Patents

Literature

79results about How to "Wear will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

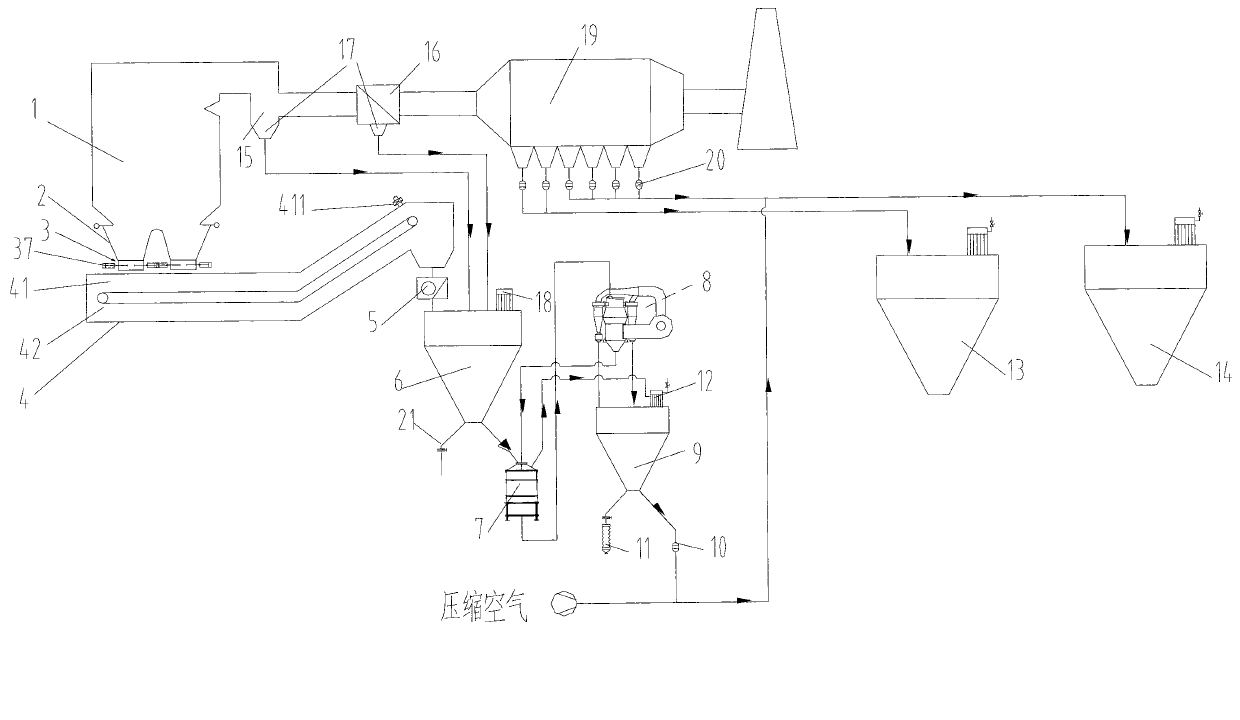

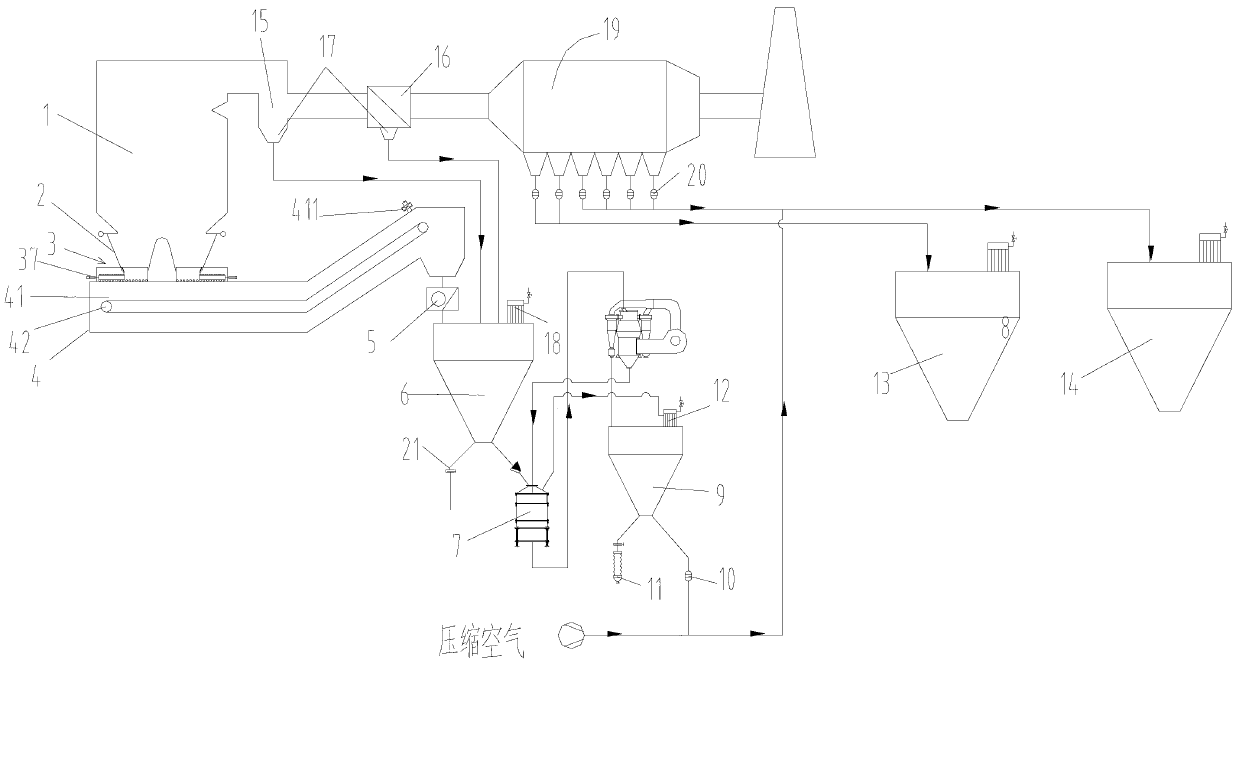

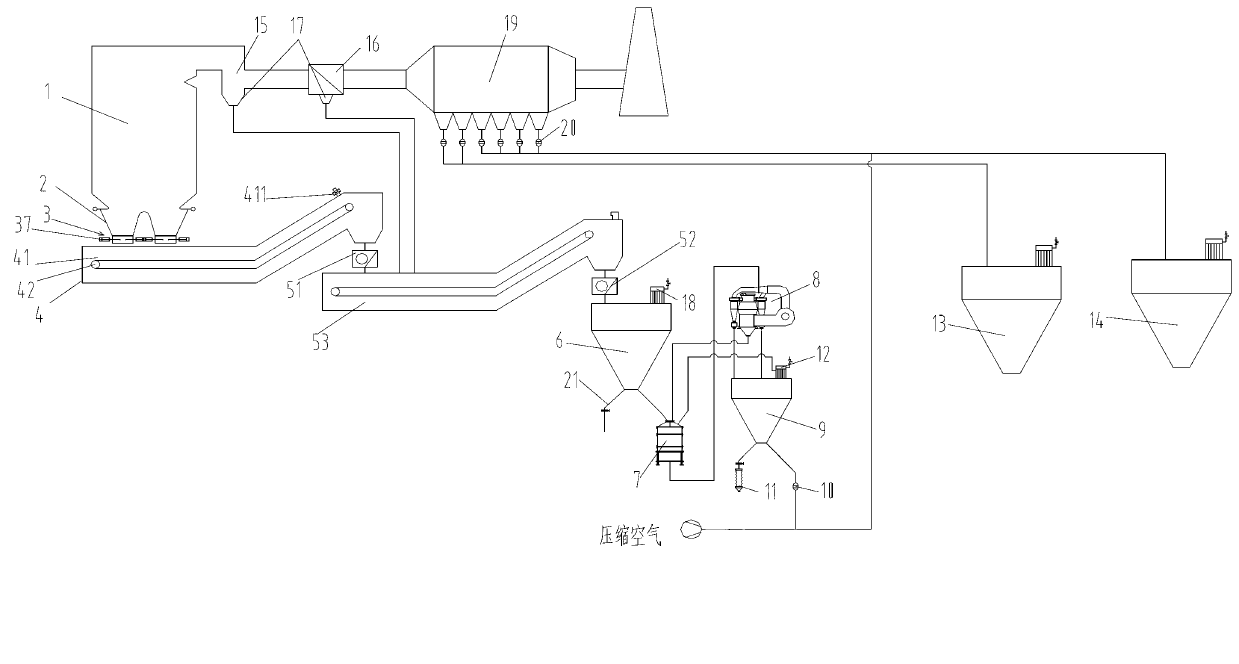

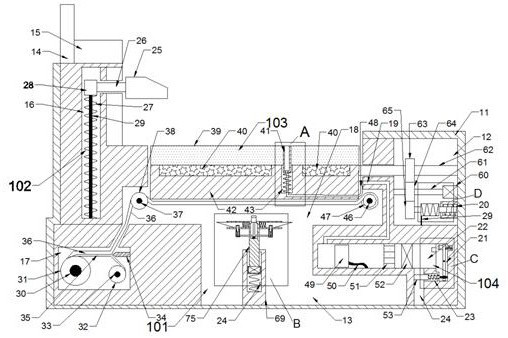

Integrated processing system and method thereof of improving use value of coal-fired boiler ash

InactiveCN103134059ASmall granularityReduce wearSolid fuel combustionSolid removalBoiler furnaceMicrometer

The invention discloses an integrated processing system and a method thereof of improving use value of coal-fired boiler ash. The integrated processing system comprises an ash processing system which is used for breaking and grinding of received boiler ash and manufacturing the boiler ash into available raw materials. The ash processing system comprises an ash breaking device, an ash grinding device and a separation device, the ash breaking device receives ash outputted by a boiler and breaks the ash into 100mm, the ash grinding device is used for grinding the ash after broken below 45 micrometers, the separation device is connected with an outlet of the ash grinding device and used for separating of the ash after ground, qualified ash is used as the available raw materials, and the unqualified ash is returned to the ash grinding device to continue to grind. The integrated processing system directly conducts breaking, grinding and separation processing for the ash, enables fine ash after ground not to pass through equipment, such as a coal pulverizing system, a boiler furnace, a coal economizer and an air pre-heater, keeps stability of the coal-fired boiler ash in the process of ash processing, and prevents the equipment, such as a pipeline, the coal economizer and the air pre-heater from being abraded by ash particles.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

High temperature wear-resistant coating for metal surface, and its preparing mand using method

ActiveCN1850917AHigh refractorinessImprove thermal conductivityLiquid surface applicatorsCoatingsWear resistantPhosphoric acid

The invention discloses a high temperature antifriction dope for metal surface and the using method. It is made up from 85% thickness phosphoric acid 22-28 portions, aluminum hydroxide 3-5 portions, water 5-8 portions, chrome 0.01-0.02 portions, thinned silica solution 6-10 portions, white steel 10-18 portions, zirconia 12-18 portions, alumina 8-12 portions, magnesia 0.03-0.05 portions, and coagulant 4-7 portions and stainless steel wire 0.3-0.6 portions.

Owner:枣庄市新达节能技术开发有限责任公司

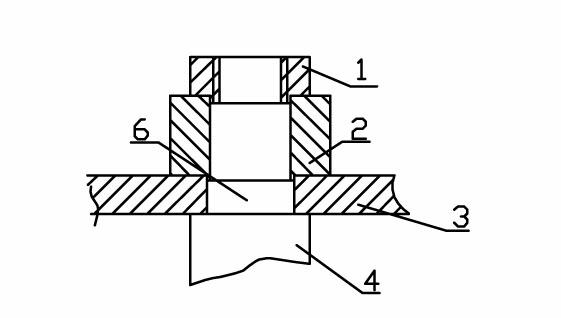

Cover-die hole-drilling device

InactiveCN102463371ASolving Tolerance Control IssuesLow skill level requiredPositioning apparatusDrill jigsPosition toleranceTechnical grade

The invention relates to a cover-die hole-drilling device, which relates to an auxiliary device for hole-drilling machining, wherein at least one positioning hole is arranged on a template, and a positioning sleeve is coaxially arranged on the positioning hole; and the hole diameter of the positioning hole is larger than that of a machined hole, and the hole diameter of the positioning sleeve is equal to that of the machined hole. The problem of workpiece-position tolerance control is solved through the positioning sleeve and the template arranged on the cover-die hole-drilling device provided by the invention. Requirements on the technical grade of an operator are reduced, production links are decreased, the quality of products is ensured, the production benefit is improved, and the cover-die hole-drilling device is worthy of being widely popularized.

