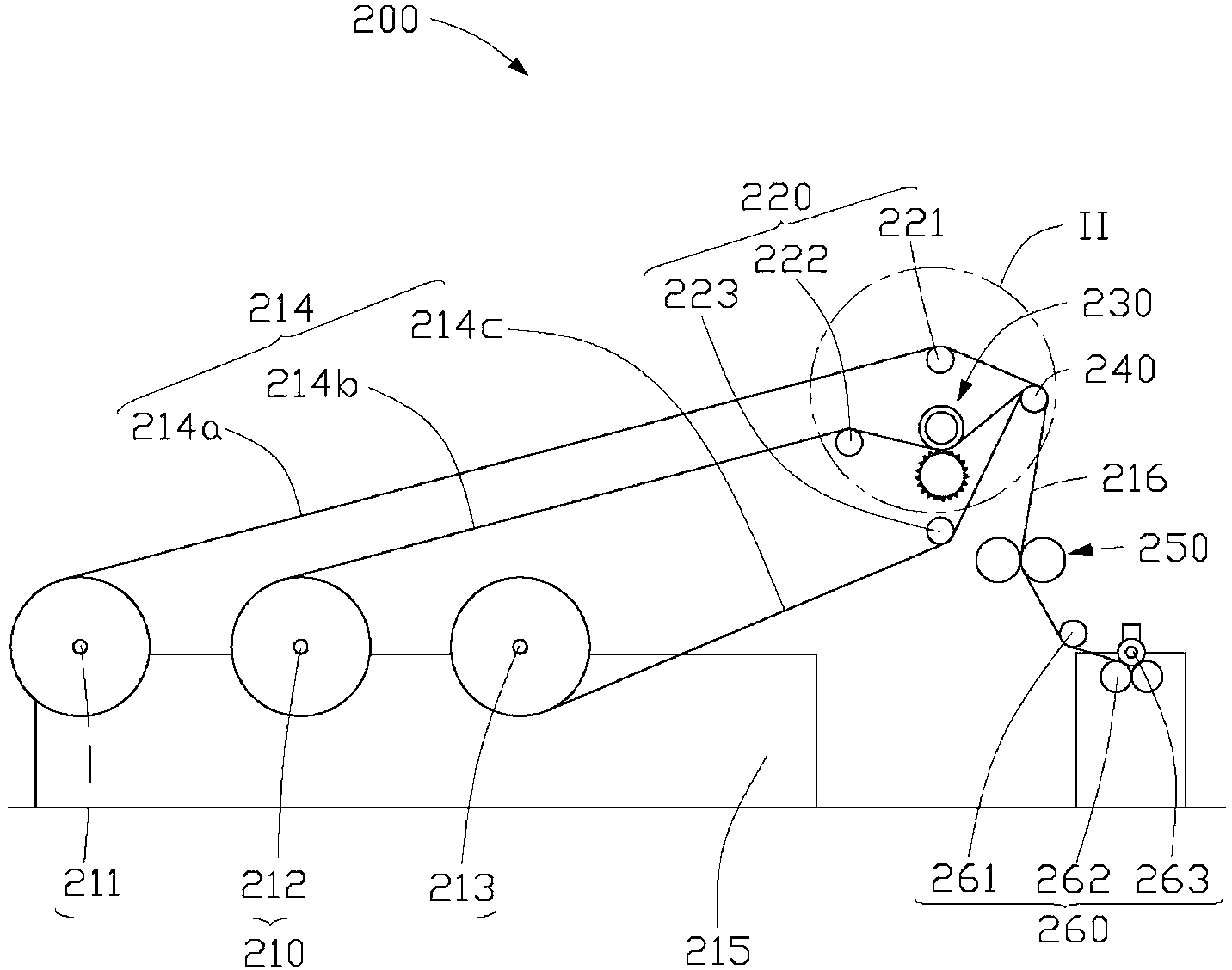

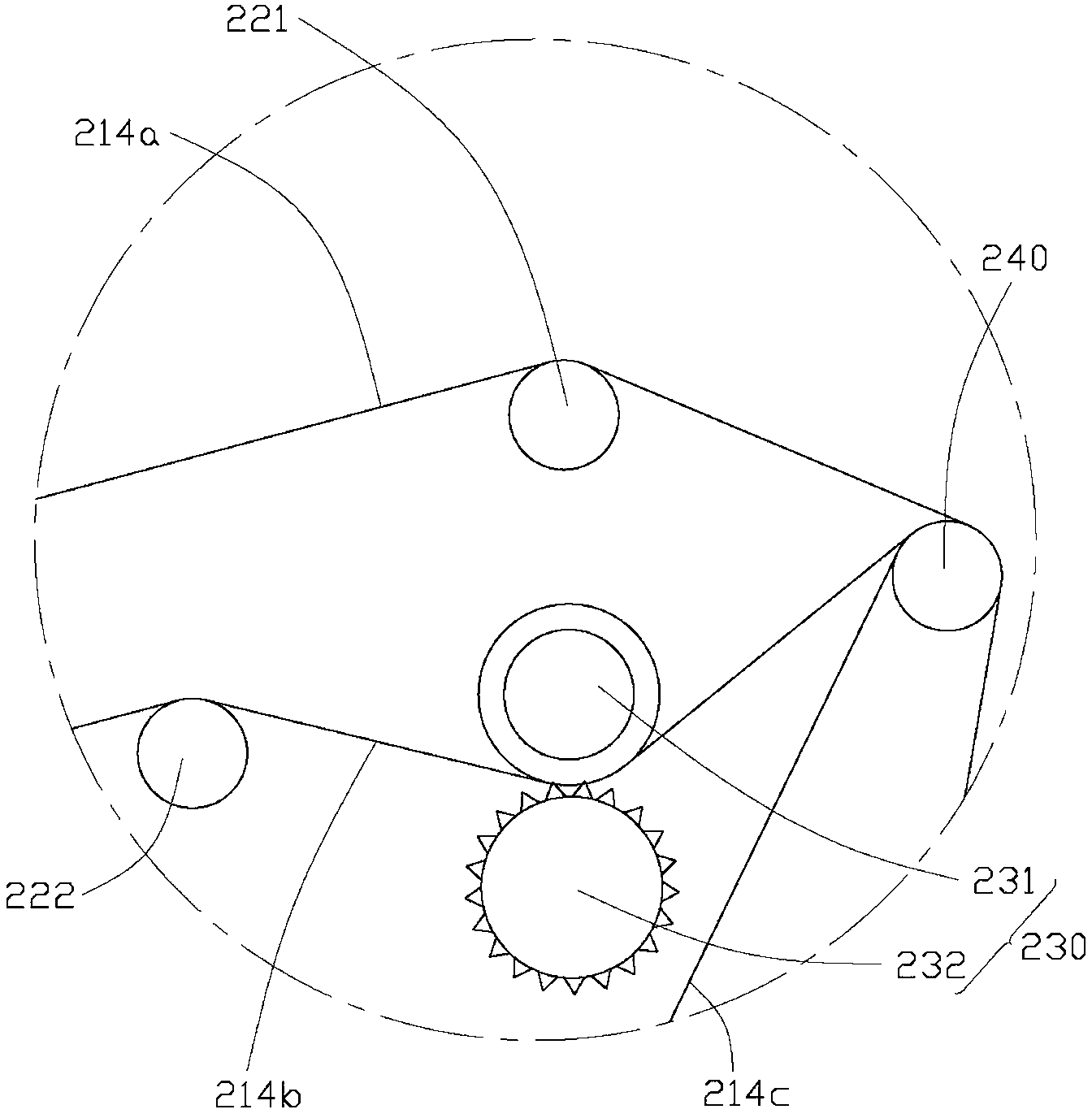

Lamb wave immunosensor and manufacturing method thereof

InactiveCN102520160ARealize arrayizationSolve the problem that cannot be arrayedMaterial analysisHigh fluxCapture antibody

The invention discloses a Lamb wave immunosensor capable of performing array, high-flux, large-sample and quick measurement on immunoreaction. The Lamb wave immunosensor comprises an upper magnet and a lower magnet, wherein a Lamb wave sensor is arranged between the upper magnet and the lower magnet; a pipeline gland is glued above the Lamb wave sensor; the Lamb wave sensor comprises a silicon thin film structure with a plurality of sample cells; a conductive stratum is arranged below the silicon thin film structure; a piezoelectric material layer is arranged below the conductive stratum; an integrated device technology (IDT) electrode layer is arranged on the piezoelectric material layer, and comprises a plurality of gear shaping electrodes and a plurality of welding spot ports; a pair of electrode ports is arranged on each of the gear shaping electrodes; marking antibodies, immune micro magnetic balls and capturing antibodies are cultivated in the sample cells; a sample cell channel is formed on the pipeline surface of the pipeline gland, which is attached to the Lamb wave sensor; and a through hole is formed in each of two ends of the sample cell channel.

