Patents

Literature

36results about How to "Surface finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for filling polyurethane sole with waste rubber

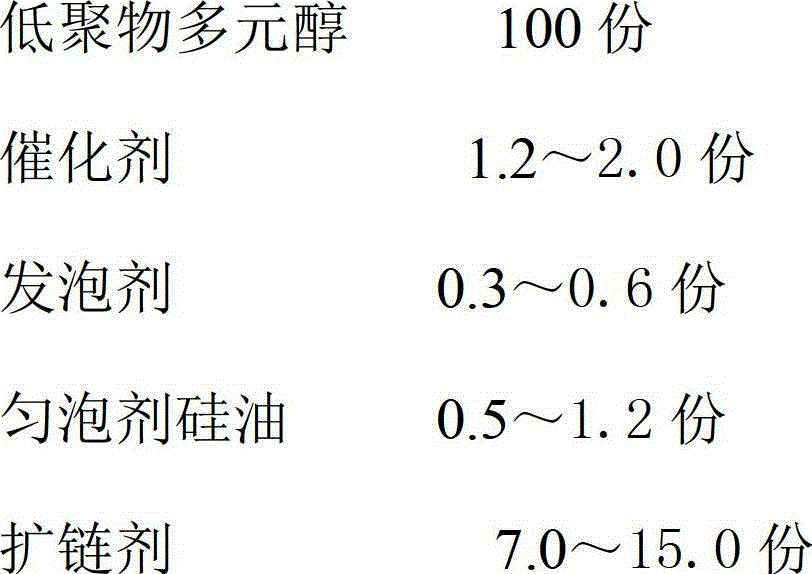

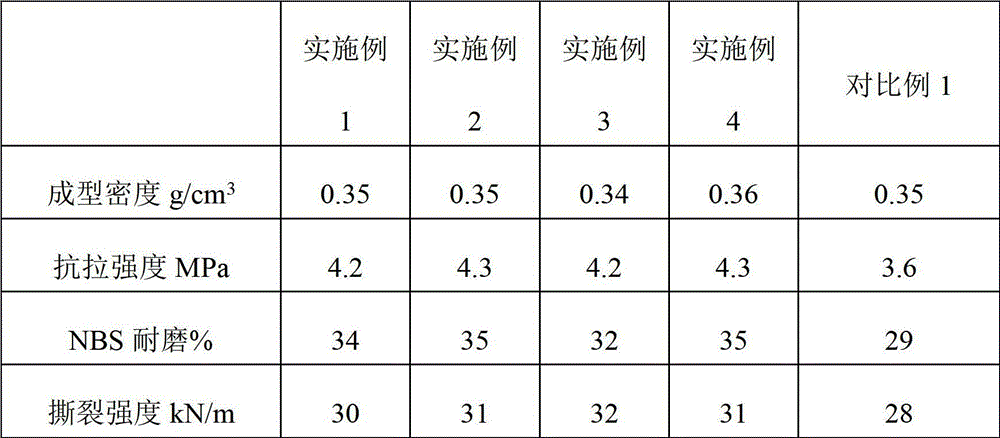

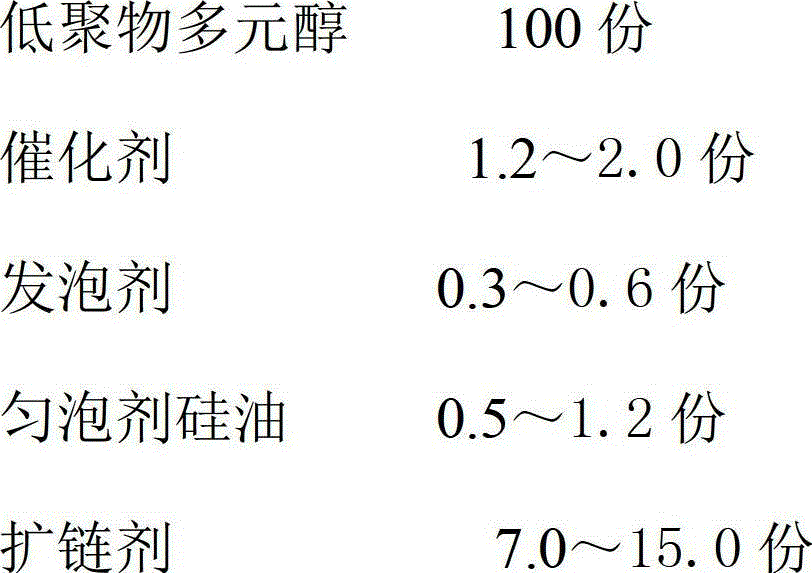

The invention provides a method for filling a polyurethane sole with waste rubber. The method comprises the following steps that A components, B components and rubber particles are mixed to be poured into a sole mold to be in reaction forming, demolding is carried out, and curing is maintained in a 60-70 DEG C drying oven for 22-24 hours to obtain the polyurethane sole filled with the waste rubber particles; the A components comprise, by weight, 100 parts of low polymer polyhydric alcohols, 1.2-2.0 parts of catalytic agents, 0.3-0.6 part of foaming agents, 0.5-1.2 parts of foam stabilizer silicone oil, and 7.0-15.0 parts of chain extender; and the B components comprise, by weight, 30-90 parts of the low polymer polyhydric alcohols, and 100 parts of diisocyanate. According to the method, the obtained polyurethane sole is uniform in foam holes, smooth in surface, and higher than a common polyurethane sole in tensile strength, abrasion resistance and tearing strength, the problem of reuse of rubber waste is resolved, and the technological process is simple and efficient.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

Softener for thick salix integra and preparation method of softener

ActiveCN103659979AImprove toughnessSmoothReed/straw treatmentWood impregnation detailsEthylenediamineBetaine

A softener for thick salix integra is made from raw materials in parts by weight as follows: 5-7 parts of ethylenediamine, 4-5 parts of tartaric acid, 4-5 parts of coco-betaine, 1-2 parts of decyl polyglucoside, 4-5 parts of ammonium dihydrogen phosphate, 10-12 parts of dandelion, 4-6 parts of chrysanthemum, 10-12 parts of coptis chinensis, 3-4 parts of camphor tree bark, 6-8 parts of povidone iodine,3-4 parts of an assistant and 100 parts of water. According to the softener, the ethylenediamine, the tartaric acid and multiple surfactants are used, so that the softener is high in permeation speed, high in softening speed and even in softening; the salix integra is good in toughness and touches smooth, and the weaving efficiency can be improved; and Chinese herbal medicines such as the camphor tree bark and the like as well as the povidone iodine are used, so that salix integra is smooth in surface, mould-proof and free of worms. The softener is applicable to softening of the thicker salix integra.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

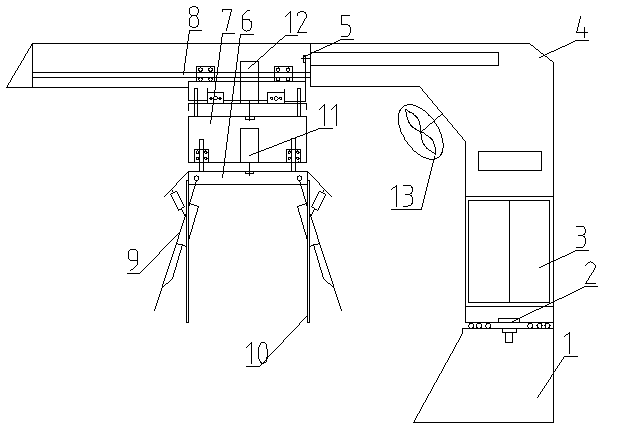

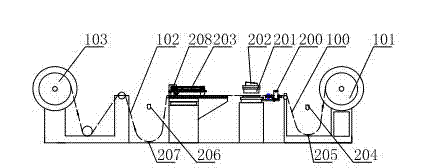

Full-automatic crawler loader for pig moulding machine

InactiveCN103506615AClean scumSurface finishIngot casting plantsCasting cleaning apparatusOperational maintenanceProduction rate

The invention provides a full-automatic crawler loader for a pig moulding machine in order to solve the problem that no mature crawler loader exists in the prior art. The full-automatic crawler loader for the pig moulding machine is characterized in that pneumatic power is used in complete equipment as the power, and slagging-off work is conducted on two sets of casting molds at the same time; a cantilever is mounted on a base, a following mechanism is mounted on the cantilever through an unthreaded bar, a positioning mechanism is mounted below the following mechanism, after the positioning mechanism determines the position of the casting molds, the following mechanism follows the casting molds to move together, meanwhile, a mechanical arm descends to make slagging-off movement, and a rear mechanism arm is lifted and moved to the periphery of a working area, slagging-off is conducted, and then restoration is achieved. According to the full-automatic crawler loader, slagging-off is complete, the surface of an aluminium pig is smooth, slagging-off movement is at a constant low speed, the full-automatic crawler loader for the pig moulding machine can be automatically suitable for variation of the production rate of the pig moulding machine, operating and maintaining are simple and convenient, working efficiency is high, and environmental protection and safety are achieved.

Owner:洛阳希诺能源科技有限公司

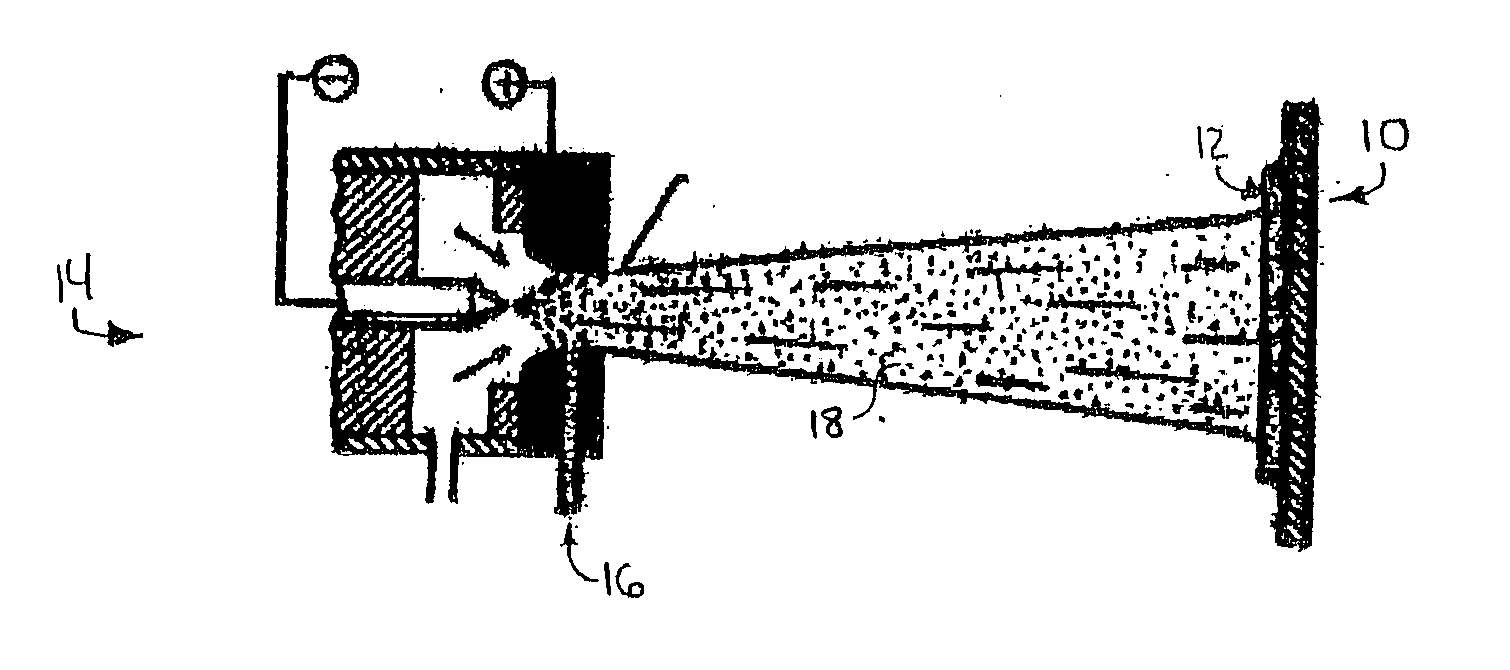

Method for post deposition of beta phase nickel aluminide coatings

InactiveUS20050053800A1High densityAccelerated corrosionMolten spray coatingPretreated surfacesSurface finishBeta phase

A method for producing an article such as a turbine component that is coated with a β-phase, high aluminum content coating, such as substantially stoichiometric NiAl, and which has a surface finish suitable for application of a ceramic topcoat. The method involves heating the coated article to near the brittle-ductile transition temperature of the coating and impacting the coating with particles of a preselected size so that the brittle coating is not adversely affected by chipping or breakage. The impacting produces a surface finish of 120 micro-inches or finer so that a ceramic thermal barrier layer can be applied over the coating. The preferred method of improving the surface finish utilizes heated peening media to impact the heated coated article, thus allowing use of a broader selection of peening media.

Owner:GENERAL ELECTRIC CO

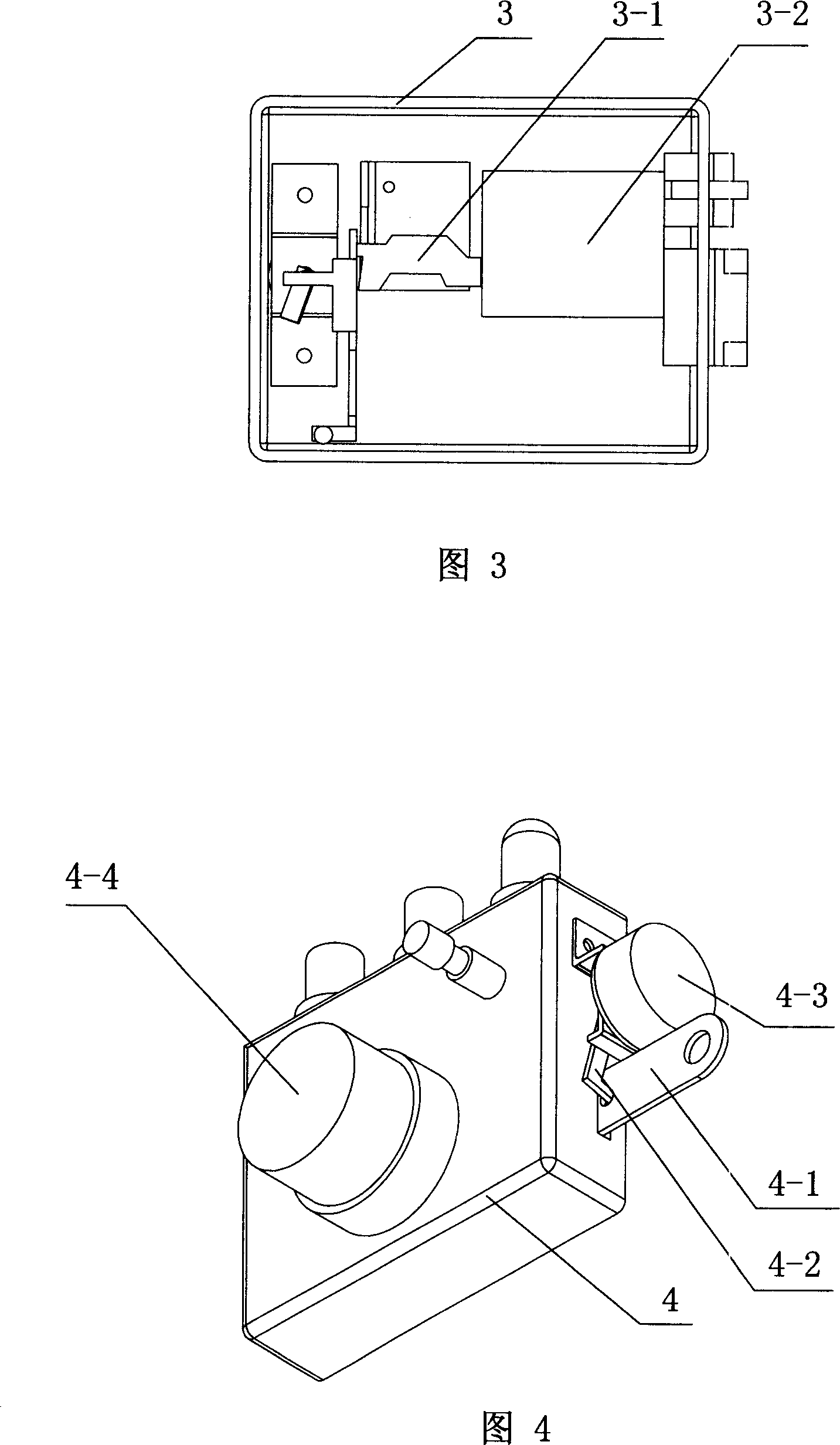

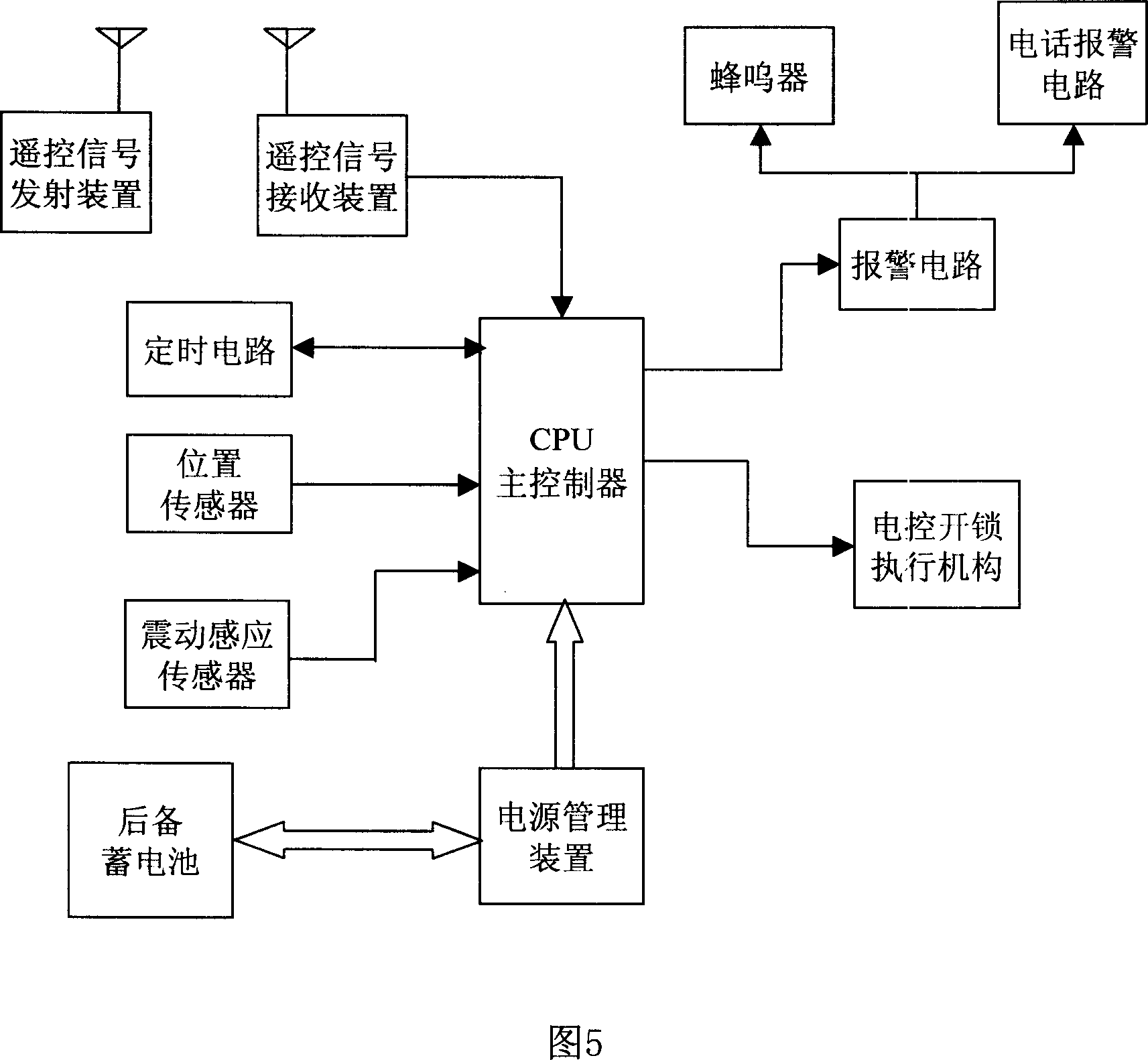

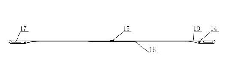

Anti-theft pick-proof door

InactiveCN1963135AImprove defenseImprove confidentialityBurglary protectionElectric permutation locksElectronic control systemEngineering