Owner:长航集团宜昌船厂有限公司

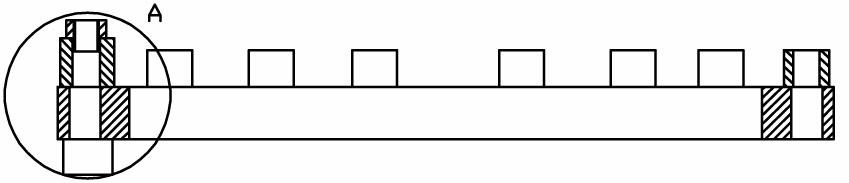

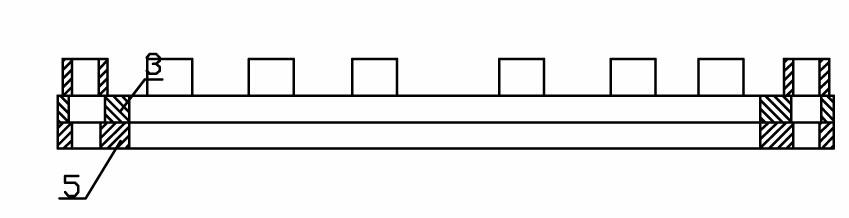

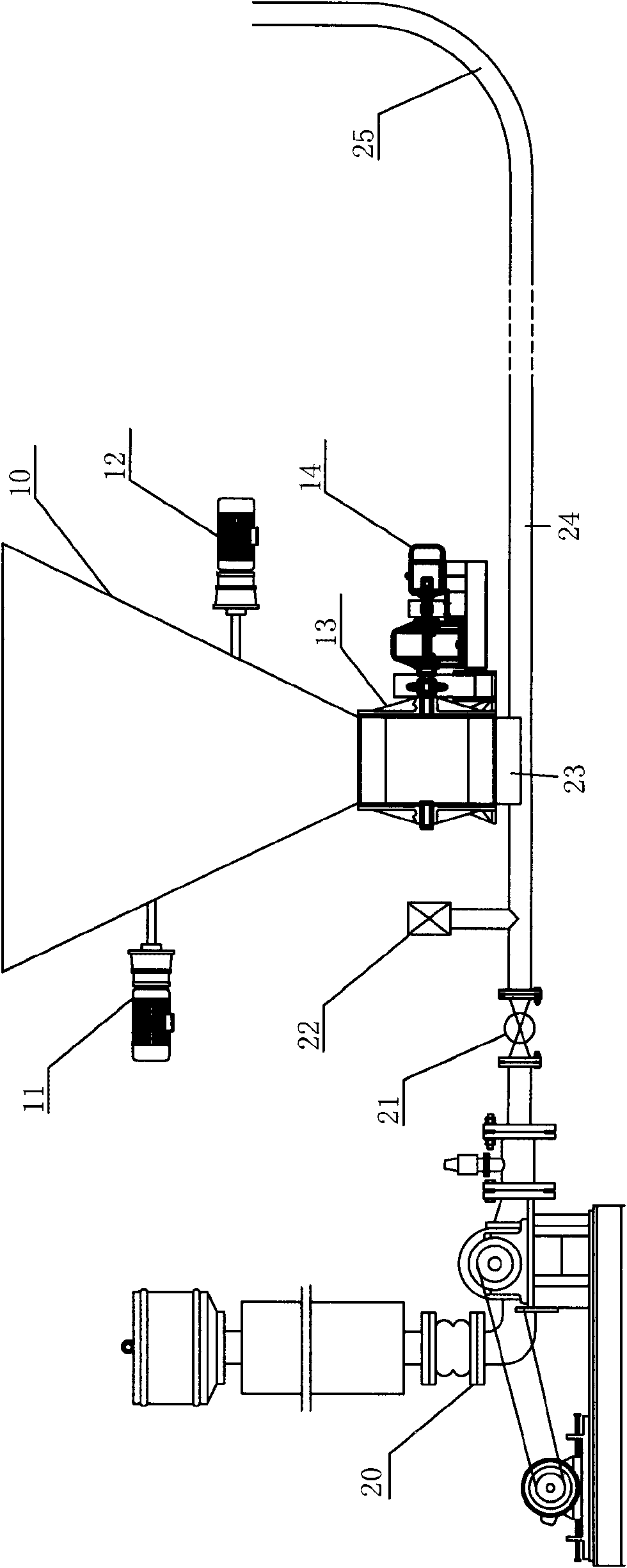

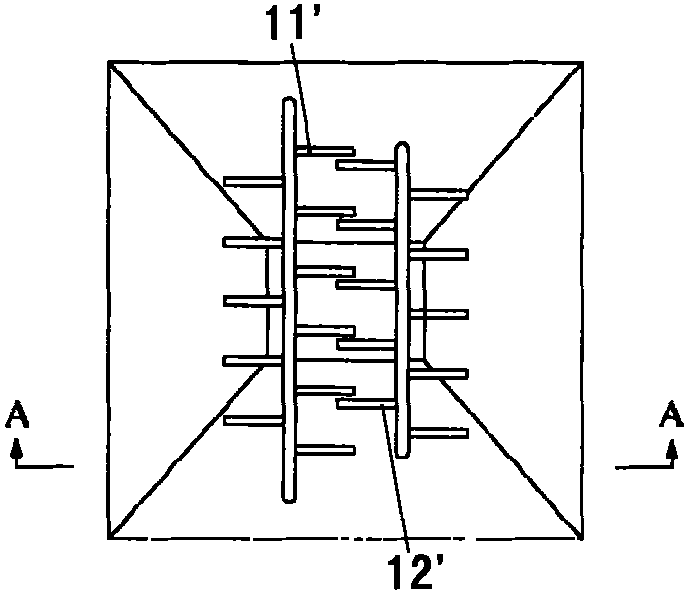

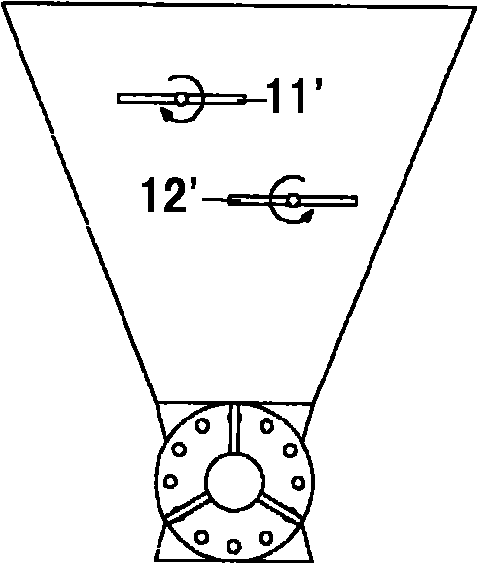

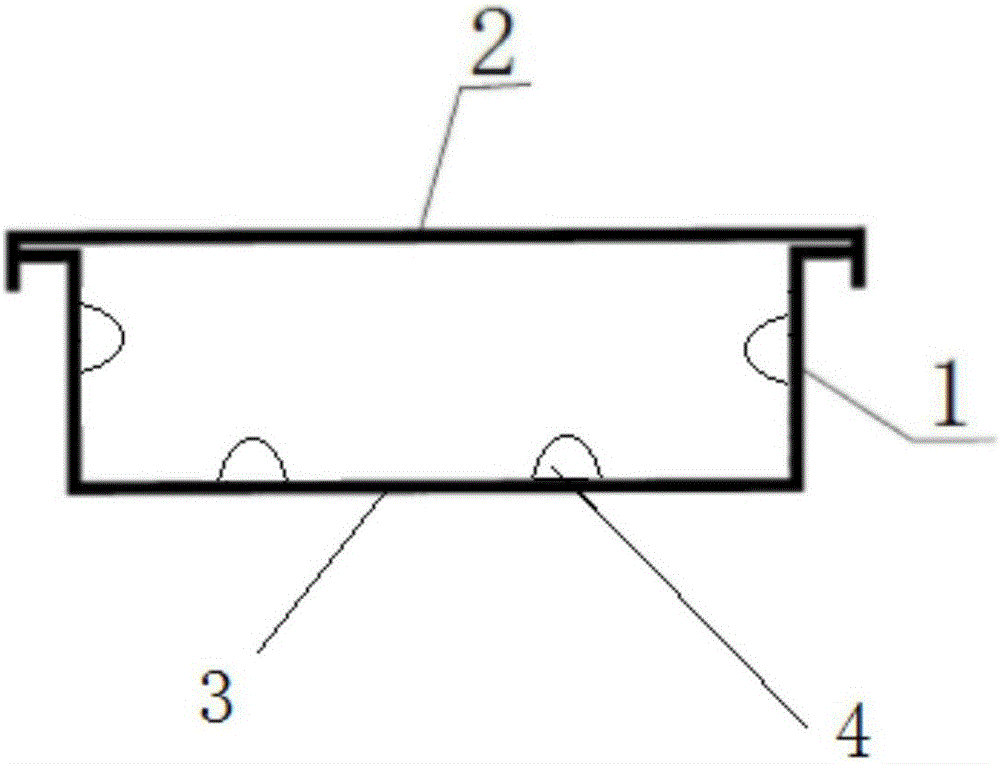

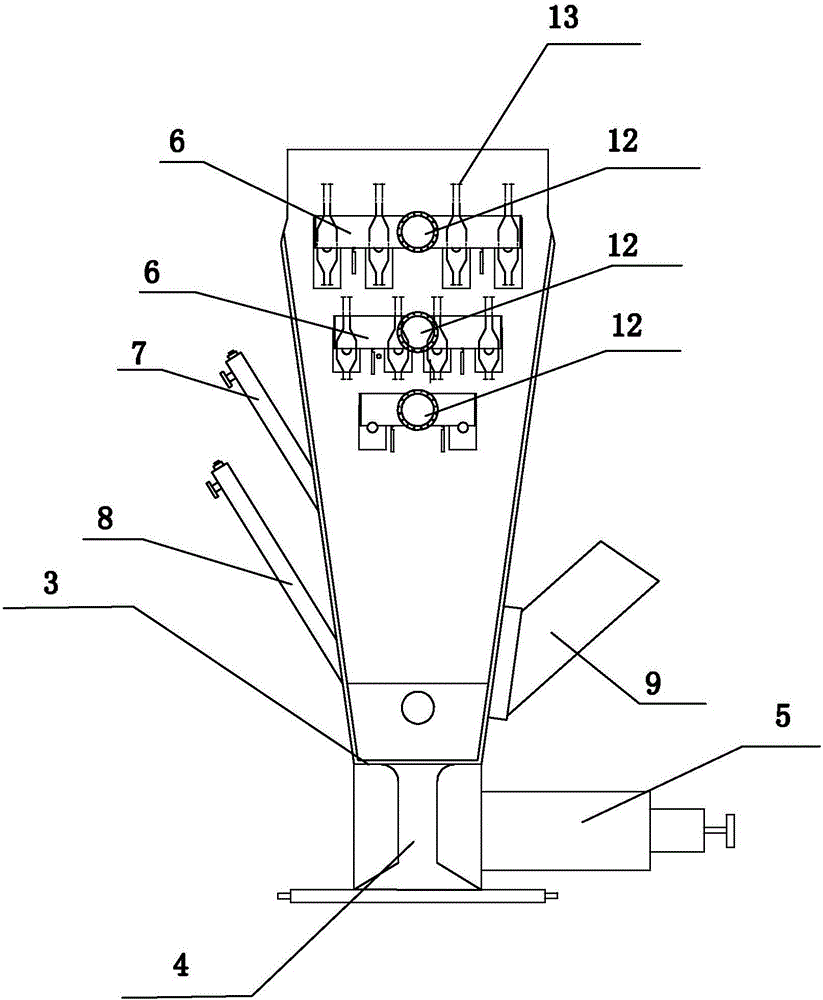

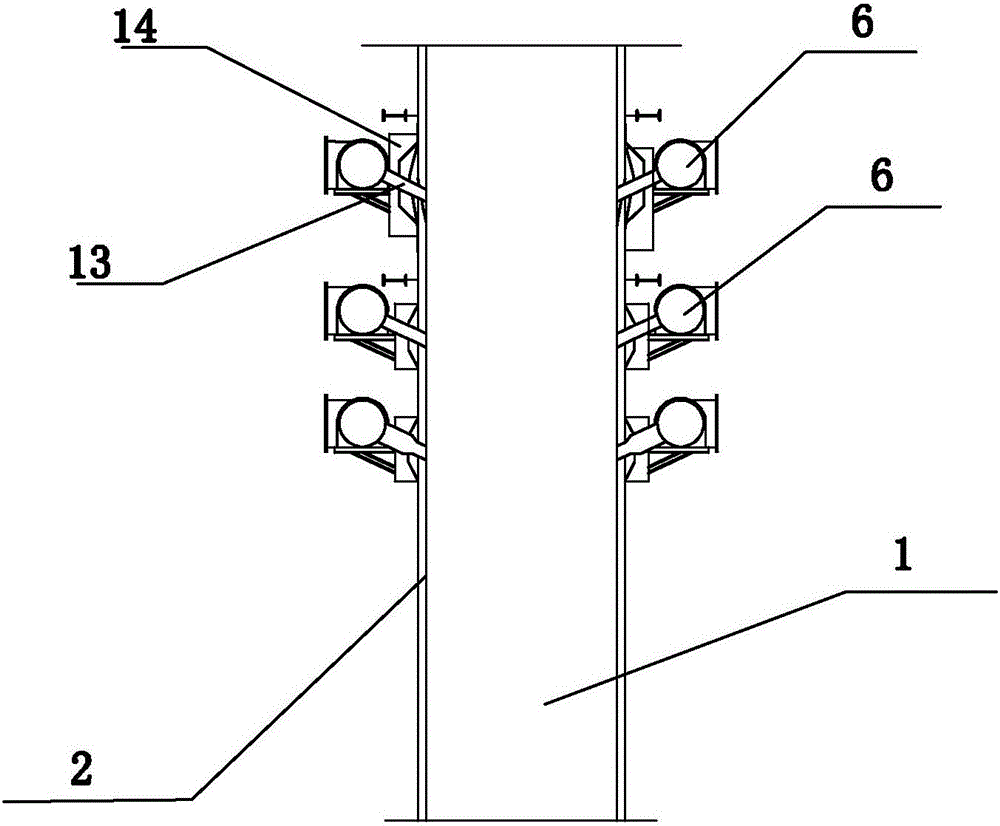

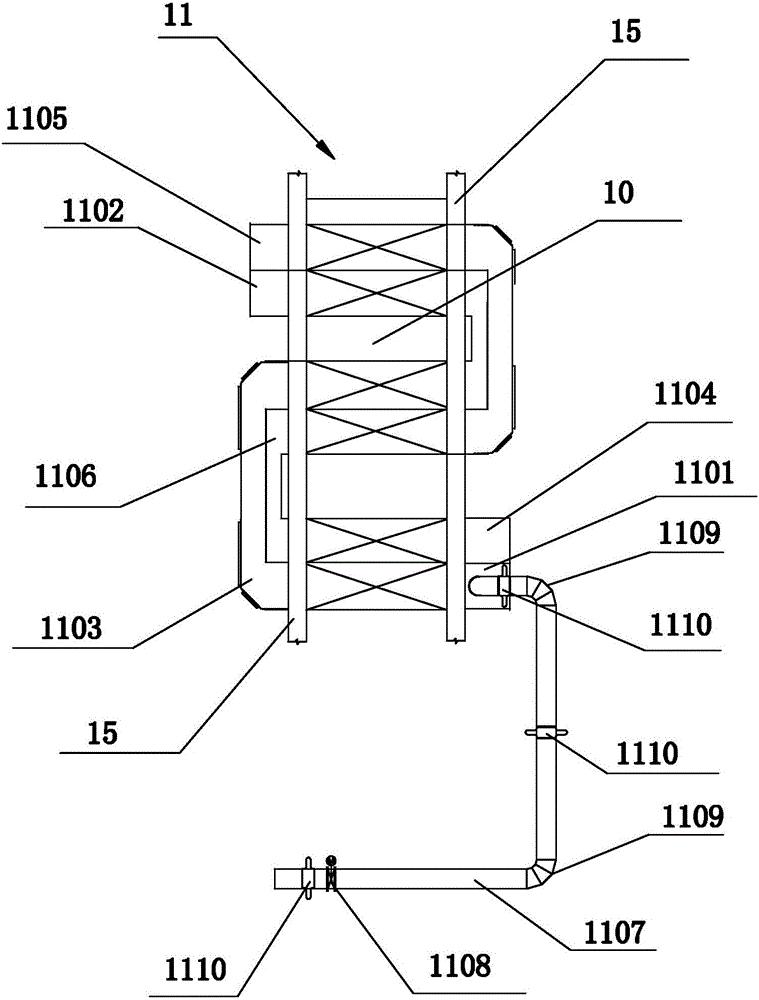

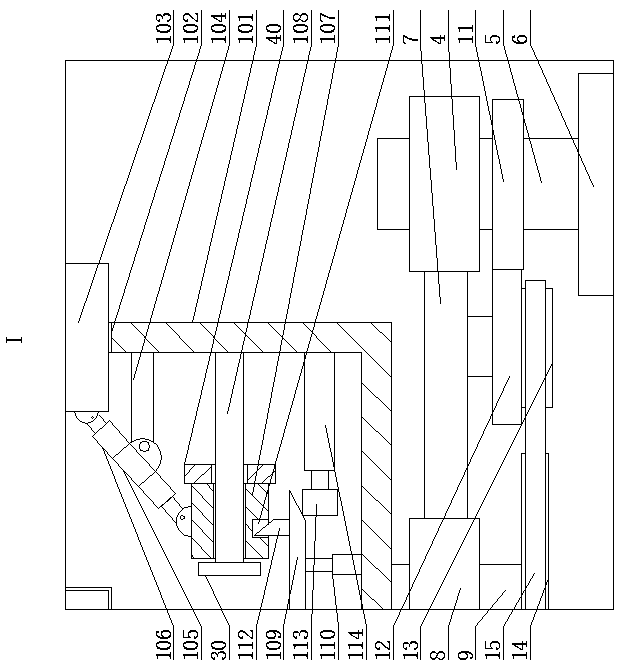

Pneumatic conveying device for conveying laminar materials

InactiveCN102602704APrevent bridgingReduce touch pointsLarge containersBulk conveyorsCement kilnEngineering

The invention discloses a pneumatic conveying device for conveying laminar materials, which is mainly composed of a metering, air locking and blanking part and a part of conveying air into a kiln; the metering, air locking and blanking part comprises a buffer blanking bin, wherein the lower port of the buffer blanking bin is connected with a rotary blanking device; two kick-out devices arranged up and down are transversely arranged in the buffer blanking bin, and the axle centers of the two kick-out devices are respectively situated at the two sides of a central line in the buffer blanking bin; and comb-shaped material kick-out teeth are arranged on a rotating shaft of the kick-out device, and the comb-shaped material kicking teeth are staggered with each other. The part of conveying air into the kiln comprises a roots blower connected with an air conveying pipeline; the rotary blanking device of the metering, air locking and blanking part is connected with the air conveying pipeline through a blanking chute; and the other end of the air conveying pipeline is connected with a multi-passage combustor of a cement kiln precombustion furnace or a cement kiln front. The pneumatic conveying device for conveying laminar materials, disclosed by the invention, can effectively convey glass fiber reinforced plastic composite materials serving as cement to replace fuel.

Owner:BEIJING JINYU MANGROVE ENVIRONMENTAL PROTECTION TECH

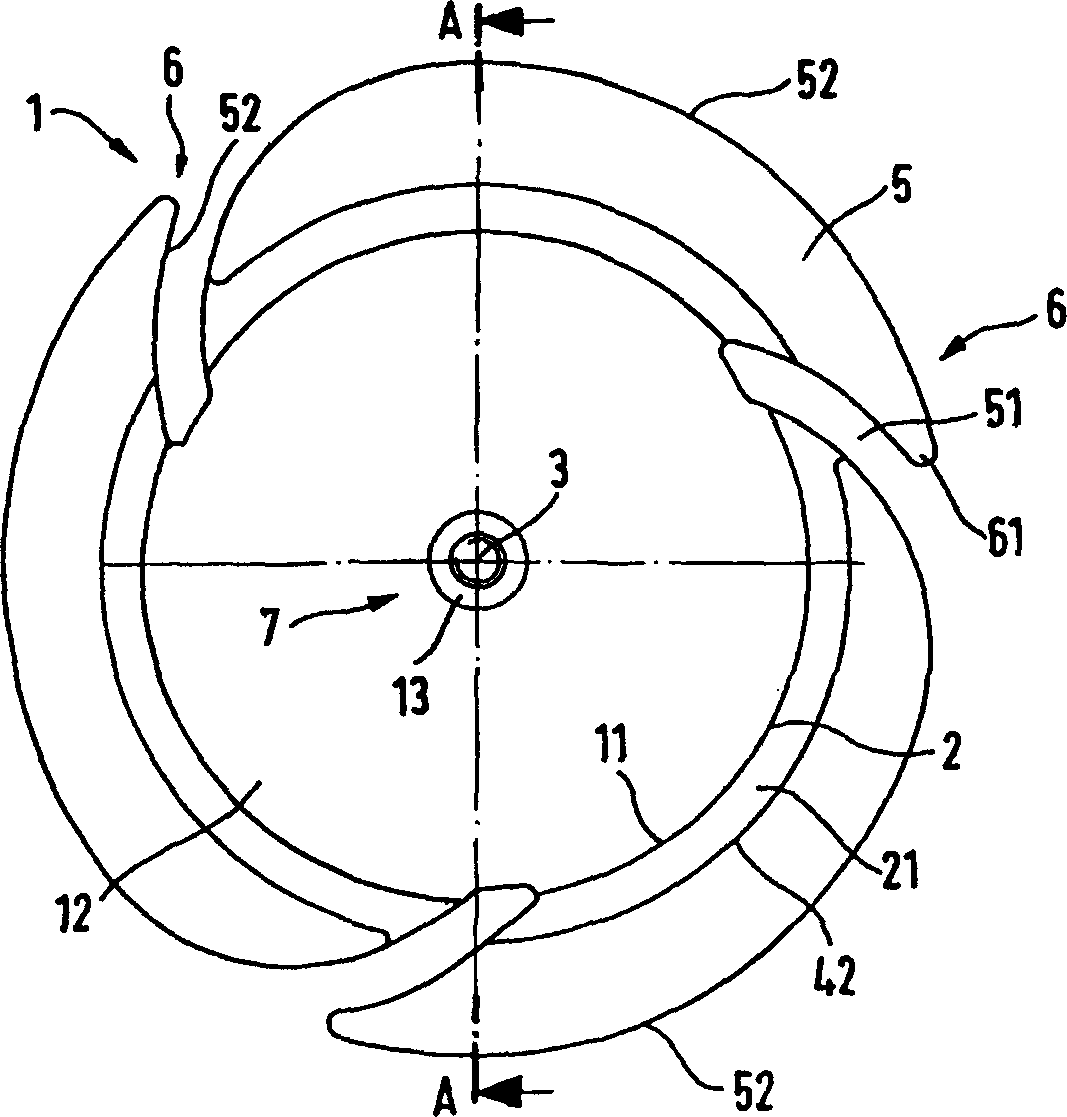

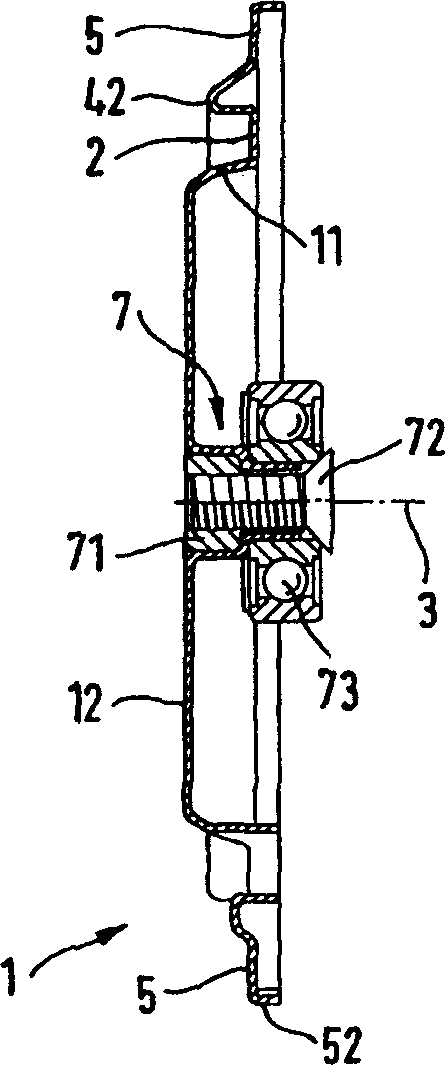

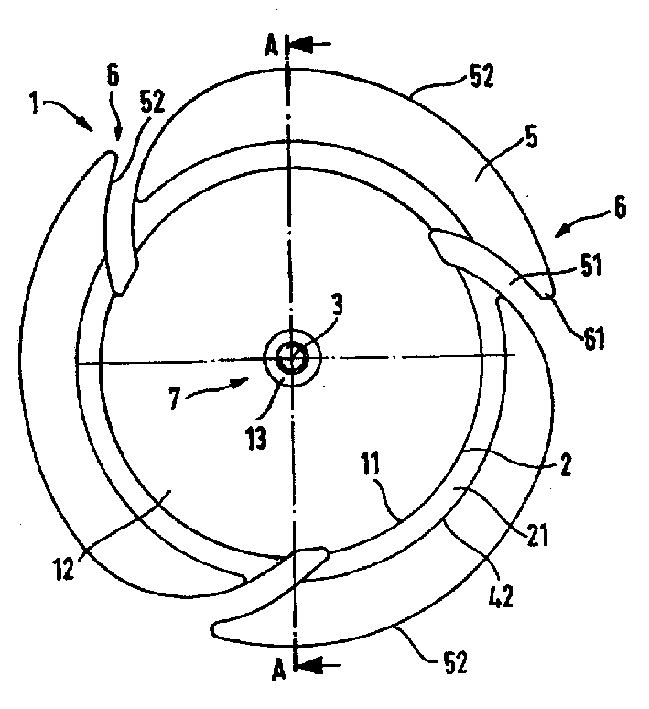

Bobbin tray seat for containing bobbins

A bobbin support is used to wind a filament on a winding position. The filament separately passes through the two ends of a bobbin tray seat for containing bobbins. A bobbin tray seat (1) for containing bobbins on a knitting machine is provided. The bobbin tray seat is made by, e.g., drawing or bending. By mounting the bobbin tray seat as a drawing component, the seat is strengthened by mechanical deformation, meanwhile, the bobbin tray seat can be made having a smaller wall thickness and a smaller mass. Thus, it is preferably made of steel plate or stainless steel plate. At least a contact head (61) of a yarn catching device is preferably installed in a peripheral (52) region thereof.

Owner:RIETER INGOLSTADT SPINNEREIMASCHENBAU AG

Wear-resistant cable bridge frame

InactiveCN105889632AImprove fire resistanceAvoid conductionPipe supportsElectrical apparatusRear quarterFrame based

The invention discloses a wear-resisting cable bridge frame. The wear-resisting cable bridge frame is characterized by comprising a bridge frame main body and a bridge frame cover plate, wherein the bridge frame main body and the bridge frame cover plate are mutually spliced; the bridge frame main body comprises a bridge frame base plate and bridge frame side plates; reinforcing ribs are separately arranged on the bridge frame base plate and the bridge frame side plates; and a plurality of anti-bug lamps are arranged outside the bridge frame main body. According to the wear-resisting cable bridge frame disclosed by the invention, by arranging fireproof paint layers, the fire resistance of the cable bridge frame is greatly improved; when fires occur, long working time of the cable can be maintained, emergency need can be guaranteed, and the loss caused by the fires is reduced; and the requirements of electrical engineering on fireproofing grade are met, and the conduction of heat is effectively prevented.

Owner:ZHENJIANG HUAYUAN JINCHANG ELECTRICAL APPLIANCES

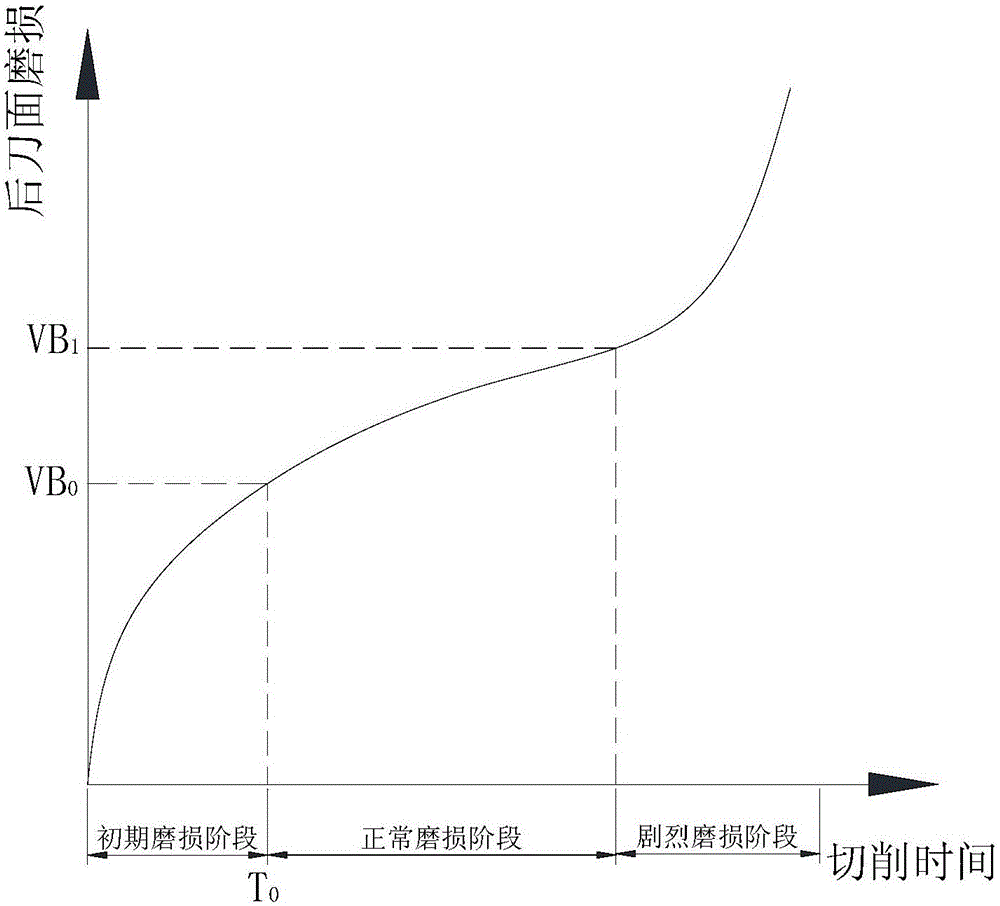

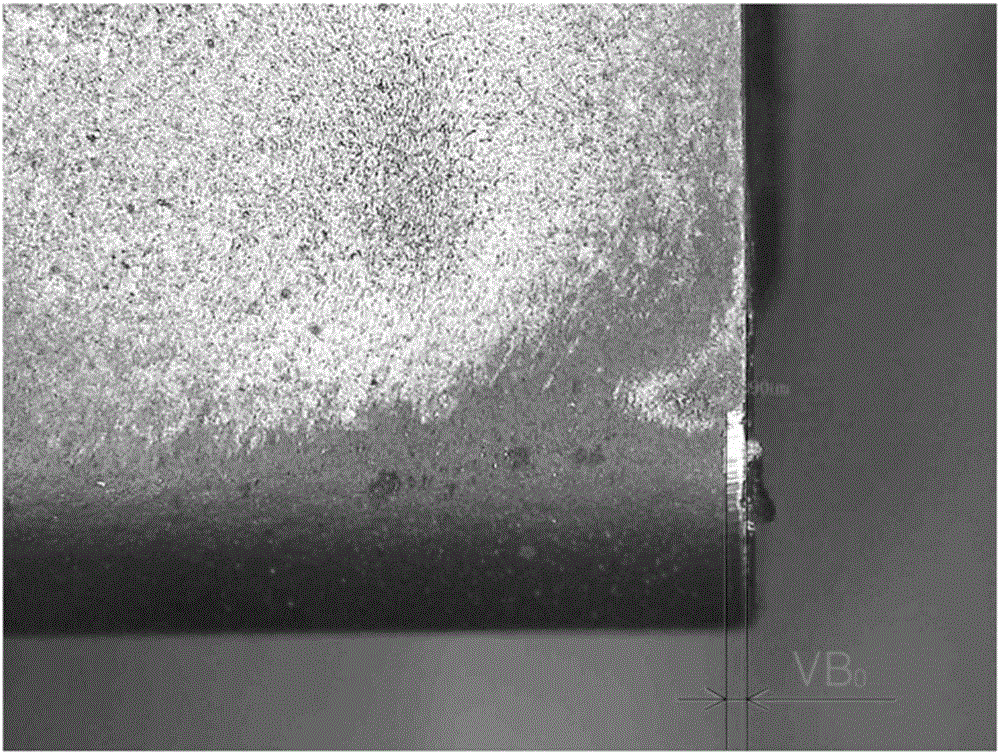

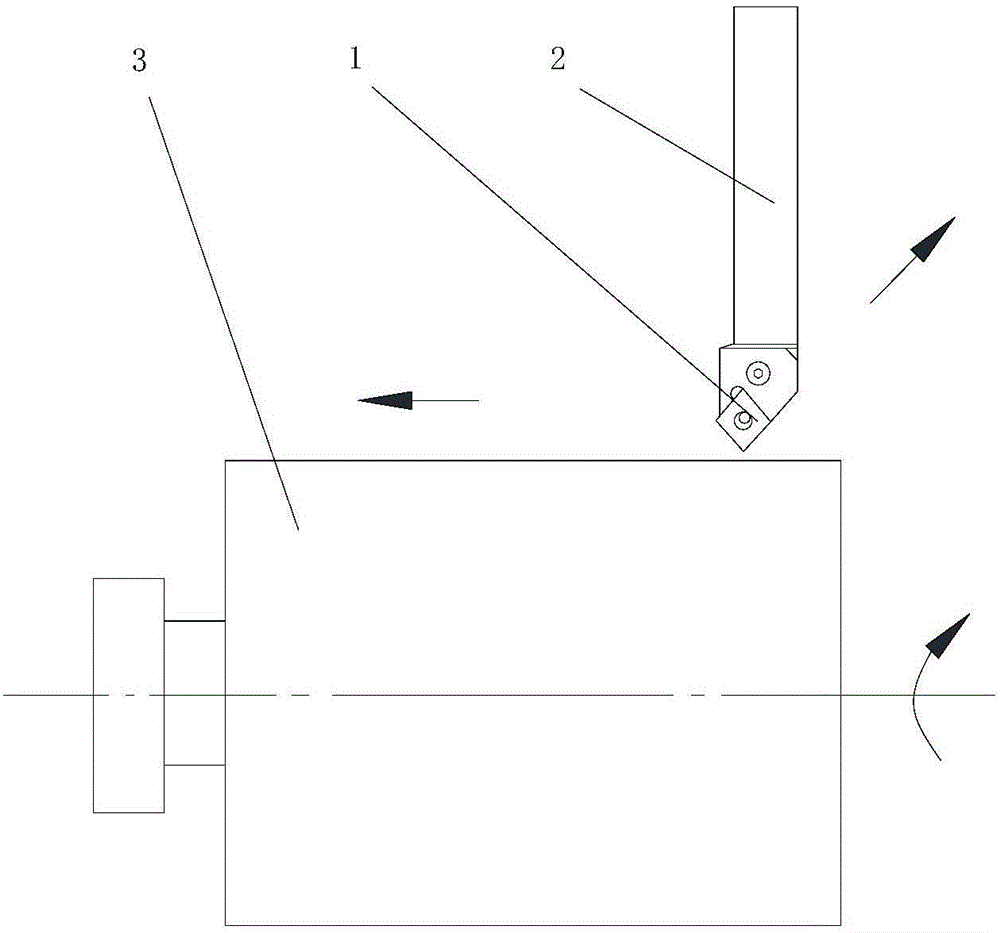

Turning blade service life comparison method

InactiveCN106736859AWear will notDoes not seriously affect machinabilityMeasurement/indication equipmentsLife timeMachine tool

The invention discloses a turning blade service life comparison method. Service life length of each turning blade can be compared according to comparisons of primary wear rate K0 of each turning blade. The primary wear rate K0 can be acquired via the following steps that (S1) primary wear cutting time is set to be T0; (S2), a cutting machine is started and cuts a work piece according to a preset cutting speed Vc, feeding load f and cutting depth ap; (S3) the blade retreats when the cutting time reaching the primary wear cutting time T0; (S4) primary wear value VB0 of a main back blade surface of the turning blade is measured; and (S5), primary wear rate K0 of the turning blade is calculated according to a formula of K0=VB0 / T0. The turning blade service life comparison method is advantaged by simple operation, high feasibility and short time consumption.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