Owner:SUZHOU SASENS CO LTD

Device and method for producing paper for daily use and paper for daily use

ActiveCN102860777AFeel goodSolve the paper thicknessMechanical working/deformationDomestic applicationsPaper sheetConductor Coil

The invention relates to a device for producing paper for daily use. The device comprises an unreeling device, an embossing roll pair, a laminating roll and a winding roll, wherein the unreeling device is used for respectively unreeling outer layer paper, middle layer paper and inner layer paper, the embossing roll pair is used for embossing the middle layer paper, the middle layer paper is provided with embossed patterns, the laminating roll is used for sequentially laminating the outer layer paper from an outer layer paper unreeling roll, the middle layer paper with embossed patterns from the embossing roll pair and the inner layer paper from an inner layer paper unreeling roll so as to form multi-layer paper and the winding roll is used for winding the multi-layer paper from the laminating roll. The invention also relates to a method for producing the paper for daily use by using the device and the paper for daily use.

Owner:海南金红叶纸业有限公司 +1

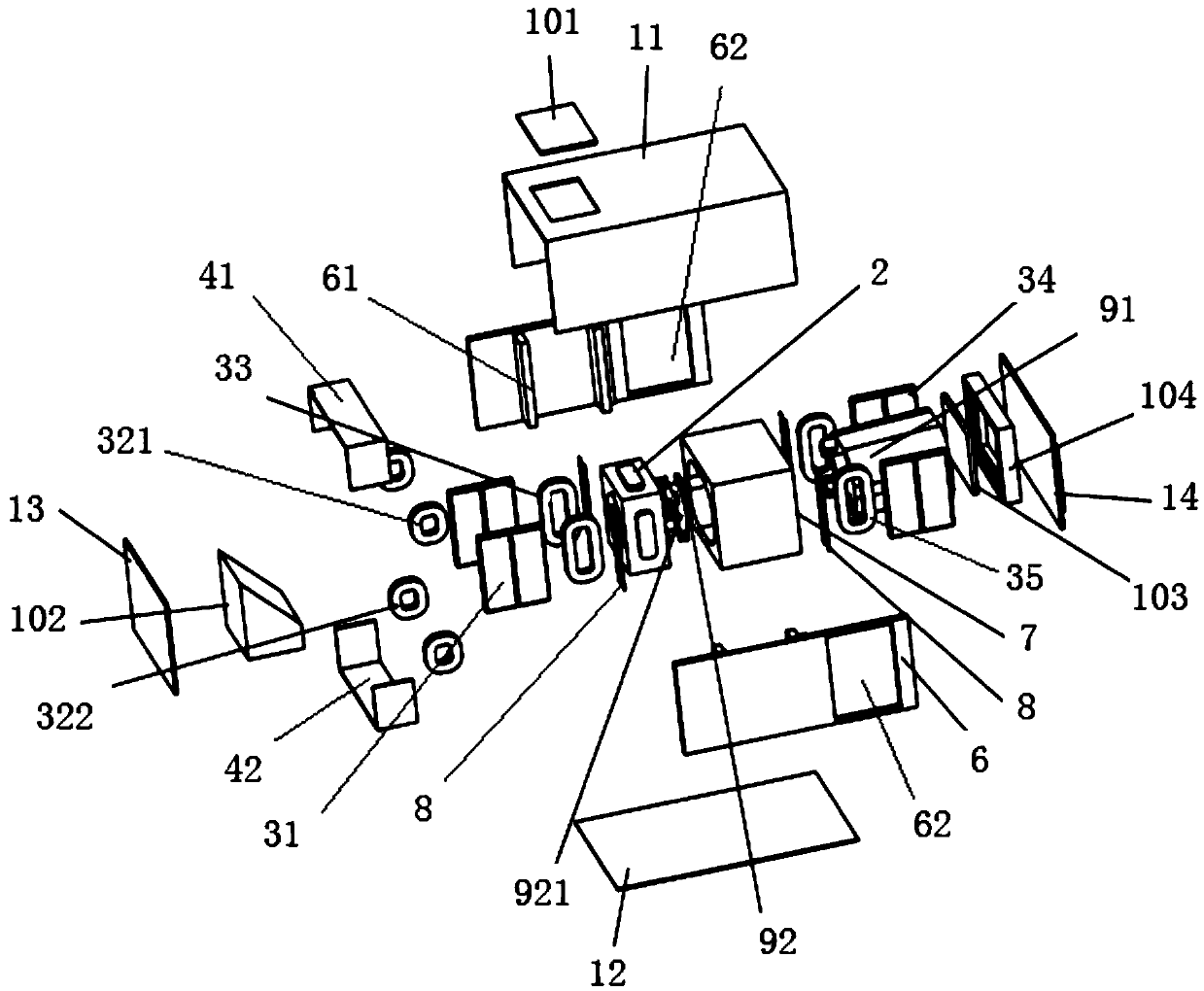

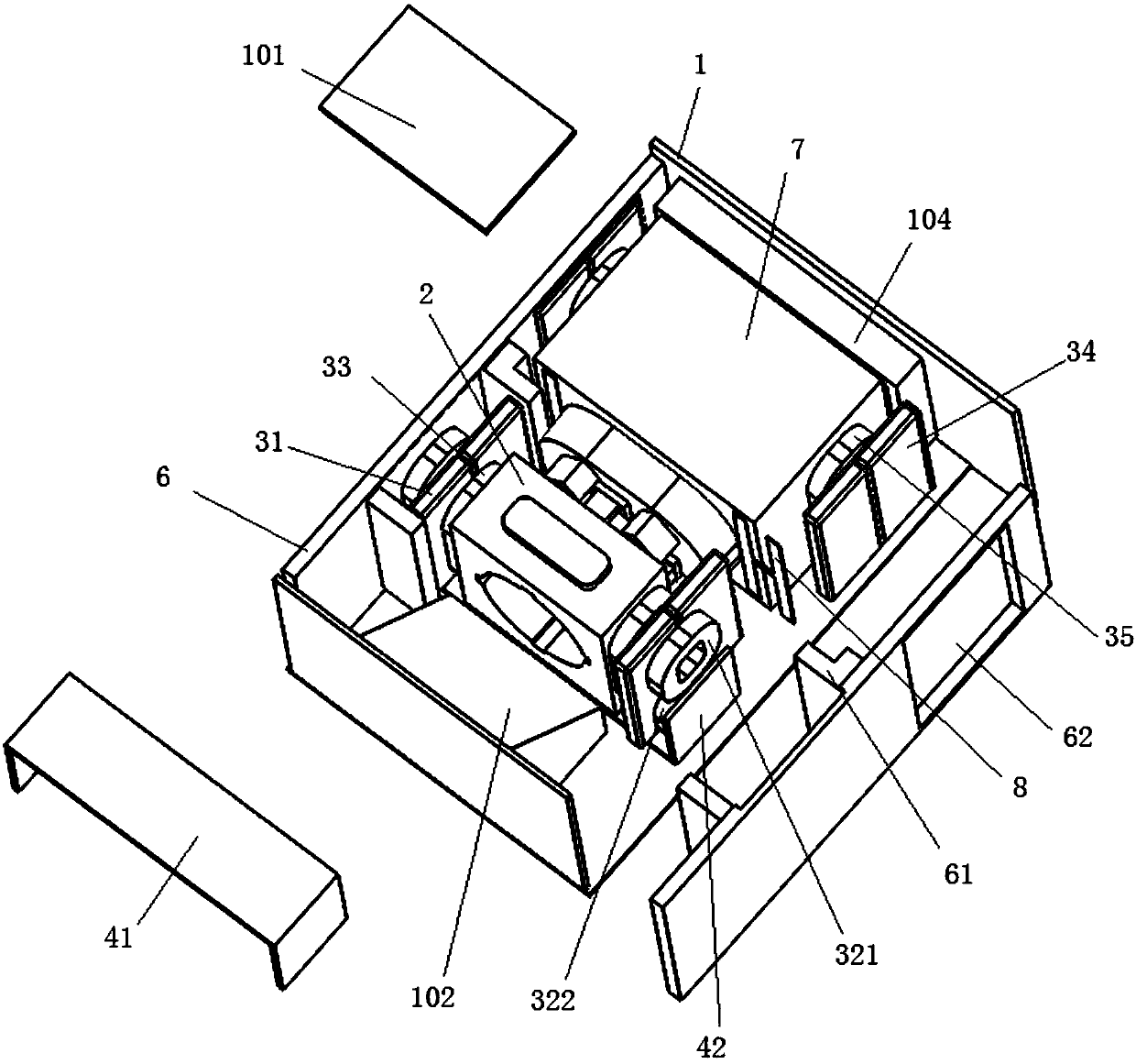

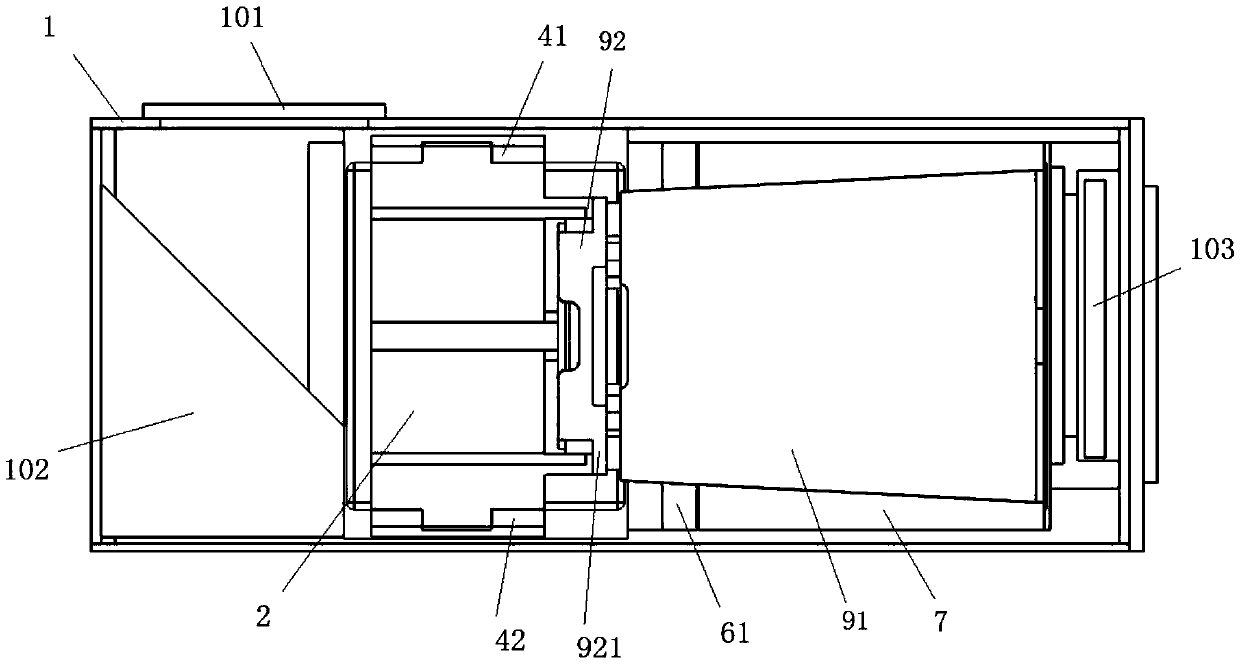

Driving structure and periscope type camera module

PendingCN109581617ALower the altitudeMeet the thickness requirementsTelevision system detailsPrintersOptical axisCamera module

The invention relates to the technical field of camera driving apparatuses, particularly relates to a driving structure and a periscope type camera module. The driving structure comprises a seat body,a bearing body, first stators and first rotors. The seat body is arranged for mounting a first lens and a liquid lens which are arranged along an optical axis and correspond to each other; the bearing body can be movably arranged inside the seat body in the mode of facing or getting away from the first lens, and the bearing body can abut against a moving plate of the liquid lens during moving todrive the moving plate to move so that the curvature of the liquid lens can be adjusted; the first stators are located on the left side and the right side of the bearing body in the optical axis direction and fixedly arranged inside the seat body; and the first promoters are located on the left side and the right side of the bearing body and fixedly arranged on the bearing body and correspond to the first stators, the first stators drive the first promoters to move, and the first promoter each comprise two first upper promoters located on the upper part of the bearing body and two first lowerpromoters located on the lower part of the bearing body. The driving structure has the advantages that the anti-shake effect is good and thickness is small.