The anti-theft and pick-proof door has an electronic cipher lock controlled door outside of the inner door. The cipher lock comprises a spring bolt, a bolt mechanical device and an electronic controlled device. The electronic controlled device includes a major controller, an executive mechanism for electronically controlled unlocking and a signal receiving device. Major controller receives and verifies the accuracy of the codes and drives the electronic control device opening the cipher lock and the unlocking spring within the inner doorand the electronic controlled door props the said electronic controlled door open. The inner door has electronically controlled cipher mechanical lock with the core of the lock connected with the electronic control device. Only if the inner door code is correct, can the key to open the lock. The major controller also has a warning circuit, a timing circuit, an electronic controlled door, and the location and vibration sensor equipped on the inner door, featuring on the characteristics of warning system for wrong entering of codes, overtime code entering and strong vibration and system locking function. A power management device and a spare battery guarantee the normal operation of the electronic control system of the door. With double protective ability added, the door is safe, secure and reliable with fine appearance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

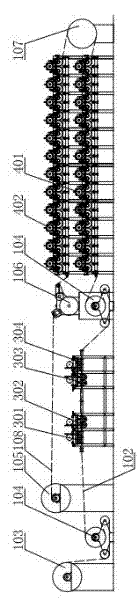

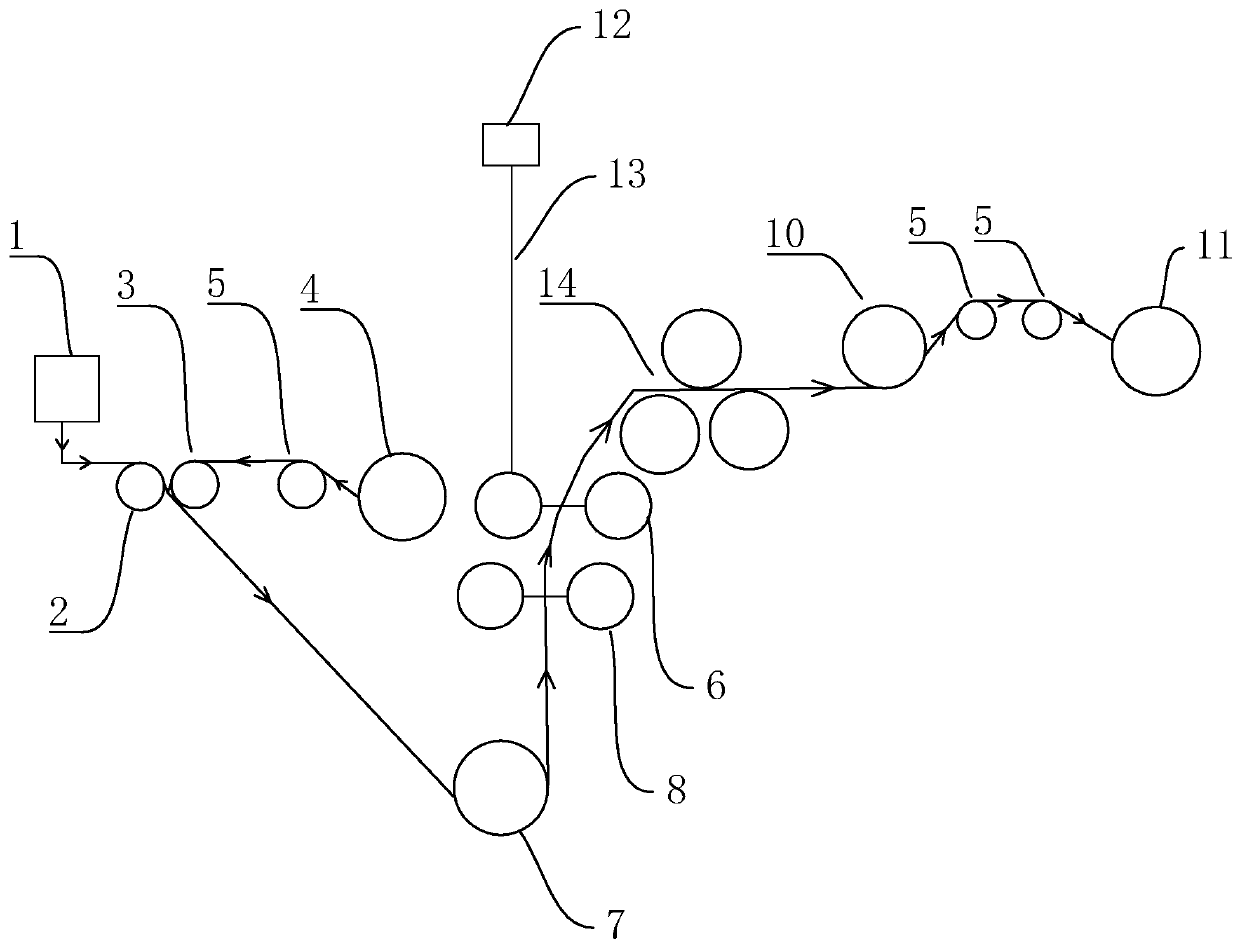

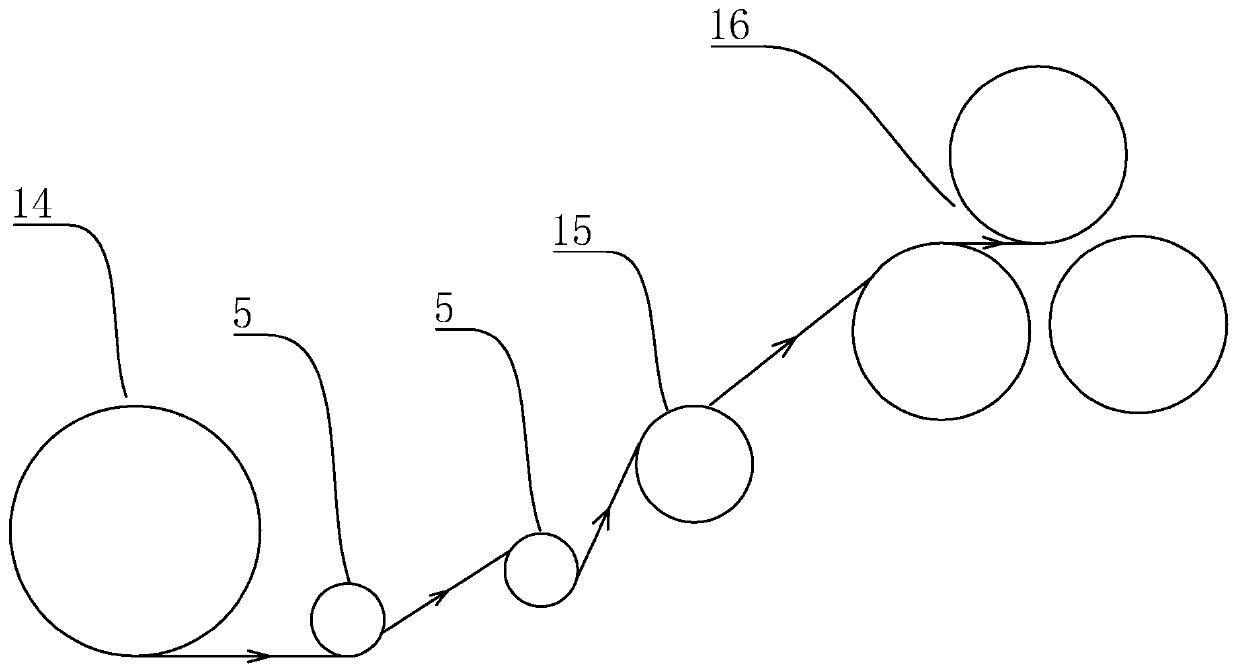

Polishing production line for steel heald

InactiveCN102189476AReduce labor intensityReduce pollutionPolishing machinesProduction lineUltimate tensile strength

The invention relates to a polishing production line for a steel heald. The polishing production line comprises a belt inner side edge polishing device and a belt surface polishing device which are connected in series with each other. In the invention, an automated continuous polishing production line is used, so that the production line has high degree of automation and high production efficiency; labor force can be saved by about 80 percent, so that production cost is greatly reduced; and the labor intensity of operating workers is reduced, and pollution to the environment is reduced.

Owner:无锡众磊氨基模塑成套设备厂

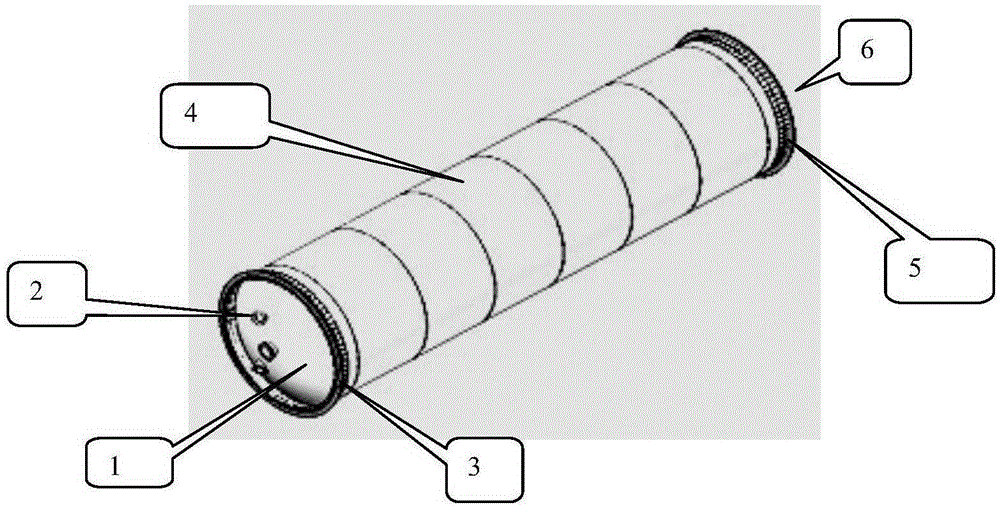

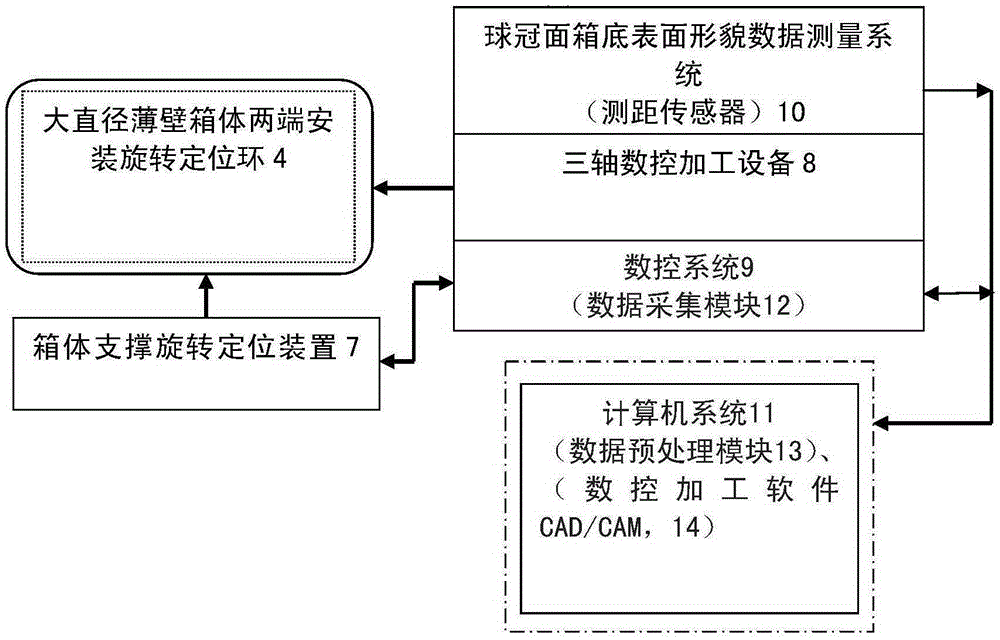

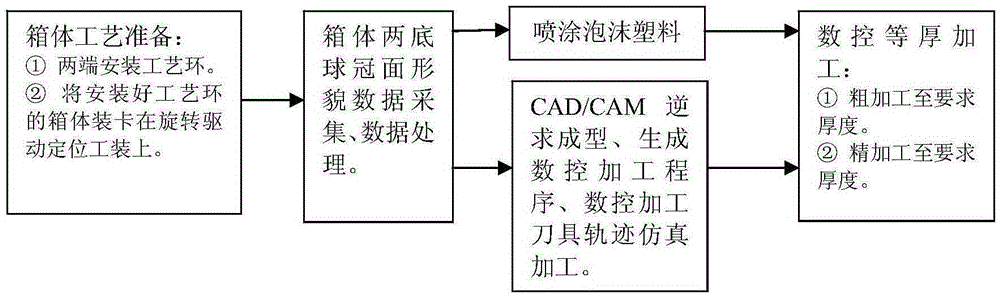

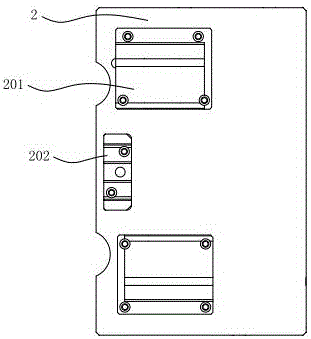

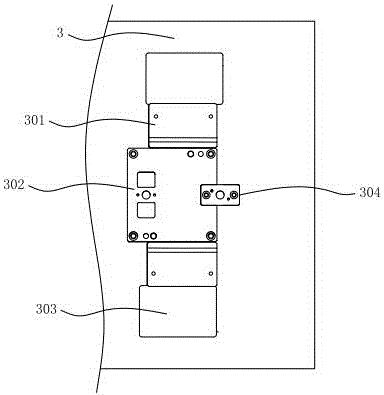

Uniform-thickness machining device and method for spherical crown face box bottom foam plastics of large-diameter thin-wall box

ActiveCN105270702AGood value for moneySatisfy surface finish and equal thicknessMilling equipment detailsRigid containersThin walledPre treatment

The invention relates to a uniform-thickness machining device and method for spherical crown face box bottom foam plastics of a large-diameter thin-wall box. The device comprises a rotating and positioning ring, a box supporting, rotating and positioning device, a three-axis numerical control machining device, a numerical control system, a spherical crown face box bottom metal surface morphology data measuring system, a computer system, a data acquisition module, a data pre-processing module and a numerical control machining software CAD / CAM module; the data acquisition module is embedded in the numerical control system; and the data pre-processing module and the numerical control machining software CAD / CAM module are embedded in the computer system. The device and method solve the uniform-thickness machining problem of foam plastics sprayed on the box spherical crown face, and it is verified and indicated through practical application that the requirements for surface smoothness and uniform thickness are met when the method is used for performing numerical control form copying on foam plastics sprayed at the spherical crown face box bottom.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