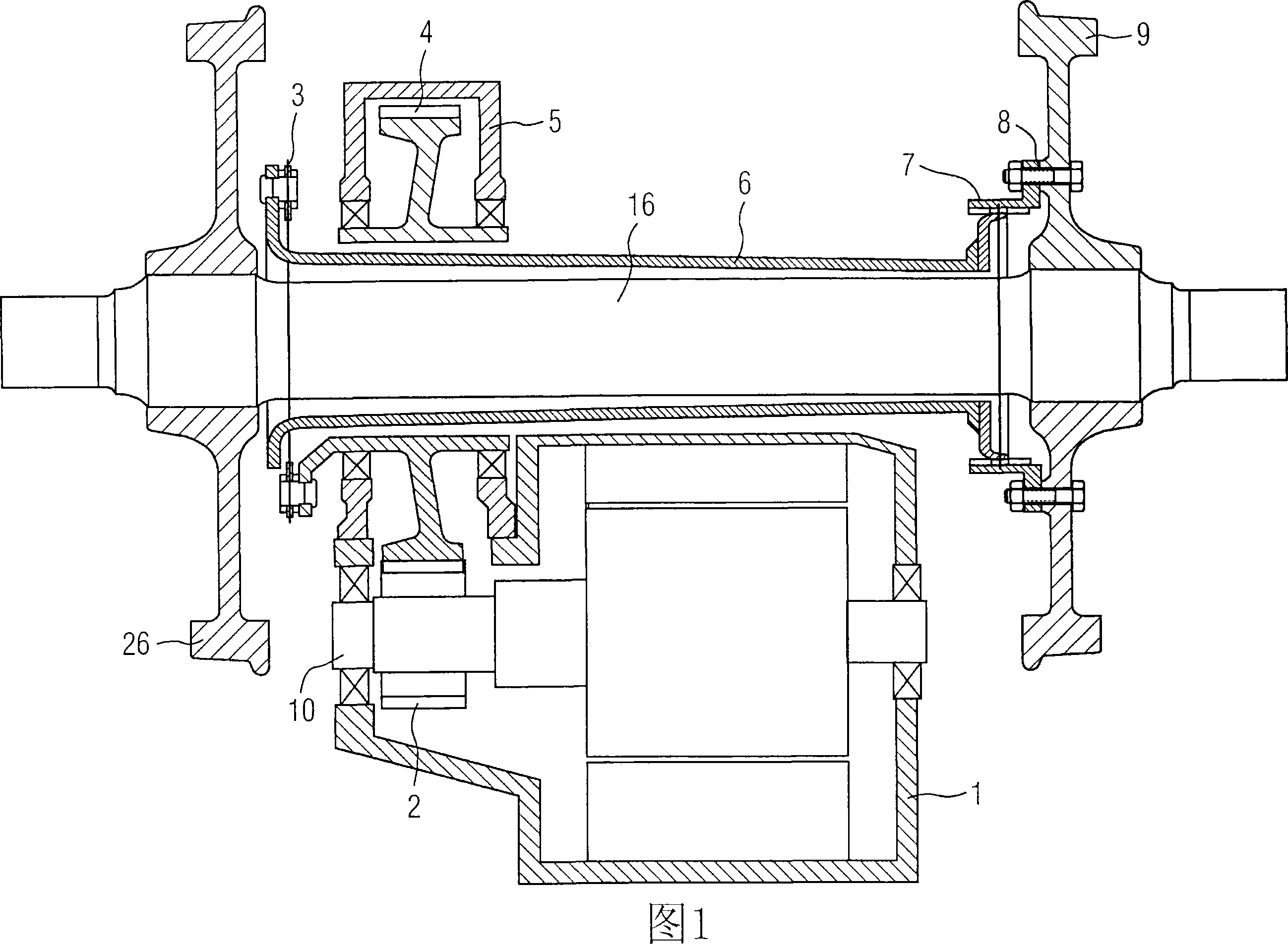

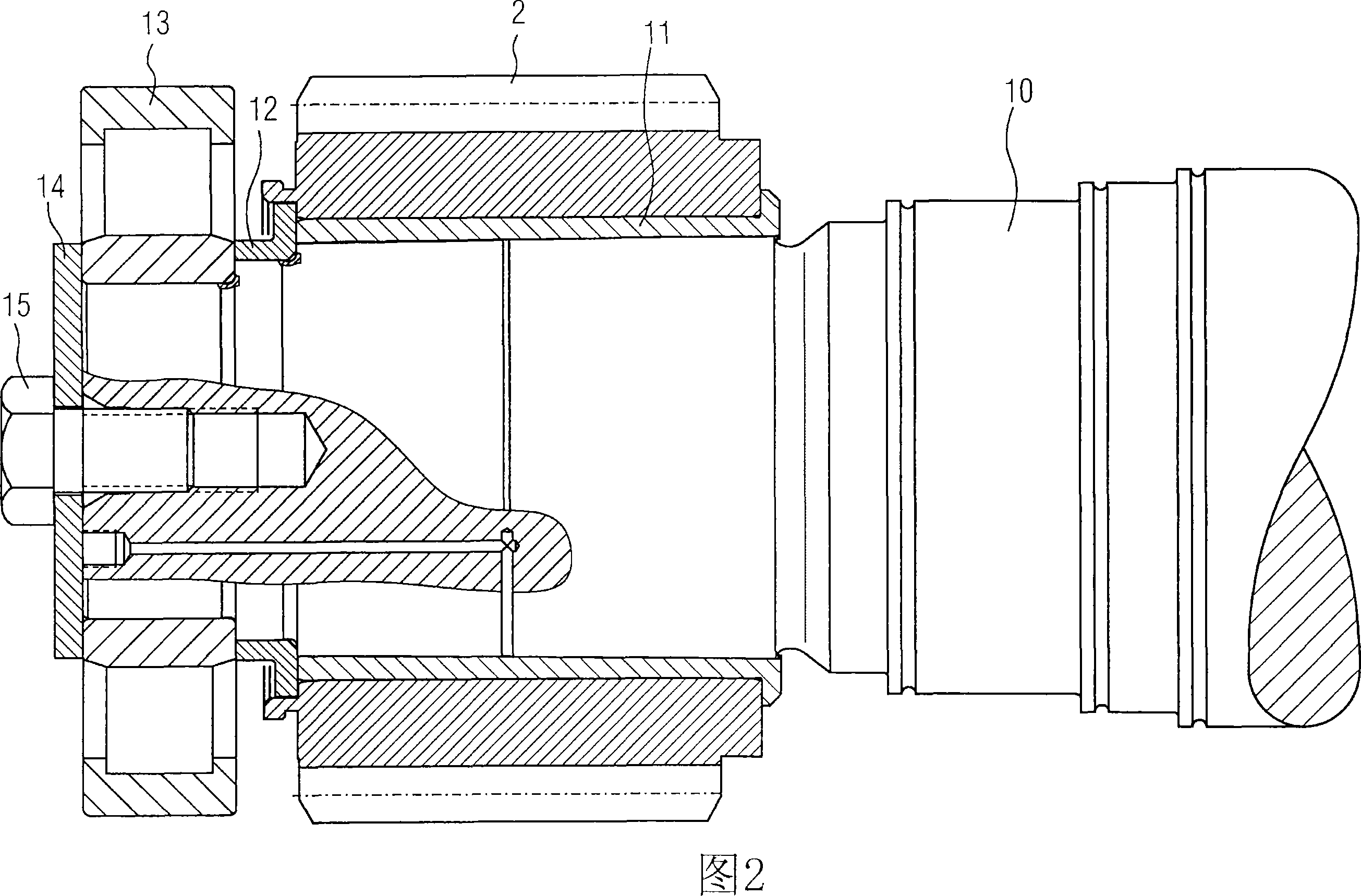

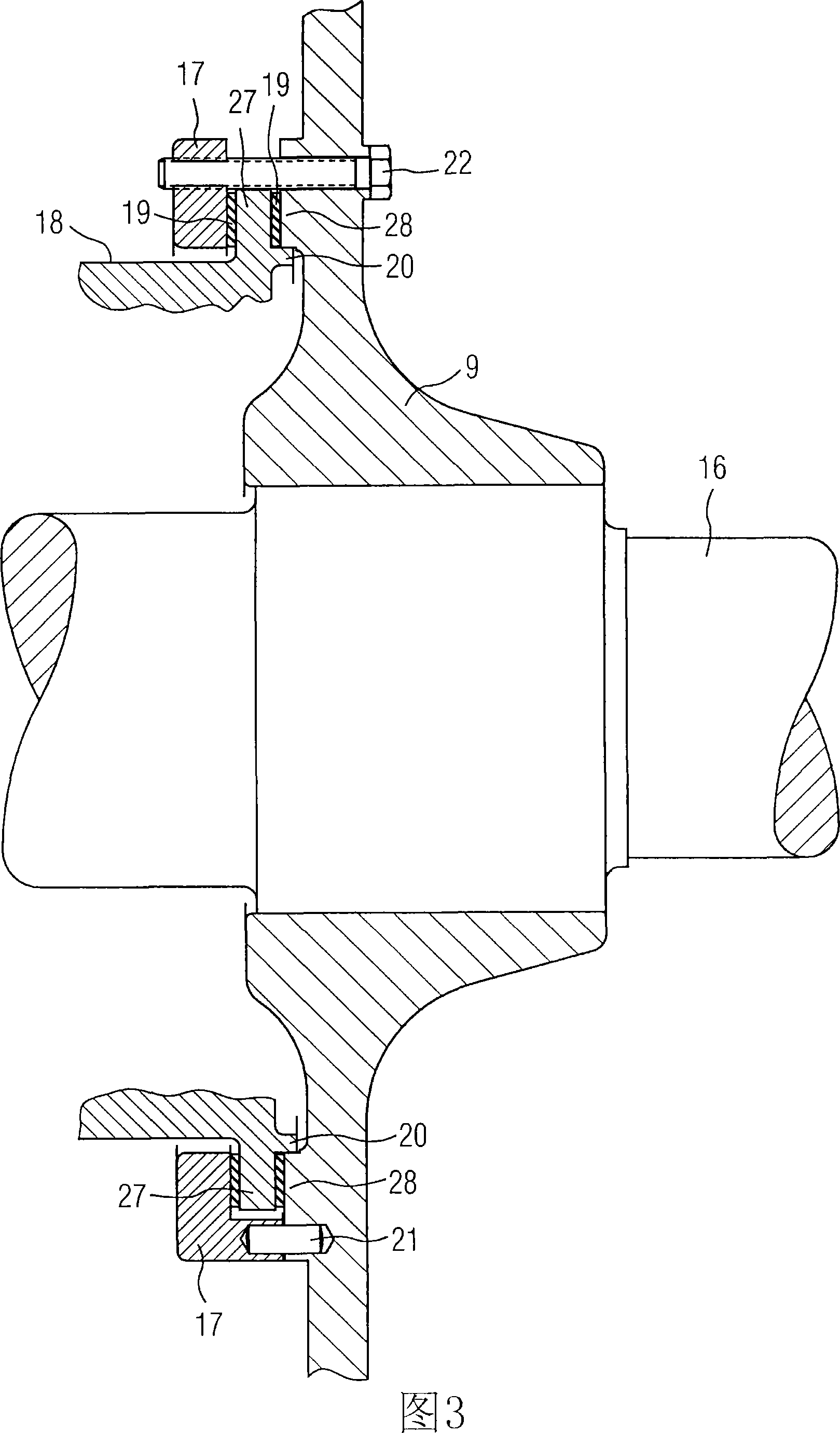

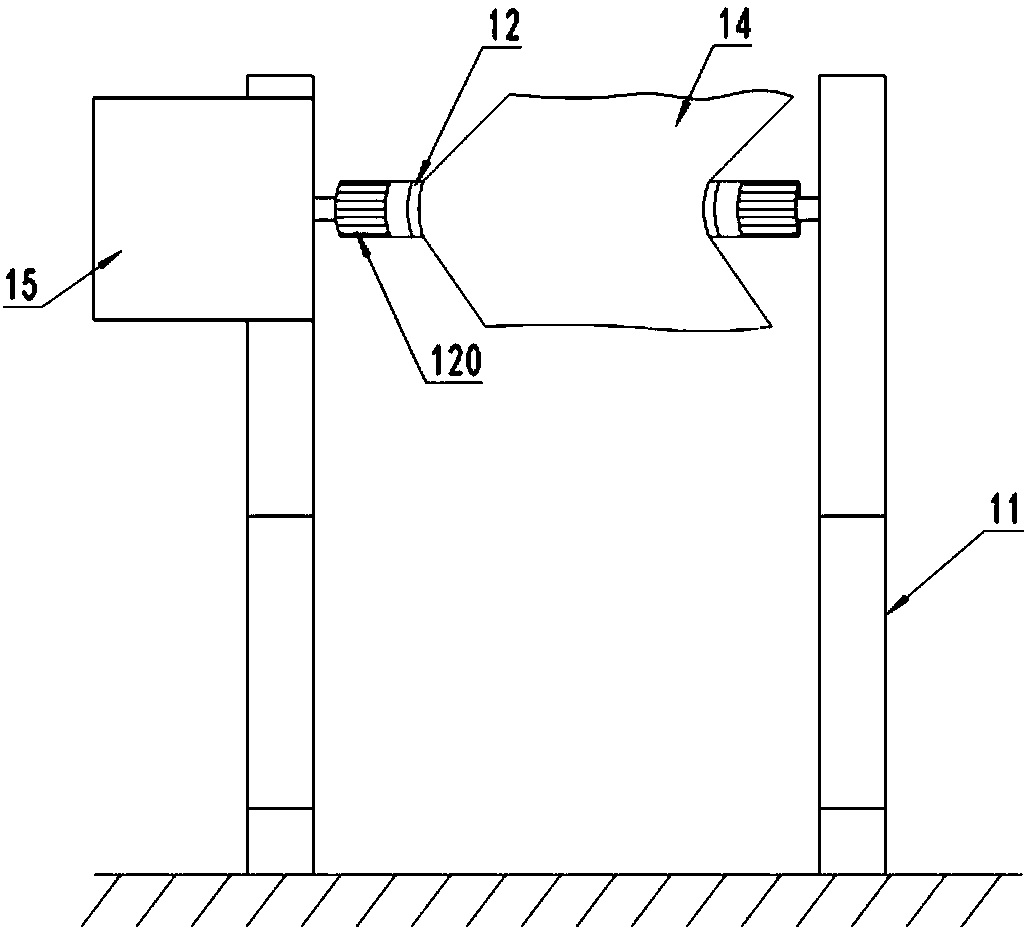

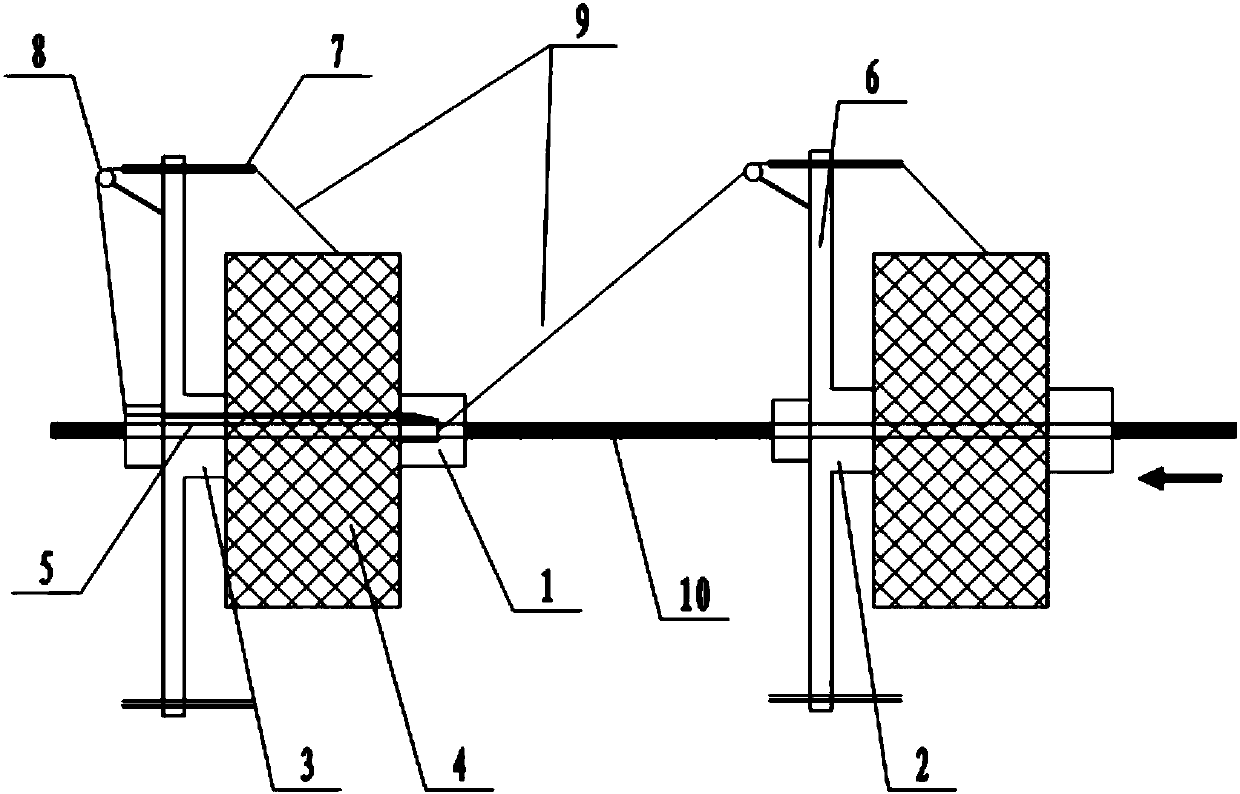

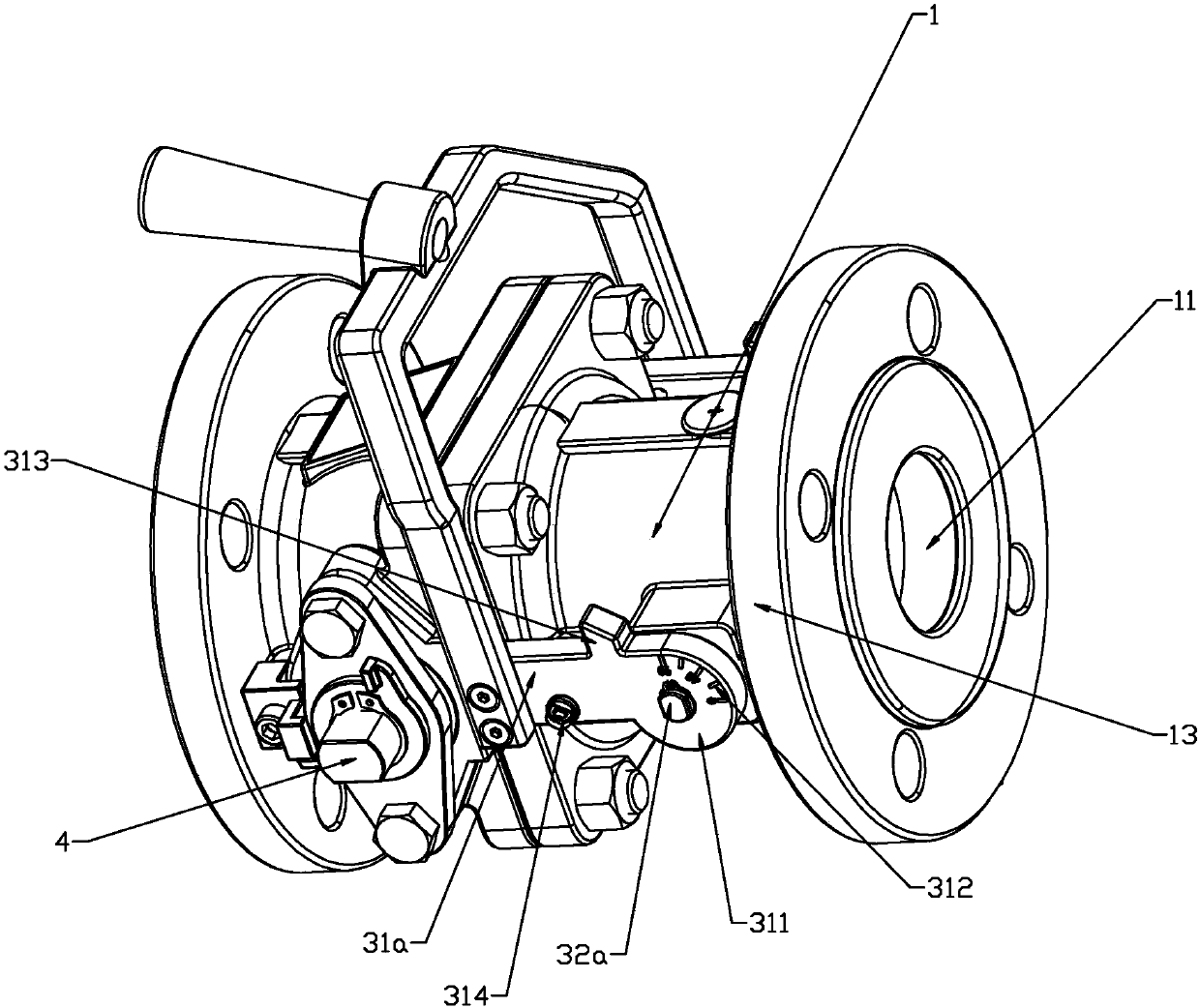

Friction clutch for at least one running wheel of a track-bound traction vehicle

InactiveCN101160475ASimple manufacturing methodEasy to reachSlip couplingElectric motor propulsion transmissionMaximum torqueEngineering

The invention relates to a slip clutch for at least one railcar running wheel (9) fixed to a shaft (16) and driven by an electric motor (1), said slip clutch having oppositely arranged annular outer teeth, wherein the outer teeth of the slip clutch are composed of a part (28) of the rotating wheel (9) and a compression ring (17, 23), the compression ring (17, 23 ) is fixedly connected with the rotating wheel (9), and a clamping ring (27) is clamped between the compression rings (17, 23) and the parts (28) of the rotating wheel (9). The slip clutch provided by the present invention is easy to prepare and easy to access. In addition, a subsequent adjustment of the maximum torque is possible.

Owner:SIEMENS MOBILITY GMBH

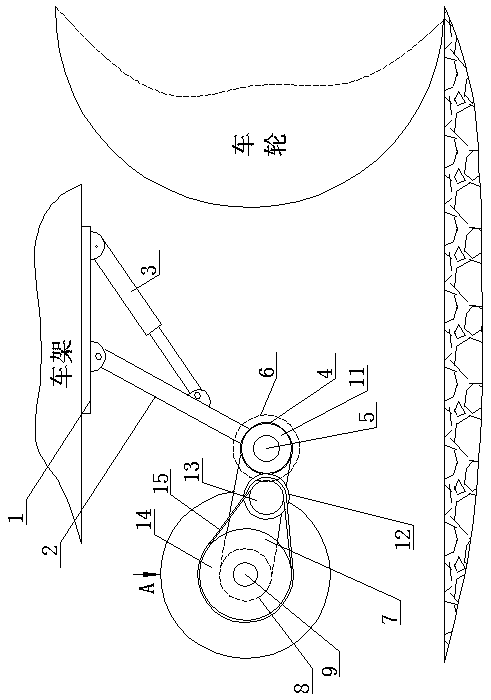

Automatic deviation correcting devices for mine belt conveyor

InactiveCN104291083AReduce in quantityReduce structural complexityConveyorsRollersActuatorControl theory

The invention relates to mining machinery, in particular to automatic deviation correcting devices for a mine belt conveyor. The automatic deviation correcting devices aim to solve the problems that by means of existing deviation correcting devices, a belt is worn, or, mineral falls and deviation is excessive in the deviation correcting operation. Accordingly, the two automatic deviation correcting devices are arranged at the two ends of a drive roller; each automatic deviation correcting device comprises return rods connected to the two ends of the drive roller, pressure sensors embedded inside the return rods, a return rod actuator and a controller, wherein the return rod actuator and the return rods are correspondingly embedded at the two ends of the drive roller, the controller and the return rod actuator are integrally arranged and are communicated with the pressure sensors in a signal transmission mode, the controller is used for ordering the return rod actuator to drive the return rods to be in the unfolding state when the deviation of the belt is detected by the pressure sensors so as to force the belt to return to the normal operation position by increasing the diameter of the return rods. By means of the technical scheme, the problems that the belt is worn, or, the mineral falls and deviation is excessive in the deviation correcting operation are avoided.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

