Uniform-thickness machining device and method for spherical crown face box bottom foam plastics of large-diameter thin-wall box

A technology of thin-walled boxes and foam plastics, applied in metal processing equipment, packaging, manufacturing tools, etc., to achieve the effect of satisfying surface finish, equal thickness, and good cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

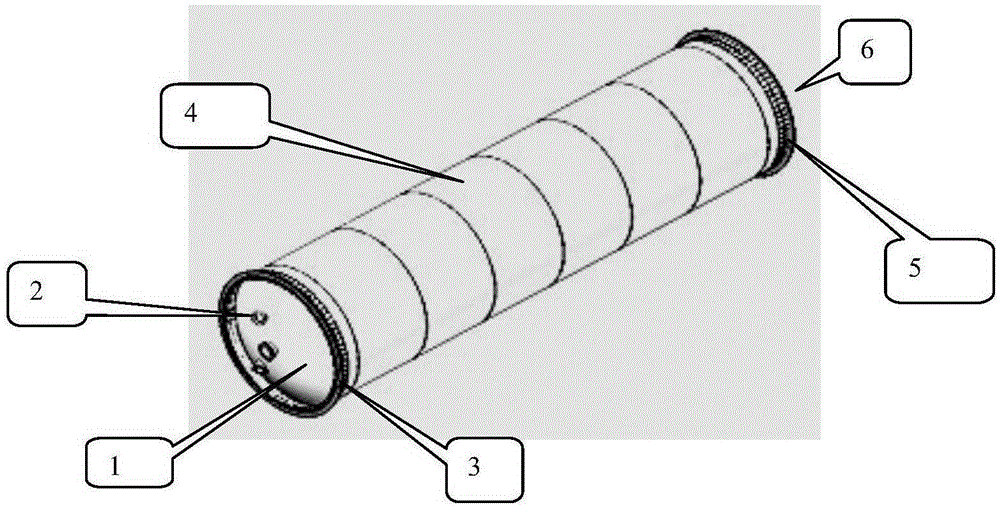

[0040] like figure 1 As shown, the large-diameter thin-walled box includes two spherical crown surface box bottoms 1, 6 and a column section 4. There are protrusions 2 on the spherical crown surface box bottom, and rotating positioning rings 3 are respectively installed on both ends of the column section 4. , 5.

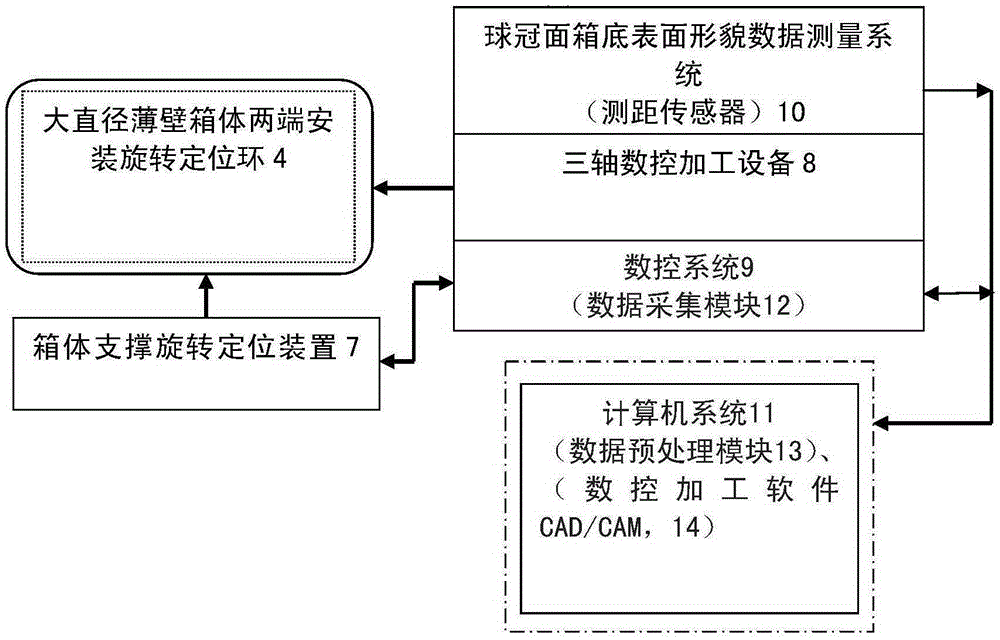

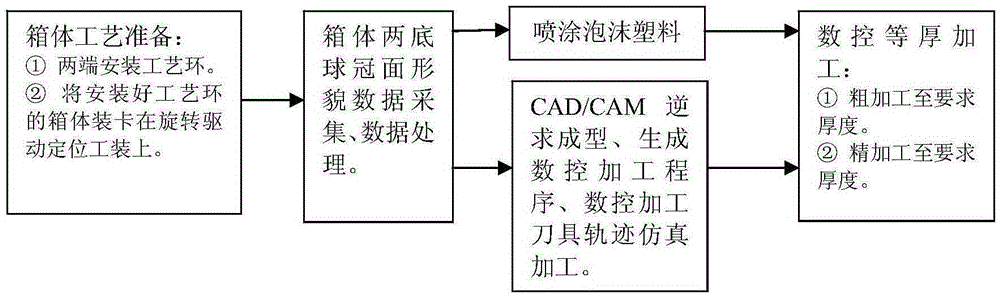

[0041] like figure 2 , image 3 , Figure 4 As shown, the processing device of the present invention includes: rotary positioning rings 3, 5, box support rotary positioning device 7, three-axis numerical control processing equipment 8, numerical control system 9, metal surface topography data measurement system 10 of the spherical crown surface box bottom, and a computer System 11, data acquisition module 12, data preprocessing module 13 and numerical control machining software CAD / C module 14, the data acquisition module is embedded in the numerical control system, and the data preprocessing module and numerical control machining software CAD / CAM module are embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com