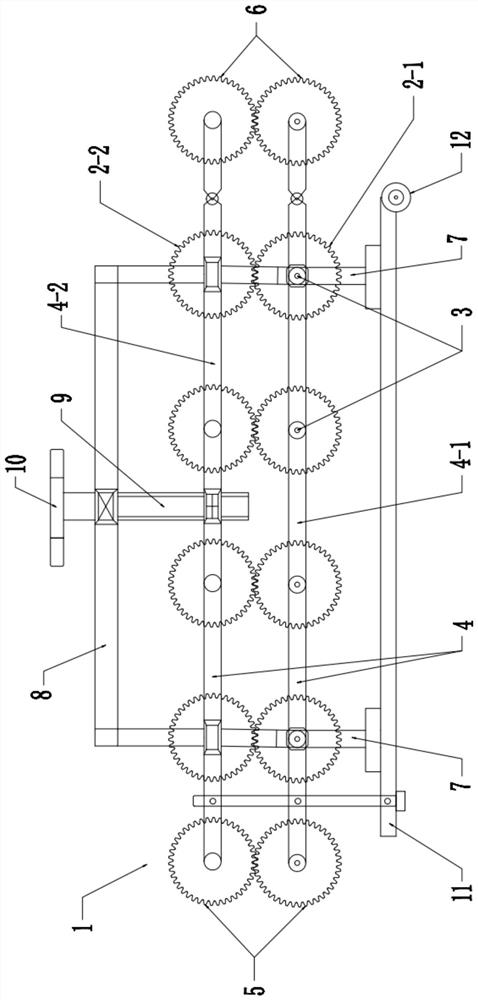

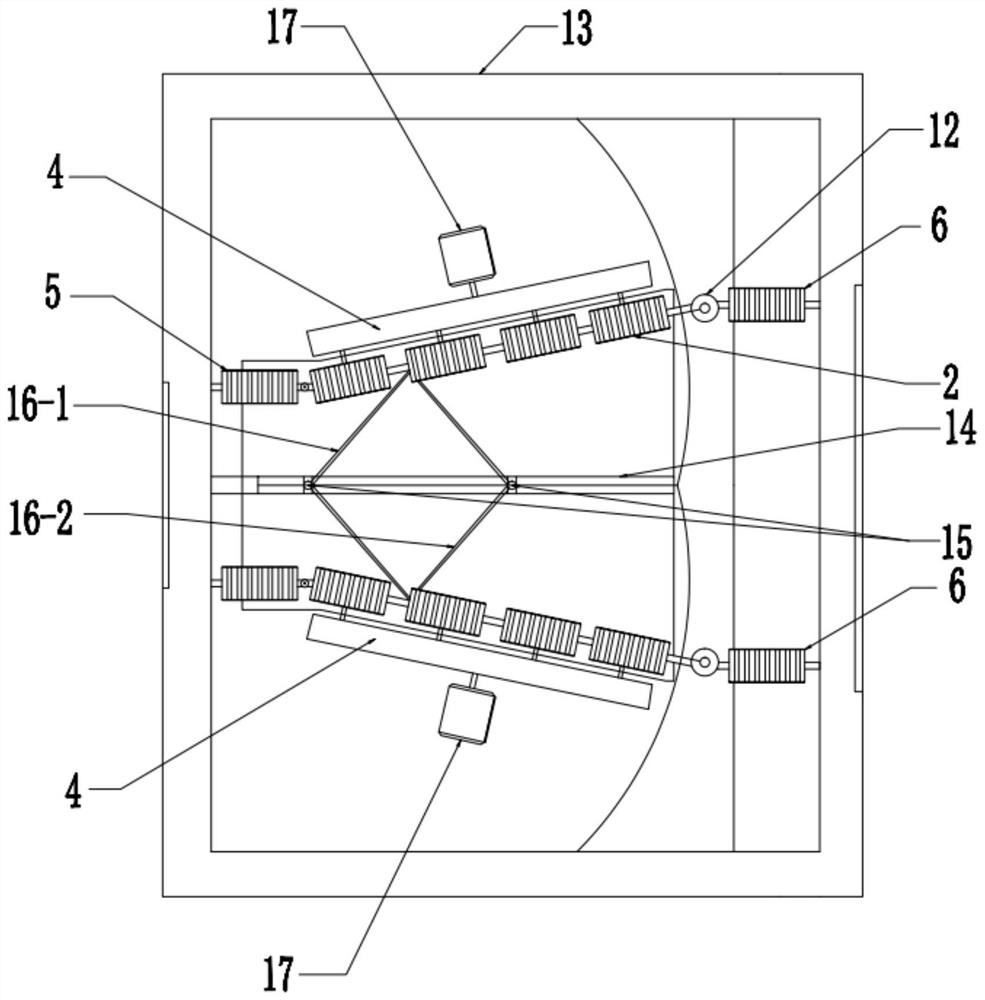

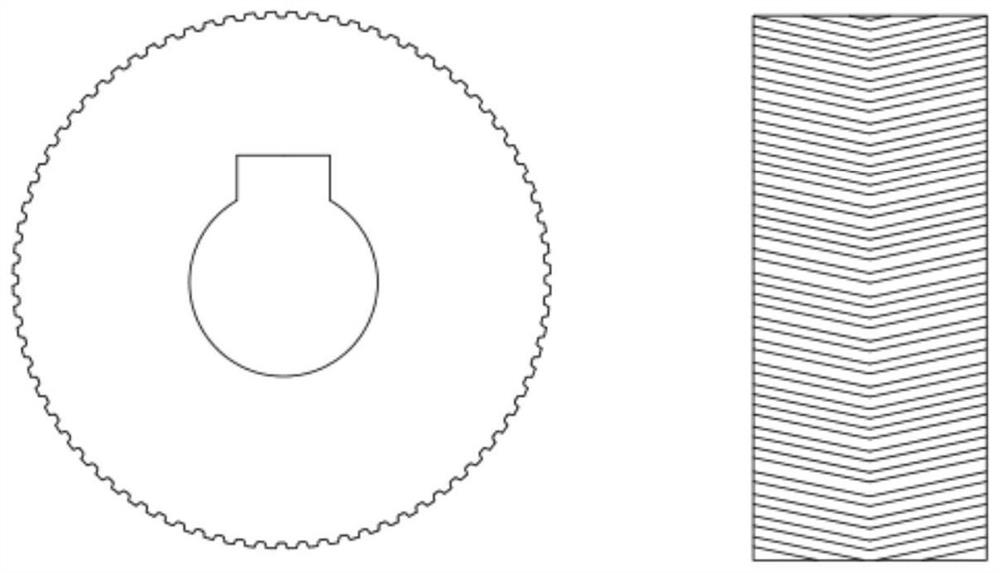

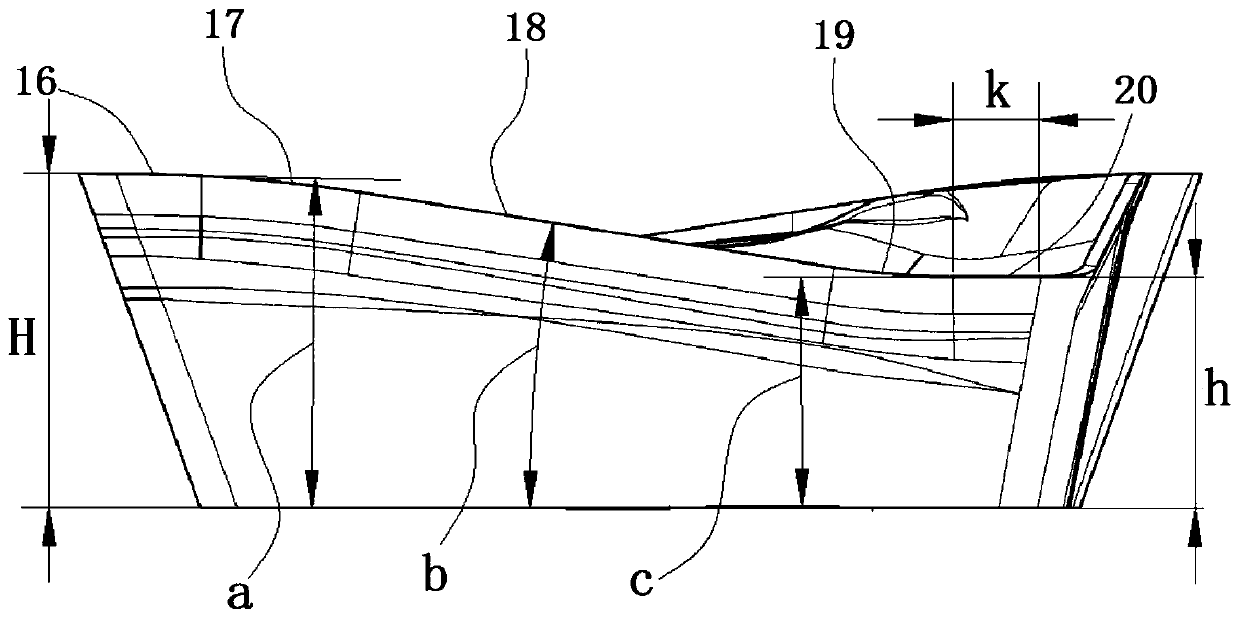

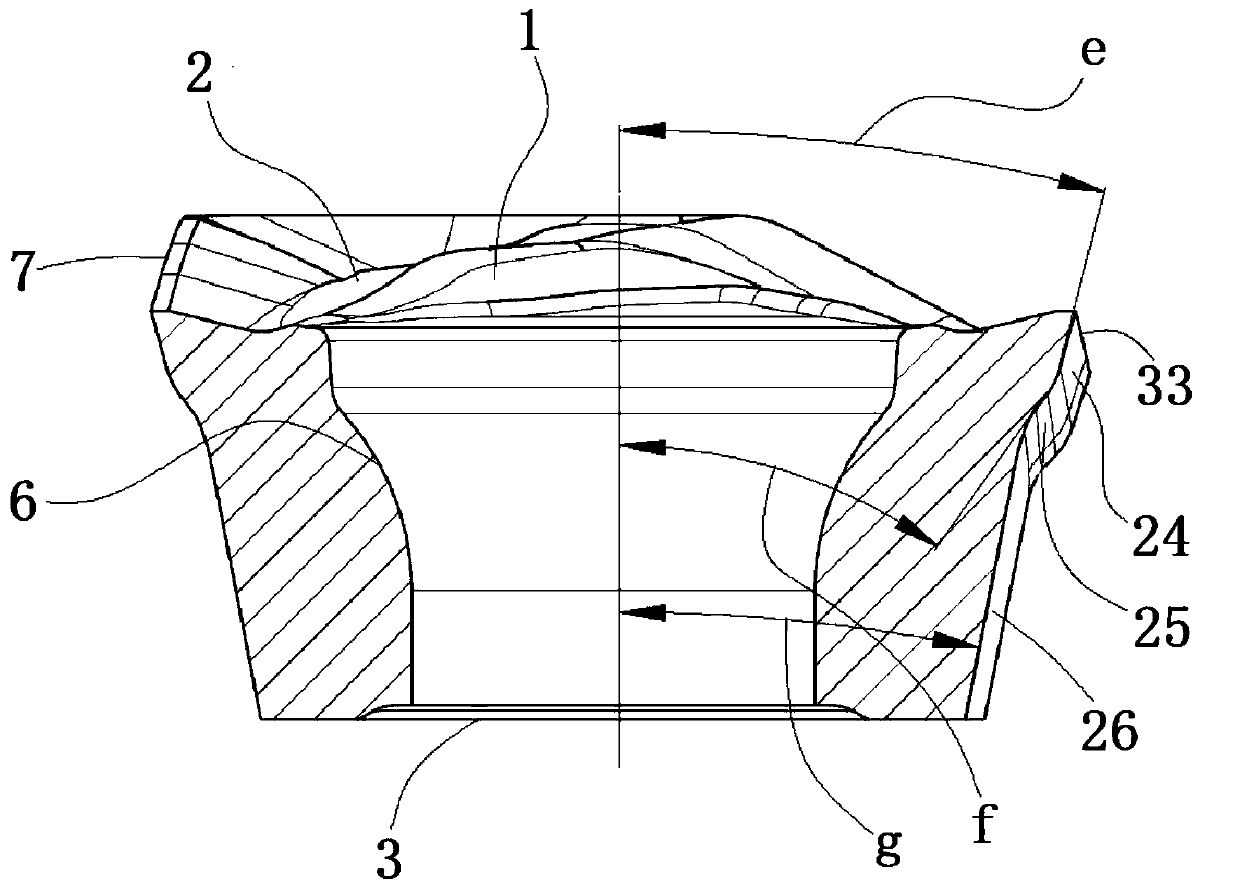

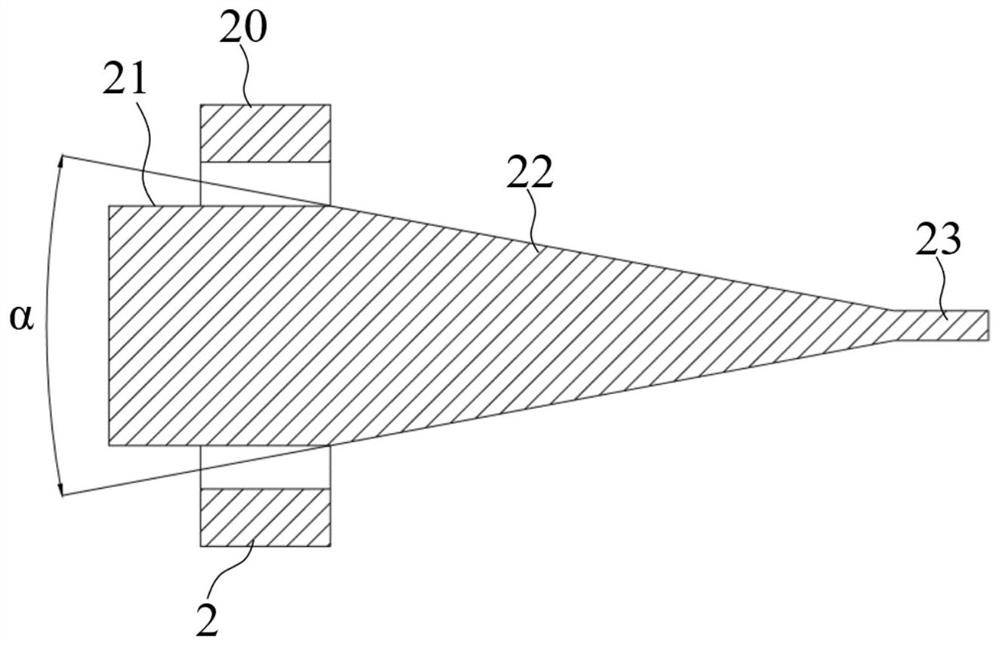

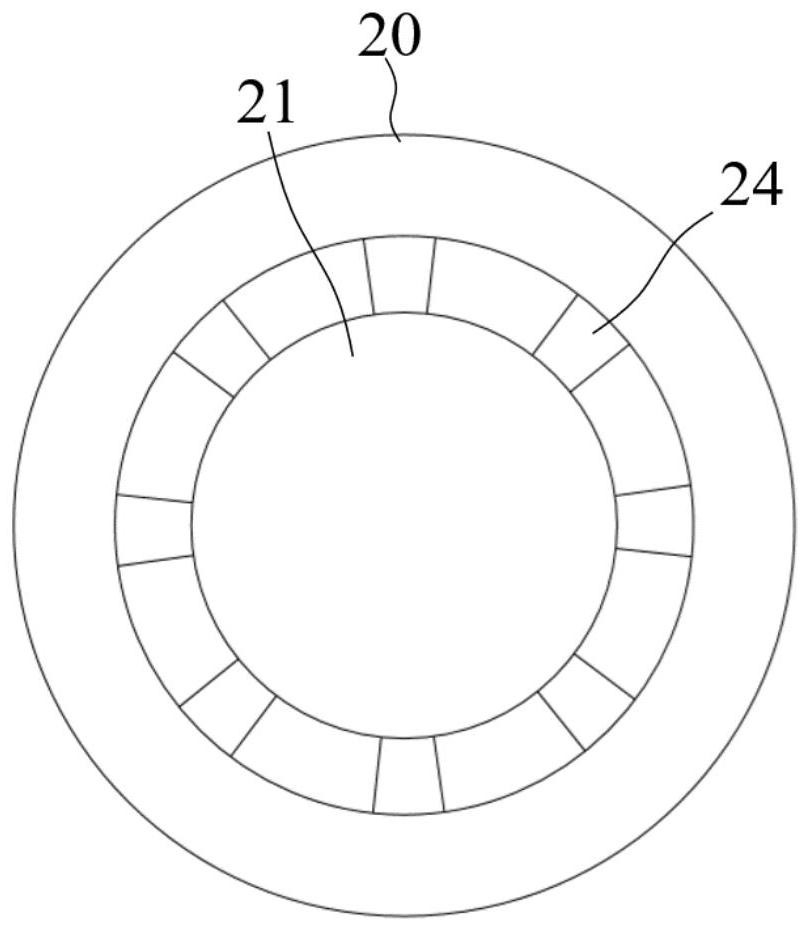

Gear transmission type film synchronous two-way stretching device and matched technological method thereof

PendingCN112793138ASuitable for simultaneous biaxial stretch processingSurface finishElectric machineGear wheel

The invention provides a gear transmission type film synchronous two-way stretching device and a matched technological method thereof. The device comprises a differential meshing gear mechanism, a meshing clamping force adjusting assembly, a main body base and a transmission motor, wherein a plurality of clamping gear sets in the differential meshing gear mechanism are arranged in a bilateral symmetry mode and are arranged in a splayed shape, in the film clamping and transmission process, the distance between the clamping gear sets on the two sides is gradually increased, and the transverse stretching effect on a film is achieved; and adjacent clamping gear sets on each side are driven by different motors or different transmissions, the rotating speed ratio of two adjacent clamping gear sets on each side is 1.1-1.5, and the longitudinal stretching effect on the film is generated through gear differential. According to the processing device, in the film conveying process, through the differential meshing gear mechanism, the stretching clamping site changes along with the clamping gear sets, so that stepless synchronous two-way stretching is achieved, and the device is suitable for conducting synchronous two-way stretching processing on the film.

Owner:SICHUAN UNIV

Method for processing automobile buffer block and special clamp used by method

InactiveCN101590601AIncrease productivitySurface finishAuxillary equipmentOther manufacturing equipments/toolsParallel computingWork in process

The invention discloses a method for processing an automobile buffer block, which comprises the following steps: (1) injection-molding a buffer block blank by an injection molding machine; (2) fixing the buffer block blank to a lathe through a first special clamp capable of clamping an outer circle surface of the buffer block, and processing a lathe groove on the inner surface of the buffer block; (3) taking a semi-finished product of the buffer block out from the first special clamp, fixing the semi-finished product to the lathe through a second special clamp capable of clamping the inner surface of the buffer block, and cutting and processing the end face of the lathe; and (4) stopping processing and retracting a cutter, and mounting a previously-processed iron piece in the processed qualified buffer block. After the structure is adopted, the method can process a plurality of the buffer blocks once so as to greatly improve the production efficiency; and simultaneously, the phenomenon of flashing or deficient filling is not caused, the surface of the product is smoother, and the processing precision is higher.

Owner:宁波安纳杰模塑科技有限公司

Low density polyurethane micropore elastomer added with thermal foamable microsphere and preparation thereof

The invention discloses a low-density microporous polyurethane elastomer added with a thermal foaming microsphere and a preparation method thereof. In accordance with the preparation ratio of 1:1 for the molar number of the active hydrogen in A composition and the molar number of the -NCO in B composition, the A composition and the B composition are completely mixed and reacted for preparing the microporous polyurethane elastomer, wherein, the A composition is prepared by heating and mixing polyester polyol A1, polyester polyol A2, chain extender, cross-linking agent, tertiary amine or organic metal catalyst, organic silicone foam homogenizing agent, a thermal foaming microsphere, water and physical foaming agent in a reactor; and the B composition is a prepolymer which is prepared by mixing diisocyanate, polyester polyol B1, polyether polyol and a side effect inhibitor in the reactor, controlling the free-NCO content to be 18-22 weight%, and reacting. By adding the thermal foaming microsphere, the invention prepares a low-density (0.28-0.32g / cm3) microporous polyurethane elastomer which is applied to the sole material; the obtained material has excellent processability and mechanical property; the prepared sole is light and comfortable and has low cost, so the competitiveness of traditional sole materials such as microporous polyurethane elastomer and EVA, and the like is improved.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

Nickel-cobalt alloy electroplating technique

The invention discloses a nickel-cobalt alloy electroplating technique which comprises the following steps: deoiling and derusting, ultrasonic cleaning, electroplating, dehydrogenation, water repelling treatment, water washing and blow-drying. The technique integrates the deoiling and derusting steps, thereby saving the procedure, lowering the cost and enhancing the efficiency. The ultrasonic cleaning step is added, so that the overall pretreatment is efficient, environment-friendly and pollution-free. In the electroplating process, the pH value of the electroplating solution is 3 or so which is weakly acidic, and the current density is 110 A / dm<2>, so the wear resistance of the electroplating coating is greatly enhanced in the specific electroplating solution; under the condition that the friction rotation speed is 15000 r / min, the reduction quantity is less than 0.02 mu m, and the coating hardness is increased; and when the pulse period is 24ms, the maximum coating hardness is 609HV which is 1.5 times of the conventional nickel-cobalt coating, the surface is smooth, and the average grain size is 14nm or so.

Owner:太仓市金鹿电镀有限公司

Plane polishing device for steel heald

InactiveCN102189473AReduce labor intensityReduce pollutionPolishing machinesProduction lineEngineering

The invention relates to a plane polishing device for a steel heald. A machine frame is provided with an upper row and a lower row, and each row is provided with a plurality of groups of polishing units; motor output shafts of the polishing units are used for driving polishing wheel shafts to rotate through belt transmission; the polishing wheel shafts are connected on the machine frame through bearings; polishing wheels are arranged on the polishing wheel shafts; a feeding bearing is arranged on the lower part between two polishing wheels; and the back surface of a belt is supported and fed by an outer ferrule of the feeding bearing, and the front surface of the belt is contacted with the outer edges of the polishing wheels. In the invention, an automated continuous polishing production line is used, so that the device has high degree of automation and high production efficiency; labor force can be saved by about 80 percent, so that production cost is greatly reduced; and the labor intensity of operating workers is reduced, and pollution to the environment is reduced.