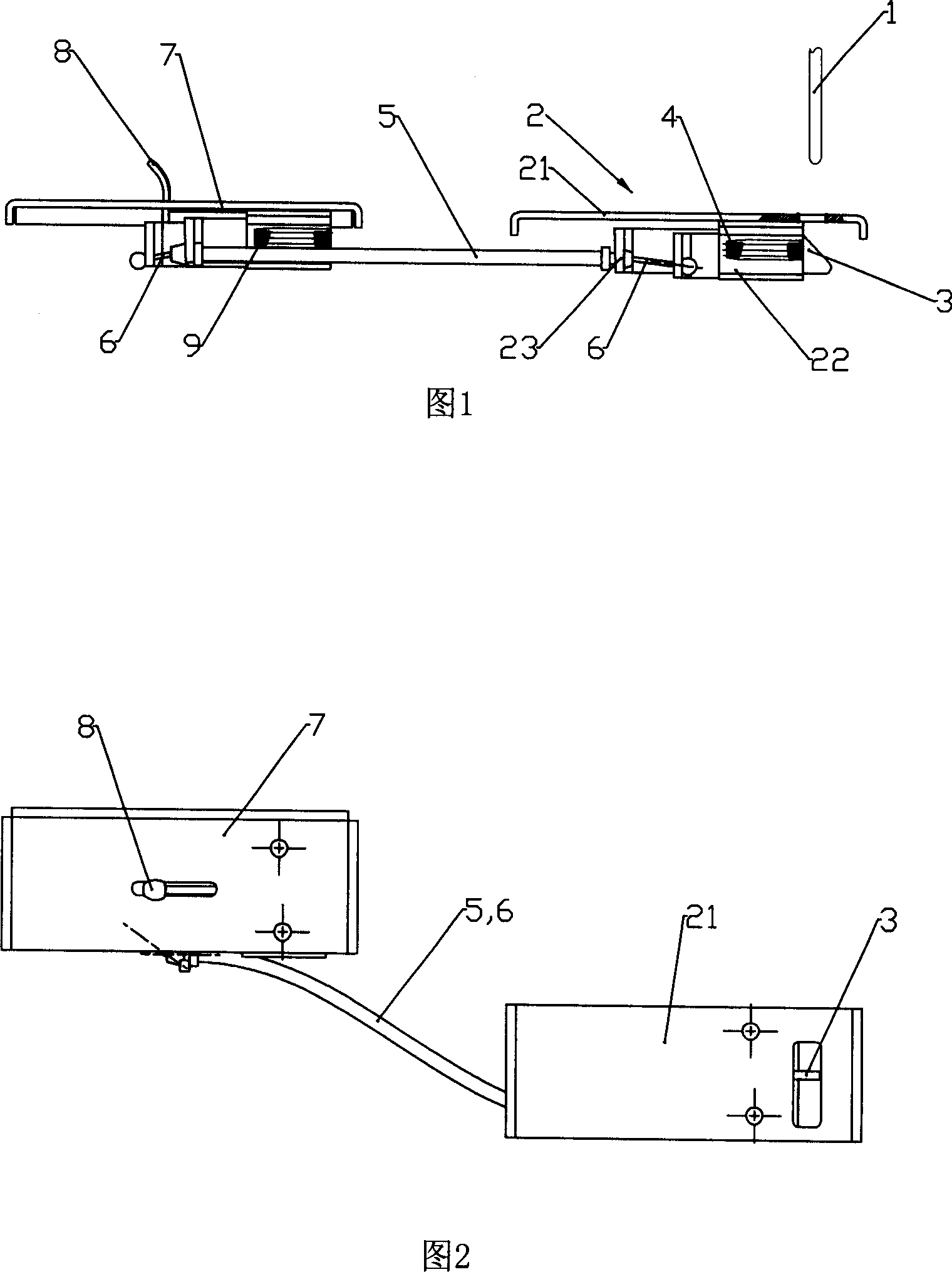

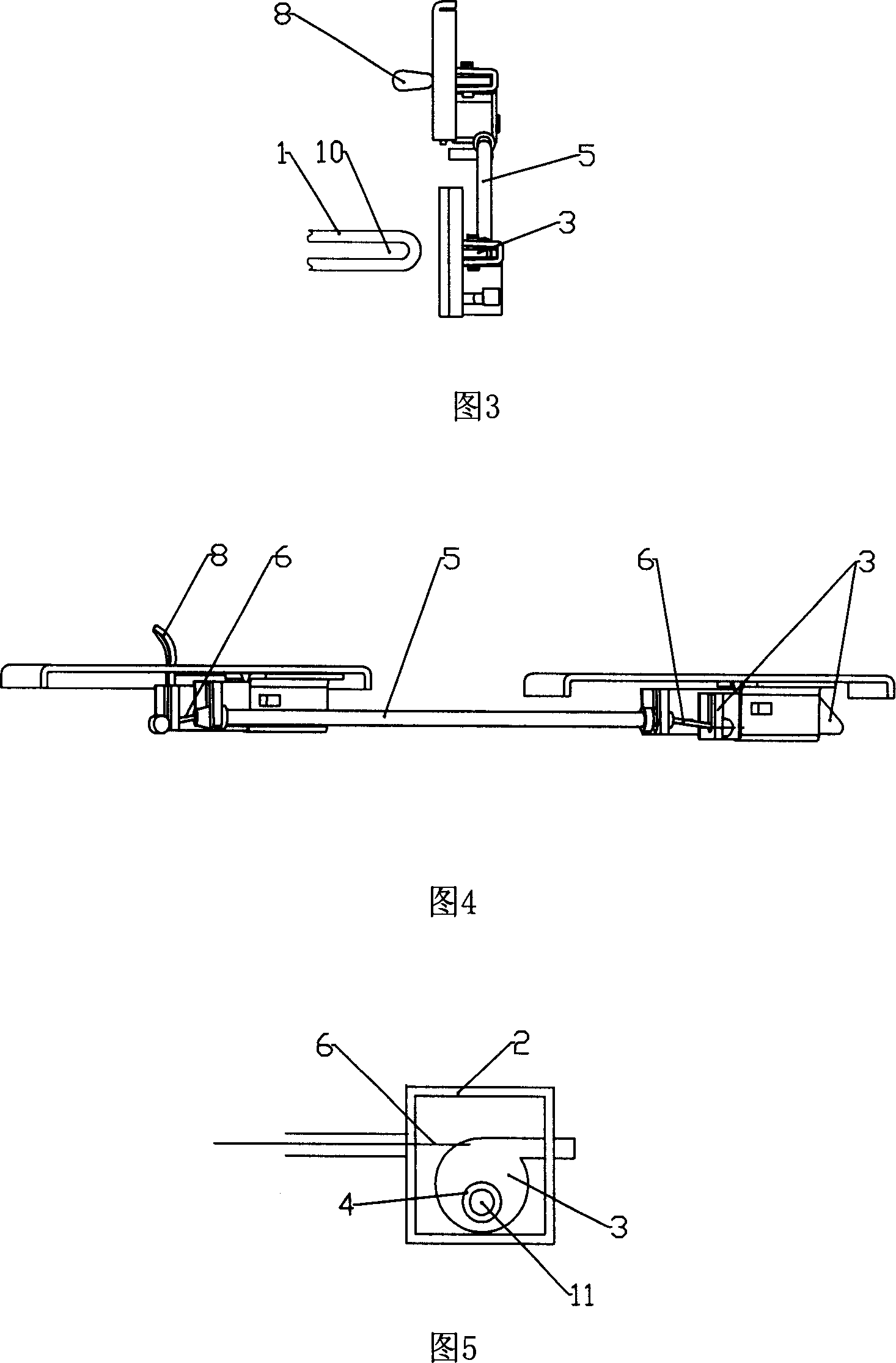

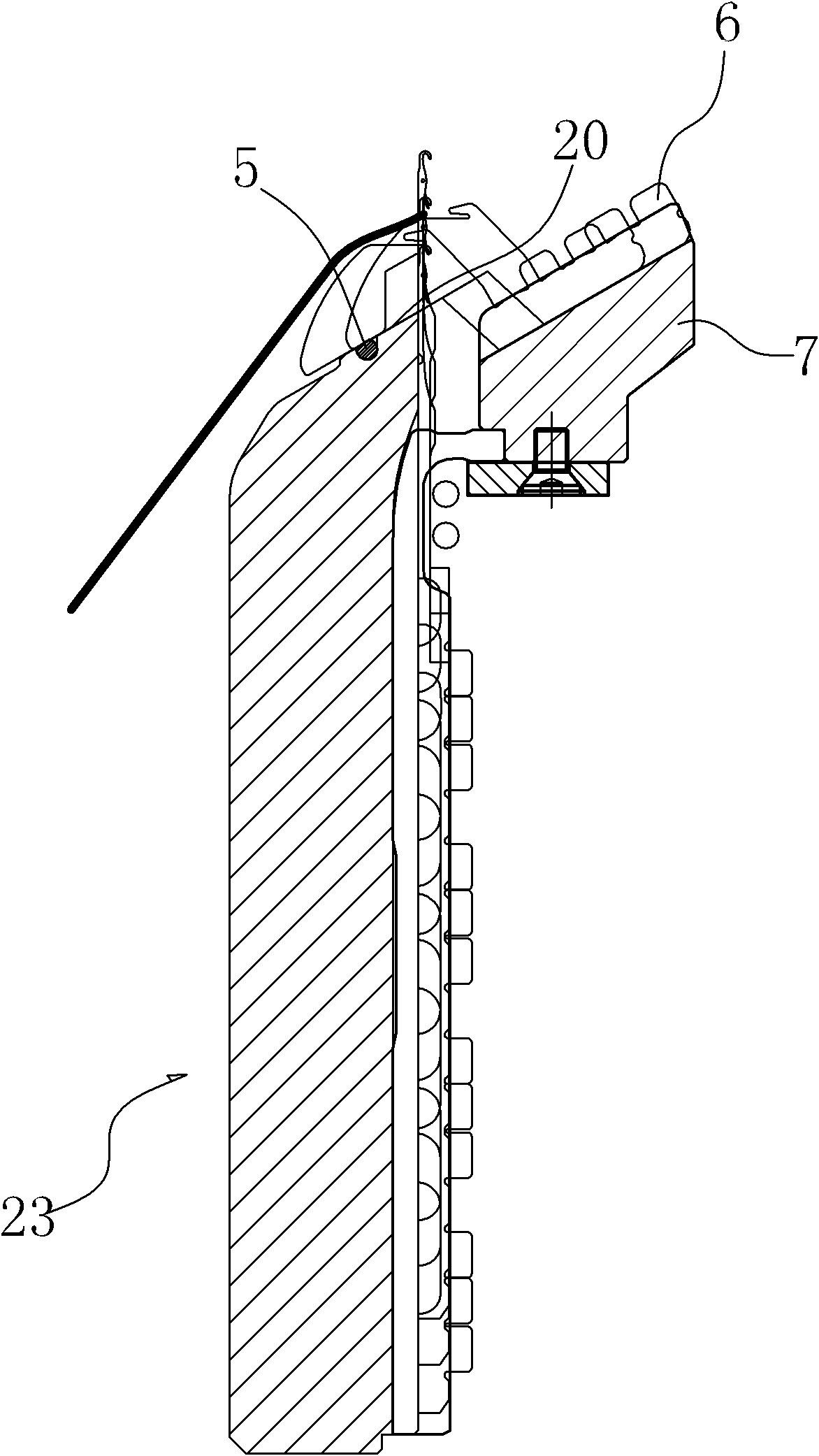

Motorcycle seat mat locking mechanism

The invention relates to a motorcycle cushion lock device, which comprises a lock element with bolt hole at the first cushion bottom plate, the first lock on the motorcycle, wherein the first lock as a sliding or rotating bolt, and a return spring for extending the bolt into the bolt hole of lock element; the contract distance of bolt can move outside the bolt hole; the bolt is connected to the flexible cable through in the flexible tube to contract the bolt; the flexible cable and the free end of flexible tube are outside the lock. The invention has simple structure.

Owner:LONGXIN IND GROUP

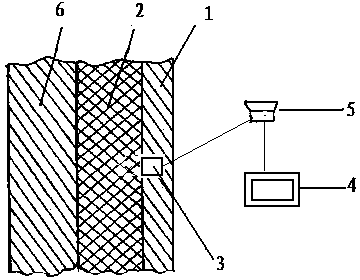

Brake pad capable of detecting and preventing abrasion

The invention discloses a brake pad capable of detecting and preventing abrasion. The brake pad comprises a steel plate and a friction block, wherein one end, close to the friction block, of the steel plate is provided with a thickness sensor which can detect the thickness of the friction block, and the thickness sensor is connected with a display device and an alarming device which are installed inside a car. The friction block is made of non-asbestos organic material with glass fibers. By adopting the structure, the thickness sensor can detect the thickness size of the friction block after being abraded and transmit the information to the display device inside the car, and when the abrasion reaches a limit size, the alarming device can be started to issue an alarm. The abrasion situation of the friction block can be monitored by a user at any time through the display device, when the abrasion is too fast, the reason can be immediately examined, and the fast abrasion can be prevented; and in addition, the thickness sensor does not need to stretch into the friction block, no abrasion is caused, so that only the friction block needs to be replaced, the steel plate is unnecessary to replace, the economical efficiency is better, and the cost is low.

Owner:SUZHOU RUNKAI AUTO PARTS MFG

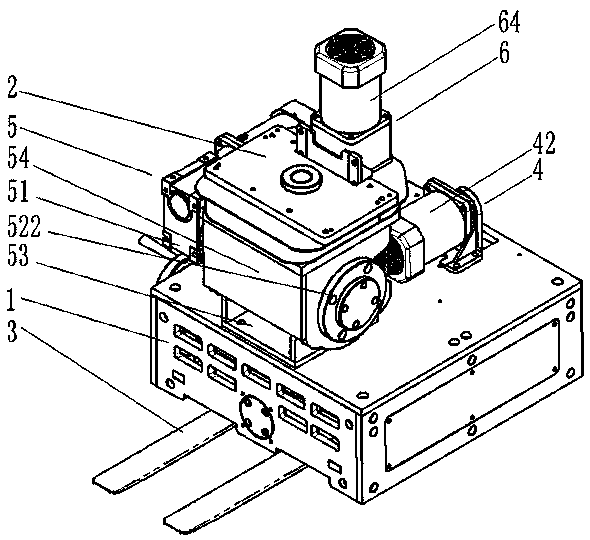

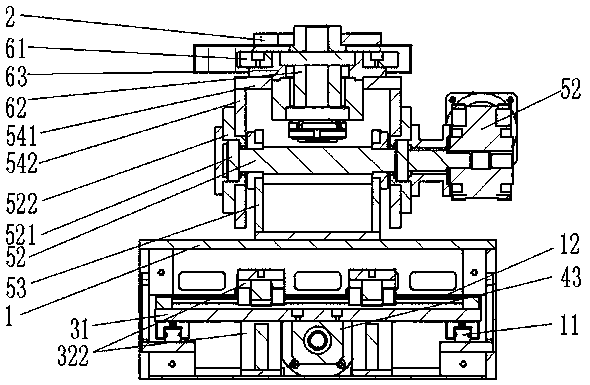

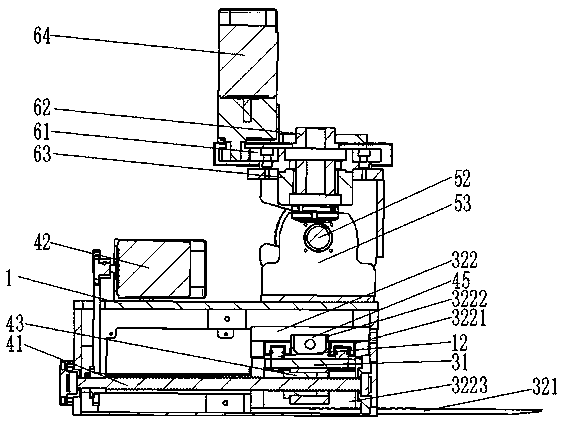

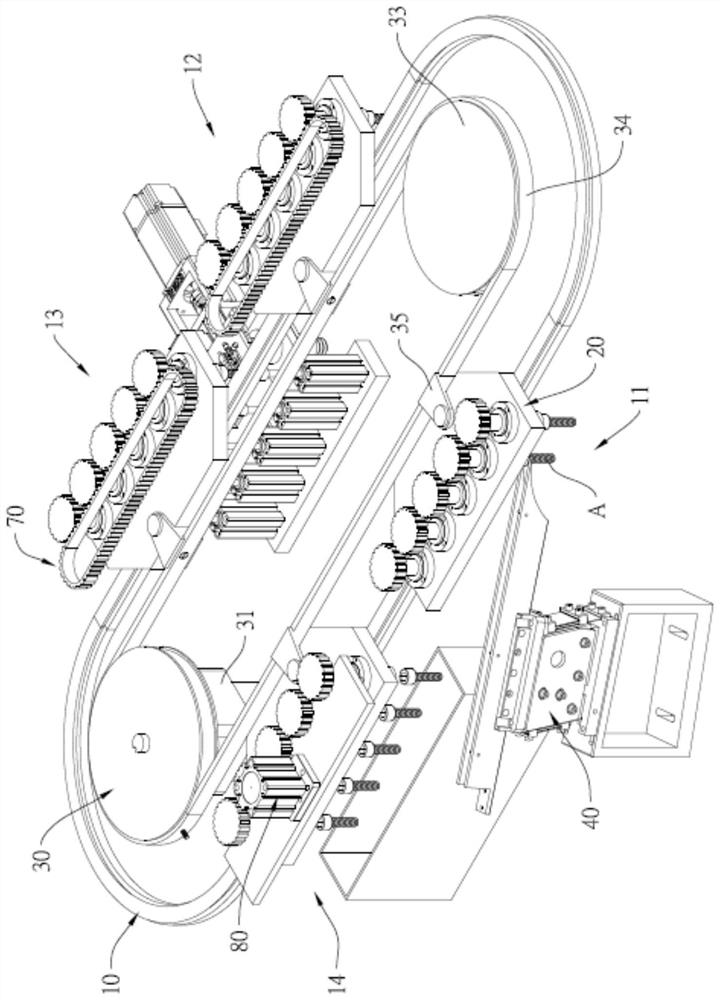

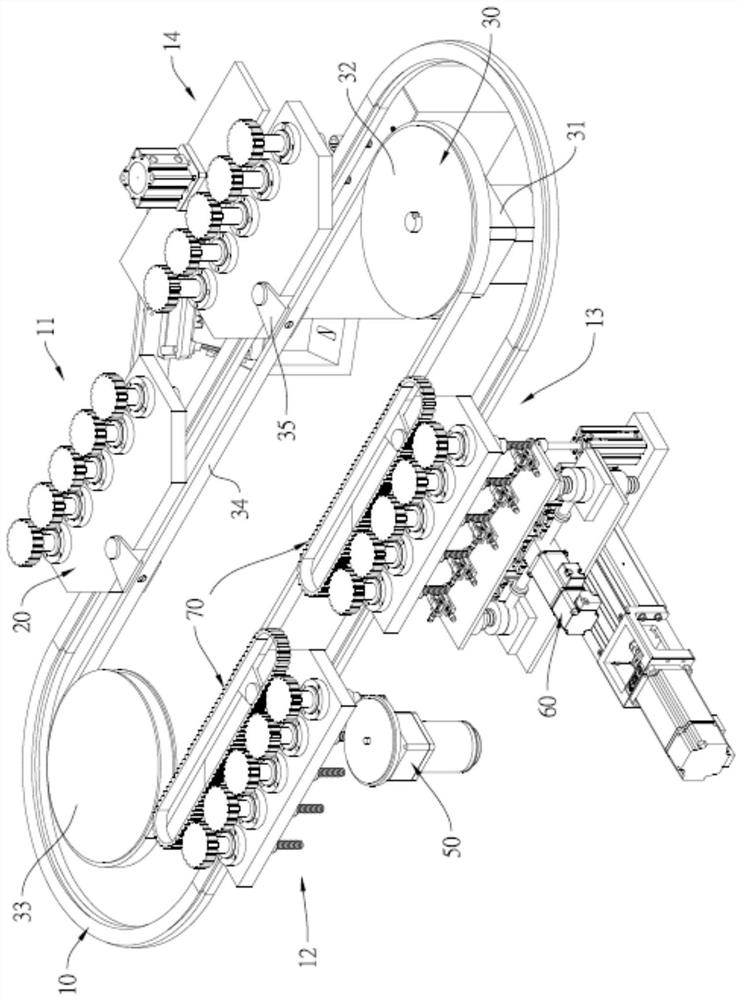

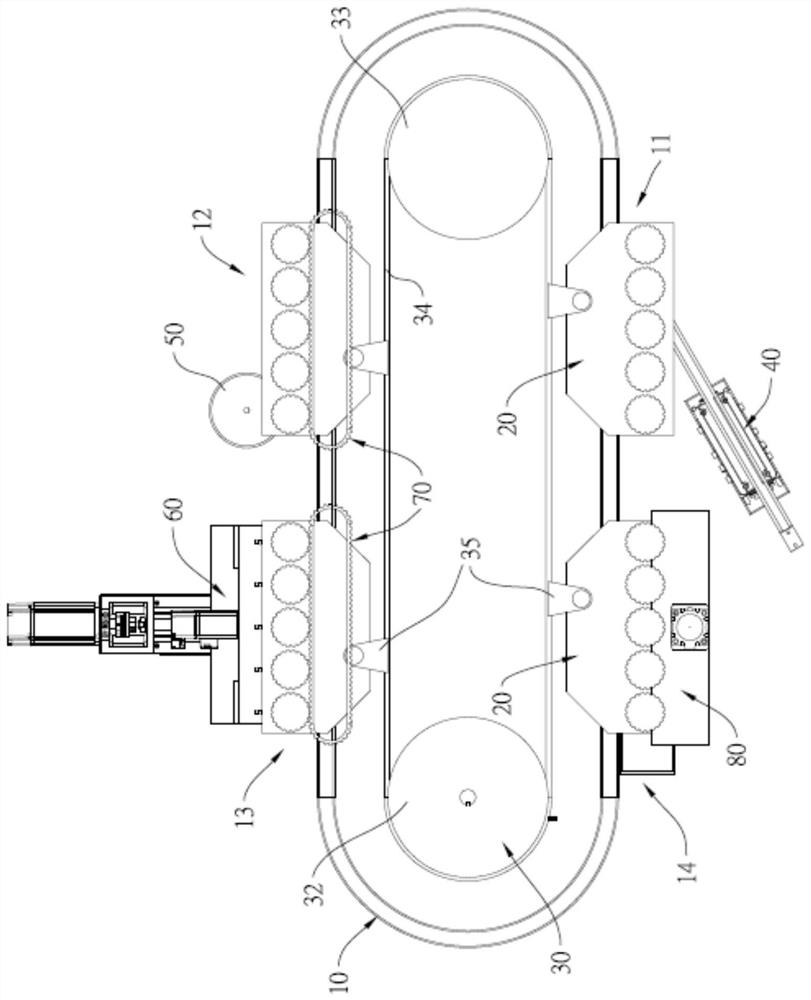

Loading and unloading equipment

PendingCN109484862AImprove mobile flexibilitySafe, stable and accurate stacking operationLifting devicesStacking articlesEngineeringManipulator

The invention provides loading and unloading equipment. The loading and unloading equipment comprises a first outer shell, a mounting part, an insertion jaw module and a distance adjusting mechanism;and the distance adjusting mechanism is used for adjusting an effective support width value of the insertion jaw module and driving the insertion jaw module to extend out of the first outer shell andto totally shrink in the first outer shell. The loading and unloading equipment with a fork (called the insertion jaw module) is provided to a common manipulator and gantry manipulator production linefor inserting in the bottoms of products to carry and stack the products. The extension length and width of the fork are adjusted according to the lengths and the widths of carried goods. When the loading and unloading equipment is mounted on a carrying robot, the fork supports the goods to shift in an appointed position; and when the fork is descended to enable the bottom to leave from the surfaces of the lower goods by 2-3 cm, the fork totally shrinks into the outer shell to gradually lose a support effect on the goods, so that the stable and accurate stacking of the goods is realized, goods packages are not damaged, and the goods are flexibly stacked in limited space.

Owner:佛山市南海区凯力五金制品有限公司

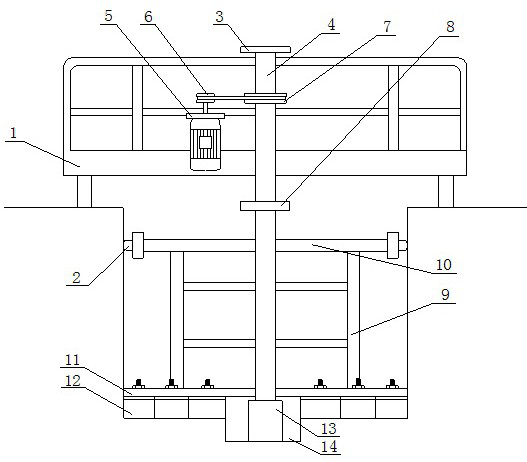

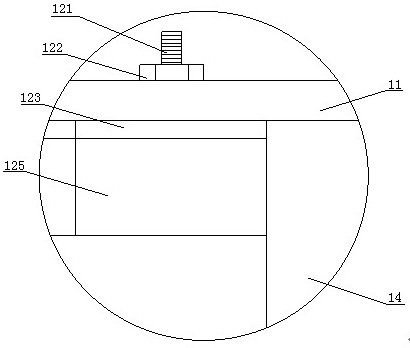

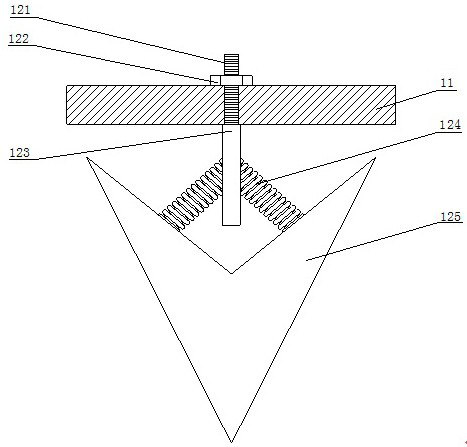

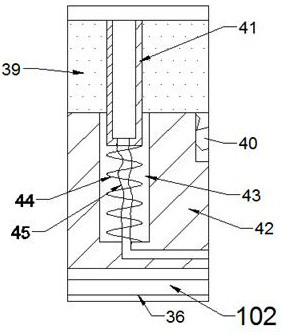

Springback mud scraping device for mud scraper

InactiveCN112237760AWear will notReduce maintenance costsSettling tanks feed/dischargeSedimentation settling tanksDrive wheelElectric machinery

The invention discloses a springback mud scraping device for a mud scraper, wherein the springback mud scraping device comprises a working bridge, walking wheels, a top plate, a central shaft, a driving motor, a transmission belt, a driven wheel, a floating plate, a connecting rod, a fixed rod, a fixed plate, a mud scraping plate, a base and a mud collecting tank; the mud scraping plate comprisesa screw rod, a nut, a mounting plate, a spring and a mud scraping plate body; through the rotation of the central shaft to drive the rotation of the fixed plate, the mud scraping plate rotates along with the fixed plate and cleans mud into the mud collecting tank, when the mud scraping plate encounters mud difficult to treat in the rotating process, the mud scraping plate body inclines in the reverse direction of rotation, and the mud difficult to treat is cleaned through springback of the spring; after the mud scraping plate body is abraded, the mud scraping plate body is in threaded connection with the mounting plate through the screw rod, and the mounting plate, the spring and the mud scraping plate body are dismounted and replaced; mud blocks difficult to treat are cleaned through resilience of the spring, large abrasion to the mud scraping plate body is avoided, the mud scraping plate can be dismounted and mounted in a segmented mode, and the maintenance cost is saved.