Owner:DONGGUAN PRECISION PHOTONICS LTD

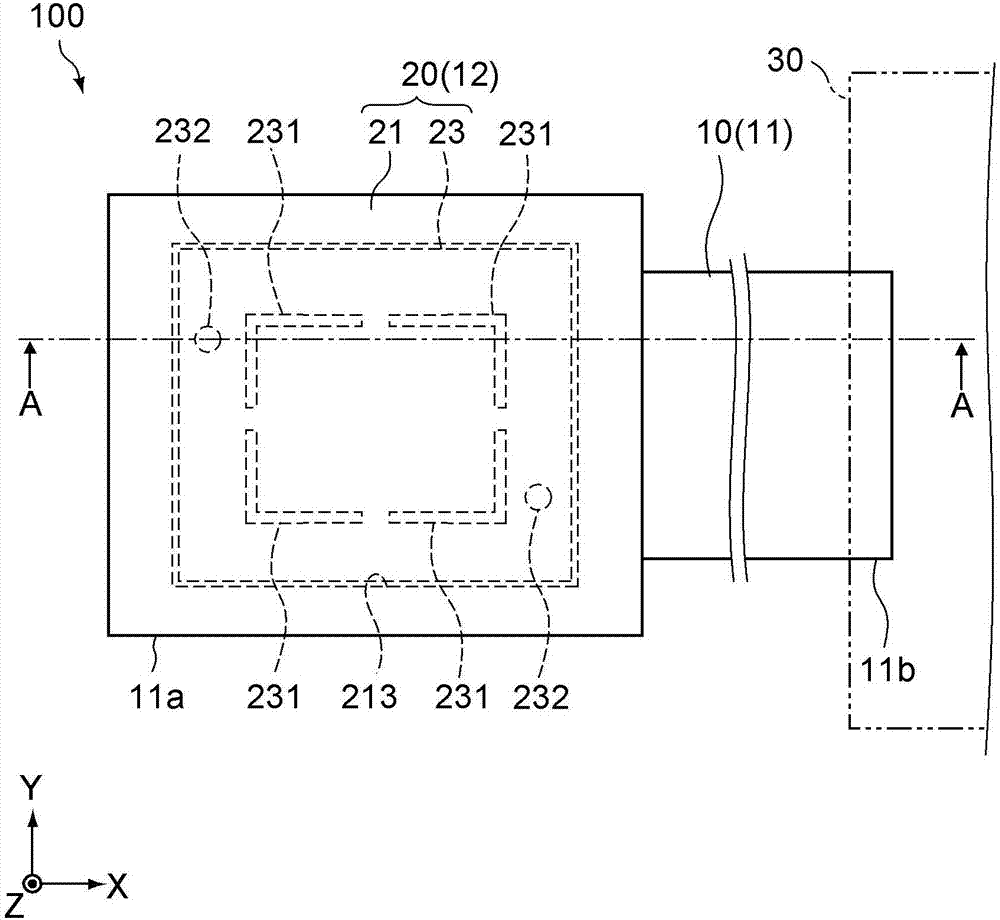

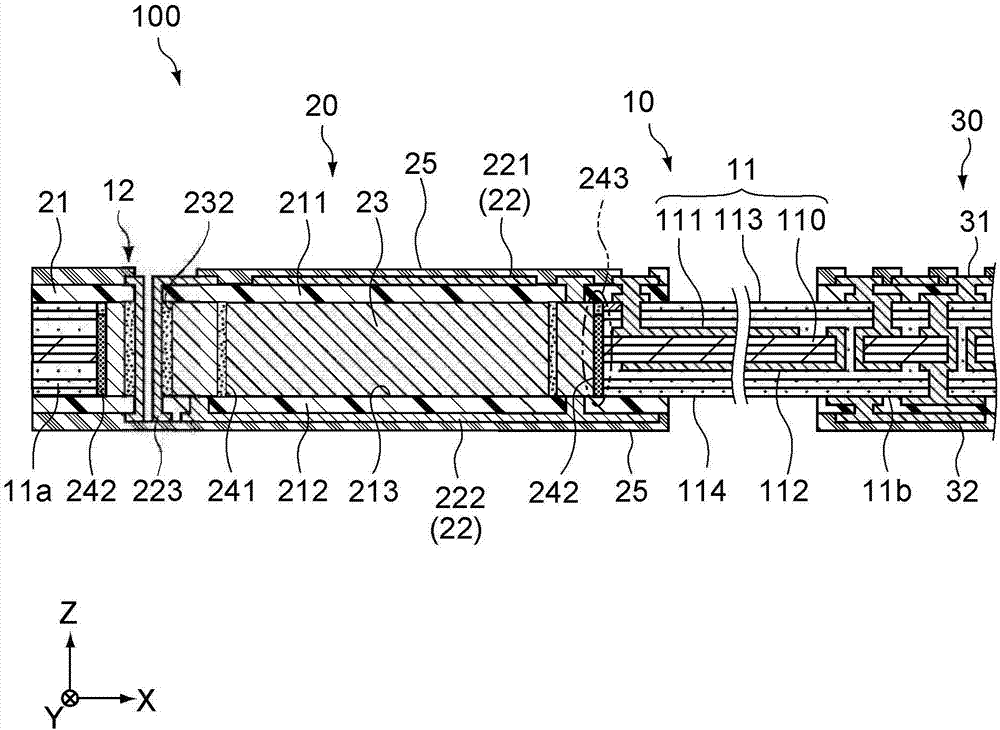

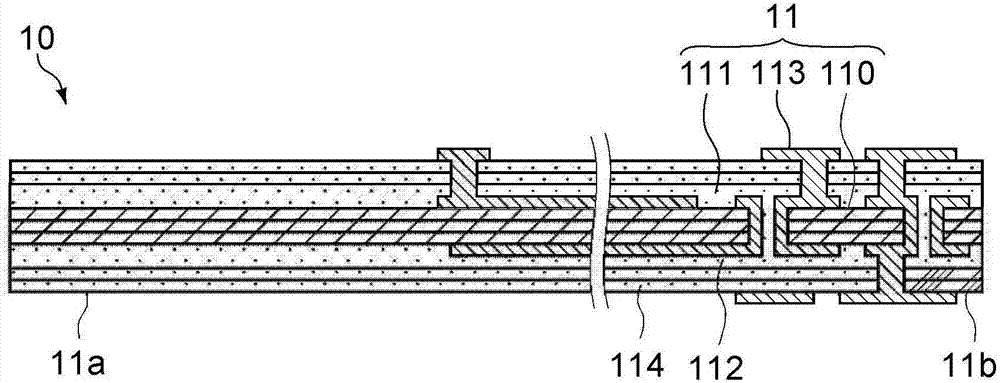

Circuit substrate and method of manufacturing same

InactiveCN107105570AHigh strengthMeet thickness requirementsPrinted circuit assemblingPrinted circuit aspectsElectrical and Electronics engineeringEngineering