Owner:无锡众磊氨基模塑成套设备厂

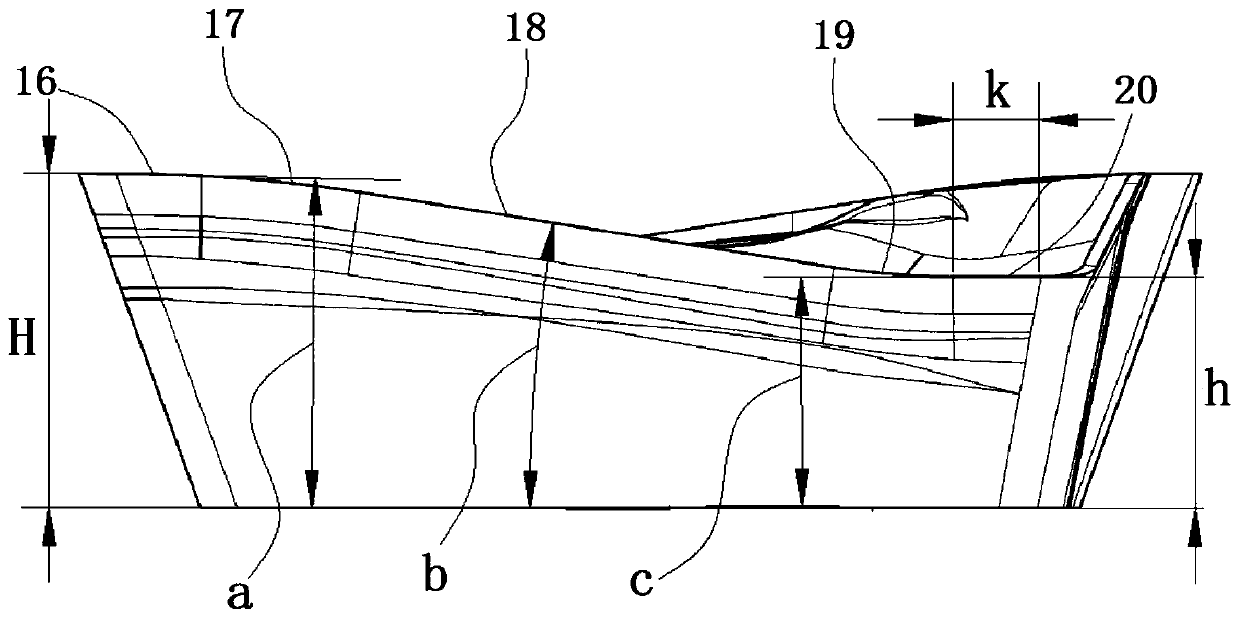

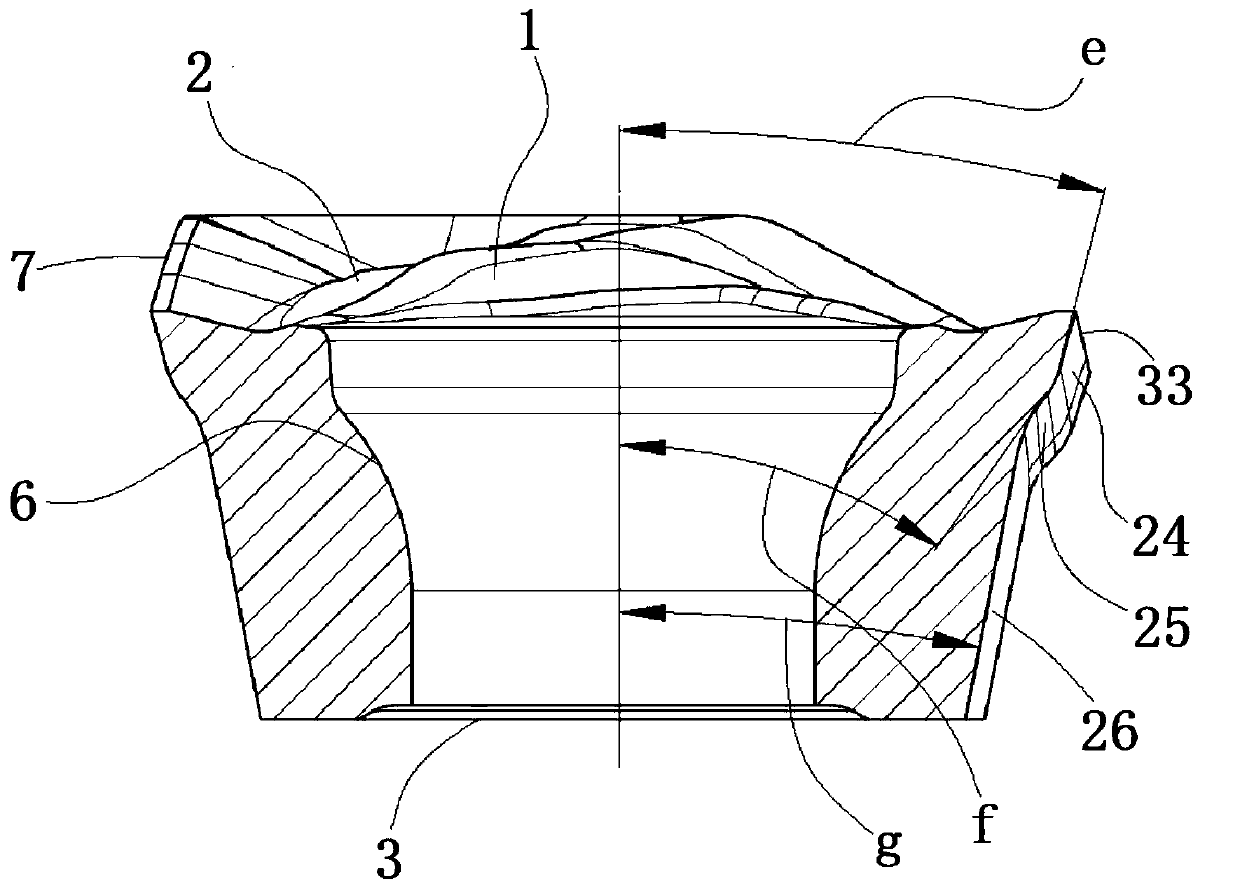

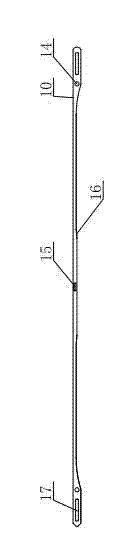

Rotatable milling blade for sidewall machining

ActiveCN110315118AImprove fitting accuracyImprove overall cutting performanceMilling cuttersMilling cutting insertsEngineeringSurface smoothness

The invention provides a rotatable milling blade for sidewall machining. The milling blade comprises an upper top surface, a lower bottom surface, two end surfaces connected with the upper top surfaceand the lower bottom surface, and an approximately cuboid blade main body defined by two side surfaces; the upper top surface and the two side surfaces extent at respective curvatures and intersect,and a first main cutting edge and a second main cutting edge are formed; the first main cutting edge is fitted on a first cutting rotating cylindrical surface with the diameter being D and orderly extends on the first cutting rotating cylindrical surface; and the second main cutting edge is fitted on a second cutting rotating cylindrical surface with the diameter being d and extends orderly on thesecond cutting rotating cylindrical surface. The vertical precision and the surface smoothness of a machined side surface at different cutting depths can be met, the cutting quality of the side surface is improved, and the cutting efficiency is improved.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