Owner:新沂市青草地农业发展有限公司

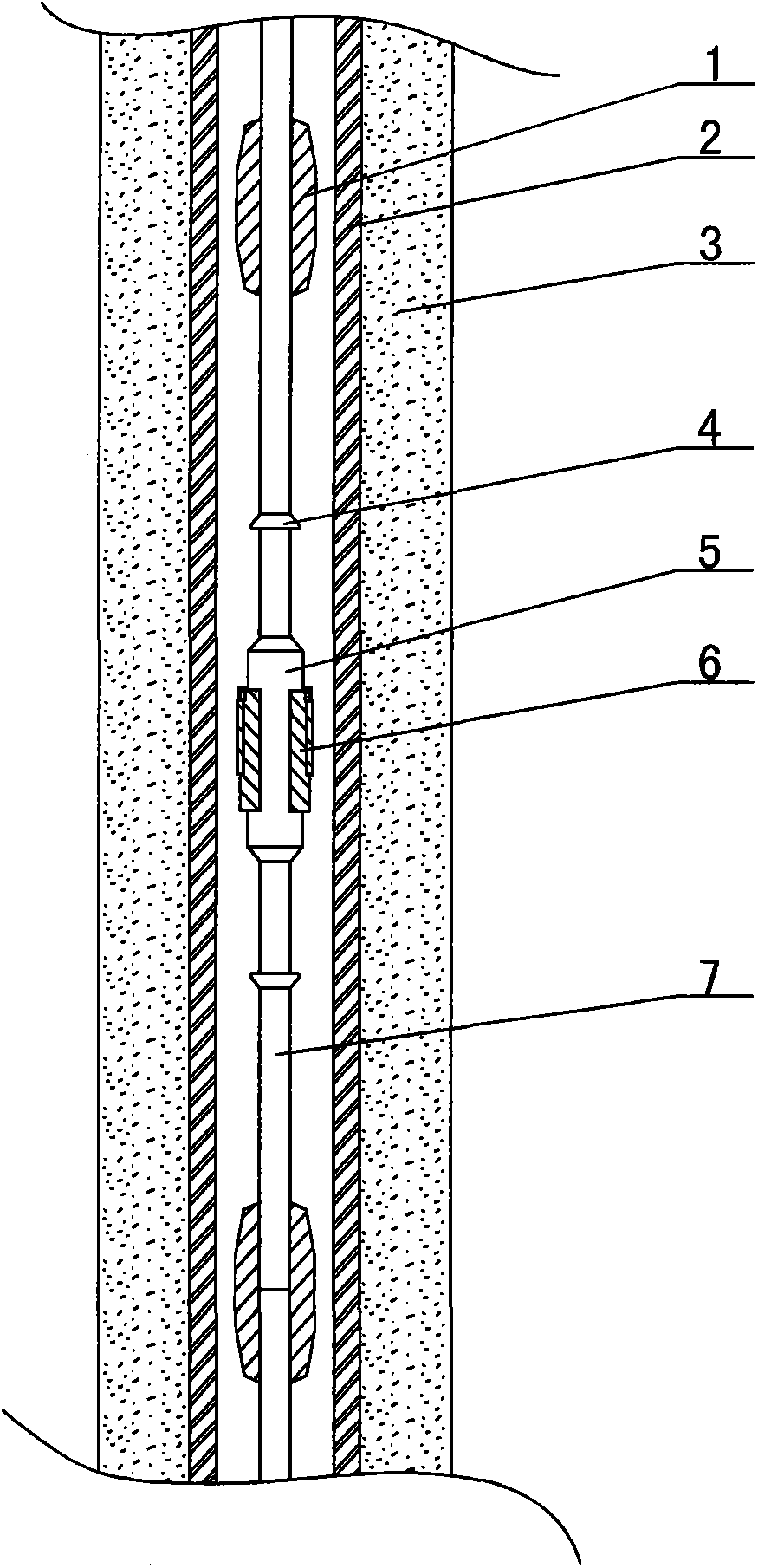

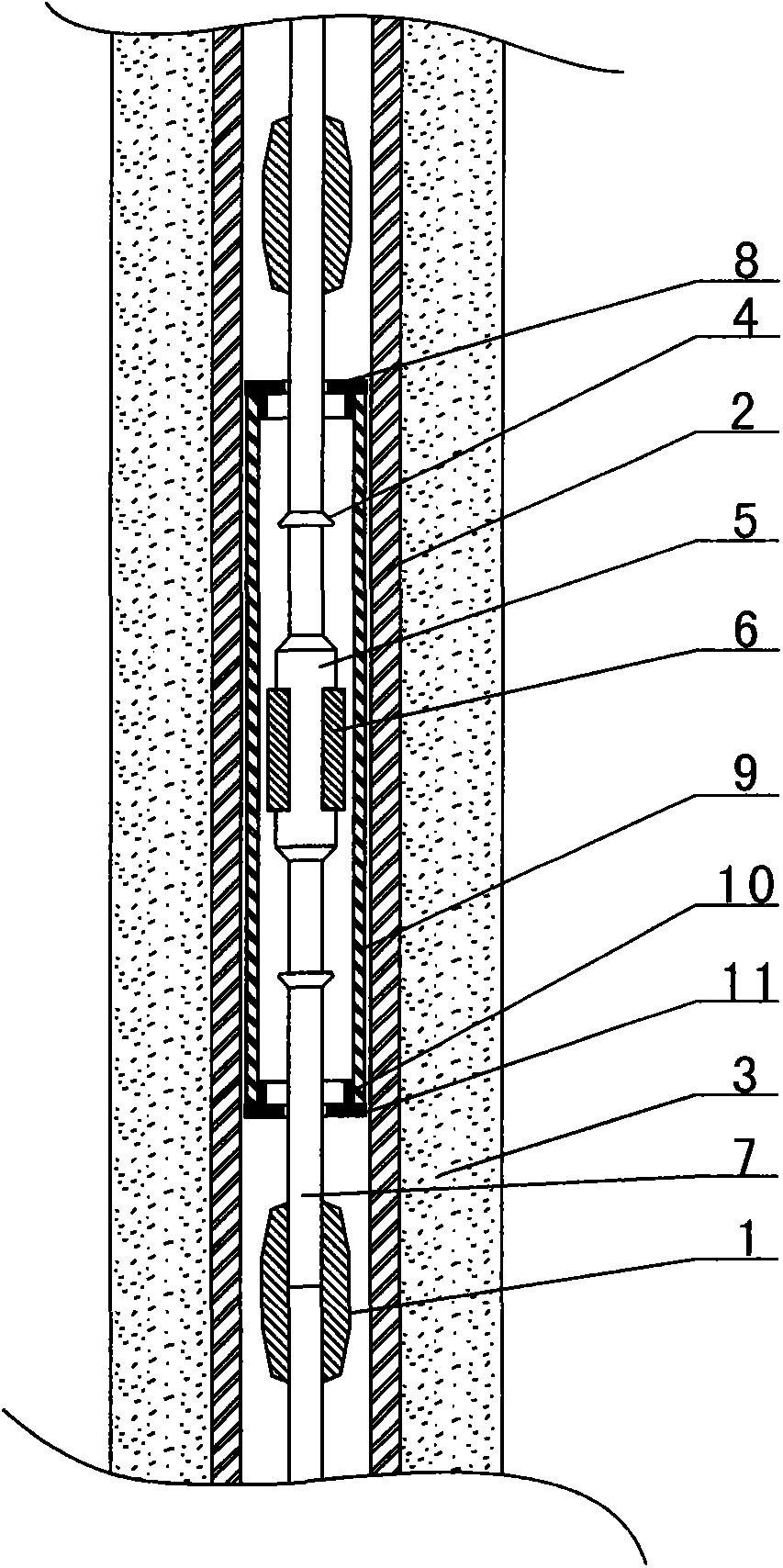

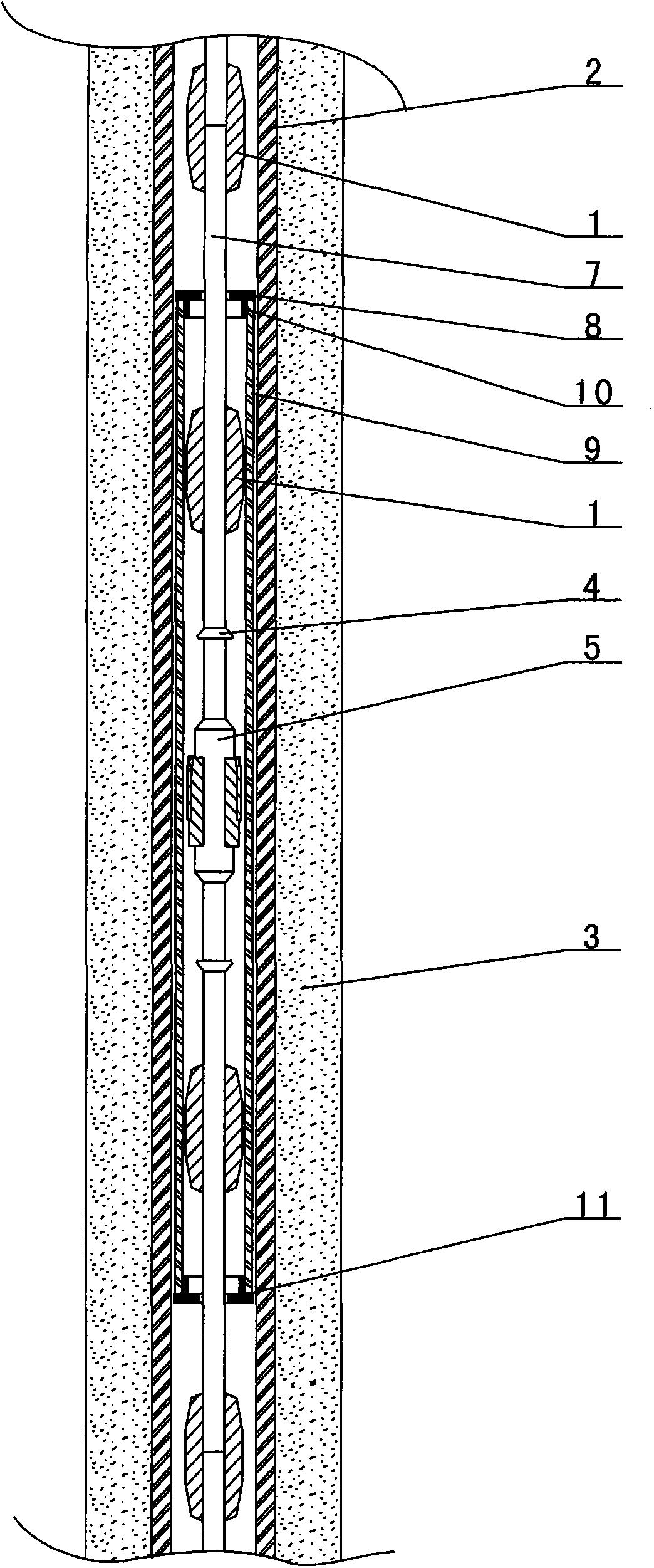

Wear-resisting centralizer structure of sucker rod of oil well

InactiveCN104047552AExtend the lifespanExtend your lifeDrilling rodsDrilling casingsOil wellIsolation effect

The invention discloses a wear-resisting centralizer structure of a sucker rod of an oil well, and relates to a centralizer. A one-end sleeve ring (8) and a the-other-end sleeve ring (11) are arranged on a sucker rod (7) at an interval; the opposite faces of the one-end sleeve ring (8) and the the-other-end sleeve ring (11) are respectively provided with a convex ring (10); two ends of a centralizer tube (9) are fixedly connected onto the convex rings (10) of the one-end sleeve ring (8) and the the-other-end sleeve ring (11); the outer edge faces of the one-end sleeve ring (8), the the-other-end sleeve ring (11) and the centralizer tube (9) are in clearance fit with the inner wall of a sucker pipe (2). According to the wear-resisting centralizer structure, the one-end sleeve ring, the the-other-end sleeve ring and the centralizer tube are additionally arranged on the sucker rod, so that the sucker rod can obtain a maximum interval in the sucker pipe, the sleeve rings and the centralizer tube have both the isolation effect and the wear-resisting effect, and the service life of the sucker rod can be effectively prolonged.

Owner:石东海

Intake method of garbage incineration boiler hearth and garbage incineration boiler equipment thereof

ActiveCN105782989ABurn fullyReduce production efficiencyFluidized bed combustionIndirect carbon-dioxide mitigationElectricityCombustion

The invention discloses an intake method of a garbage incineration boiler hearth and garbage incineration boiler equipment thereof, and belongs to the technical field of garbage incineration boiler operation methods and equipment thereof. The intake method comprises the following steps: a) a primary intake temperature of an air chamber is reduced; and b) the position of an intake pipe on a secondary intake furnace wall is raised. The garbage incineration boiler equipment comprises an air preheating device, a direct connecting pipe, an electric circular air door and a DCS distributed control system; the air preheating device includes a preheating pipe, an air inlet and an air outlet; the direct connecting pipe includes multiple sections of straight pipes and multiple 90-degree shrimp elbows; one end of the direct connecting pipe is connected with a primary intake port of the air preheating device, and the other end is directly communicated with an air chamber intake port below the hearth; the electric circular air door is arranged on one section of straight pipe; the DCS distributed control system can be disconnected or electrically connected with the electric circular air door; and three sets of furnace wall intake pipes are respectively arranged on the front and back walls of the upper and middle parts of the hearth. The Intake method of the garbage incineration boiler hearth and the garbage incineration boiler equipment thereof have the following beneficial effects: the furnace slag caking phenomenon and the furnace slag blockage cannot be generated; and the outlet temperature of the hearth is high, so that the combustion is sufficient.

Owner:NINGBO ZHONGMAO YAOBEI THERMAL POWER CO LTD

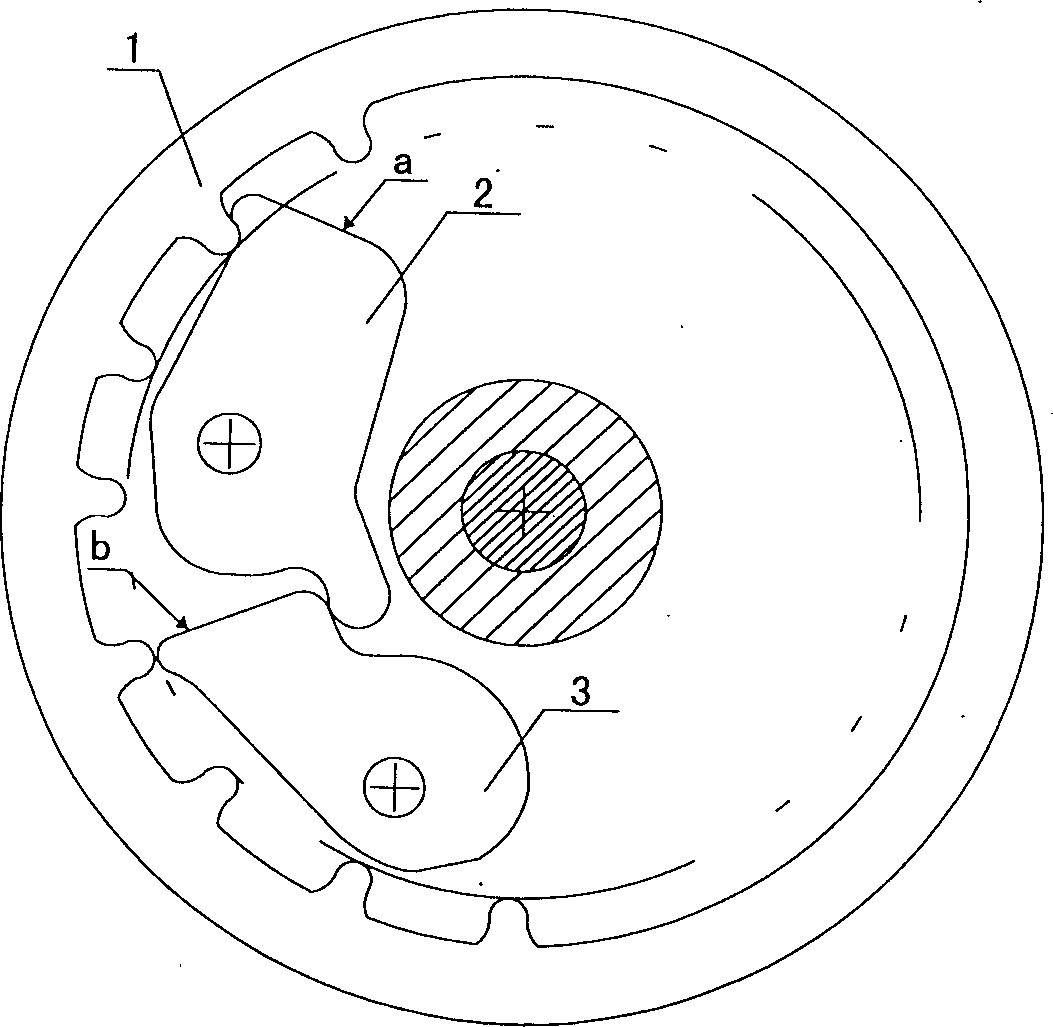

Double-lever interlocking change-over mechanism and method for automatic watch

InactiveCN1374570AImprove wear resistanceReduced wear resistanceAutomatic windingManufacturing technologyGear wheel

The present invention relates to the manufacture of watch. The double-lever interlocking change-over mechanism consists of gear, double swing links, ratchet wheel, isolating ring, wheel sleeve, nail and toothed shaft assembled together. The key point of the mechanism is that the gear with both inner and outer teeth and the double swing links constitute one enclosed transmission chain for transferring motion and force in single way. The mechanism has mesh between gear and automatic hammer and mesh between toothed shaft and automatic spring winding wheel. The mechanism is high in reliability, long in service life, low in cost and high in efficiency.

Owner:刘越雄

Vehicle auxiliary braking device

InactiveCN111391800ASimple structureIngenious ideaBraking element arrangementsMotronicMechanical engineering

The invention discloses a vehicle auxiliary braking device. The device comprises a fixing plate, the left side of the bottom of the fixing plate is hinged to the upper end of a connecting rod; the right side of the bottom of the fixing plate is hinged to the upper end of an electric telescopic rod; the lower end of the electric telescopic rod is hinged to the middle of the connecting rod; a firstshaft seat is fixedly mounted at the lower end of the connecting rod; a friction wheel is fixedly installed at one end of the first rotating shaft, the left side of the first shaft seat is fixedly connected with the right side of a supporting plate, the left side of the supporting plate is fixedly connected with the right side of a second shaft seat, a second rotating shaft is rotatably installedin the second shaft seat through a bearing, and a brake wheel is fixedly installed at one end of the second rotating shaft. The auxiliary braking device is simple in structure and ingenious in conception, abrasion to wheels during vehicle braking is reduced by arranging the auxiliary brake wheel, the roundness of the wheels is kept, and therefore stable running of a vehicle is facilitated, actualrequirements can be met, and the auxiliary brake wheel is suitable for popularization.