Owner:TAIYO YUDEN KK

Prefabricated stair mold

Owner:内蒙古中朵远大建筑工业有限公司

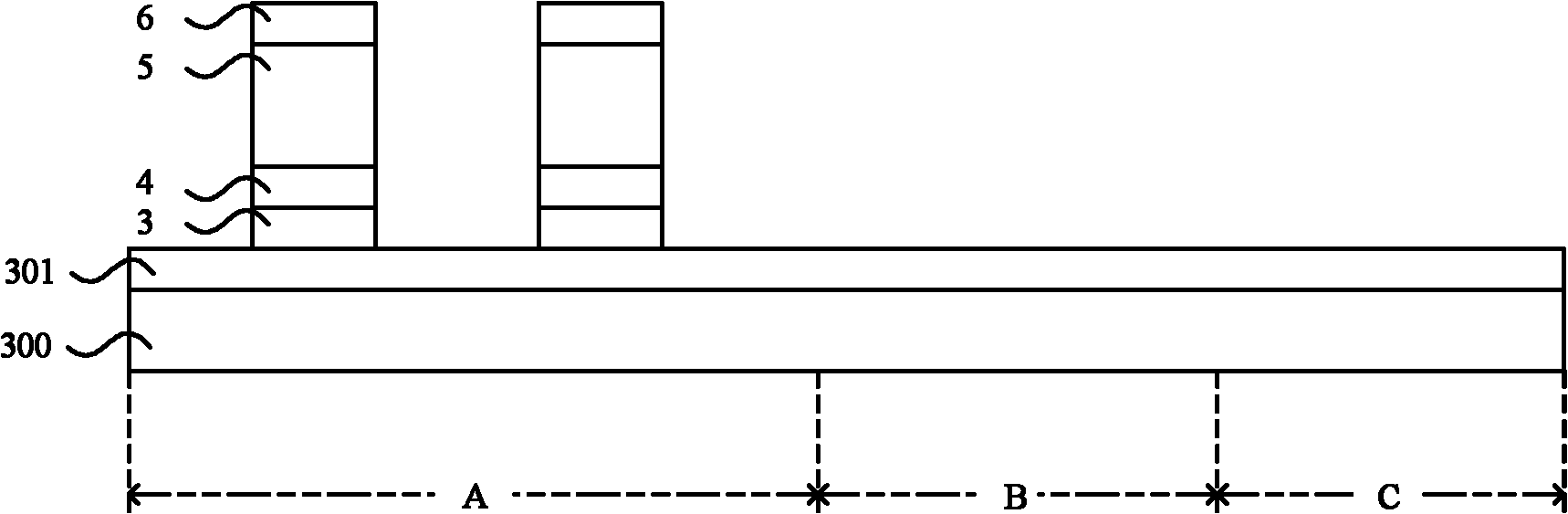

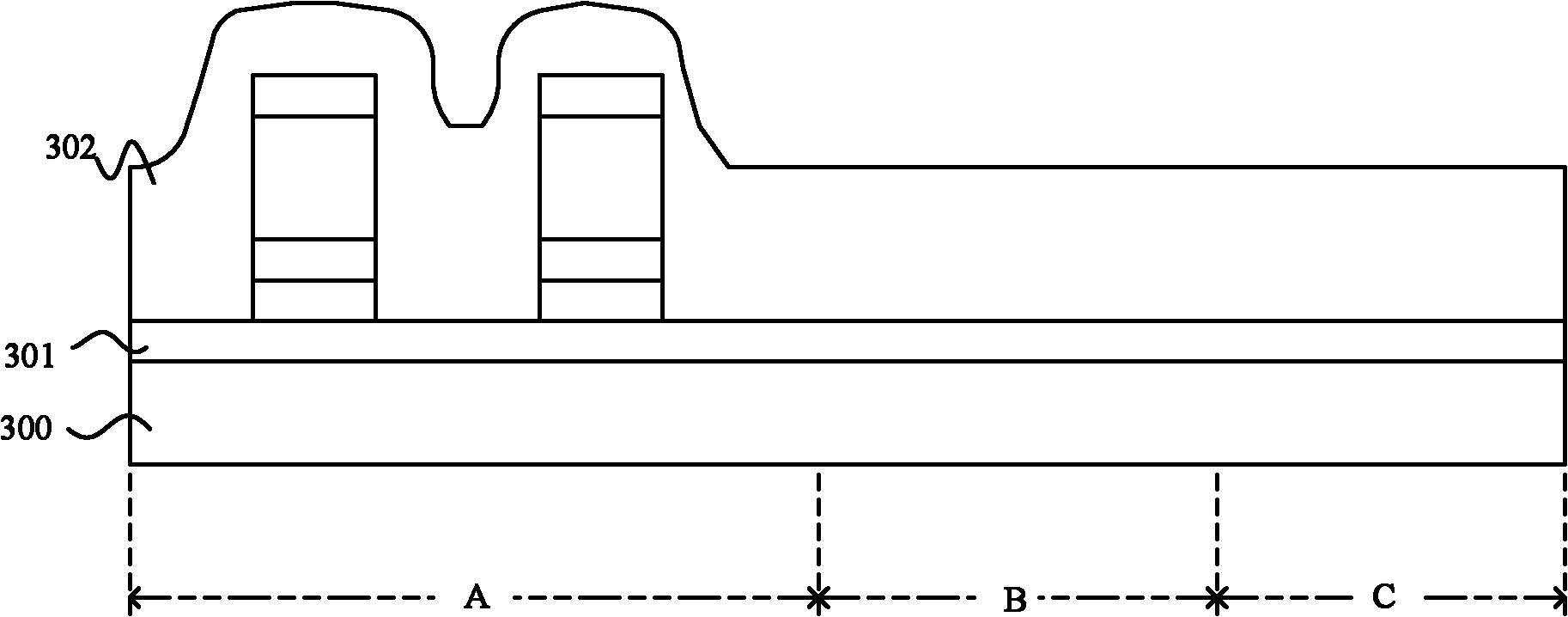

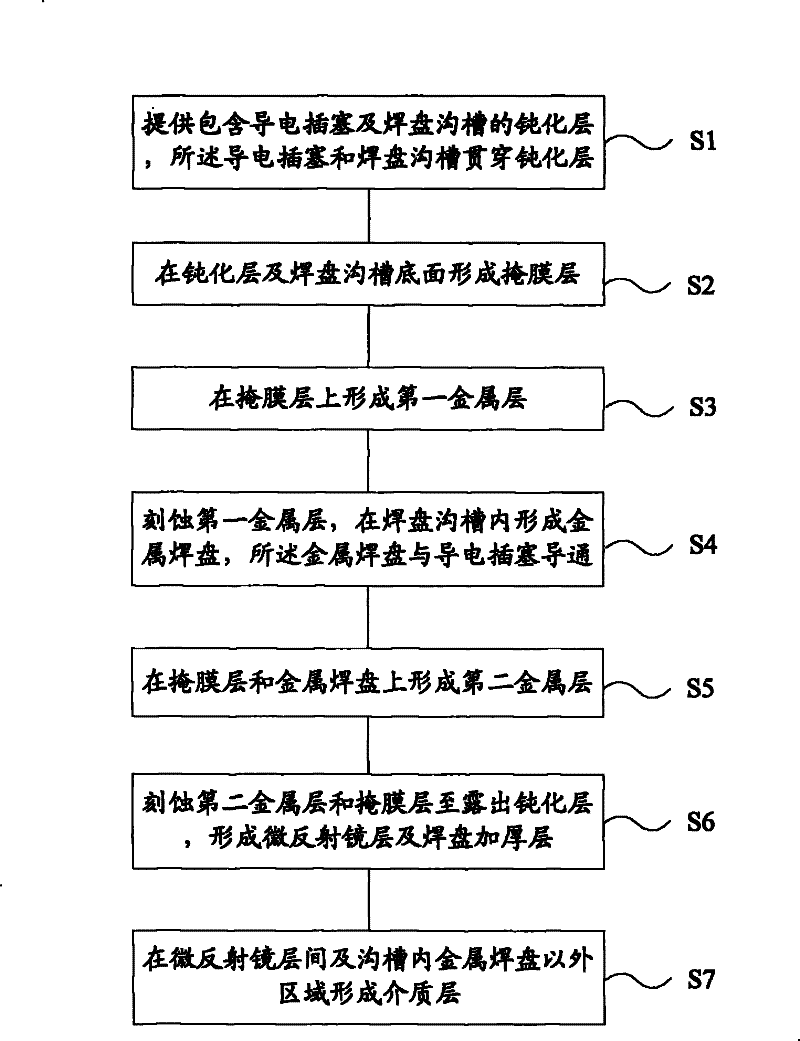

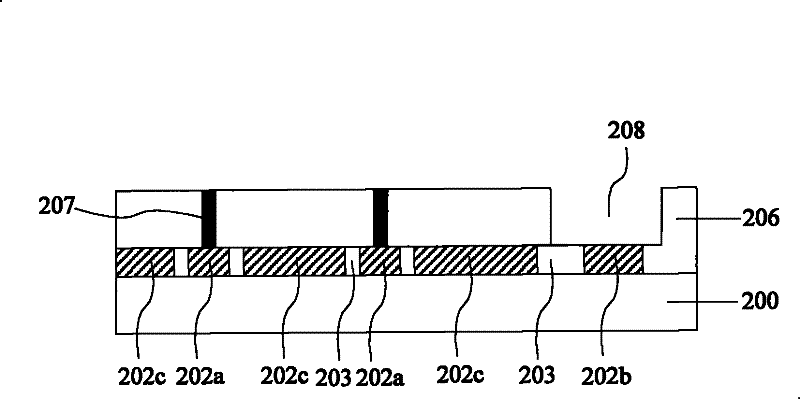

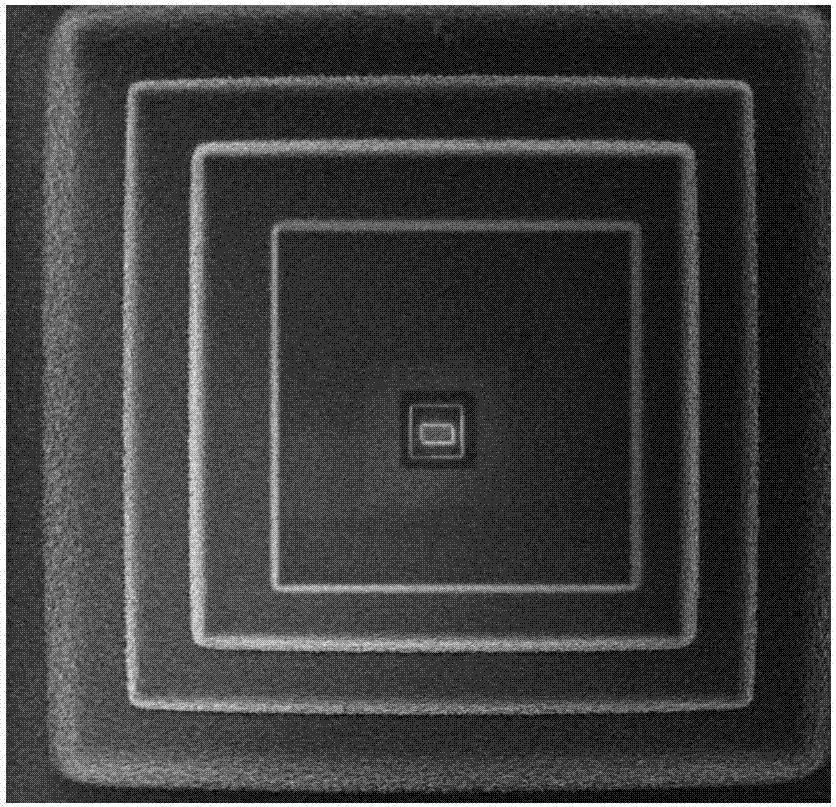

Micro mirror layer, liquid crystal on silicon (LCOS) display device and manufacturing method thereof