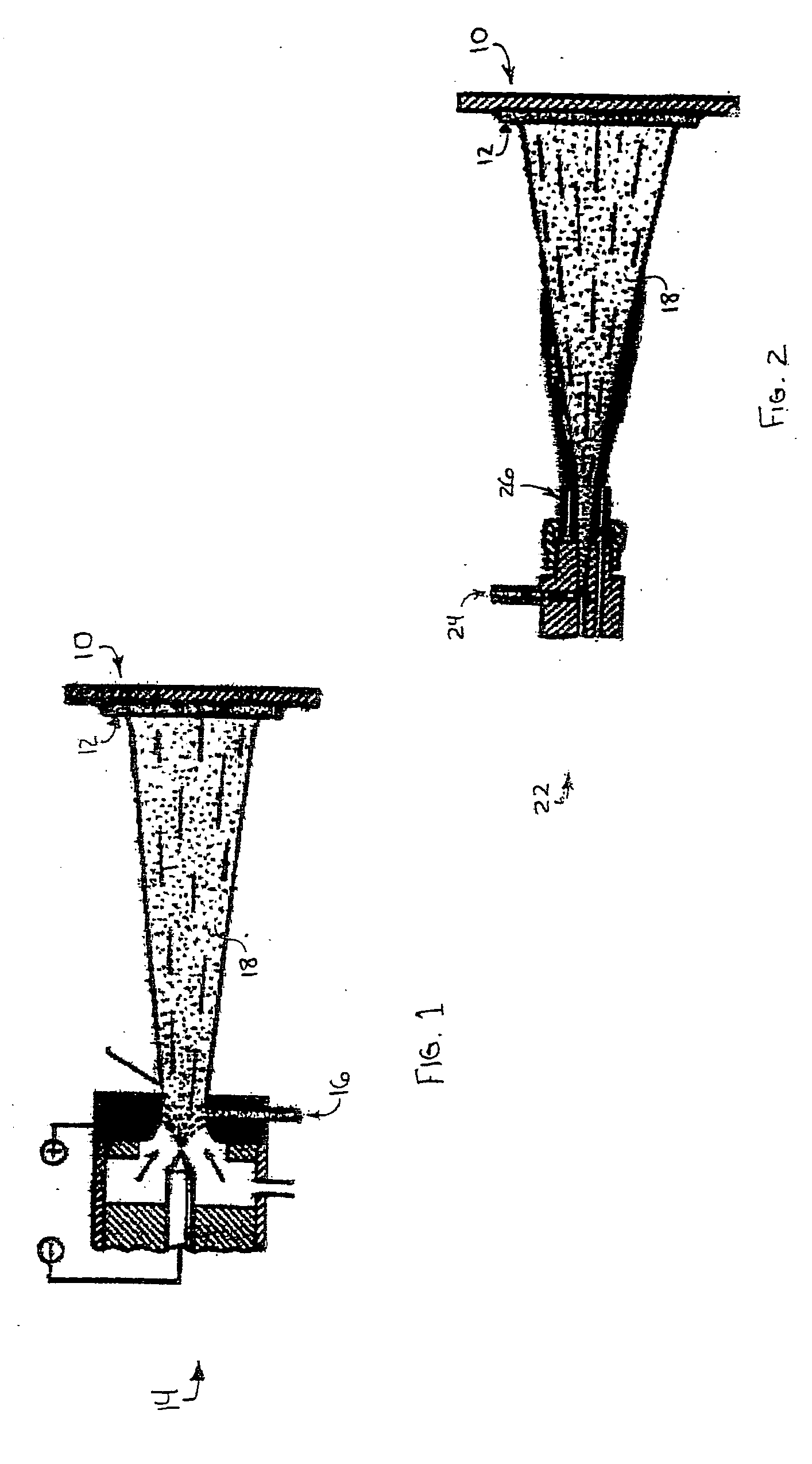

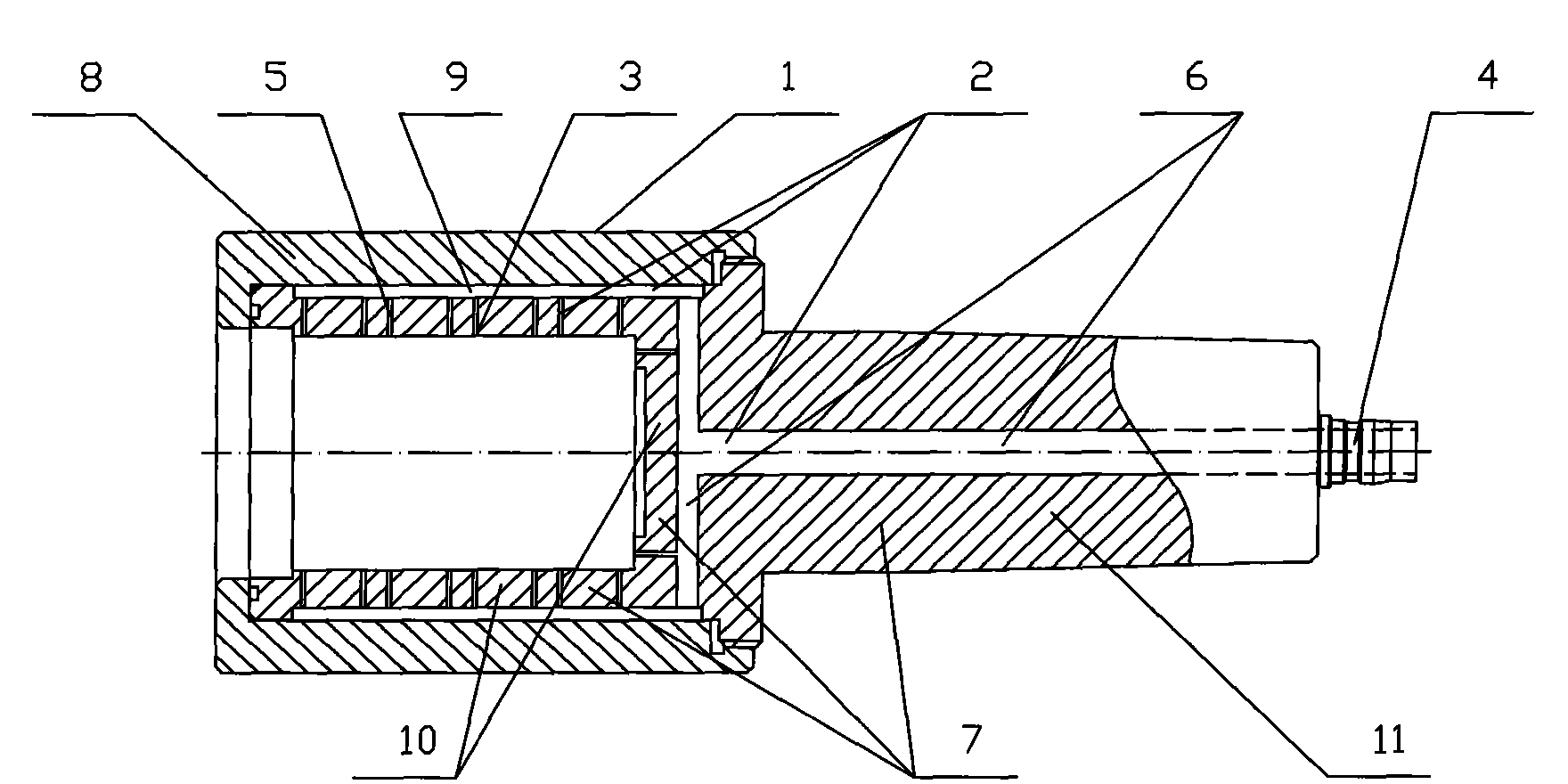

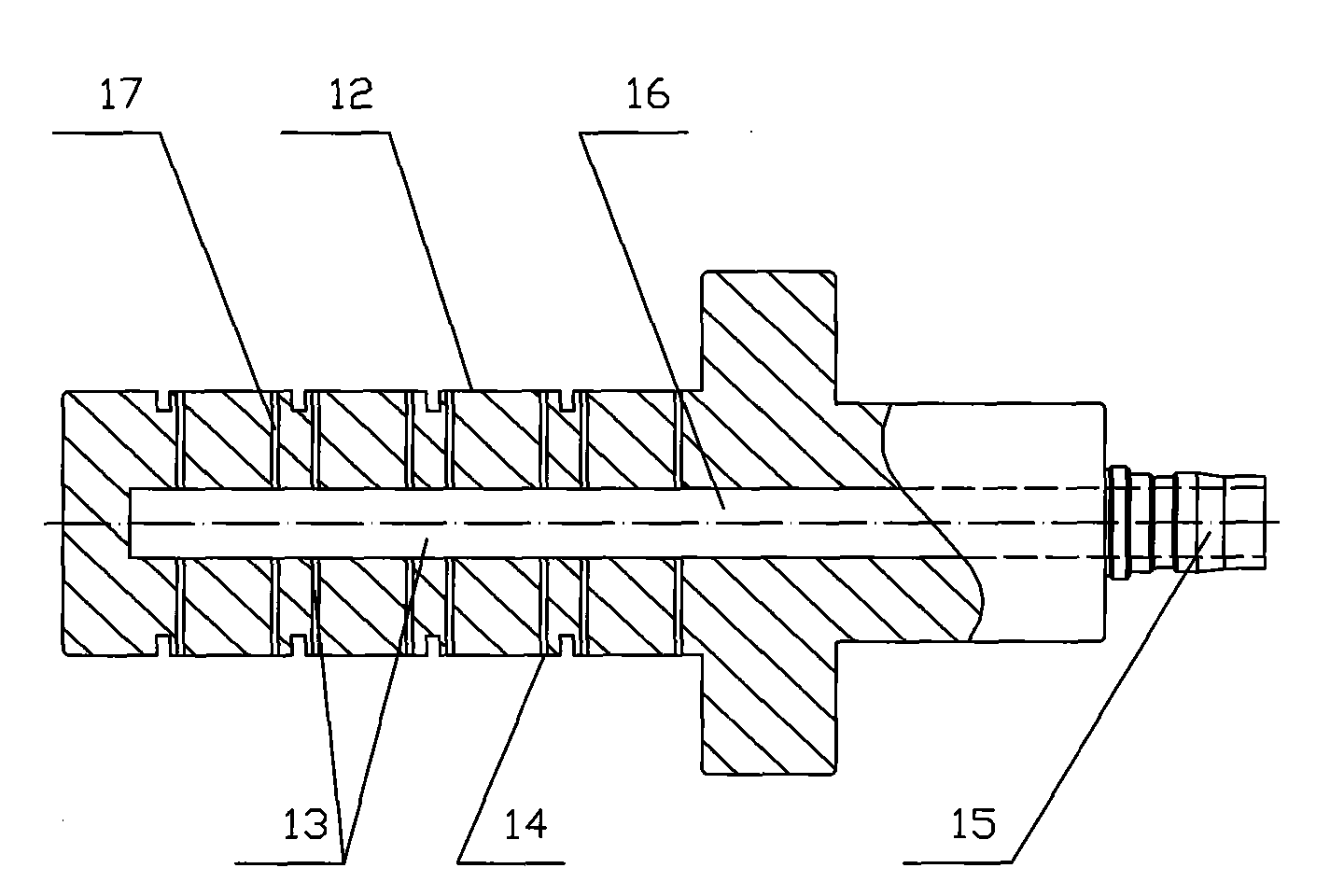

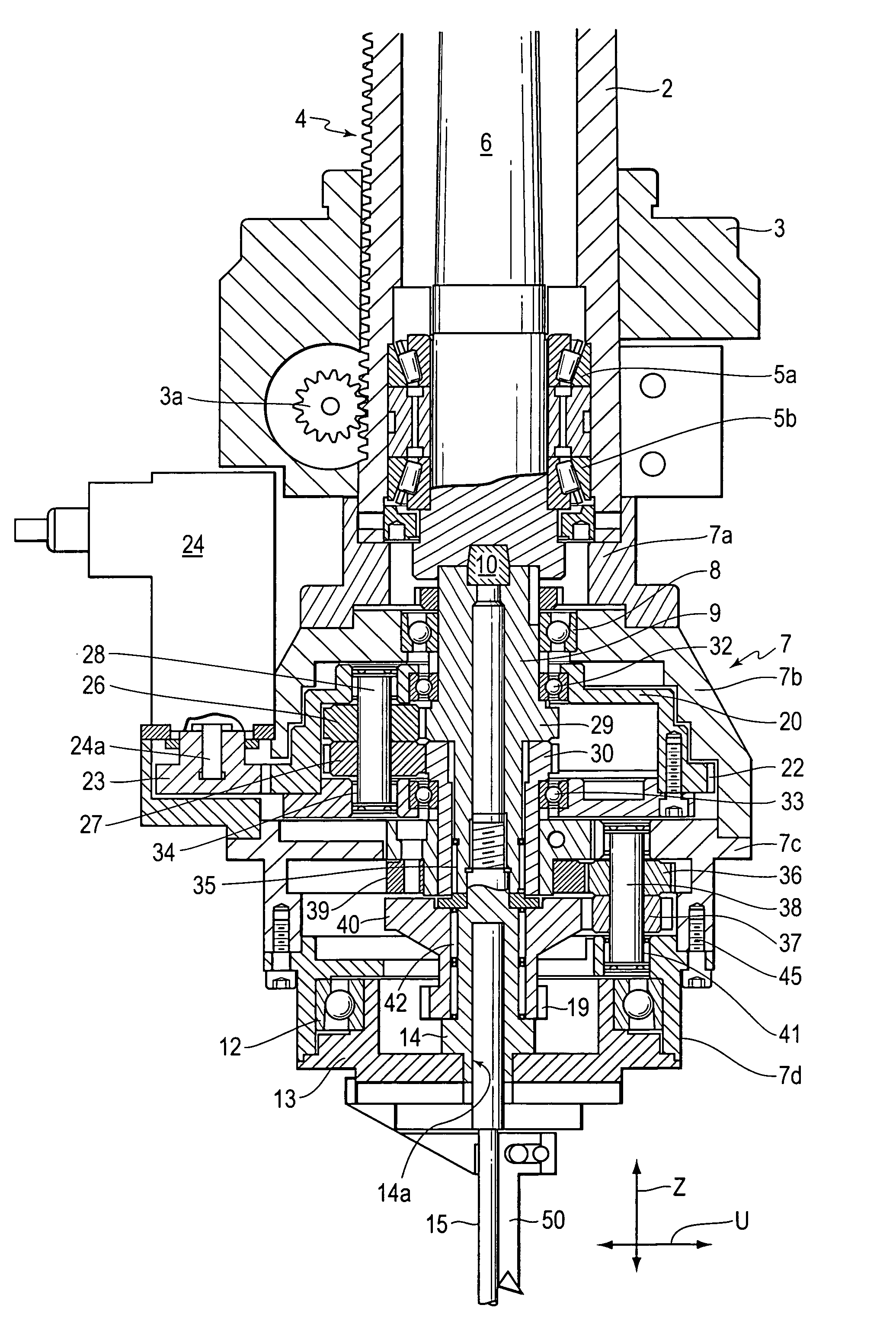

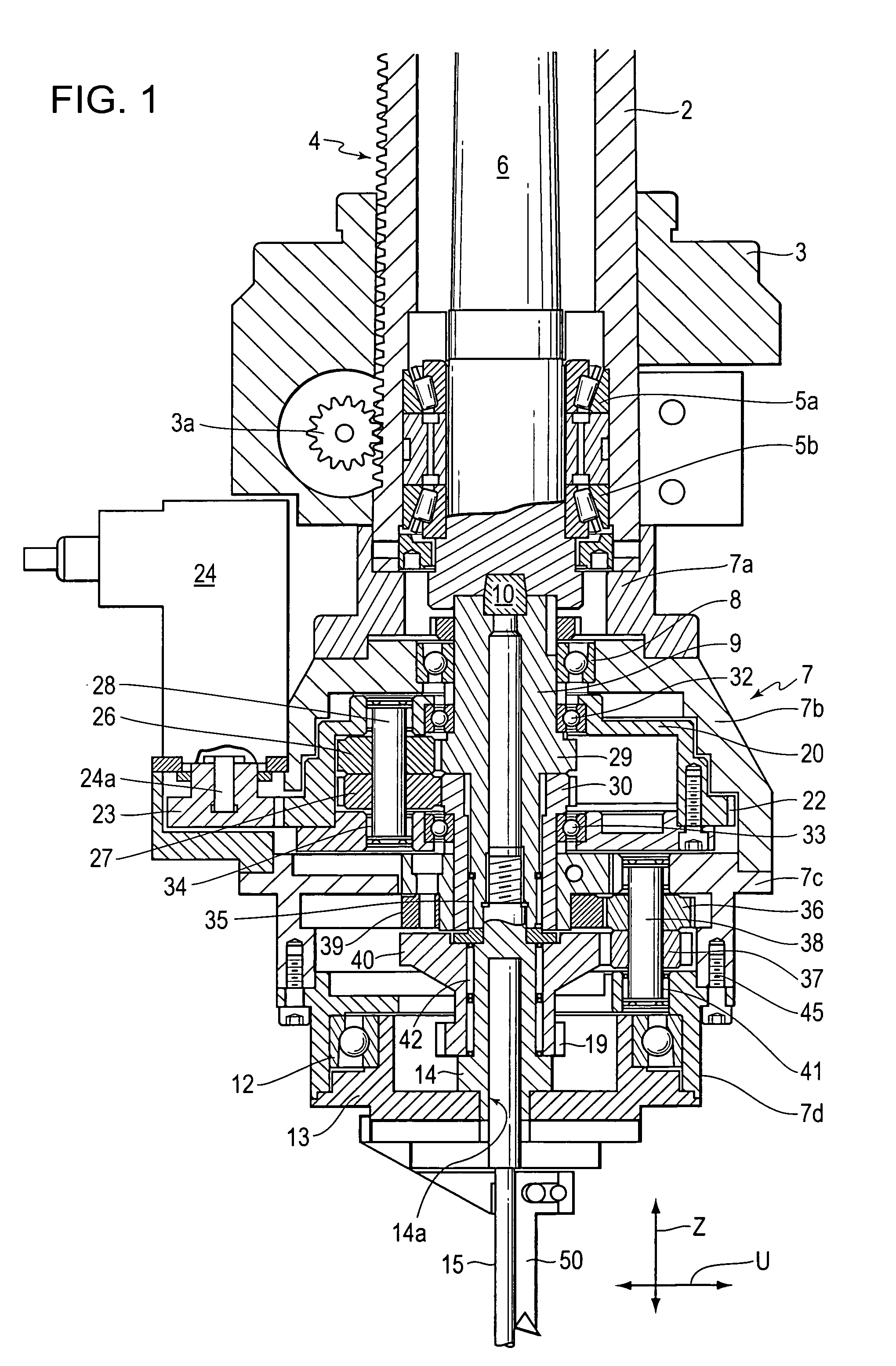

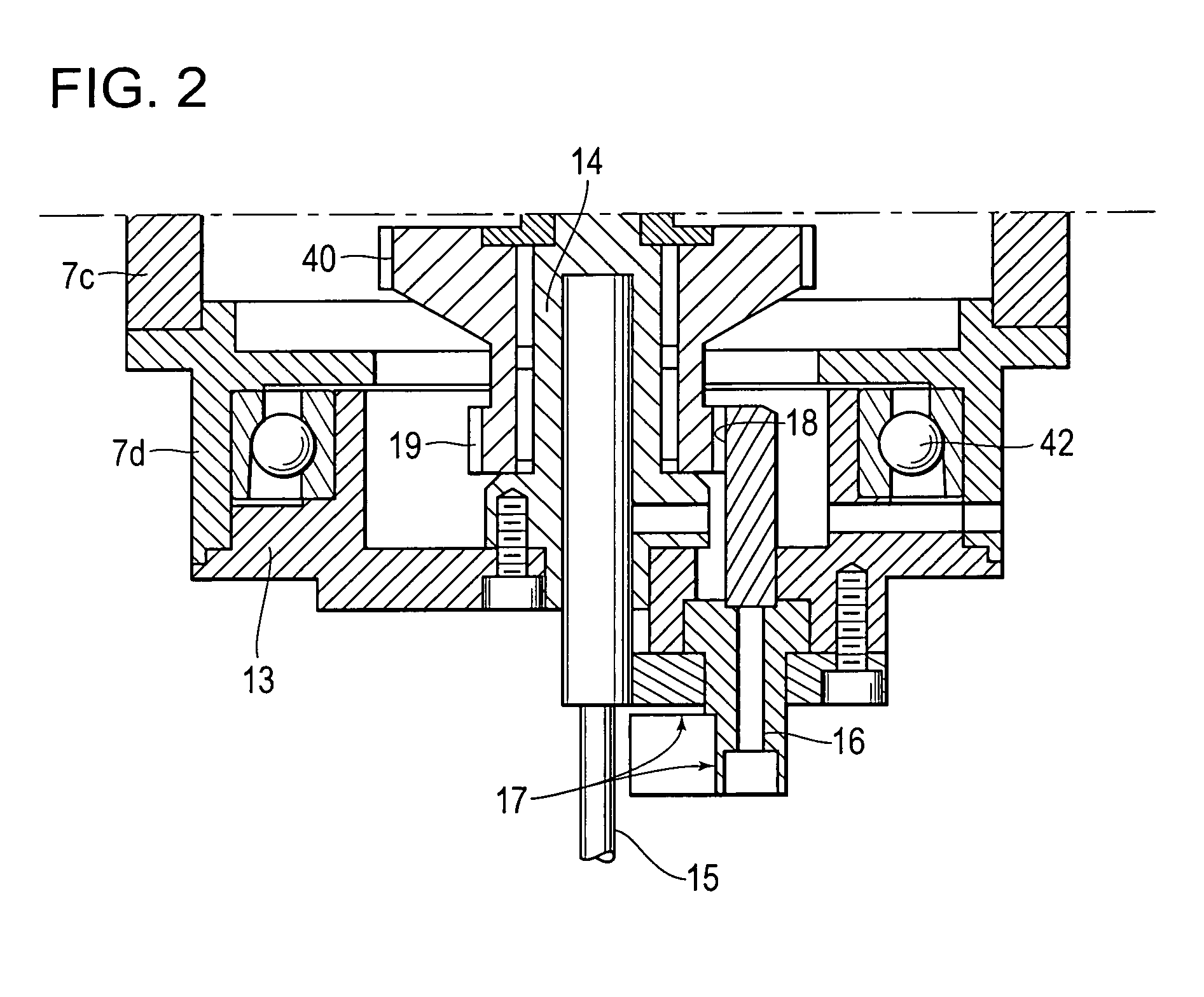

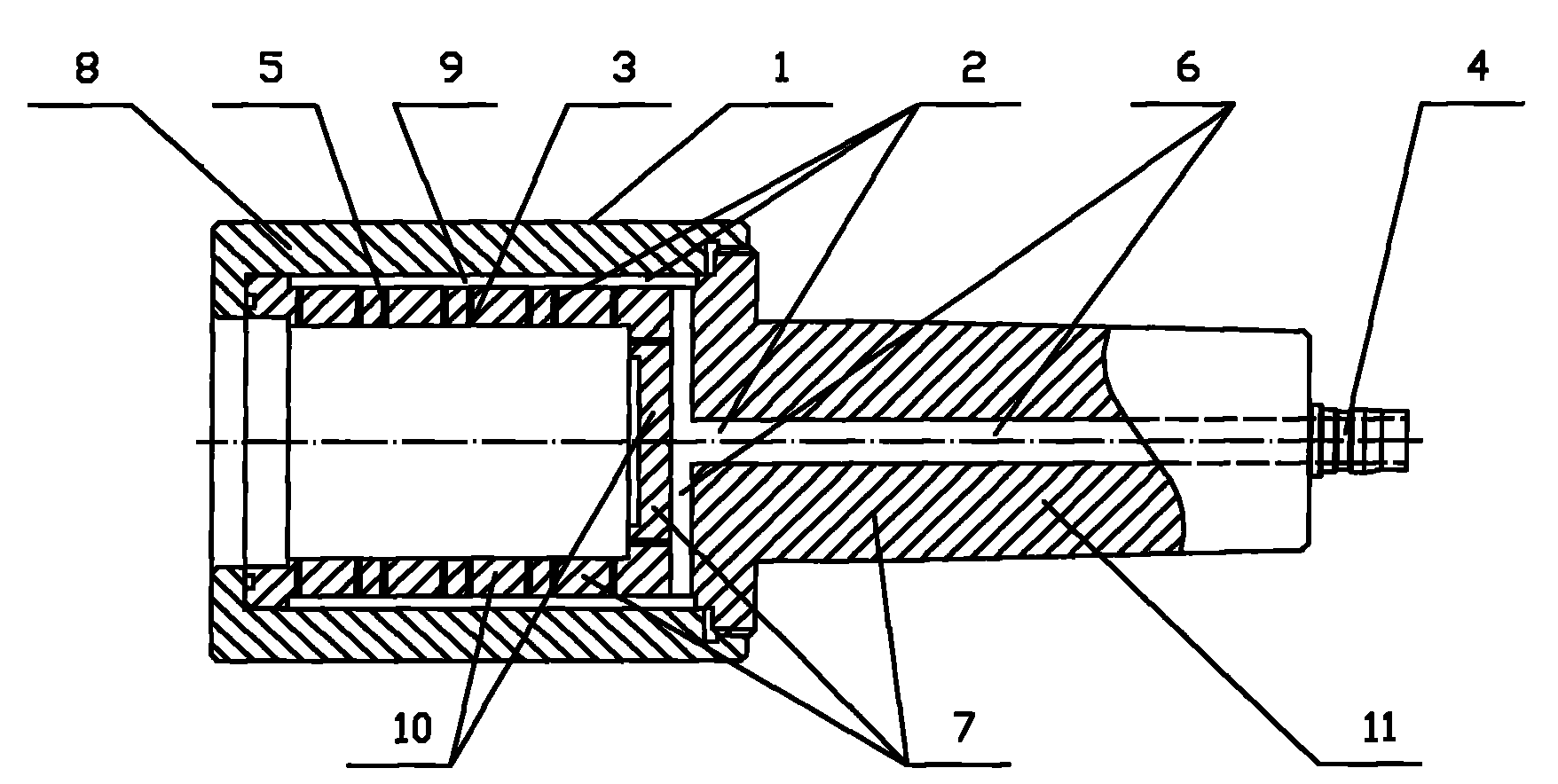

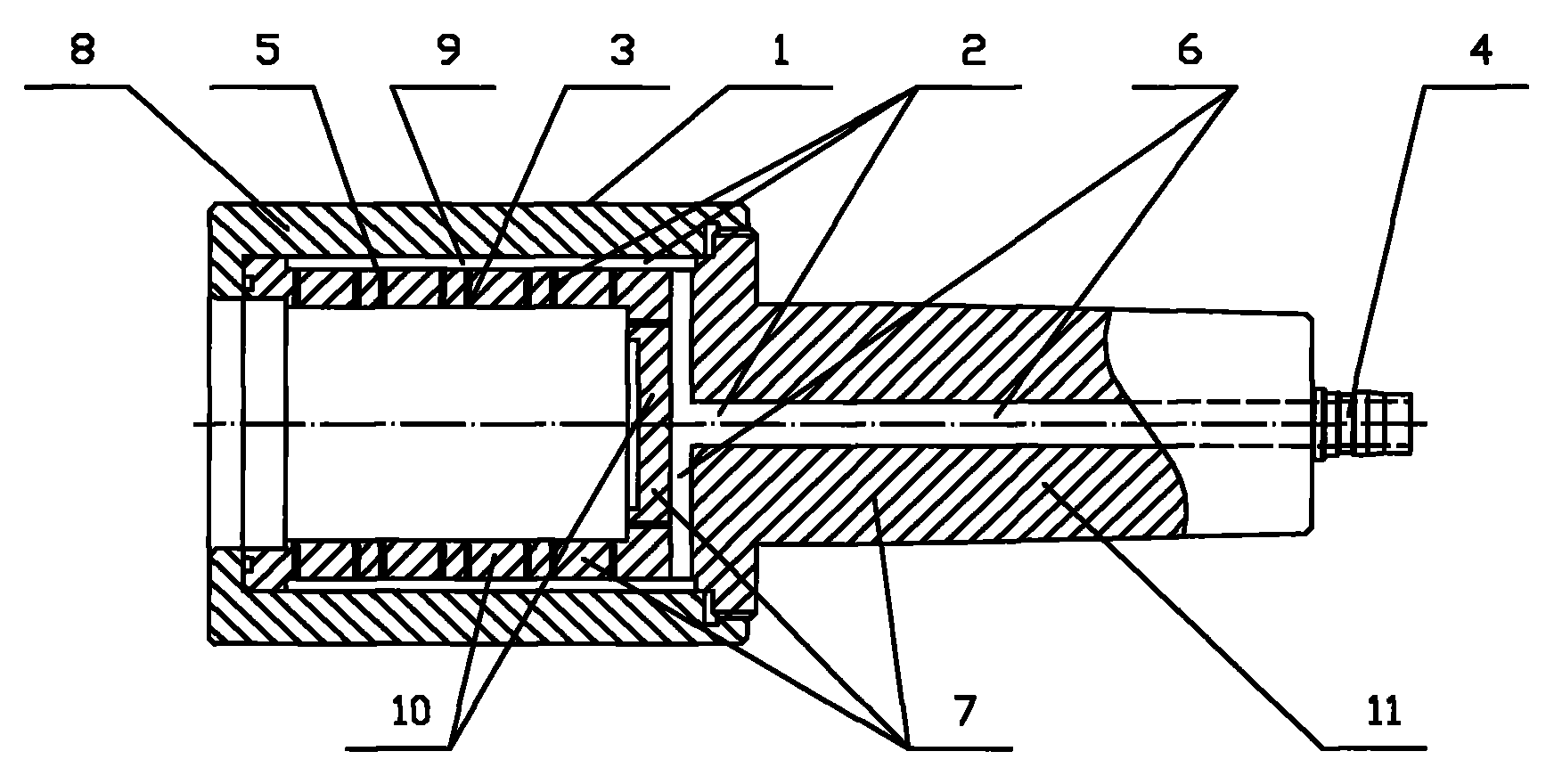

Boring head with tool advance independent of rotation

InactiveUS7048482B2Surface finishThread cutting toolsTransportation and packagingFree rotationGear wheel

The transmission of the rotational movement to the driving pinion of the carriage is provided by:a first gear train with a cage mounted so that it can rotate about the axial shaft and the crown wheel of which meshes with a pinion fitted onto the shaft of an electric motor carried by the body, this train carrying at least two superposed planet pinions and meshing, in the case of the upper one, with a set of teeth formed around the axial shaft and, in the case of the lower one, with an output sun gear,a second train, the sun gear of which is secured to the output sun gear of the first train and meshes with the upper planet pinion of at least one set of superposed planet pinions which are mounted so that they are free to rotate in a continuation of the body, the lower planet pinion meshing with a set of teeth which, formed on the driving pinion of the carriage, is distinct from the set of teeth that collaborates with the rack of this carriage,these two sun gears having ratios which are other than 1 and inverse, while the electric motor driving the cage and the one translating the quill are powered under the control of the command and control unit.