Owner:数源汇通(北京)医药科技有限公司

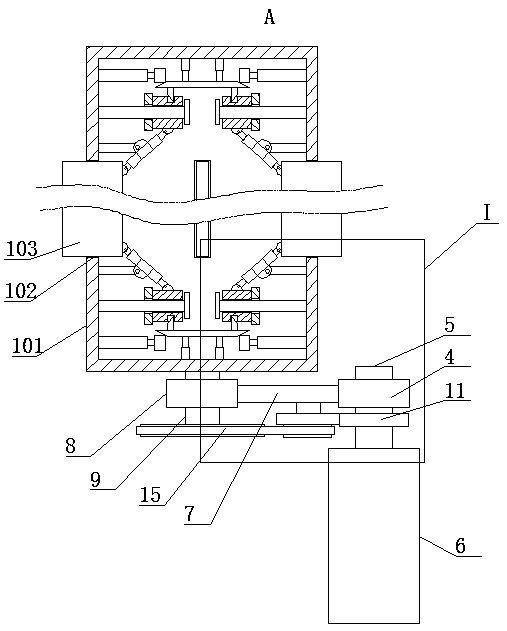

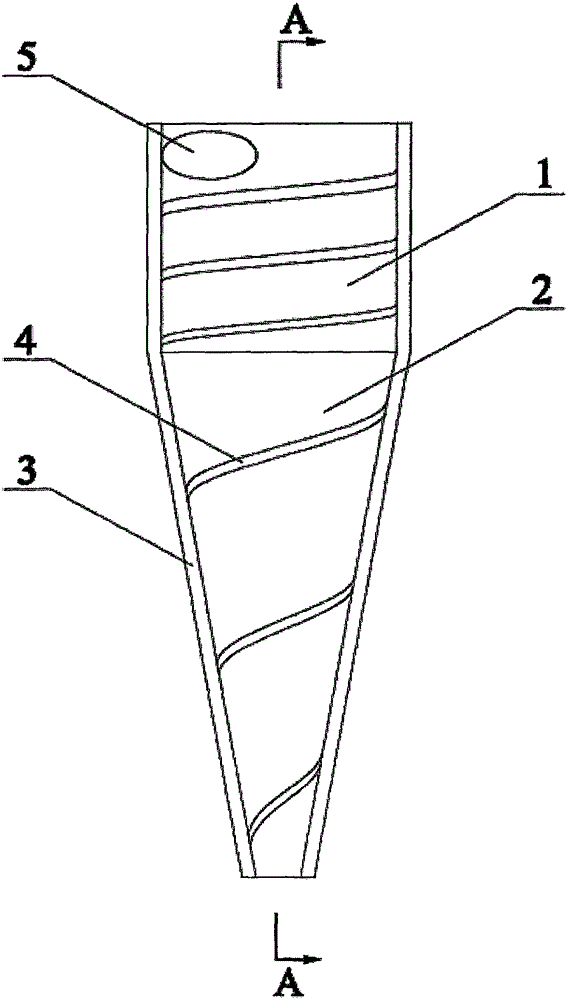

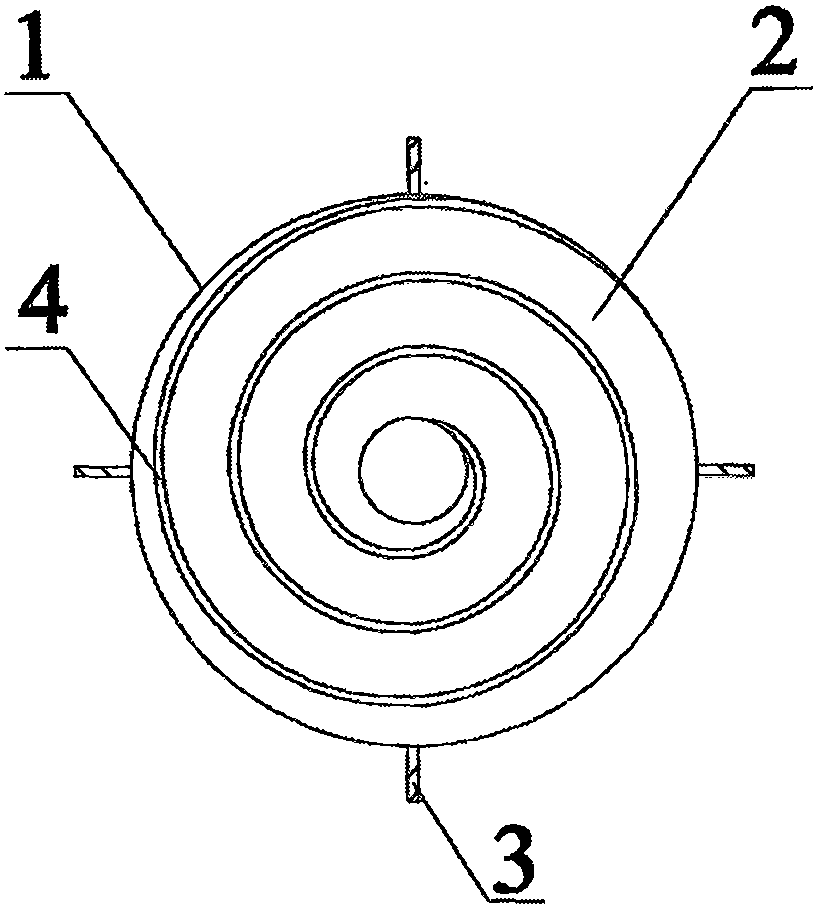

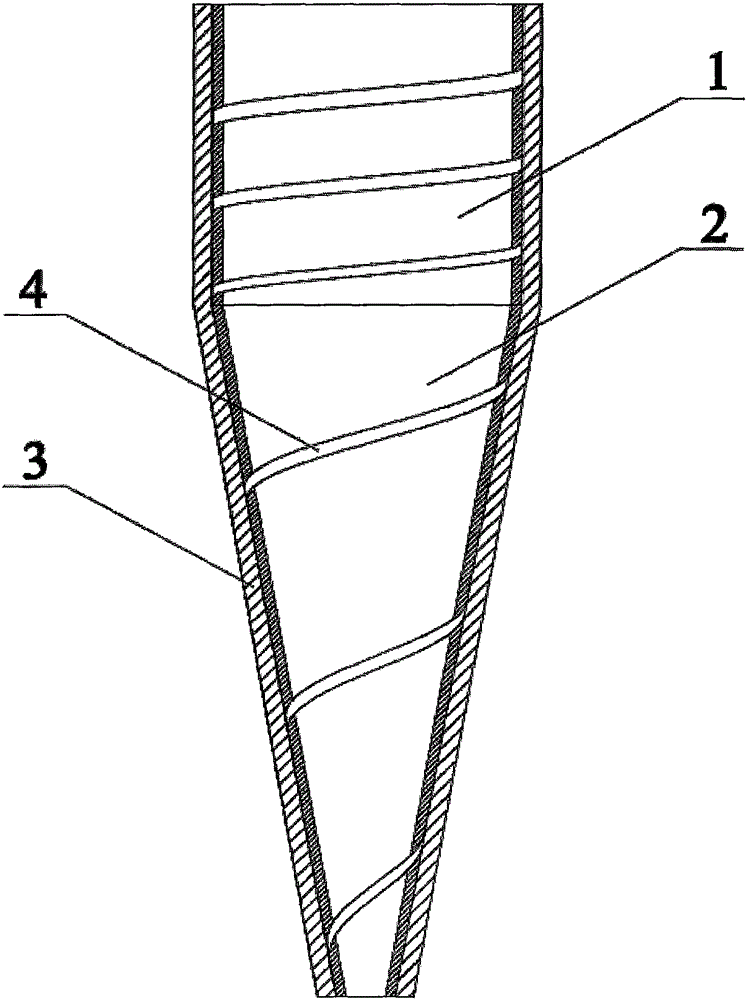

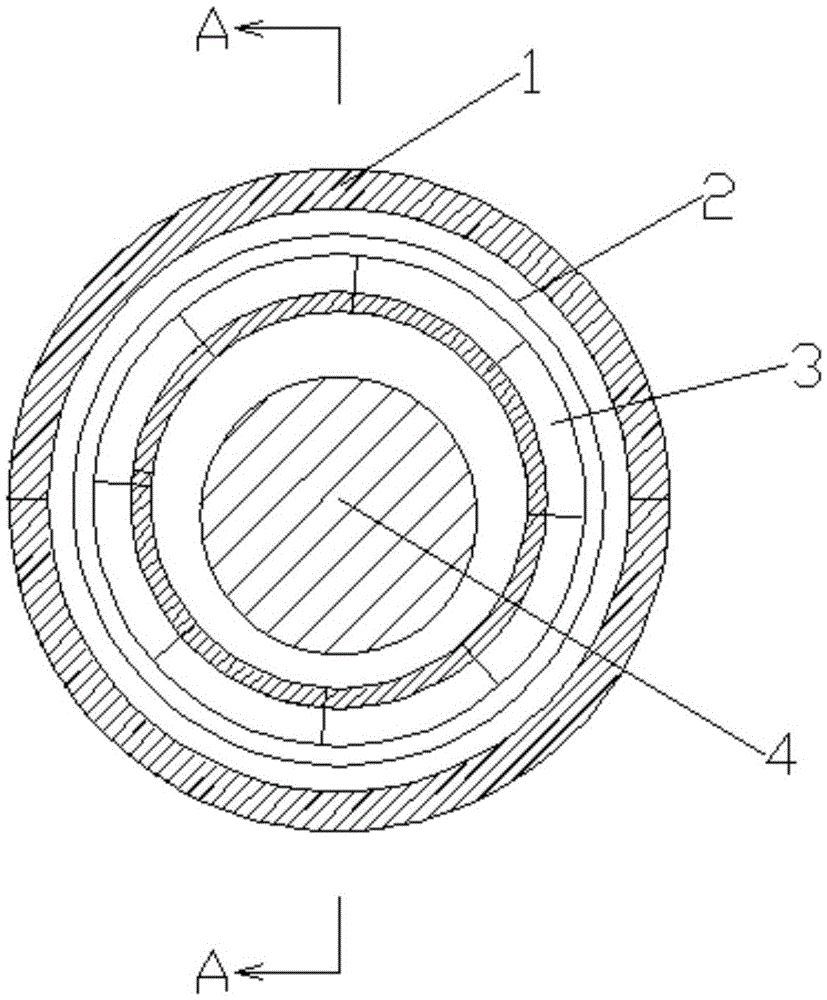

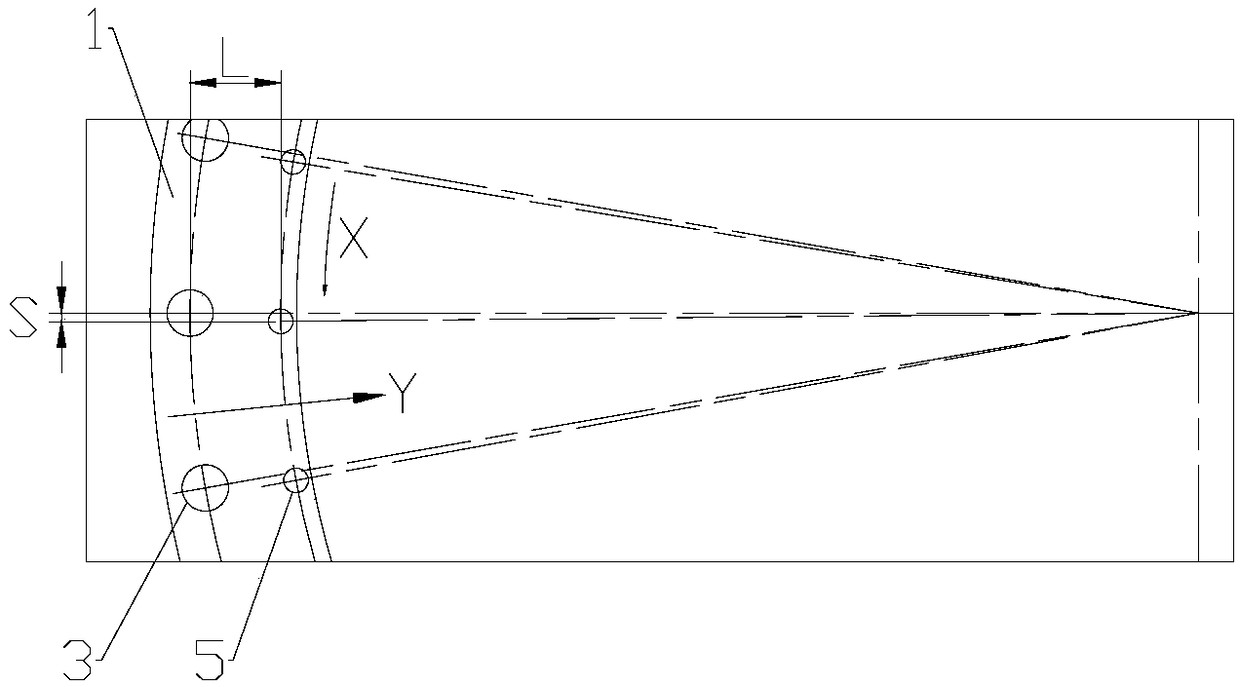

Spiral seam lining for improving wear resistance of cyclone or cyclone deduster

InactiveCN106362876AReduce manufacturing costSimple lining processReversed direction vortexCycloneEngineering

The invention relates to a spiral seam lining for improving the wear resistance of a cyclone or a cyclone deduster. The spiral seam lining is positioned in the cyclone or the cyclone deduster, and is formed by a cylinder body (1) and a cone body (2), the outer wall of the cylinder body (1) and the cone body (2) is vertically welded with rib plates (3), the width of the rib plates is 5-40 mm, the thickness of the rib plates is 2-10 mm, the quantity of the rib plates is 3-5, the cylinder body (1) and the cone body (2) are provided with a spiral seam (4), the width of the spiral seam is 5-40 mm, the spiral seam screws in a clockwise downward manner until the spiral seam reaches the bottom of the cone body (2), the diameters of the cylinder body (1) and the cone body (2) of the lining are 10-80 mm smaller than the diameters of the cylinder body and the cone body of the cyclone or the cyclone deduster, and are two times the width of every outer wall welding rib plate (3), the height of the lining is same to the height in the cyclone or the cyclone deduster, and the cone angle of the lining is same to that of the cyclone or the cyclone deduster; and the upper portion of the cylinder body (1) is provided with an elliptical inlet (5) which is connected with the inlet of the cyclone or the cyclone deduster. The spiral seam lining has the advantages of use of common making materials, simple structure, simple process, low cost, high wear resistance, convenience in replacement, and long service life.

Owner:WUHAN UNIV OF SCI & TECH

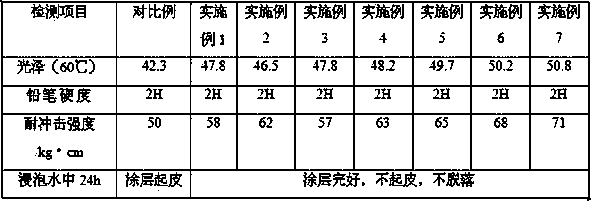

Coating paint for plywood and preparation method of coating paint

The invention relates to a coating paint for plywood and a preparation method of the coating paint. The coating paint is prepared from the following raw materials in parts by mass: 50-60 parts of epoxy modified acrylic resin, 18-24 parts of hexamethoxy methyl melamine resin, 7-12 parts of butyl acrylate, 3-6 parts of dibutyl phthalate, 0.015-0.028 part of 2-amino-2-methyl-1-propyl alcohol, 3-6 parts of polyacrylate resin, 0.15-0.25 part of cellulose acetate butyrate, 0.15-0.25 part of polysiloxane, 8-15 parts of alcohol-soluble fast yellow GR, 4-10 parts of dimethyl ether, 0.5-2 parts of water-proofing agent, 7-15 parts of isopropyl alcohol, 3-6 parts of isopropyl acetate, and 7-12 parts of distilled water. The paint provided by the invention has good appearance, processability and weatherability, and is not easy to be abraded after the plywood is coated with the paint, and the plywood can be kept attractive and durable for a long period of time.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

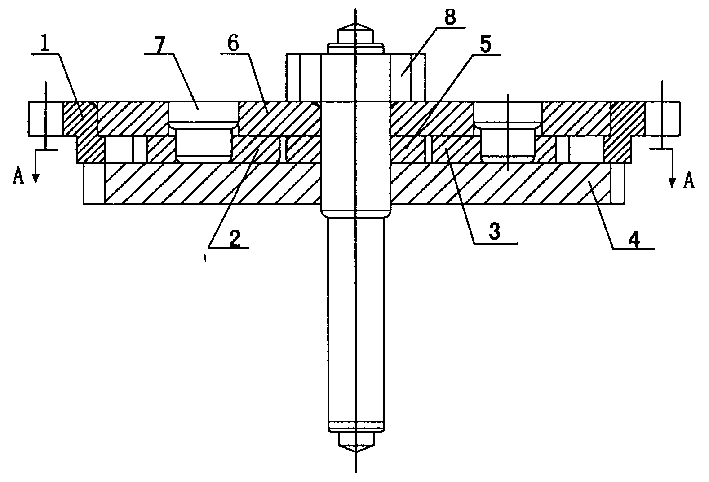

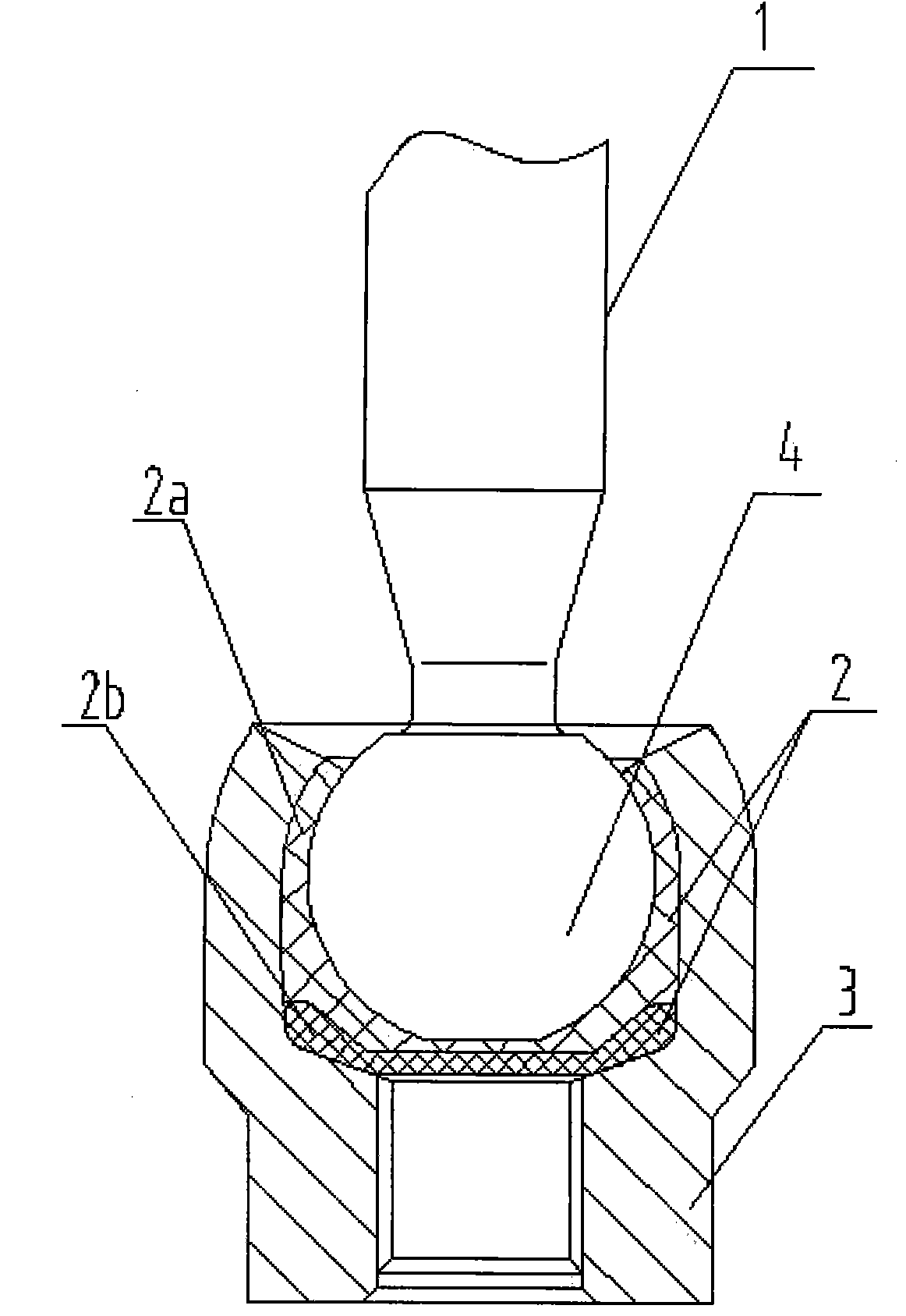

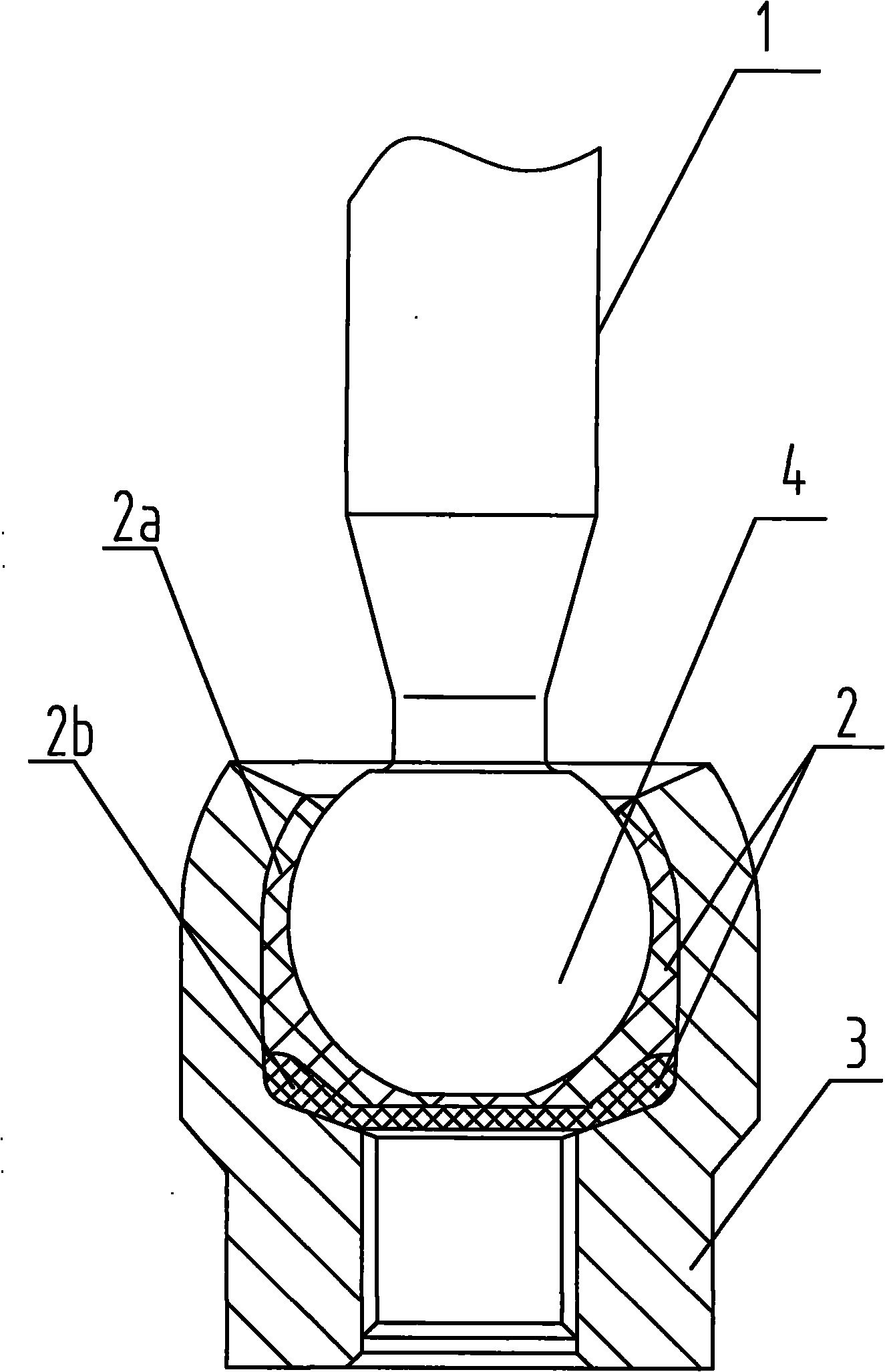

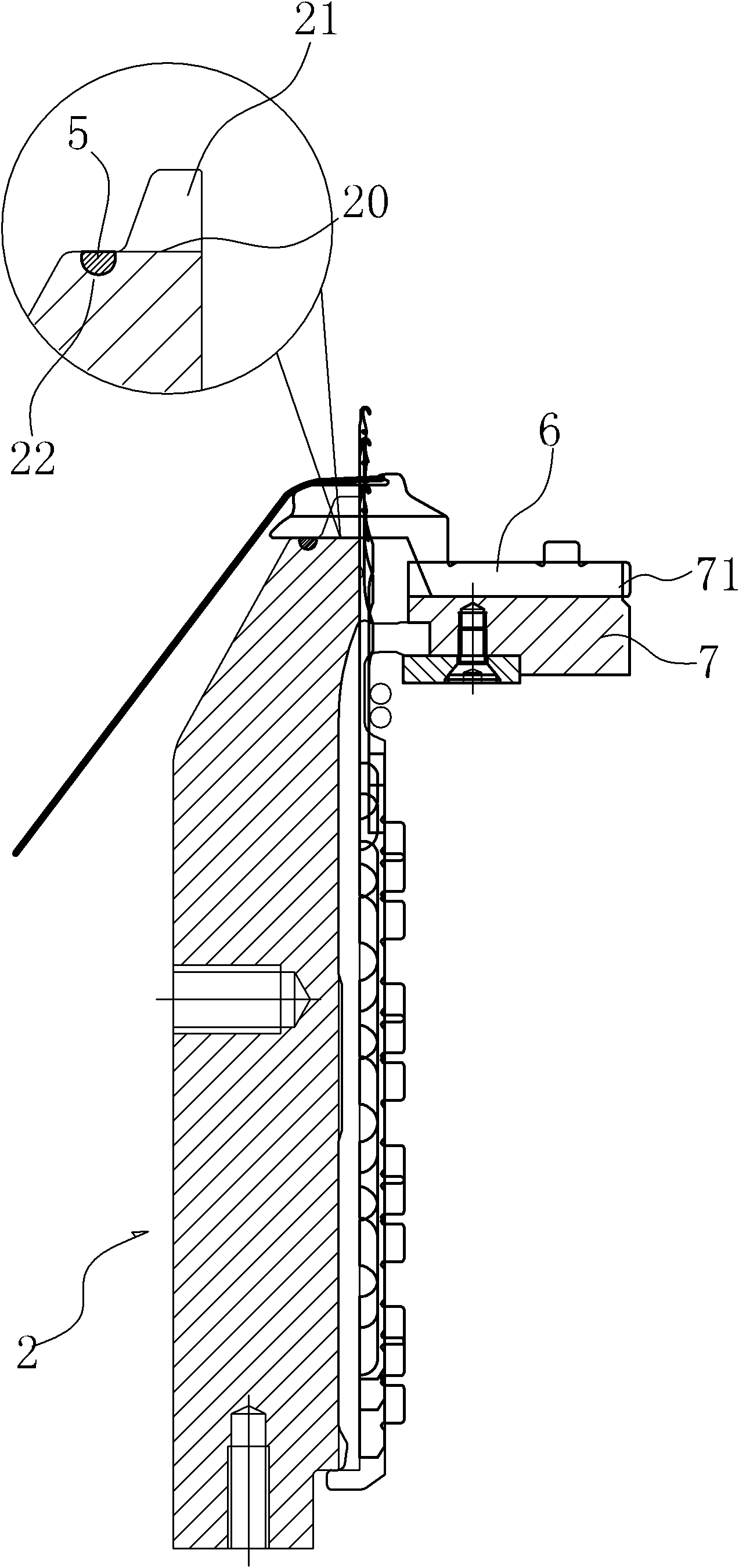

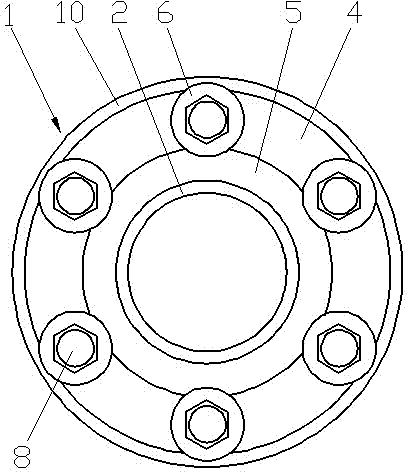

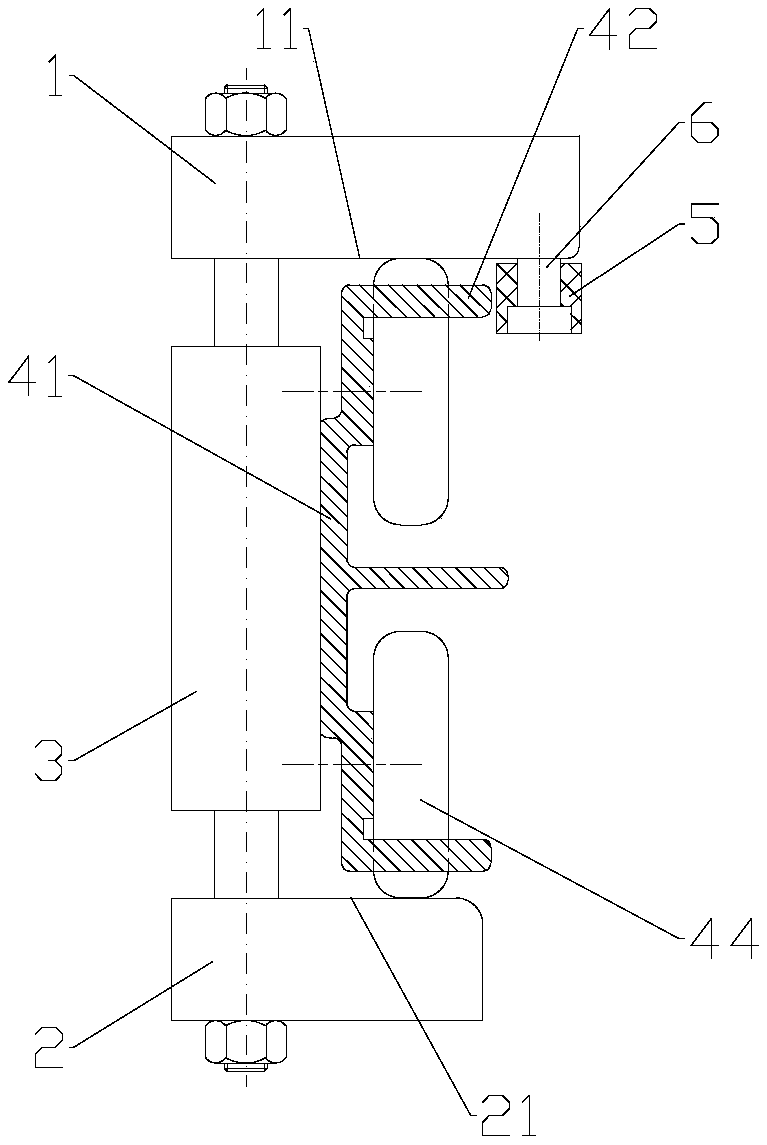

Double-ball pin cup steering linkage

InactiveCN101825136AImprove wear resistanceWear will notPivotal connectionsElastic plasticEngineering

The invention discloses a double-ball pin cup steering linkage, which comprises a steering linkage (1), a ball cup (2) and a ball cup sleeve (3), the steering linkage (1) is provided with a ball (4), the ball cup (2) consists of an upper ball cup (2a) and a lower ball cup (2b) which are provided with spherical cavities, wherein the upper ball cup (2a) is matched with the ball (4) in a clearance fit manner, and the lower ball cup (2b) is made of elastic plastic, and is compressed in the ball cup sleeve (3) by the upper ball cup (2a). The invention has the advantages of simple structure and high practicability; since the ball cup is arranged as a structure with the upper and the lower parts and the lower ball cup is resilient, when the upper ball cup directly contacted with the ball is abraded, the resilient lower ball cup can makes up for the overlarge clearance produced due to abrasion, consequently, the stability of the steering linkage in use is ensured, and the service life of the product is greatly prolonged.