ActiveCN101866083BMeet thickness requirementsSemiconductor/solid-state device manufacturingNon-linear opticsDisplay deviceDielectric layer

The invention provides a micro mirror layer, a liquid crystal on silicon (LCOS) display device and a manufacturing method thereof, wherein the method for manufacturing the micro mirror layer comprises the following steps that: a passivating layer comprising a conducting plug and a pad groove is provided, and the conducting plug and the pad groove penetrate through the passivating layer; a maskingfilm layer is formed at the passivating layer and the bottom surface of the pad groove; a first metal layer is formed on the masking film layer; the first metal layer is etched, and a metal pad is formed in the pad groove and is conducted with the conducting plug; a second metal layer is formed on the masking film layer and the metal pad; the metal layer and the masking film layer are etched tillthe passivating layer is exposed so as to form the micro mirror layer, and the second metal layer on the metal pad is retained; and a dielectric layer is formed in the micro mirror layer and the areabeyond the metal pad in the groove. The invention can form an even and thin micro mirror layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

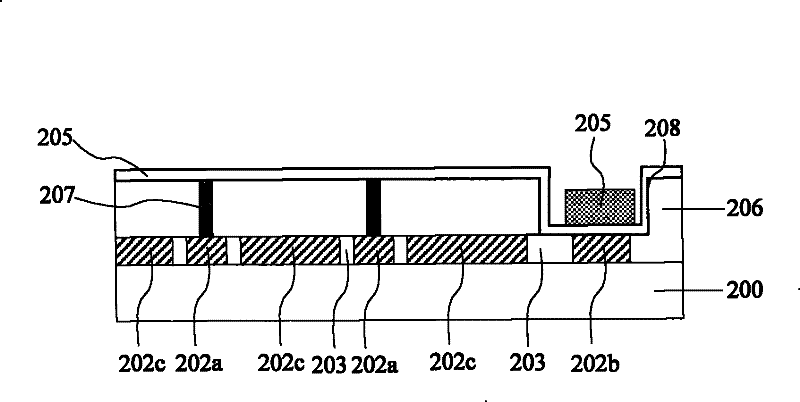

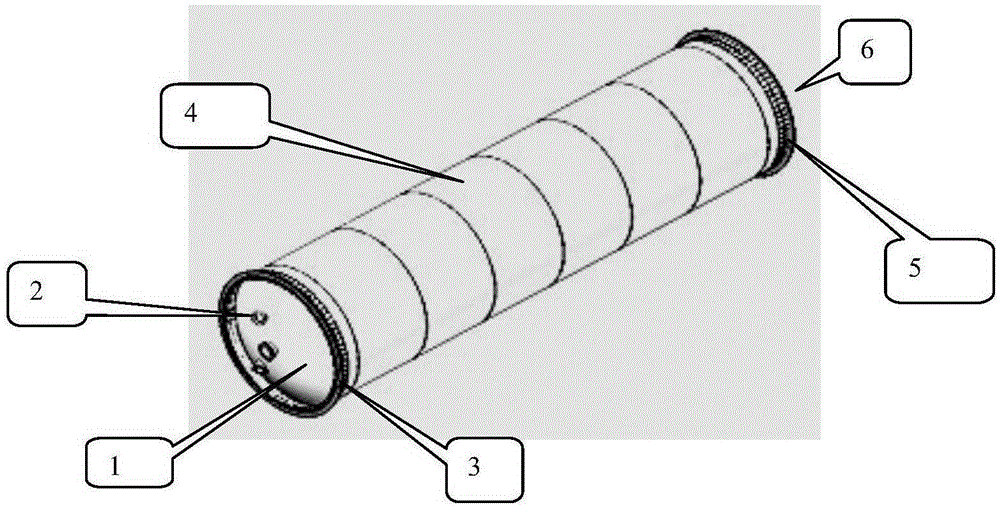

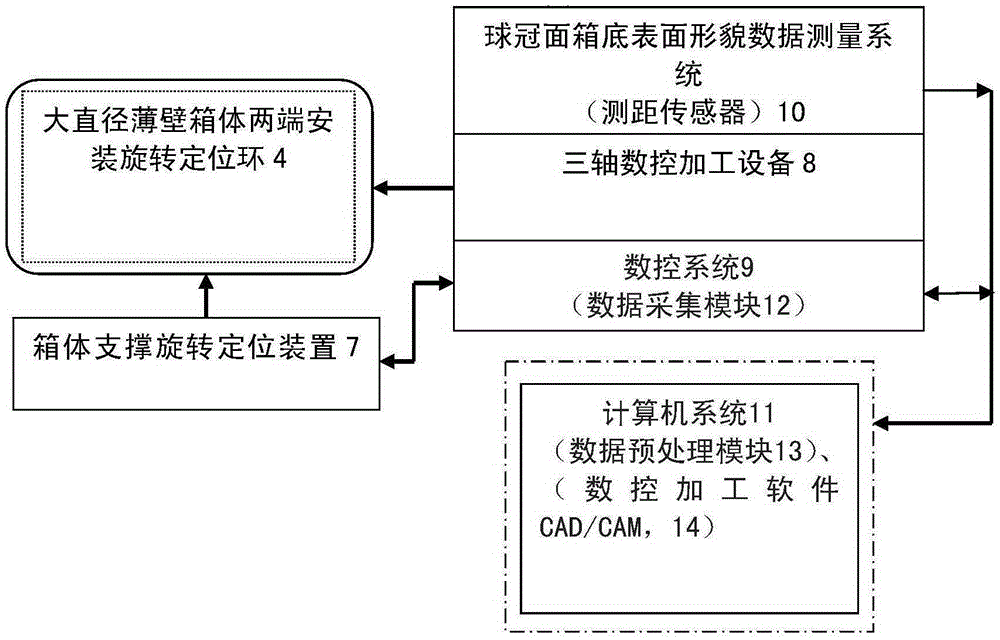

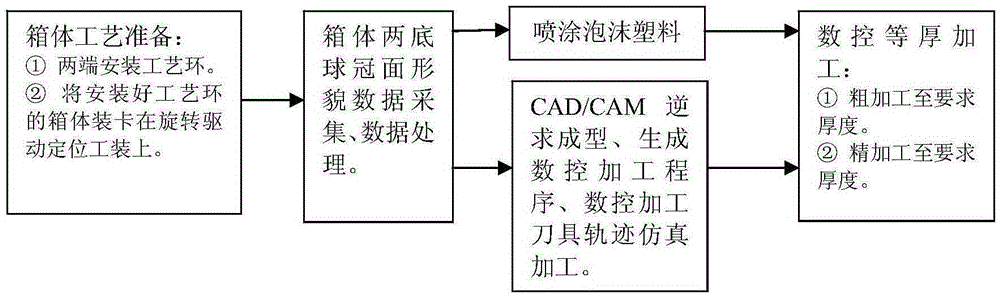

Uniform-thickness machining device and method for spherical crown face box bottom foam plastics of large-diameter thin-wall box