Owner:MASHIIN SERUDEI

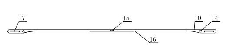

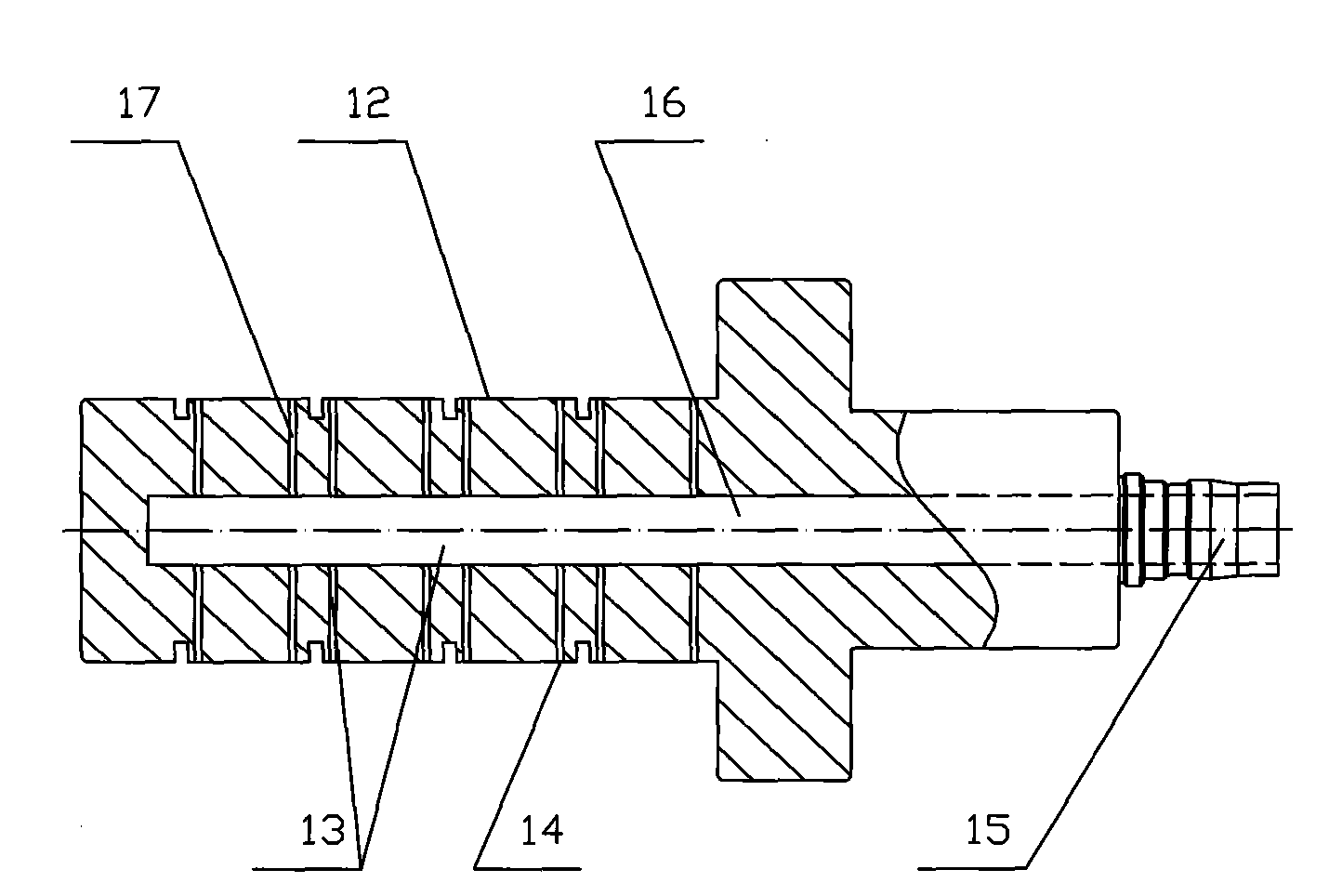

Turntable-type multi-station pen point automatic processing machine tool with pipe contraction function

ActiveCN102873540ASmall diameterSurface finishOther manufacturing equipments/toolsAutomatic processingPower equipment

The invention discloses a turntable-type multi-station pen point automatic processing machine tool with a pipe contraction function. An upper tool body, a lower tool body and a rotary workbench are arranged in a machine cover; a plurality of stations are an upper row of processing mechanisms and a lower row of processing mechanisms and are distributed above and below the rotary workbench; the processing mechanisms perpendicularly process a pen material; the rotary workbench can rotate the pen material to the next station; the processing mechanisms are arranged at the tail end of a power head; the processing mechanisms are provided with a transmission mechanism and power equipment which are used for driving the workbench to rotate and the power head to move, an oil spraying mechanism, an oil pump set, an oil tank, a control cabinet and a pipe contraction mechanism arranged on the power head; the oil spraying mechanism, the oil pump set and the oil tank are used for spraying oil towards the tool bodies; the pipe contraction mechanism comprises a ball seat and at least three balls; the balls are accommodated in the ball seat; the pipe contraction mechanism precisely compresses pipe materials through rotation and revolution of the balls; the surface of the contracted pipe is smooth; the pipe contraction mechanism is suitable to contract a needle pipe pen point; and therefore, the turntable-type multi-station pen point automatic processing machine tool can manufacture a bullet-type pen point and is applicable to pipe contraction of a needle pipe pen point.

Owner:LOTUS STATIONERY

Layer-by-layer self-assembly film, preparation method and application thereof

ActiveCN107929810AShorten the timeImprove efficiencyTissue regenerationProsthesisLayer by layer self assemblyInjury wounds

The invention discloses a layer-by-layer self-assembly film, a preparation method and application thereof. The layer-by-layer self-assembly film is formed by laying polymer layers with opposite electrical properties and dropwise adding charged therapeutic drugs; the distribution and rearrangement time of polymer in a mode of sucking unreacted solution through a vacuum extractor to produce flowingliquid phase is reduced, a step of washing with clear water is avoided, formed negative and positive ionic polymer layers are smoothly fitted, and the film can be applied to various wound surfaces through design of dies; a 100 to 20000nm ultrathin film can be formed, materials in contact with organisms are obviously reduced, and foreign body rejection reaction is reduced. The film is wide in material selection and drug selection ranges. Types and dosages of drugs can be selected, the effects of antibacterial property, anti-inflammatory property and promotion of wound healing are achieved; thefilm has flexible and convenient processibility, is suitable for the requirements of repairing of various injury wound surfaces, and is stable in product quality and good in reproducibility.

Owner:ZHEJIANG UNIV

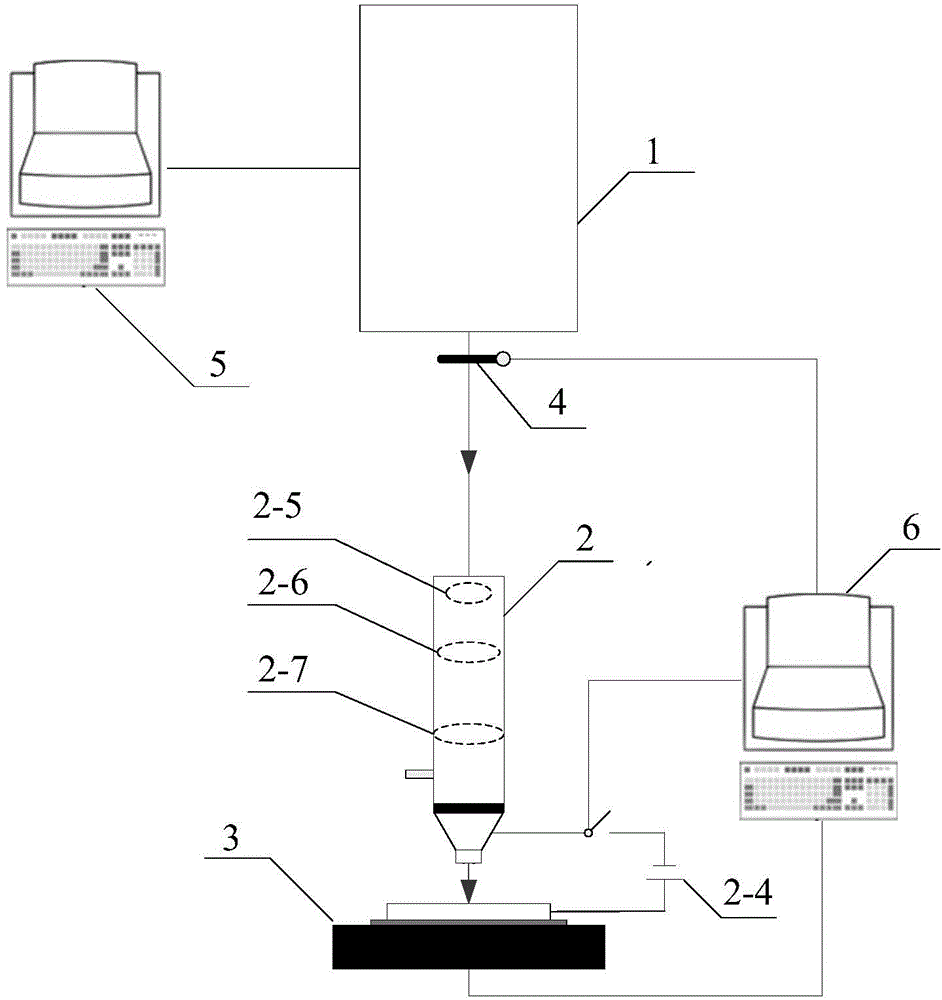

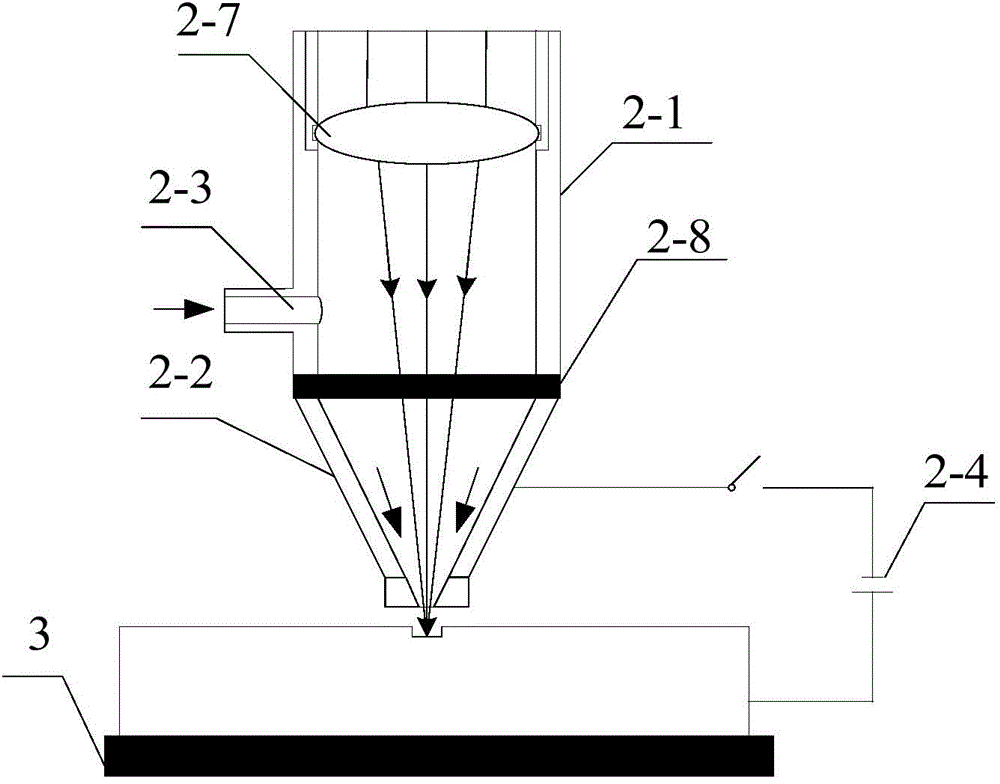

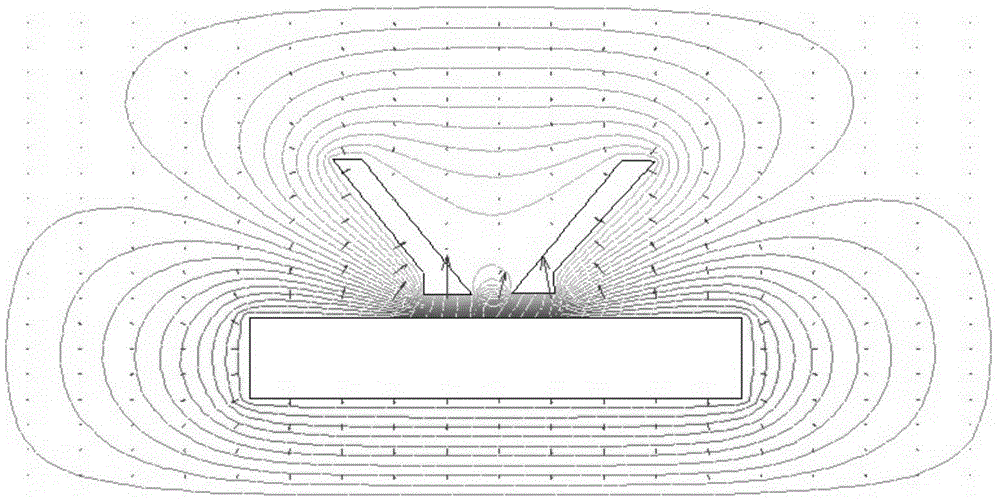

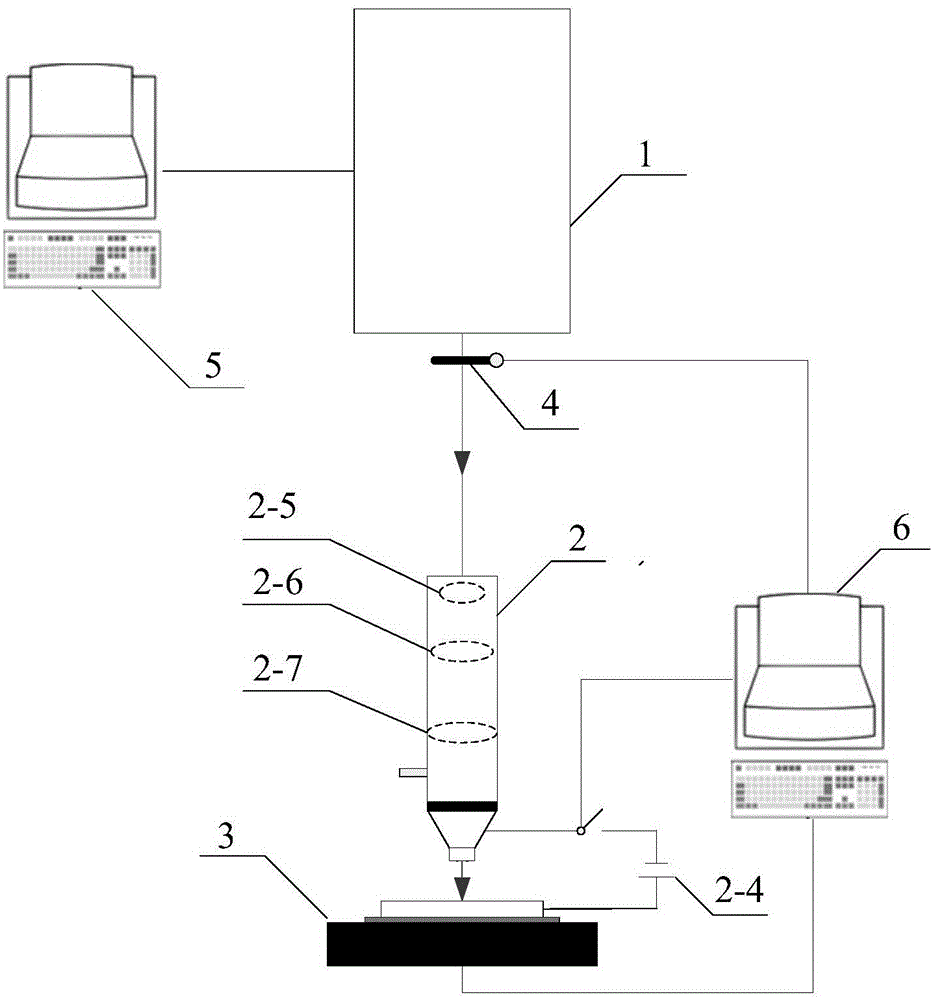

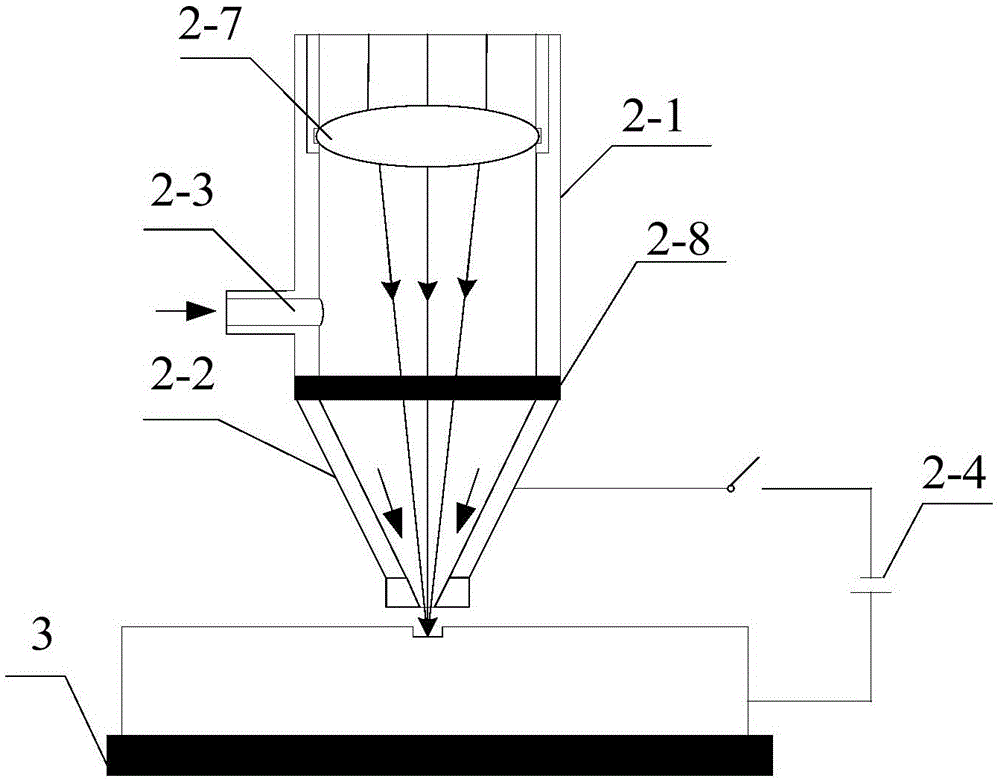

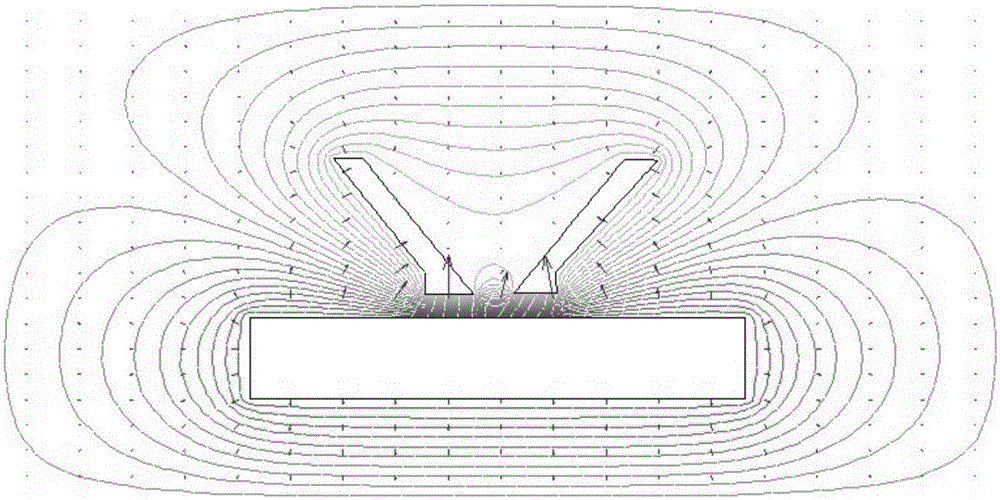

Electrostatic field assistance-based laser processing technology and processing equipment thereof

InactiveCN104096979AQuality improvementReduce transmissionLaser beam welding apparatusLaser processingEngineering

The invention discloses an electrostatic field assistance-based laser processing technology and processing equipment thereof. The processing equipment comprises a laser device, an integrated laser head and a motion platform used for bearing a sample, wherein the laser outlet of the integrated laser head is positioned on the upper end of the motion platform; the integrated laser head comprises a cylindrical backend body and a cylindrical frontend body arranged at the front end of the cylindrical backend body; the cylindrical backend body and the cylindrical frontend body are in insulating connection; a laser beam alignment and focusing system for focusing laser beams is arranged in the cylindrical backend body; a gas inlet for introducing auxiliary gas into the cylindrical backend body is formed in the side wall of the cylindrical backend body; the cylindrical frontend body is connected with the negative electrode of a direct-current main, the positive electrode of the direct-current main is connected with the sample, thus an assistant highfield is formed, the binding force borne by atoms on the surface of the sample is reduced, layered stripping of a material can be easily performed by the laser, the stripped product is taken away by the auxiliary air quickly, and the heat accumulation in the material is effectively avoided.