Owner:四川望锦机械有限公司

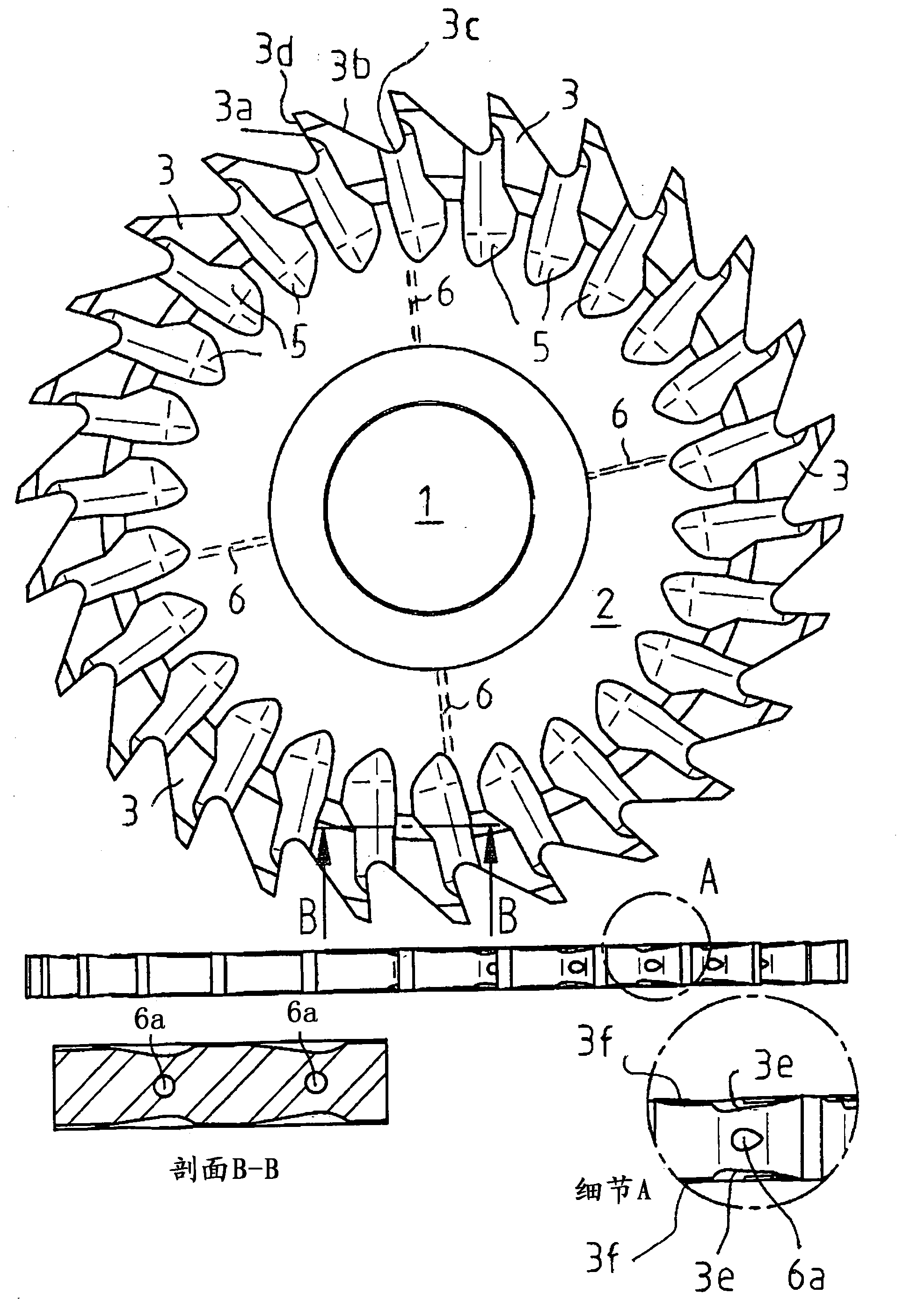

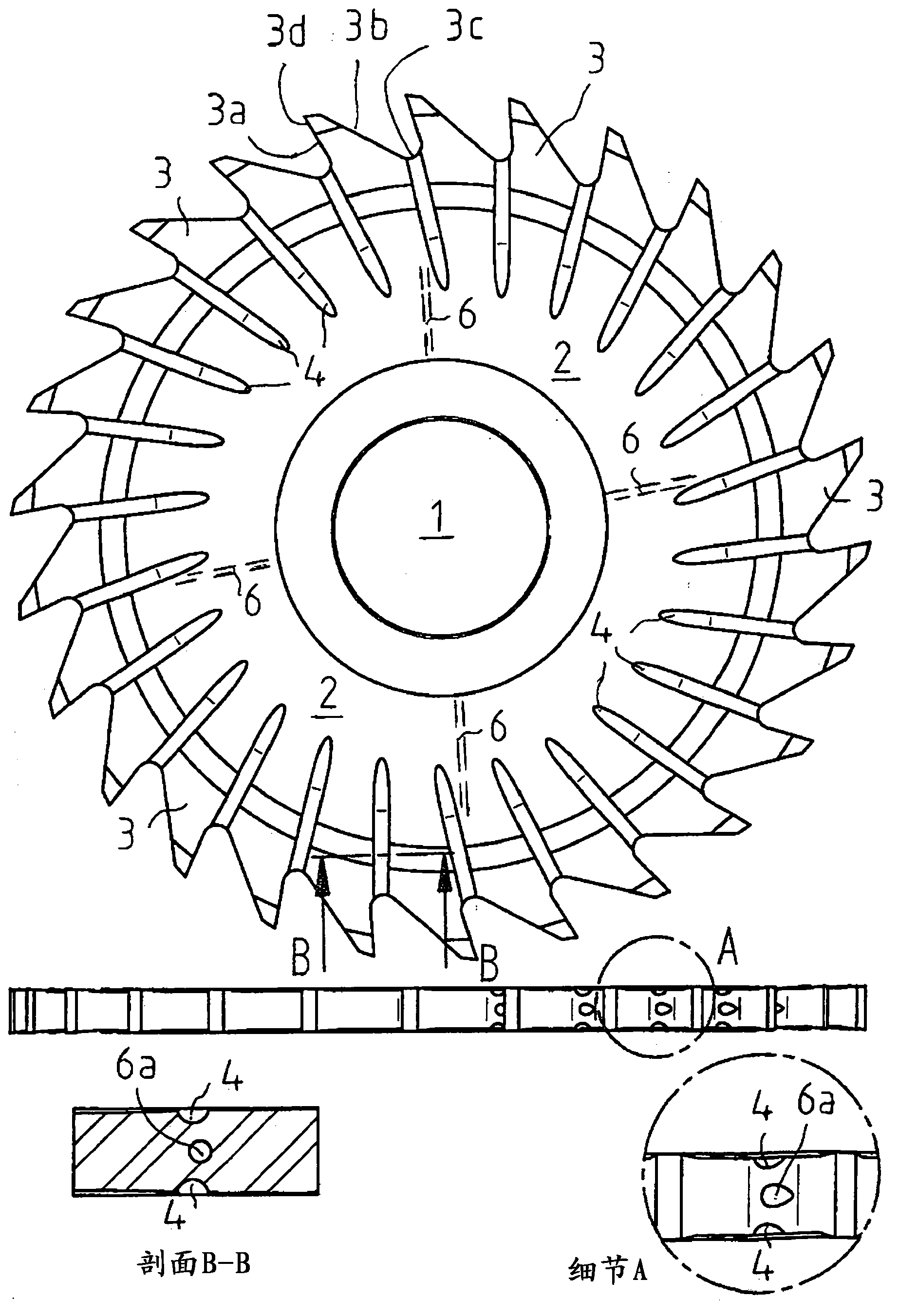

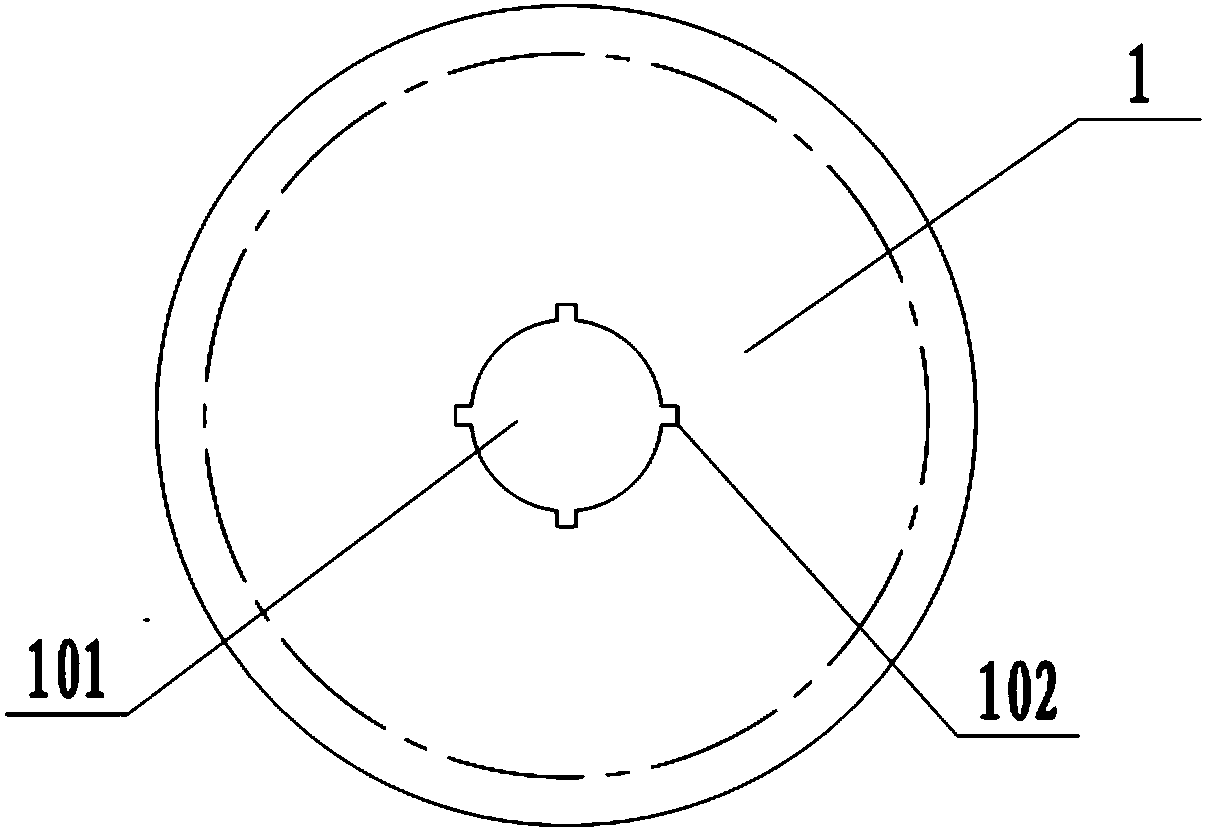

Hydrodynamically guided circular saw blade

ActiveCN102869468AReduce vibrationQuality improvementMetal sawing accessoriesMetal sawing toolsCircular sawEngineering

The invention relates to a circular saw blade, which comprises a supporting body (2), cooling channels (5) provided in the inner region of the supporting body (2) and running in the radial direction, and teeth (3) provided in the region of the outer periphery of the supporting body. The cooling channels (5) emerge from the circular saw blade in the region of the tooth bases (3c) or in the region of the flanks (3b) of the teeth (3). Furthermore, the circular saw blade has pockets (4) which, starting from a tooth base (3c) or a flank (3b) of a tooth (3), extend inwardly into the region of the supporting body (2).

Owner:ARNO FRIEDRICHS HARTMETALL GMBH & CO KG

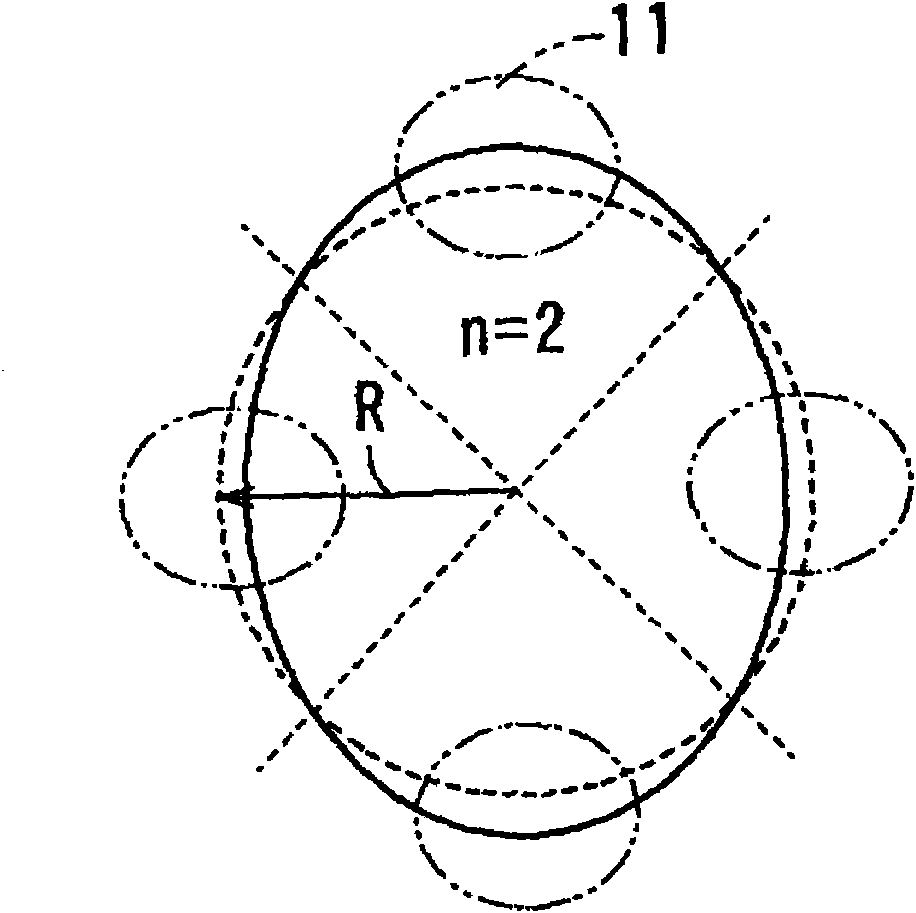

Cabling yarn binding machine with stranding mold

The invention belongs to the technical field of optical cable manufacturing equipment, and provides a cabling yarn binding machine with a novel stranding mold. The cabling yarn binding machine comprises a machine frame and a mold body, and is characterized in that the mold body is provided with a beam cable channel for a cable core to pass, the cross section of the beam cable channel is circular,the inner wall of the mold body is provided with at least one yarn guiding slot, chamfers of the yarn guiding slots are set in a polished manner, the mold body is arranged at the end, which is close to a first hollow rotating shaft, of a second hollow rotating shaft, a small-opening end of the beam cable channel is arranged in a mode of facing towards the first hollow rotating shaft, the first hollow rotating shaft is internally provided with an in-shaft yarn guiding pipe, and the in-shaft yarn guiding pipe is communicated with the beam cable channel. The cabling yarn binding machine realizesdirectional abrasion for the stranding mold, does not cause influences for the roundness of the stranding mold after long-time use and improves the service life of the stranding mold.

Owner:SHANDONG PACIF OPTICS FIBER & CABLE CO LTD

Sinker abrasion-resistant device for weaving machine

InactiveCN102425029AUniform hardnessHigh hardnessWeft knittingStructural engineeringMechanical engineering

The invention relates to the technical field of knitting machines, in particular to a sinker abrasion-resistant device for a weaving machine. A needle cylinder with the abrasion-resistant device comprises a needle cylinder, wherein a sinker through groove matched with a sinker plate at outer edge is molded on the top of needle cylinder; an annular groove is formed on the surface of the top of the needle cylinder; an abrasion-resistant steel wire is arranged in the groove; and the sinker is rubbed with the abrasion-resistant steel wire along the through groove in the process of reciprocating. Due to the adoption of the technical scheme, the annular groove is formed on the surface of the top of the needle cylinder with the through groove, and the annular abrasion-resistant steel wire is arranged in the groove so as to ensure that the surface hardness of the through groove and the hardness of the sinker are uniform. Usually, the hardness of the abrasion-resistant steel wire is higher than that of the sinker, so that the abrasion-resistant steel wire cannot be abraded for a long time. In addition, the sinker abrasion-resistant device can ensure that sinkers in the sinker plate groove can be more smoothly woven after adopting the technical scheme, ensures the quality of woven cloth and prolongs the service life of the needle cylinder and the sinker plate.

Owner:洪荣豪

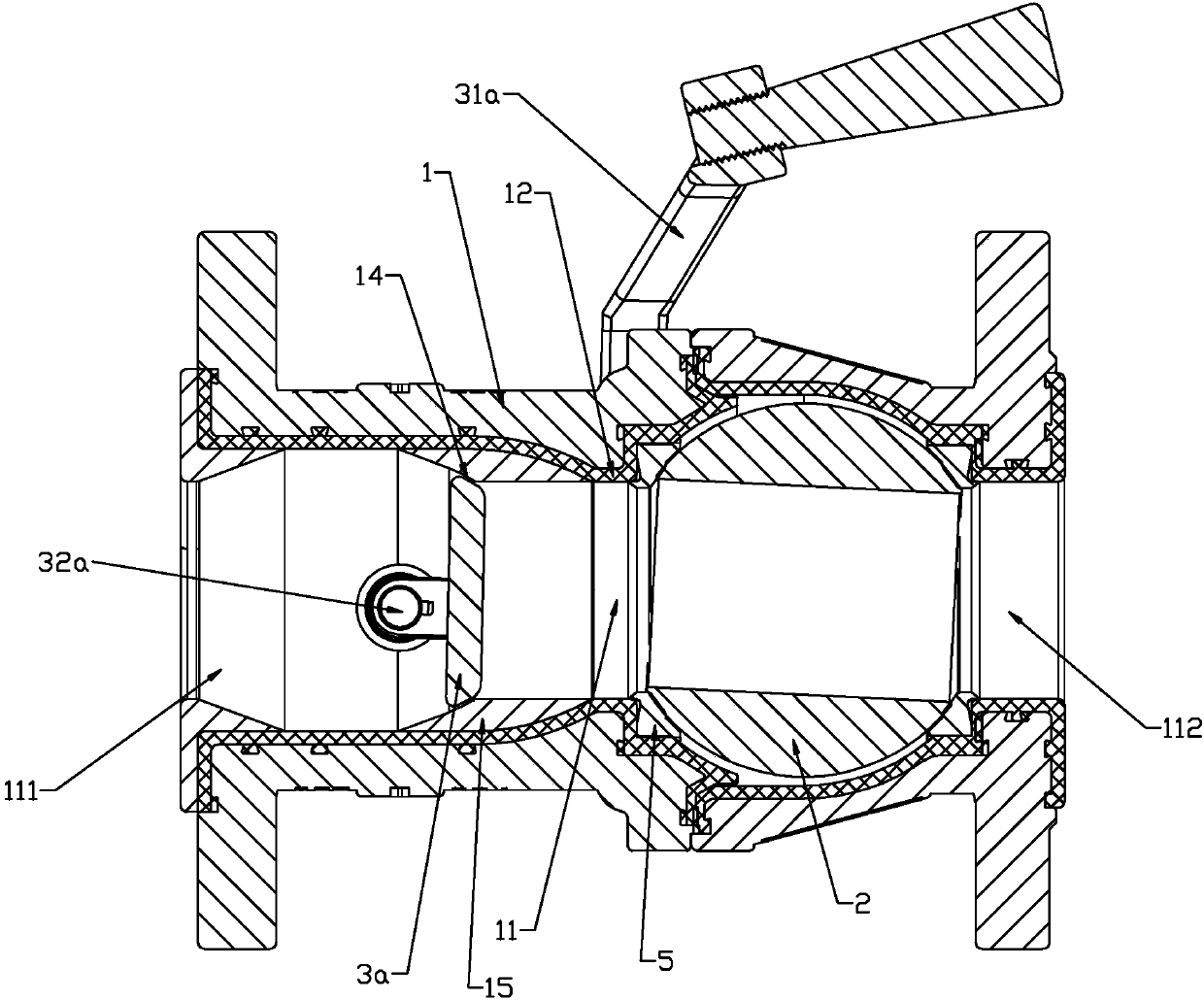

Fluorine-lined ball valve with sealing piece protecting function

ActiveCN107725817APrevent backflowAir pressure reductionPlug valvesValve housingsBall valveParticle material

The invention relates to a fluorine-lined ball valve with a sealing piece protecting function. The fluorine-lined ball valve comprises a valve body, a fluorine-lined ball body, a valve rod and a mainvalve seat. The valve body is internally provided with a flow channel; the valve rod controls the fluorine-lined ball body to make action so as to achieve cutting-off and communicating of the flow channel; the main valve seat is mounted at the flow channel and is in seal fit with the fluorine-lined ball body; the flow channel is provided with an inner communicating end communicating with a tank car and an outer communicating end communicating with the outside world; a fluorine lining is arranged on the inner wall of the flow channel; the fluorine-lined ball valve further comprises an particlematerial sealing piece and an operation piece which are arranged at the flow channel and located between the inner communicating end and the fluorine-lined ball body; the particle material sealing piece has a first communicating state and a second cutting-off state relative to the flow channel under control of the operation piece; and a positioning piece is arranged between the fluorine lining andthe main valve seat. By adopting the technical scheme, through the fluorine-lined ball valve with the sealing piece protecting function, the situation that a fluorine-lined open-close piece and the valve seat are damaged due to particle materials is avoided.