ActiveCN105270702AGood value for moneySatisfy surface finish and equal thicknessMilling equipment detailsRigid containersThin walledPre treatment

The invention relates to a uniform-thickness machining device and method for spherical crown face box bottom foam plastics of a large-diameter thin-wall box. The device comprises a rotating and positioning ring, a box supporting, rotating and positioning device, a three-axis numerical control machining device, a numerical control system, a spherical crown face box bottom metal surface morphology data measuring system, a computer system, a data acquisition module, a data pre-processing module and a numerical control machining software CAD / CAM module; the data acquisition module is embedded in the numerical control system; and the data pre-processing module and the numerical control machining software CAD / CAM module are embedded in the computer system. The device and method solve the uniform-thickness machining problem of foam plastics sprayed on the box spherical crown face, and it is verified and indicated through practical application that the requirements for surface smoothness and uniform thickness are met when the method is used for performing numerical control form copying on foam plastics sprayed at the spherical crown face box bottom.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

Additive for quick chemical nickel-phosphorus plating of environment-friendly aluminum alloy

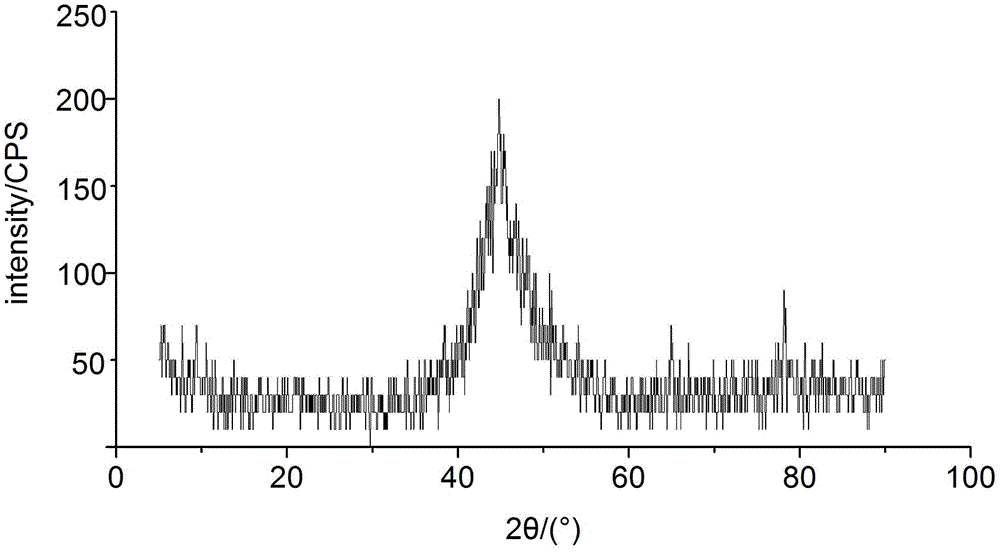

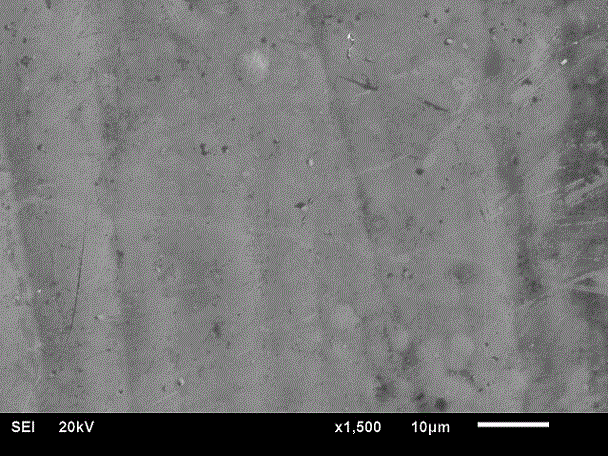

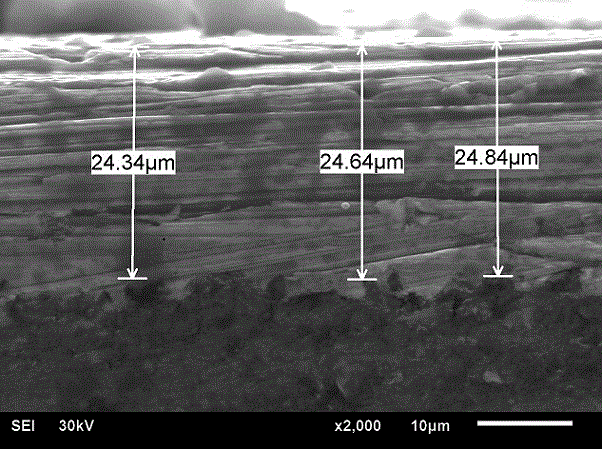

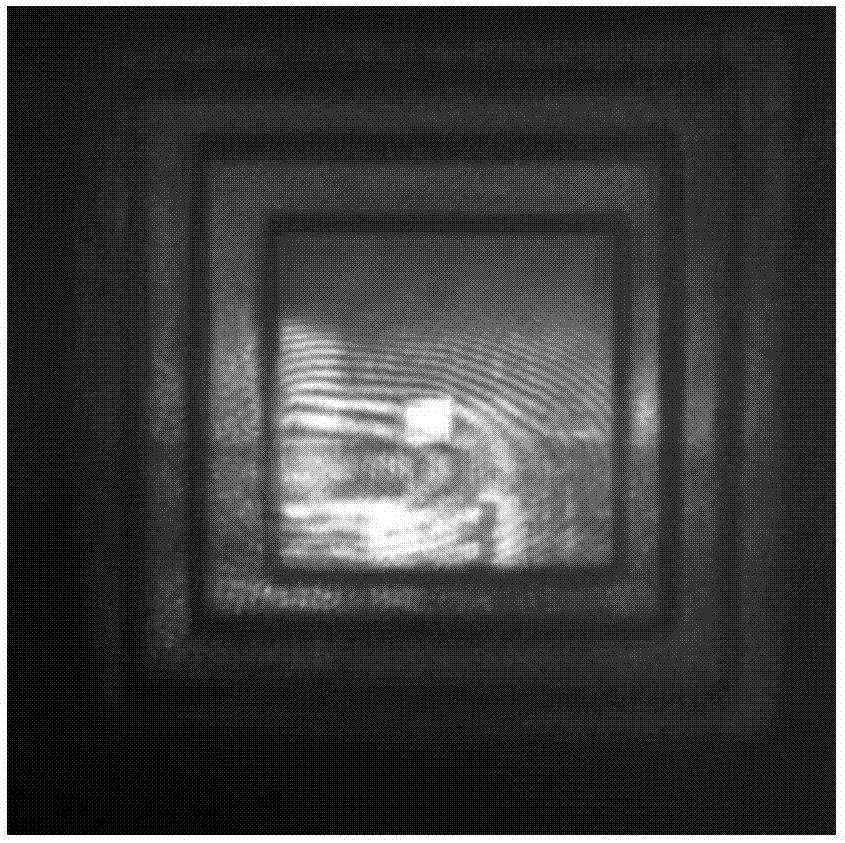

ActiveCN104561948AMeet the requirements of corrosion resistanceRapid depositionLiquid/solution decomposition chemical coatingYTTERBIUM OXIDEAntimony potassium tartrate

The invention relates to an additive for quick chemical nickel-phosphorus plating of environment-friendly aluminum alloy, which is composed of A, B, C and D components, wherein the A component comprises 20-60mg / L of yttrium oxide, 20-60mg / L of ytterbium oxide, 100-500mg / L of sodium tetraborate, 20-40ml / L of a 1:1 dilute sulphuric acid and the balance of water; the B component comprises a complexing agent and the balance of water; the C component comprises 1-4mg / L of copper sulfate, 0.5-2mg / L of antimony potassium tartrate, 1-5mg / L of ammonium molybdate, 4-10mg / L of allyl iodide, and the balance of water; and the D component comprises an intermediate and the balance of water. By using the additive disclosed by the invention, nickel-phosphorus can be quickly and stably deposited, the plating thickness reaches 5.6-6.0 mu m after plating is performed for 10 minutes, the plating thickness can reach 24.3-25.0 mu m after continuous plating is performed for 1 hour, the average plating speed is more than 24.3 mu m / h, and the plating layer is amorphous, uniform and dense, high in hardness and good in corrosion resistance.