Owner:XI AN JIAOTONG UNIV

Carbon fiber composite board forming process

The invention discloses a carbon fiber composite board forming process, and relates to the technical field of carbon fiber composite structural member forming. The carbon fiber composite board comprises the following steps of layer paving, glue brushing, pressing, curing and demolding to obtain the carbon fiber composite board. The carbon fiber composite board forming process is simple, material waste and environmental pollution are avoided in the forming process, the prepared carbon fiber composite board is high in volume density, high in bearing capacity, smooth in surface, free of cracks and wrinkling and folding.

Owner:YIXING YITAI CARBON FIBER WEAVING

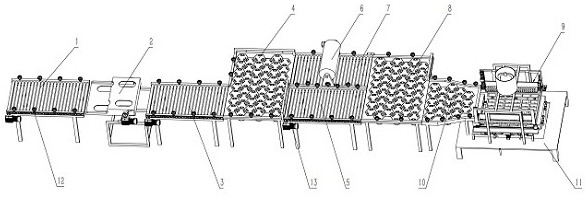

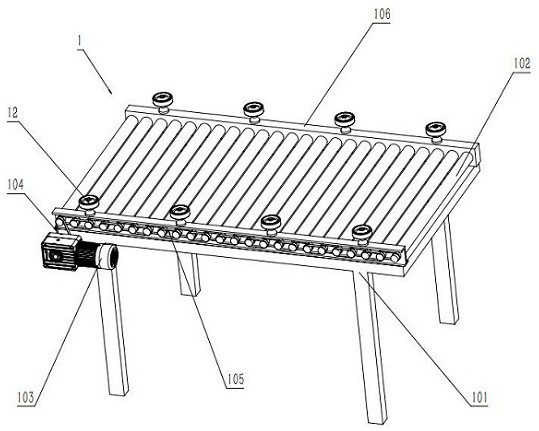

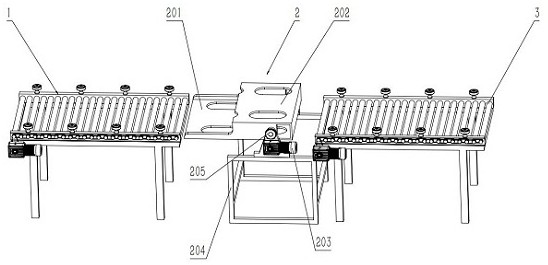

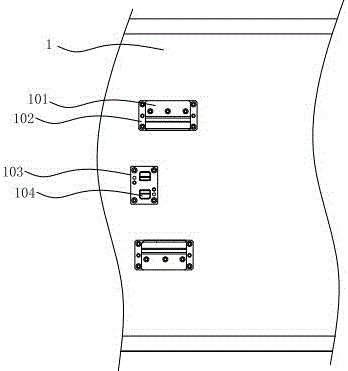

Conveying posture adjusting device for insulation board production line and monitoring method

ActiveCN114474321AImprove the effect of adsorption and penetrationFlatness trimmingControl devices for conveyorsShaping conveyorsElectrical and Electronics engineeringMachine tool

The invention relates to the technical field of intelligent production equipment, and discloses an intelligent automatic production line which can enable machining equipment such as a numerical control machine tool on a line body to automatically complete a preset procedure route and a technological process under the control of a specified program or instruction. The invention relates to a conveying posture adjusting device for an insulation board production line and a monitoring method. The conveying posture adjusting device can enable a conveying mechanism and other additional devices to automatically carry out auxiliary control or operation such as product conveying, measuring, sorting and packaging, and particularly relates to a conveying posture adjusting device for an insulation board production line and a monitoring method. Comprising a feeding rolling conveying belt, a turnover mechanism, a discharging rolling conveying belt, universal conveying belts, a flattening mechanism, a blanking mechanism and adsorption permeation equipment, wherein the universal conveying belts comprise a first universal conveying belt, a second universal conveying belt and a discharging universal conveying belt; the posture of the insulation board base plate is adjusted by controlling a plurality of universal driving units on a discharging universal conveying belt, so that the insulation board base plate can enter a blanking supporting plate of a blanking mechanism in a manner of being aligned with an adsorption groove of the adsorption permeation equipment; normalization processing is carried out on multiple types of size information of the insulation board substrate, such as length, height, width, surface flatness and other different types of size information of the insulation board substrate, and then the production state of an insulation board production line is reflected on the whole through calculation.

Owner:XUZHOU COLLEGE OF INDAL TECH

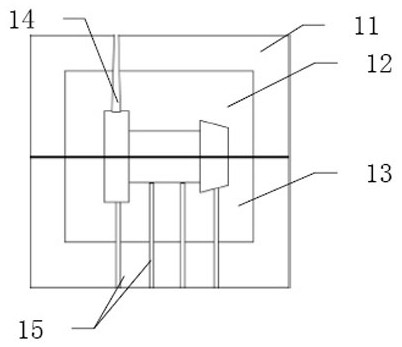

A preformed module structure in a lock bracket mold

The invention relates to a pre-forming module structure for manufacturing a lock-bracket die. The pre-forming module structure is composed of an upper module, a lower module and a stripping module. The pre-forming module structure is simple and convenient to use. The product machined though the pre-forming module structure is small in internal stress of a forming face and a punching face, and smooth and neat in surface. Meanwhile, the pre-forming module structure can be used for rapidly completing pre-forming of the product, in this way, the machining time is shortened, time and labor are saved, the human resource cost is lowered, the automation degree is high, and the production efficiency is greatly improved.

Owner:WUXI WANHUA MACHINERY

A laser processing technology and processing device based on electrostatic field assistance

InactiveCN104096979BEasy to peel offAvoid accumulationLaser beam welding apparatusLaser processingClassical mechanics

Owner:XI AN JIAOTONG UNIV

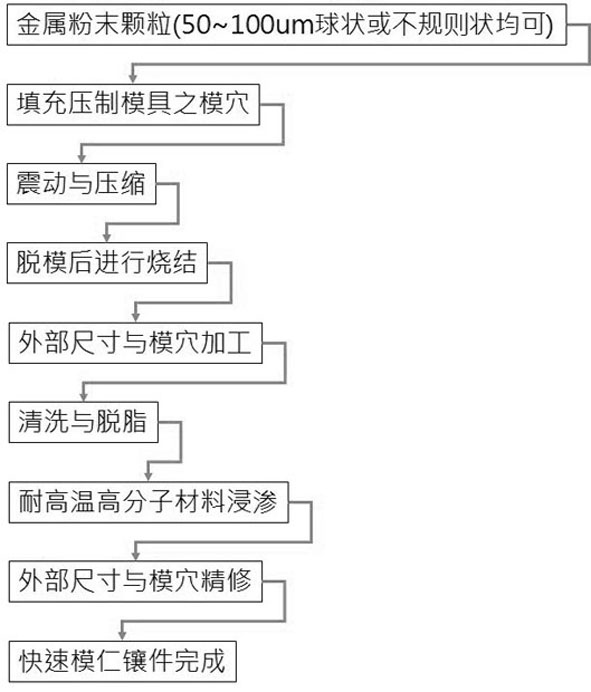

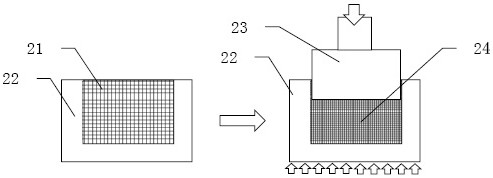

Forming method of temporary metallic mold

PendingCN113560578ALow costEasy to processTurbinesOther manufacturing equipments/toolsMachining processHigh polymer

The invention belongs to the technical field of metallic mold machining processes, and particularly relates to a forming method of a temporary metallic mold. The method comprises the steps that firstly, a model is filled with metal powder and a binder, a metal green body is formed after heating, then demolding and sintering are conducted, then rough machining is conducted according to the mold design of a product, high polymer materials are used for infiltration after cleaning and degreasing are conducted, and finally, finish machining is conducted to obtain the temporary metallic mold. According to the technical scheme provided by the invention, through metal powder filling and sintering, rapid forming of a metal block is achieved; compared with high-density metal adopted in the prior art, the formed metal block is low in cost and easy to machine, the machining time can be shortened, and the cutter loss can be reduced; then through the infiltration of the high polymer materials, the strength required by the mold time exceeding 1000 times can be rapidly obtained, and the surface smoothness and compactness required by a mold core are met; and the forming method of the temporary metallic mold is beneficial to operation, low in cost and particularly easy to popularize and use.

Owner:SUZHOU ZHONGYAO TECH CO LTD

A kind of softener for thick wolfberry and preparation method thereof

ActiveCN103659979BImprove toughnessSmoothOther chemical processesReed/straw treatmentEthylenediamineBetaine

A softener for thick salix integra is made from raw materials in parts by weight as follows: 5-7 parts of ethylenediamine, 4-5 parts of tartaric acid, 4-5 parts of coco-betaine, 1-2 parts of decyl polyglucoside, 4-5 parts of ammonium dihydrogen phosphate, 10-12 parts of dandelion, 4-6 parts of chrysanthemum, 10-12 parts of coptis chinensis, 3-4 parts of camphor tree bark, 6-8 parts of povidone iodine,3-4 parts of an assistant and 100 parts of water. According to the softener, the ethylenediamine, the tartaric acid and multiple surfactants are used, so that the softener is high in permeation speed, high in softening speed and even in softening; the salix integra is good in toughness and touches smooth, and the weaving efficiency can be improved; and Chinese herbal medicines such as the camphor tree bark and the like as well as the povidone iodine are used, so that salix integra is smooth in surface, mould-proof and free of worms. The softener is applicable to softening of the thicker salix integra.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Indexable milling inserts for sidewall machining

ActiveCN110315118BImprove fitting accuracyImprove cutting performanceMilling cuttersMilling cutting insertsSurface finishStructural engineering

The invention provides a rotatable milling blade for sidewall machining. The milling blade comprises an upper top surface, a lower bottom surface, two end surfaces connected with the upper top surfaceand the lower bottom surface, and an approximately cuboid blade main body defined by two side surfaces; the upper top surface and the two side surfaces extent at respective curvatures and intersect,and a first main cutting edge and a second main cutting edge are formed; the first main cutting edge is fitted on a first cutting rotating cylindrical surface with the diameter being D and orderly extends on the first cutting rotating cylindrical surface; and the second main cutting edge is fitted on a second cutting rotating cylindrical surface with the diameter being d and extends orderly on thesecond cutting rotating cylindrical surface. The vertical precision and the surface smoothness of a machined side surface at different cutting depths can be met, the cutting quality of the side surface is improved, and the cutting efficiency is improved.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

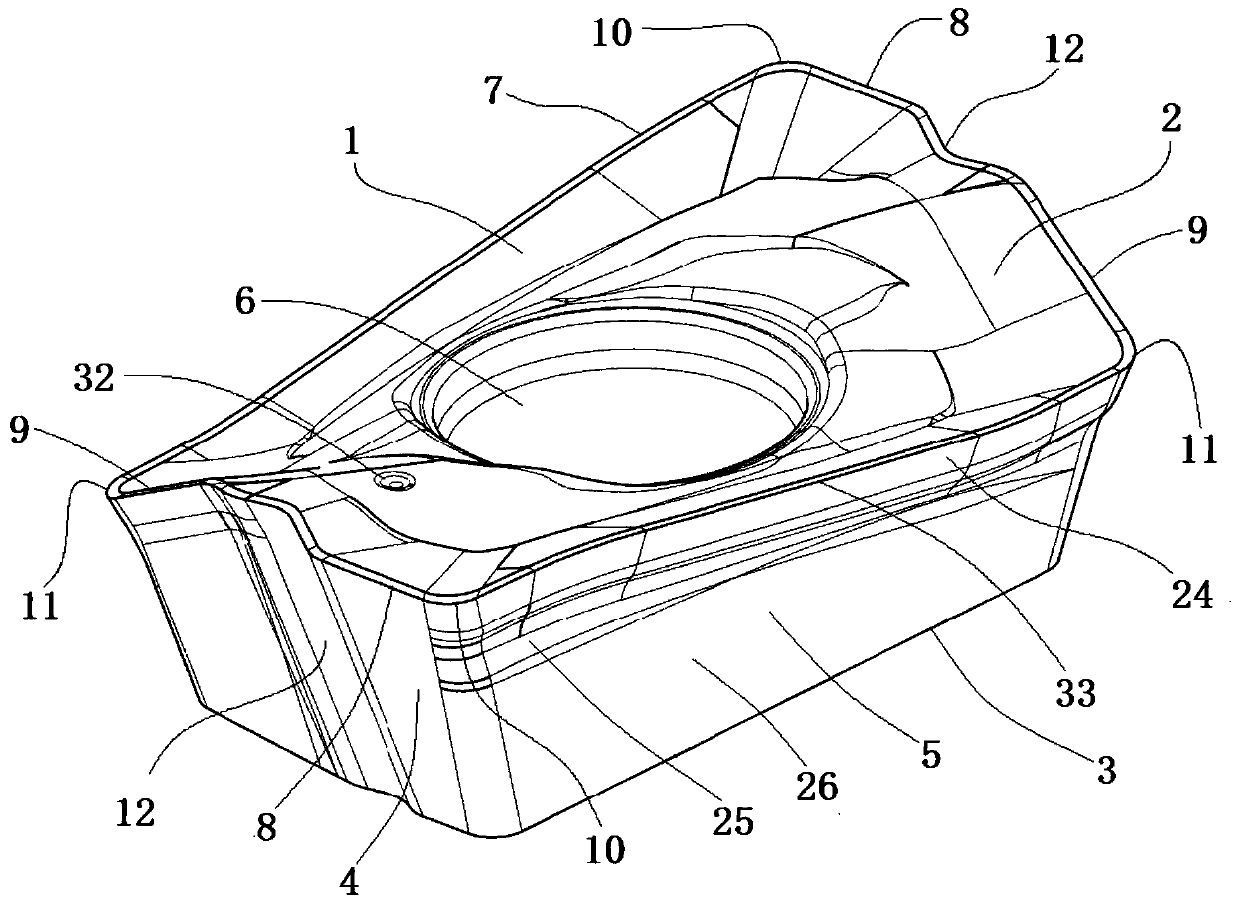

Abrasion-resistance baseboard of conveying machinery and manufacturing method of abrasion-resistance baseboard

InactiveCN104416985AImprove wear resistanceNot easy to wearConveyorsSynthetic resin layered productsGlass fiberBaseboard

The invention discloses an abrasion-resistance baseboard of conveying machinery, and the abrasion-resistance baseboard comprises a baseboard body (1) with grooves on the surface thereof; the baseboard body (1) is made of glass fiber reinforced plastics and the surface thereof is provided with an abrasion-resistance coat; the abrasion-resistance coat is composed of an UV (ultraviolet) paint filler layer (2), an UV abrasion-resistance base coat (3) and an UV elastic surface coat (4) in sequence from inside to outside. Because the baseboard body is made of the glass fiber reinforced plastics, the surface thereof is provided with the grooves, and the surface of the baseboard body is provided with the abrasion-resistance coat by a particular technology, the manufactured abrasion-resistance baseboard of the conveying machinery is excellent in abrasive resistance, difficult to wear and long in service life and can overcome the disadvantage that an iron baseboard is weak in abrasive resistance, easy to wear and short in service life; besides the abrasion-resistance baseboard is smooth in surface, cannot wear a conveyer belt, and overcomes the disadvantage that a ceramic baseboard is unsmooth in surface and easily wears the conveyor belt.

Owner:HUZHOU QIANJIN BAOYUN MACHINERY CASTING

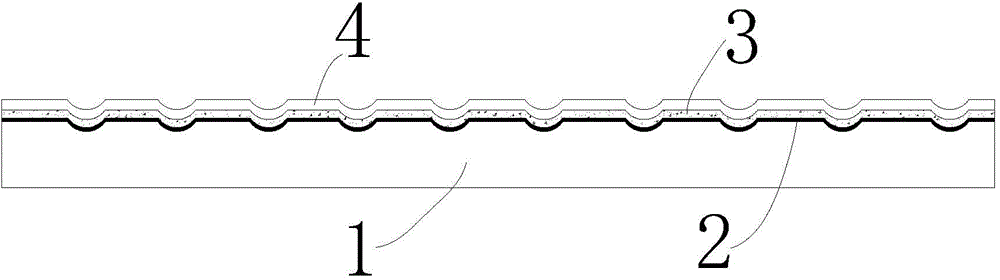

Multilayer multifunctional composite fabric and composite process thereof

PendingCN110065282AGood shading effectImprove purification effectSynthetic resin layered productsMetal layered productsHot-melt adhesiveTextile

The invention relates to the field of composite fabric processing, in particular to a multilayer multifunctional composite fabric and a composite process thereof. By arranging a first shading layer, an inner core and a second shading layer, the effects that the shading effect is improved, and the composite fabric is durable and sunproof can be achieved; by adding a modified silicon material, the purification capacity to the environment is increased, and the comprehensive function of the composite fabric is further improved; by means of the cold and hot rolling process, the surface of the innercore material can be smoother, the selection requirements on the inner core material are lowered, and then the cost can be controlled; by means of the rewinding step, the effect that the intermediateinterlayer is reduced and deformed can be achieved; by compositing the first shading layer, the second shaking layer and the fabric through a hot melt adhesive, the environmental protection and efficient processing effects can be achieved.

Owner:常州金富复合材料有限公司

Method for processing automobile buffer block and special clamp used by method

InactiveCN101590601BIncrease productivitySurface finishAuxillary equipmentOther manufacturing equipments/toolsInjection molding machineProcessing accuracy

The invention discloses a method for processing an automobile buffer block, which comprises the following steps: (1) injection-molding a buffer block blank by an injection molding machine; (2) fixing the buffer block blank to a lathe through a first special clamp capable of clamping an outer circle surface of the buffer block, and processing a lathe groove on the inner surface of the buffer block; (3) taking a semi-finished product of the buffer block out from the first special clamp, fixing the semi-finished product to the lathe through a second special clamp capable of clamping the inner surface of the buffer block, and cutting and processing the end face of the lathe; and (4) stopping processing and retracting a cutter, and mounting a previously-processed iron piece in the processed qualified buffer block. After the structure is adopted, the method can process a plurality of the buffer blocks once so as to greatly improve the production efficiency; and simultaneously, the phenomenon of flashing or deficient filling is not caused, the surface of the product is smoother, and the processing precision is higher.

