Abrasion-resistance baseboard of conveying machinery and manufacturing method of abrasion-resistance baseboard

A technology for conveying machinery and wear-resistant primer, applied in the field of conveying machinery, can solve the problems of poor wear resistance, short service life, conveyor belt wear, etc., and achieve the effects of good wear resistance, long service life and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

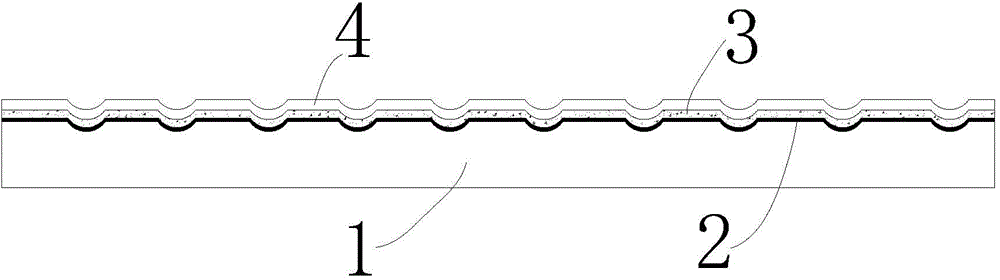

[0031] Example 1. A wear-resistant bottom plate of conveying machinery, such as figure 1 As shown, it includes a bottom plate body 1 with grooves on the surface; the bottom plate body 1 is made of glass fiber reinforced plastic, and its surface is provided with a wear-resistant paint surface; the composition of the wear-resistant paint surface is from inside to outside It is UV putty layer 2, UV wear-resistant primer layer 3 and UV elastic topcoat layer 4 in sequence. The UV putty layer 2 is a UV putty coating of 208060511; the UV wear-resistant primer layer 3 is a UV high wear-resistant primer coating of 318900511; the UV elastic topcoat 4 is a model of 288040511 UV High Elastic Topcoat Coating.

[0032] The method for manufacturing the aforementioned wear-resistant bottom plate of a conveying machine comprises the following steps:

[0033] ① Use glass fiber reinforced plastic to make the bottom plate body with grooves on the surface;

[0034] ②Roller coating with UV wate...

Embodiment 2

[0039] Example 2. A wear-resistant bottom plate of conveying machinery, such as figure 1 As shown, it includes a bottom plate body 1 with grooves on the surface; the bottom plate body 1 is made of glass fiber reinforced plastic, and its surface is provided with a wear-resistant paint surface; the composition of the wear-resistant paint surface is from inside to outside It is UV putty layer 2, UV wear-resistant primer layer 3 and UV elastic topcoat layer 4 in sequence. The UV putty layer 2 is a UV putty coating of 208060511; the UV wear-resistant primer layer 3 is a UV high wear-resistant primer coating of 318900511; the UV elastic topcoat 4 is a model of 288040511 UV High Elastic Topcoat Coating.

[0040] The method for manufacturing the aforementioned wear-resistant bottom plate of a conveying machine comprises the following steps:

[0041] ① Use glass fiber reinforced plastic to make the bottom plate body with grooves on the surface;

[0042] ②Roller coating with UV wate...

Embodiment 3

[0047] Example 3. A wear-resistant bottom plate of conveying machinery, such as figure 1 As shown, it includes a bottom plate body 1 with grooves on the surface; the bottom plate body 1 is made of glass fiber reinforced plastic, and its surface is provided with a wear-resistant paint surface; the composition of the wear-resistant paint surface is from inside to outside It is UV putty layer 2, UV wear-resistant primer layer 3 and UV elastic topcoat layer 4 in sequence. The UV putty layer 2 is a UV putty coating of 208060511; the UV wear-resistant primer layer 3 is a UV high wear-resistant primer coating of 318900511; the UV elastic topcoat 4 is a model of 288040511 UV High Elastic Topcoat Coating.

[0048] The method for manufacturing the aforementioned wear-resistant bottom plate of a conveying machine comprises the following steps:

[0049] ① Use glass fiber reinforced plastic to make the bottom plate body with grooves on the surface;

[0050] ②Roller coating with UV wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com