Owner:哈尔滨三泳金属表面技术有限公司

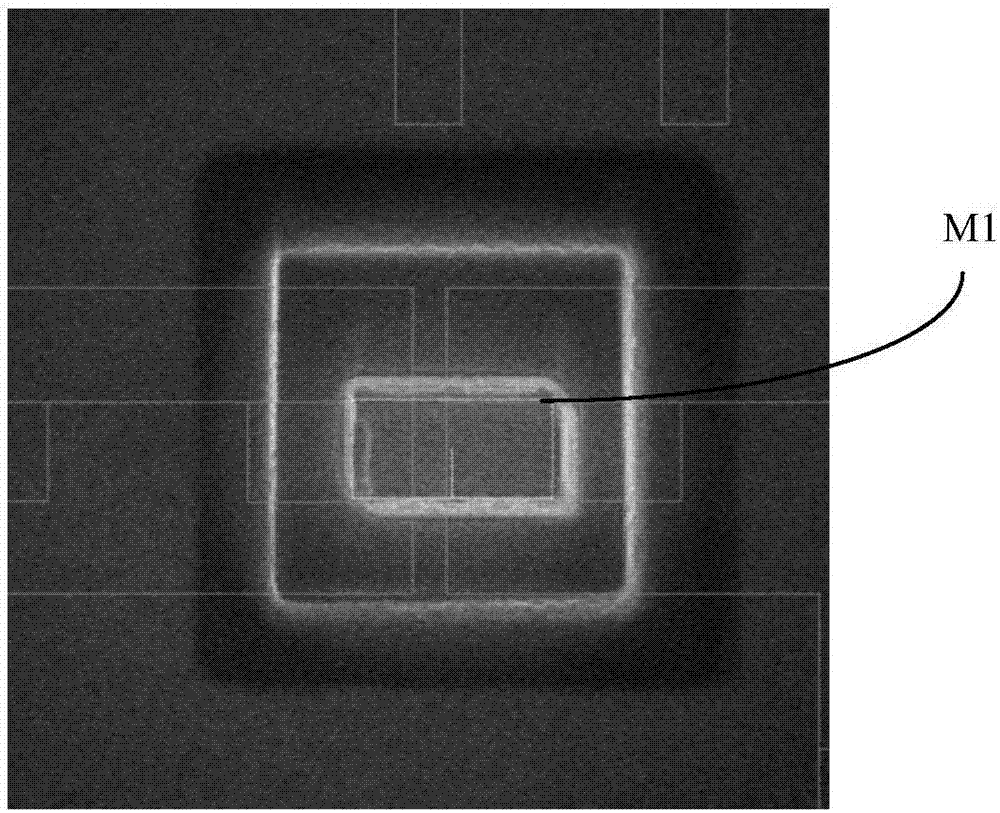

Modification method for flip-chip packaging integrated circuit

InactiveCN107093565AAvoid damageImprove modification efficiencySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEtchingIon beam

The invention relates to a circuit modification method for a flip-chip packaging integrated circuit. The integrated circuit comprises a substrate, and a chip packaged on the substrate in a flip-chip mode, and a surface of the chip fitting the substrate has a to-be-modified region. The method comprises steps that (1), the chip is ground; (2), first etching for the chip after grinding is carried out through employing a focusing ion beam in combination with an auxiliary etching gas; (3), imaging of the chip after etching is carried out, and the position of the to-be-modified region is determined according to a circuit image acquired through imaging; (4), second etching for the chip after the first etching is carried out through employing the focusing ion beam in combination with the auxiliary etching gas, and the to-be-modified region is exposed; a circuit of the to-be-modified region is modified through utilizing the focusing ion beam. The method is advantaged in that circuit modification for the chip employing flip-chip packaging can be carried out, and circuit modification efficiency is high.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

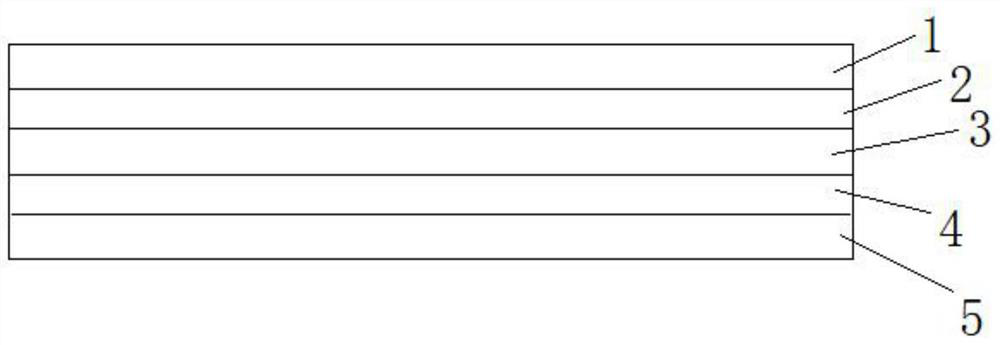

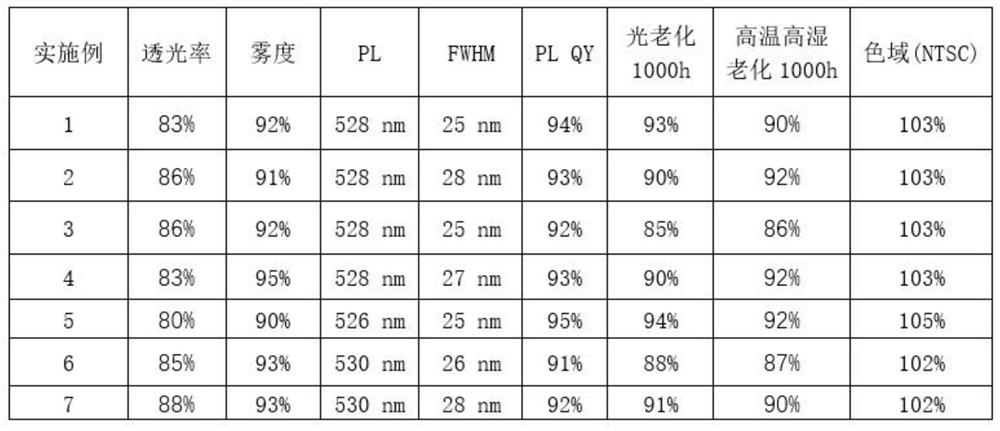

Preparation method of perovskite quantum dot film

InactiveCN112109410AHigh fluorescence quantum yieldIncrease brightnessLaminationLamination apparatusElastomerThermoplastic elastomer

The invention discloses a preparation method of a perovskite quantum dot film. The method comprises the following steps: 1) preparation of perovskite quantum dot polymer particles; and 2) preparationof a perovskite quantum dot film: enabling PP particles, EVOH particles and the perovskite quantum dot polymer particles prepared in the step 1) to respectively pass through a vacuum feeding system, adding the mixture into an extruder A, an extruder B, an extruder C, an extruder D and an extruder E, and extruding to form a film through a multi-layer co-extrusion casting machine to obtain the required perovskite quantum dot film. According to the method, a thermoplastic elastomer is used as a dispersing agent, perovskite quantum dot polymer particles are prepared by using a high-temperature thermal injection method, tedious centrifugation, separation and redispersion are not needed, and the perovskite quantum dot polymer particles and other polymers are directly co-extruded to obtain the perovskite quantum dot film, so that the method is simple in process and low in cost, the implementation efficiency is improved; and meanwhile, the optical performance and stability of the perovskite quantum dot can be ensured.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com