Owner:宁波安纳杰模塑科技有限公司

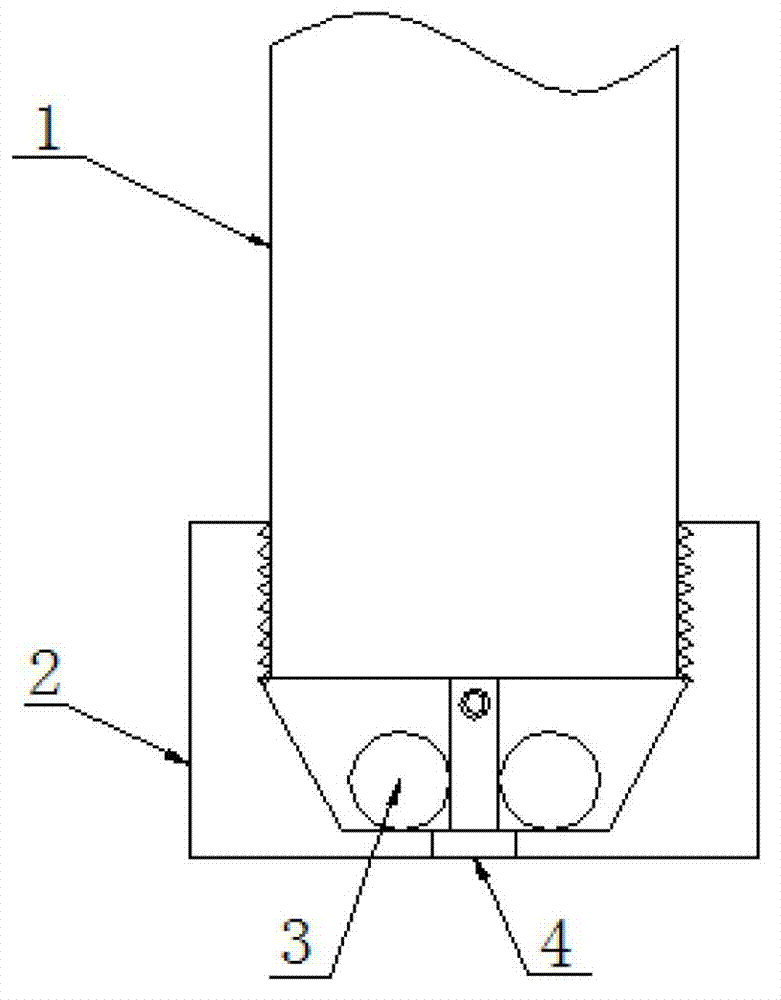

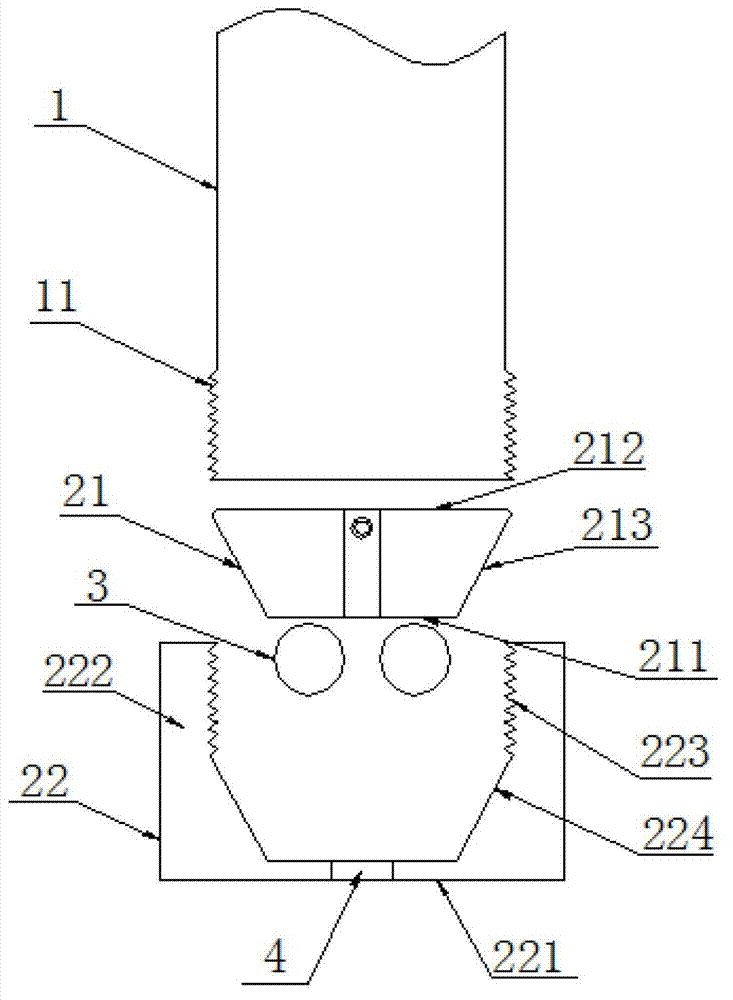

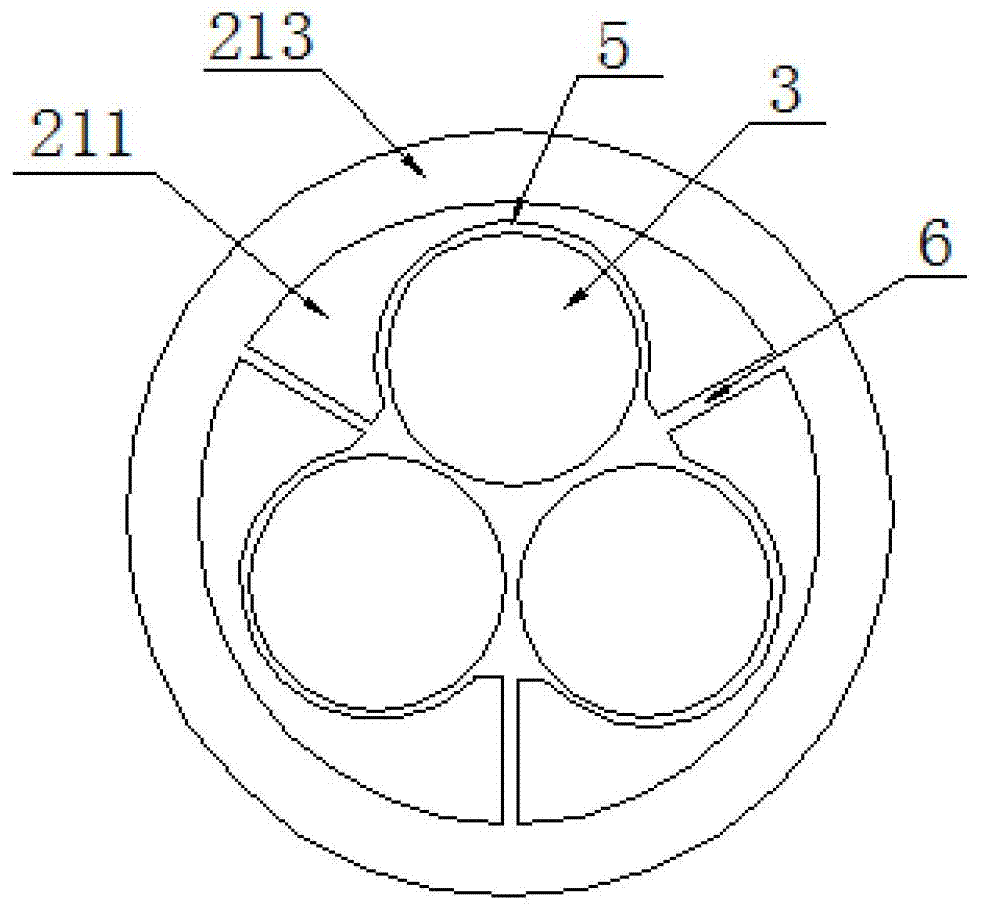

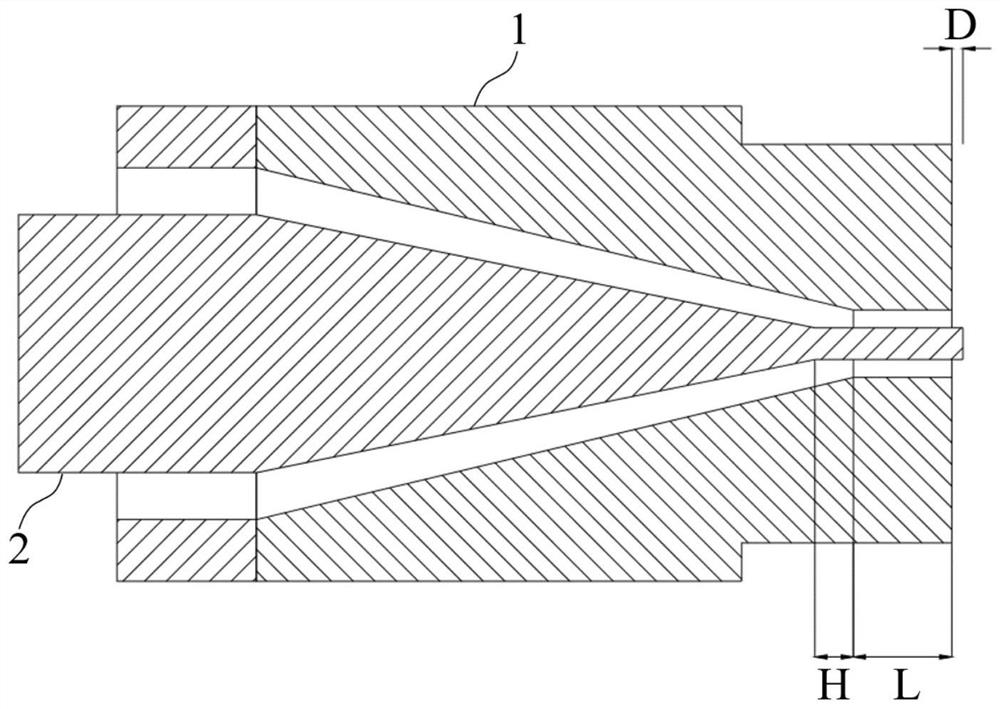

Injection molding equipment for hollow pipe fitting

The invention discloses injection molding equipment for a hollow pipe fitting, and belongs to the field of injection molding equipment. The injection molding equipment comprises an injection molding machine, a cooling and shaping unit, a traction unit and a cutting unit, wherein an injection mold is arranged on the injection molding machine, and comprises a mold sleeve, a taper angle hole section,a diameter bearing hole section and a mold core; the taper angle hole section is formed in the middle of one end surface of the mold sleeve in the central axis direction of the mold sleeve; the diameter bearing hole section is formed in the middle of the other end surface of the mold sleeve in the central axis direction of the mold sleeve, and communicates with the taper angle hole section; the mold core is connected with the mold sleeve, and comprises a taper section and a mold core section; the taper section is arranged in the taper angle hole section; and one end of the mold core section is connected with the taper section, and the other end of the mold core section penetrates through the diameter bearing hole section and extends out of the mold sleeve. The injection mold on the injection molding machine can quickly mold the hollow pipe fitting with uniform density and smooth surface, and can accurately guide injection molding products to enter the cooling and shaping unit for molding; the traction unit prevents the injection molding products from being accumulated; and finally, by the cutting unit, the required length of the hollow pipe fitting is obtained. The injection molding equipment has the characteristics of high production efficiency and high product quality.

Owner:扬州吉山津田光电科技有限公司

Method for producing hot-rolled ferritic stainless steel strip steel

InactiveCN100535168CImprove organizationImprove high temperature plasticityRoll mill control devicesHeat treatment process controlSurface finishChemical composition

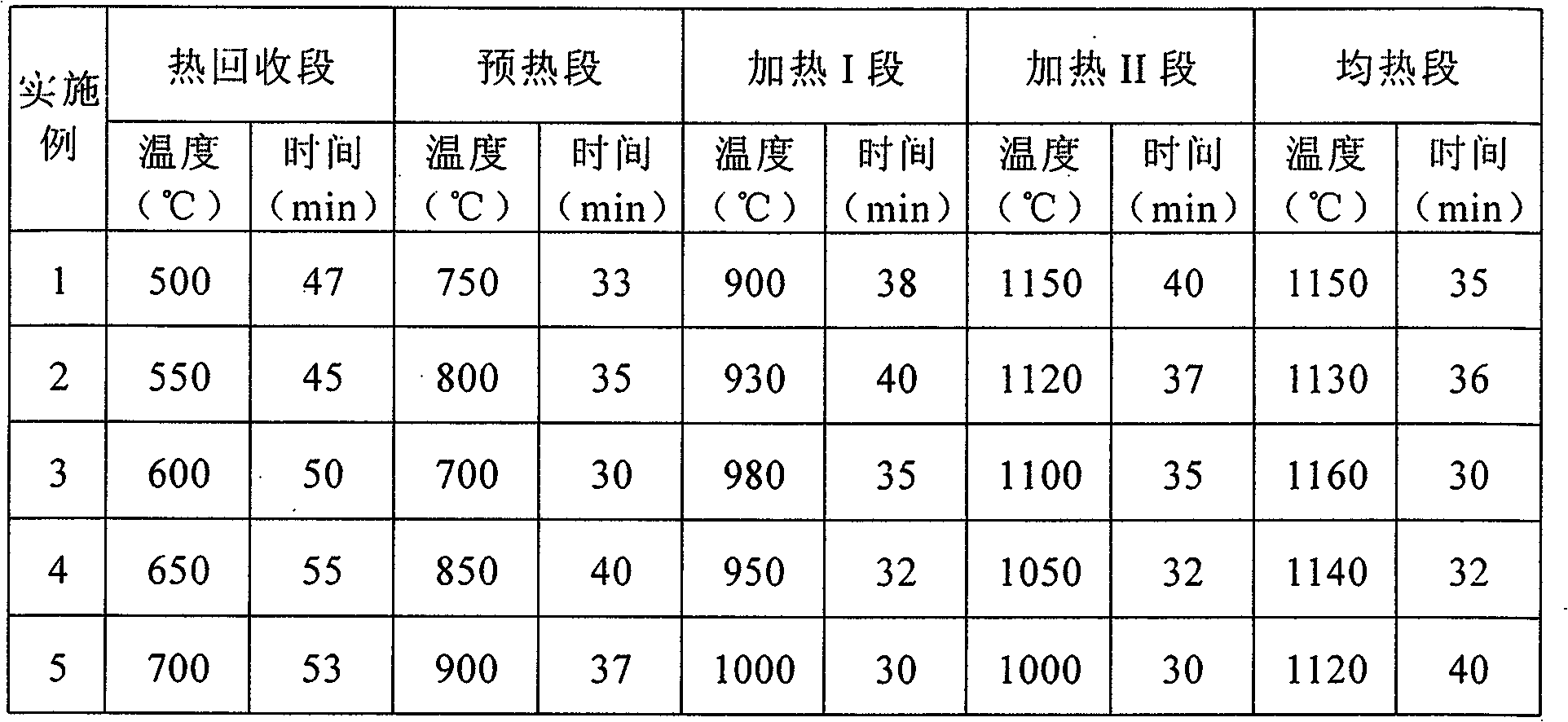

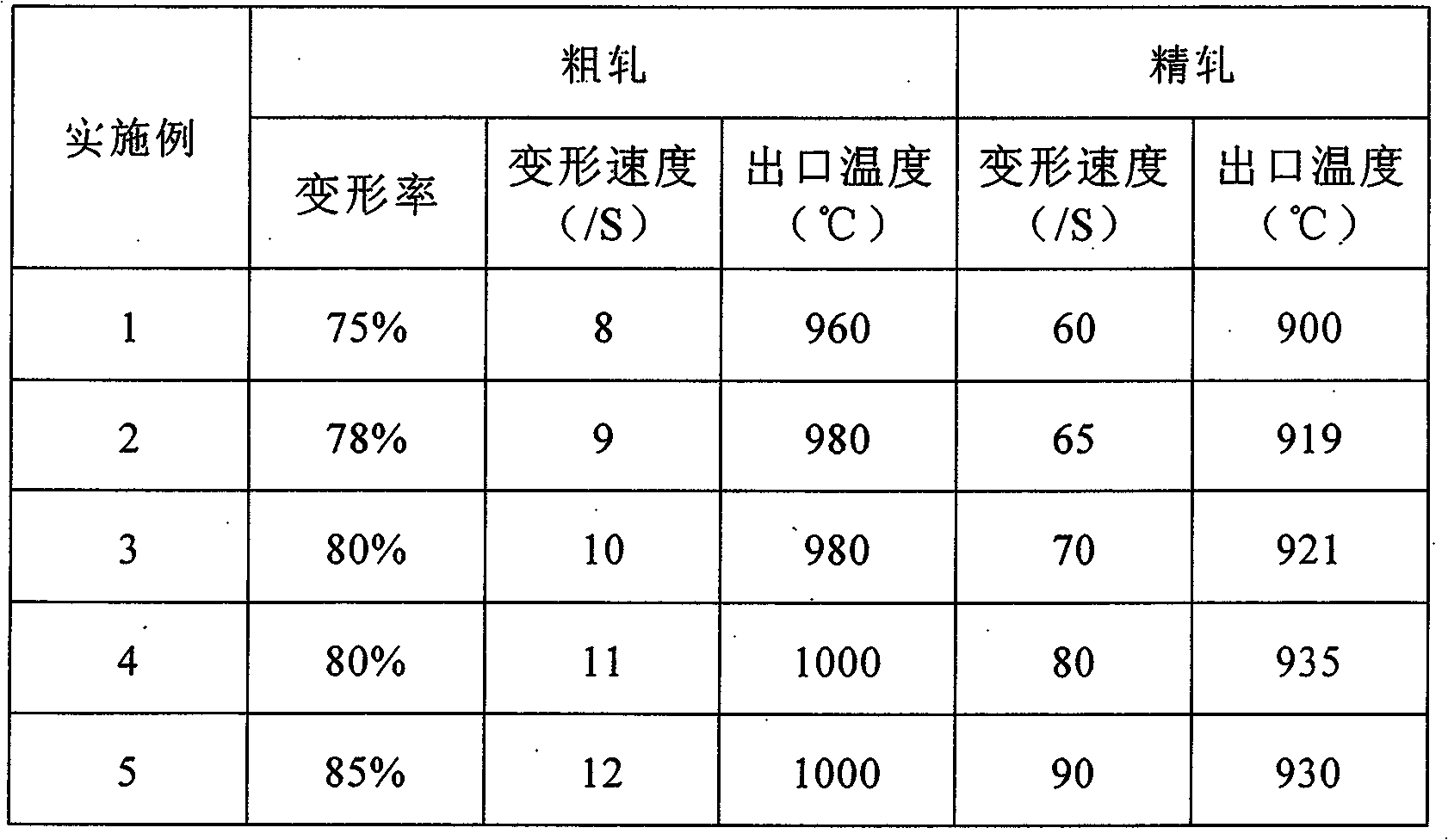

The invention discloses a method for producing a hot-rolled ferrite stainless strip steel, which comprises the following steps: 1) the chemical components by weight percentage are: 0.025-0.04 percent of C, less than or equal to 1.00 percent of Si, 0.25-0.4 percent of Mn, less than or equal to 0.030 percent of S, less than or equal to 0.035 of P, 12-12.5 percent of Cr and the rest is Fe; 2) a billet is formed by smelting and casting; 3) heating: the heating temperature zone for heating are divided into a heat recovery section, a preheating section, a I heating section, a II heating section and a holding section; furnace gas is controlled to be neutral atmosphere of non-oxidizing atmosphere; 4) when in heat rolling and rough rolling, the rolling temperature is 1,120 DEG C-1,160 DEG C, and the deforming speed during rolling is 10 / s-12 / s; 5) finish rolling: the deforming speed of the last pass rolling is 60 / s-90 / s, and the outlet temperature of the finish rolling is more than 900 DEG C; 6) cooling is carried out after rolling, and then reeling is carried out. The method of the invention has the advantages that the method guarantees not only the edge quality of the hot-rolled strip steel but also the stamping property of the cold-rolled strip steel, improves the surface finish quality and lowers the production cost, and has high production efficiency and rolling yield, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com