Owner:得威阀门有限公司

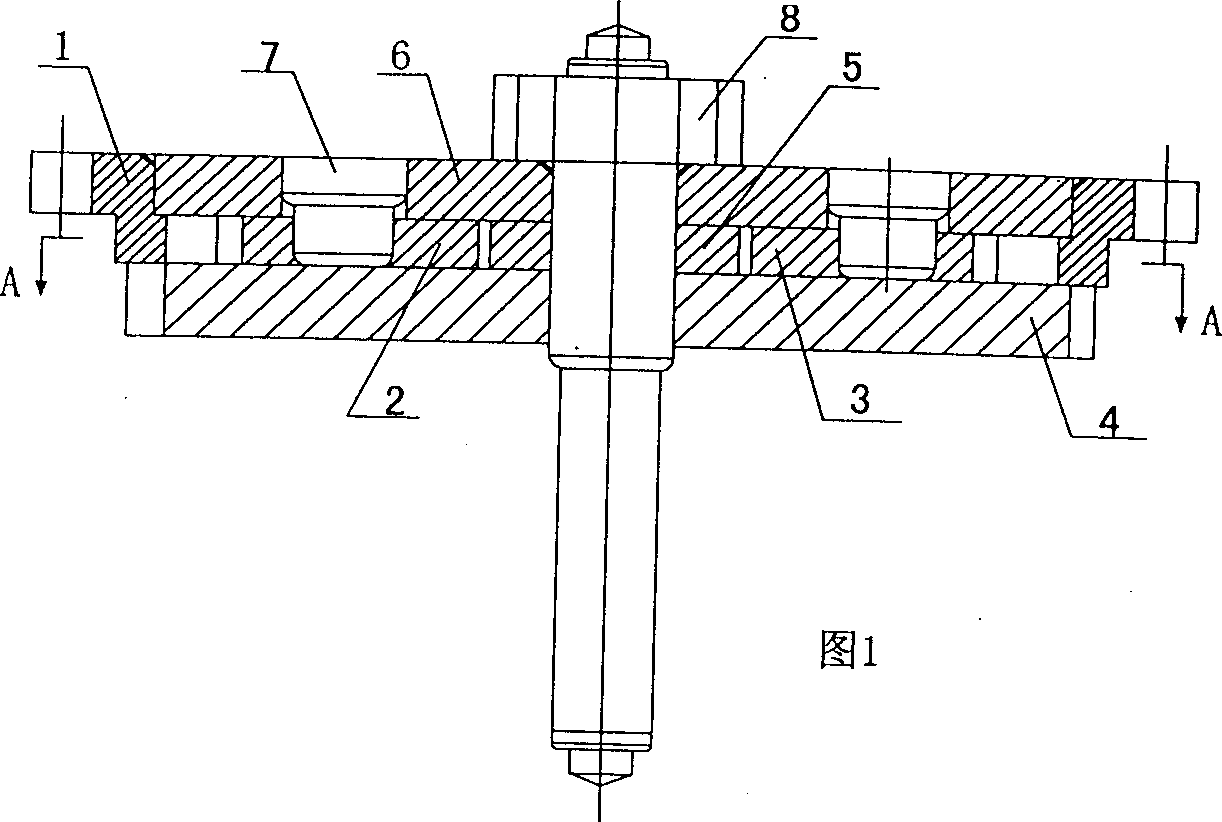

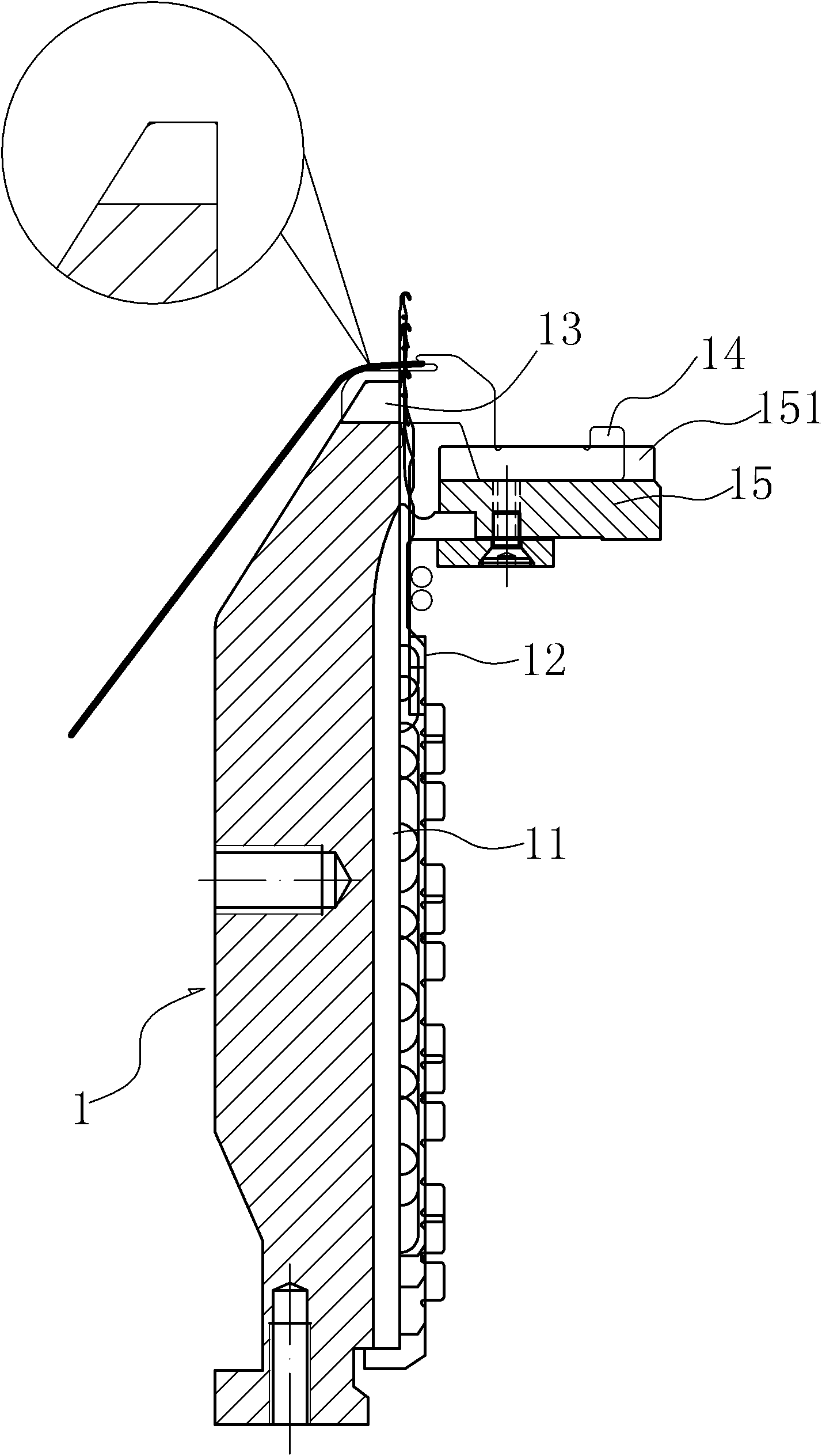

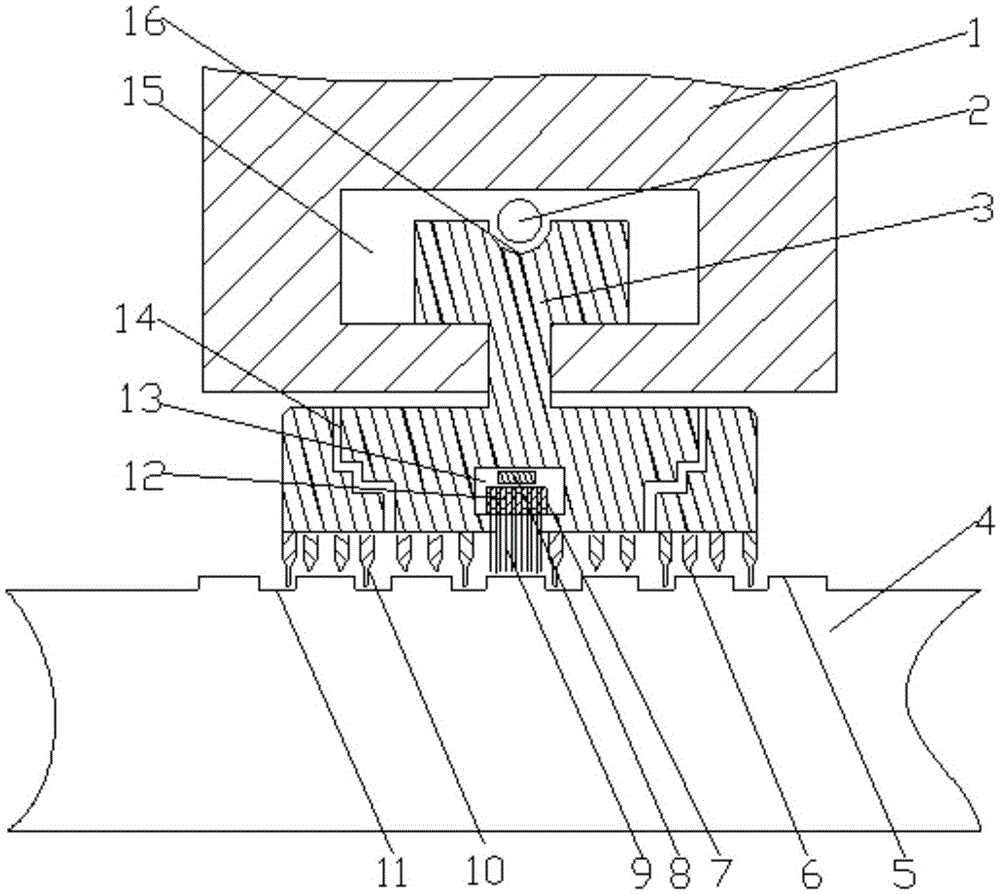

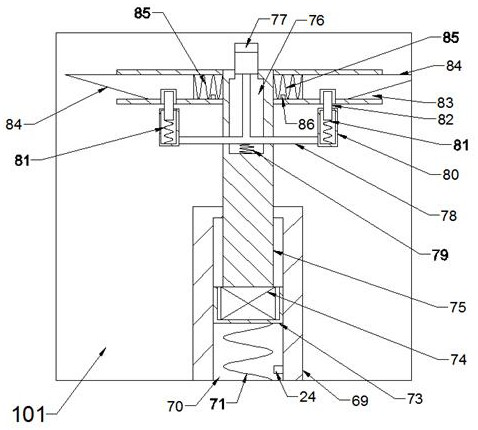

High pressure cylinder shaft seal device for power station steam turbine

A high pressure cylinder shaft seal device for a power station steam turbine aims to solve the problem of the big shaft seal gap of a high pressure cylinder of the power station steam turbine. The high pressure cylinder shaft seal device comprises a high pressure cylinder shaft seal cover, a round spring, arc-shaped shaft seal blocks, a rotating shaft, bosses, low sealing teeth, brush sealing bodies, a leaf spring, high sealing teeth, grooves, an annular brush sealing body cavity and an annular shaft seal ring cavity. The annular shaft seal ring cavity is formed in the inner side face of the high pressure cylinder shaft seal cover; the sections of the arc-shaped shaft seal blocks are in an I shape; the multiple arc-shaped shaft seal blocks constitute a shaft seal ring; the outer ends of the arc-shaped shaft seal blocks are arranged in the shaft seal ring annular cavity; a semicircular groove channel is formed in the outer edges of the arc-shaped shaft seal blocks in the circumferential direction; the lower half part of the round spring is fastened in the semicircular groove, and the upper half part of the round spring is exposed between the shaft seal ring and the annular shaft seal ring cavity; the annular brush sealing body cavity is formed in the center of the inner side faces of the arc-shaped shaft seal blocks; the multiple brush sealing bodies constitute a brush sealing ring; and the outer side end of the brush sealing ring is arranged in the brush sealing body annular cavity in a sleeved mode.

Owner:SHANXI GUOFENG COAL POWER CO LTD +1

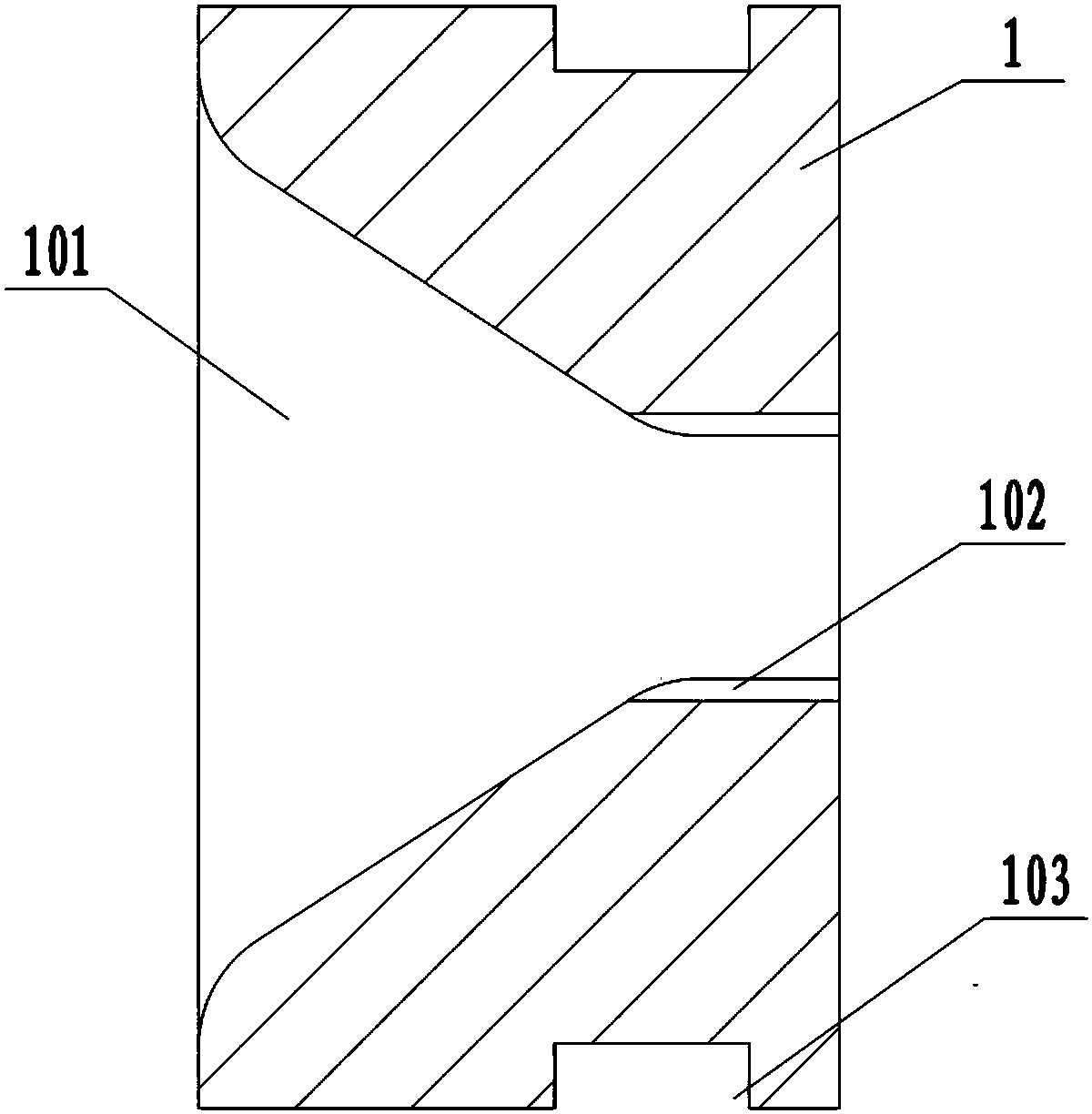

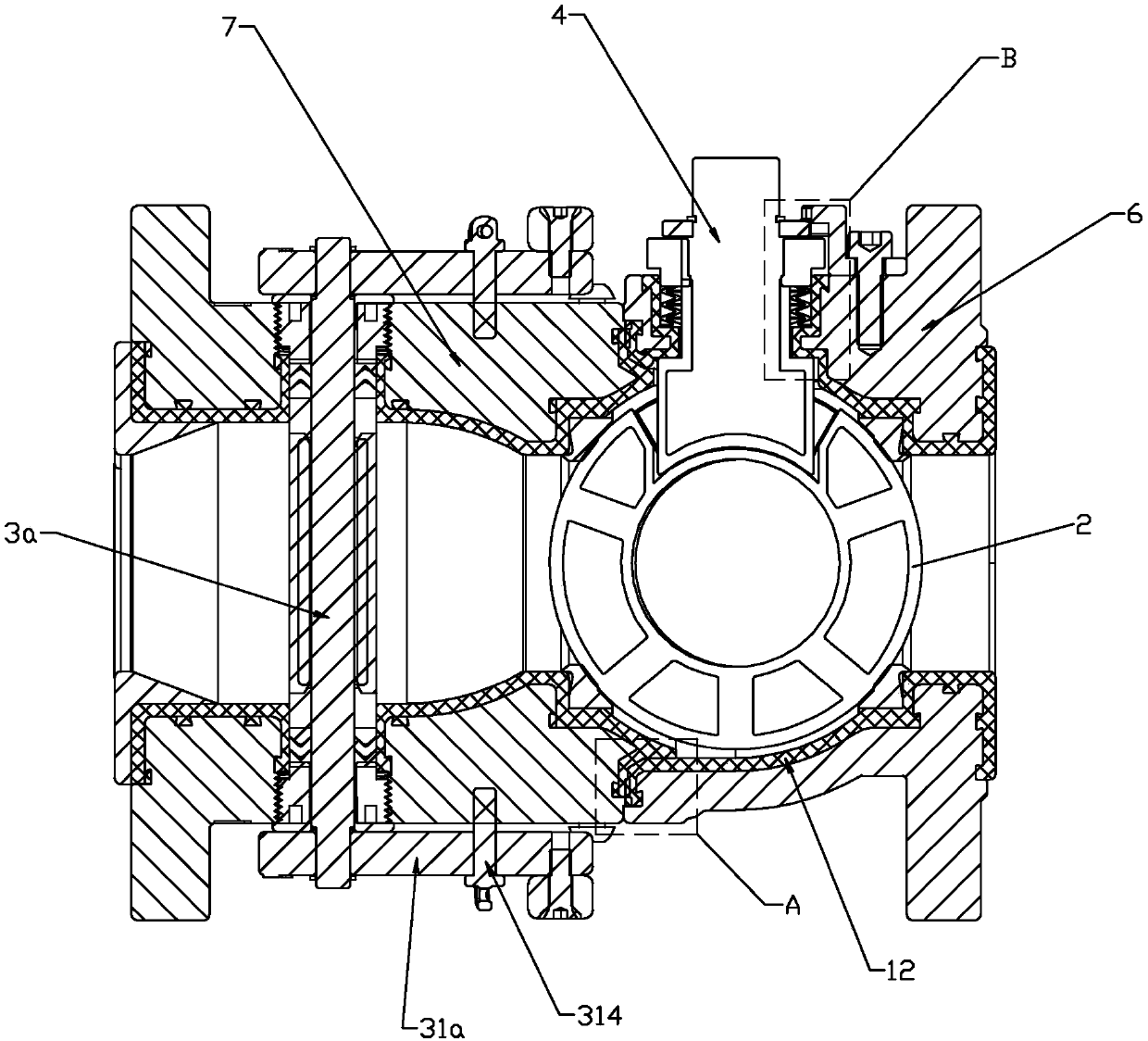

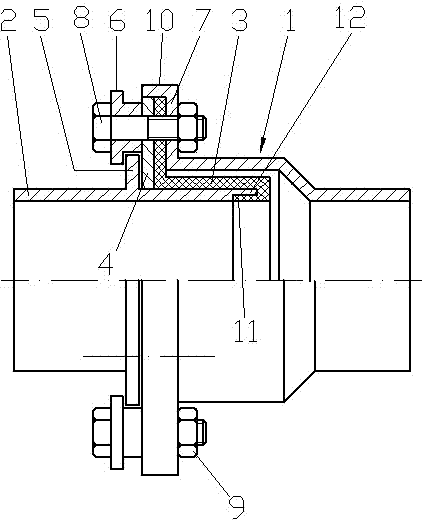

Maintenance-free rotating compensator

ActiveCN104747853AWear will notReduce wearPipeline expansion-compensationAdjustable jointsSilicon rubberWorkload

A maintenance-free rotating compensator comprises an outer pipe (1) and an inner pipe (2) and is characterized in that a flange (5) is arranged in the middle of the inner pipe, a locating ring (4) and a sealing sleeve (3) are sequentially arranged on the right side of the flange in a sleeving mode, and the pipe portion of the sealing sleeve is in sealing contact with the outer circle of the inner pipe; the pipe portion of the sealing sleeve extends into the outer pipe, a gap is reserved between the pipe portion of the sealing sleeve and the inner wall of the outer pipe, a flange (7) is arranged at the left end of the outer pipe, and the left end of the sealing sleeve is located on the left side of the flange along a convex edge which extends in the radial direction; multiple bolts (8) penetrate through the locating ring, the convex edge of the sealing sleeve and the flange, a nut located at the left end of the bolt is screwed up so that the convex edge of the sealing sleeve presses the flange, and the sealing sleeve is made of a silicon rubber material. Due to the fact that the sealing sleeve is made of the silicon rubber material, after the inner wall of the sealing sleeve is abraded, the elasticity of silicon rubber still enables the pipe portion of the sealing sleeve to make contact with the inner pipe in a sealing mode, the sealing performance is maintained, maintenance workload is greatly reduced, and compared with an existing rotating compensator, the service life of the maintenance-free rotating compensator is prolonged.

Owner:江苏耀宇新型管业有限公司

Long-acting water-based anti-loose fastener liquid glue processing precision coating device

PendingCN114308547AWear will notStable structureLiquid surface applicatorsCoatingsMaterials scienceFastener

Owner:耐落螺丝(昆山)有限公司

Sole film pasting equipment using novel material

InactiveCN111874712AReduce excessive wearWear will notApparel holdersArticle deliveryEngineeringStructural engineering

The invention discloses sole film pasting equipment using a novel material. The equipment comprises a shell, a first transmission space is arranged at the right side of the shell, a main space is arranged at the lower side of the first transmission space, a backrest is fixedly arranged on the upper side surface of the shell, a person can sit on the backrest through the backrest, a seat is fixedlyarranged at the right side of the backrest, and the seat is a position where the person can sit. A first sliding space is formed at the left side of the shell, a winding space is formed at the lower side of the first sliding space, and a working space is formed at the upper side of the winding space. Before mountain climbing, memory metal and a high-friction material can be used for jointly manufacturing a friction film meeting different soles, the film is pasted on a sole, excessive abrasion of a shoe due to terrain and other factors can be greatly reduced during mountain climbing, the shoe can be greatly protected against abrasion during climbing, the friction force between the shoe and the ground can be increased, the climbing process can be safer, and the phenomena of slipping and thelike can be avoided.

Owner:ZHEJIANG DA BO WEN SHOES CO LTD

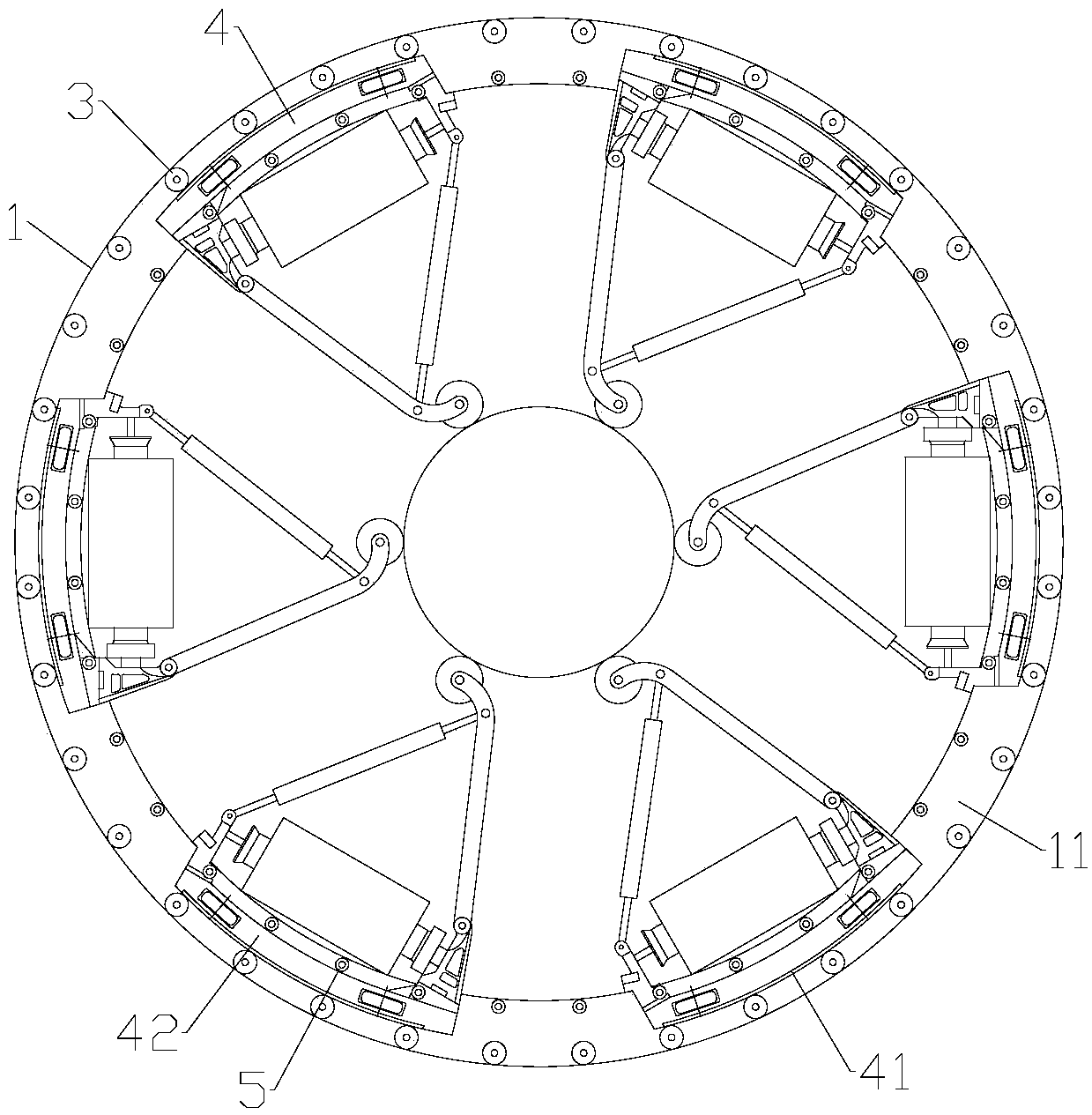

Circular loom

The invention discloses a circular loom, belongs to the field of plastic weaving machinery, and solves the problem of high using cost of shuttle derailment preventing in the prior art. The circular loom is characterized in that derailment preventing wheels are arranged on part, located on the inner circle side of the operating trajectory of the shuttle, of the lower surface of an upper door ring,upper protruded edges which protrude towards the center of the circular loom are arranged on the upper side of the shuttle, the upper protruded edges extend towards the back from the front end of theshuttle, the upper protruded edges are located on the same horizontal height of the derailment preventing wheels, gaps are reserved between the upper protruded edges and the derailment preventing wheels, multiple derailment preventing wheels are distributed in the circumferential direction of the upper door ring, and the spacing between the two adjacent derailment preventing wheels is not greaterthan the extending lengths of the upper protruded edges. The circular loom is mainly used for effectively preventing the derailment of the shuttle.

Owner:雁峰集团有限公司

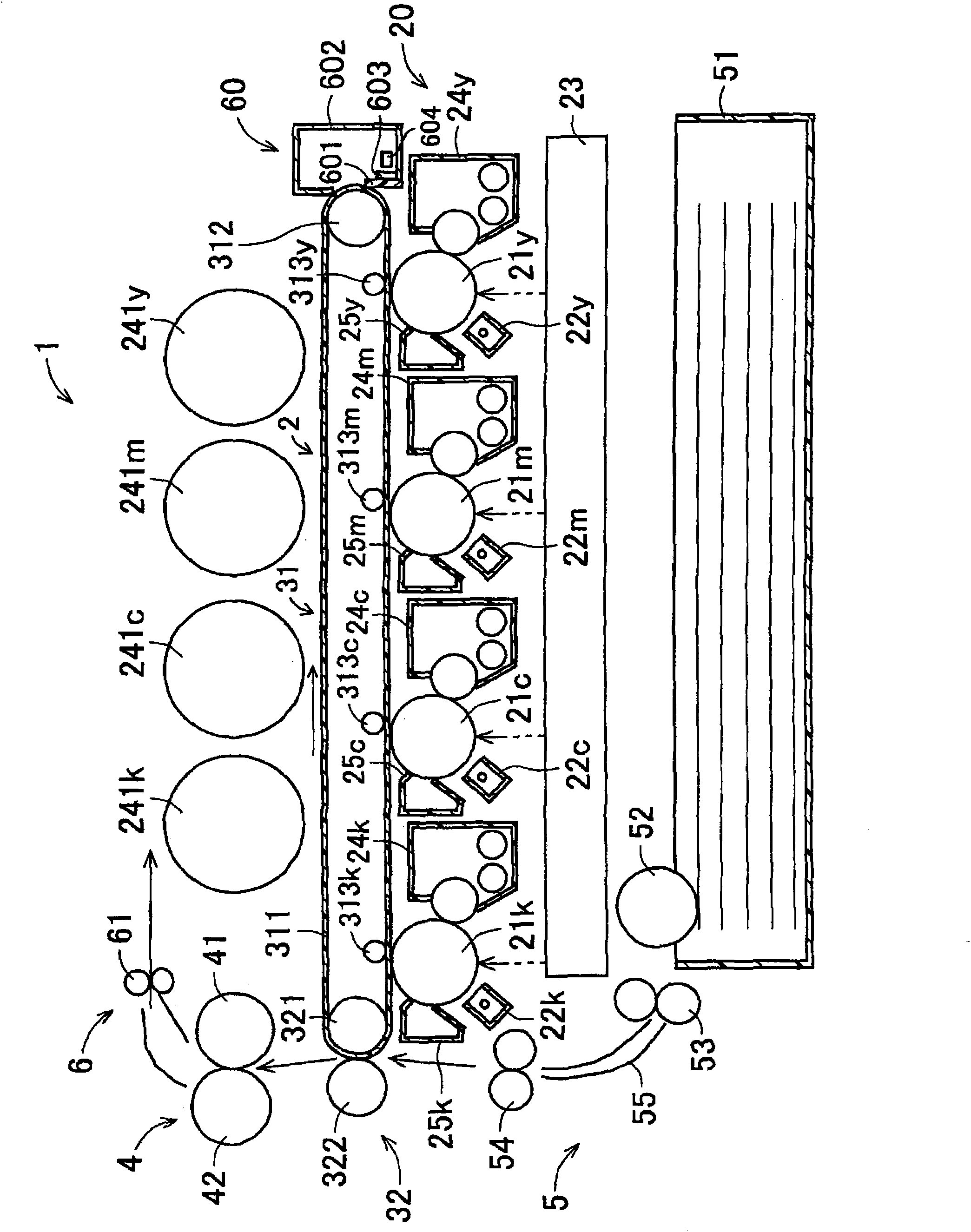

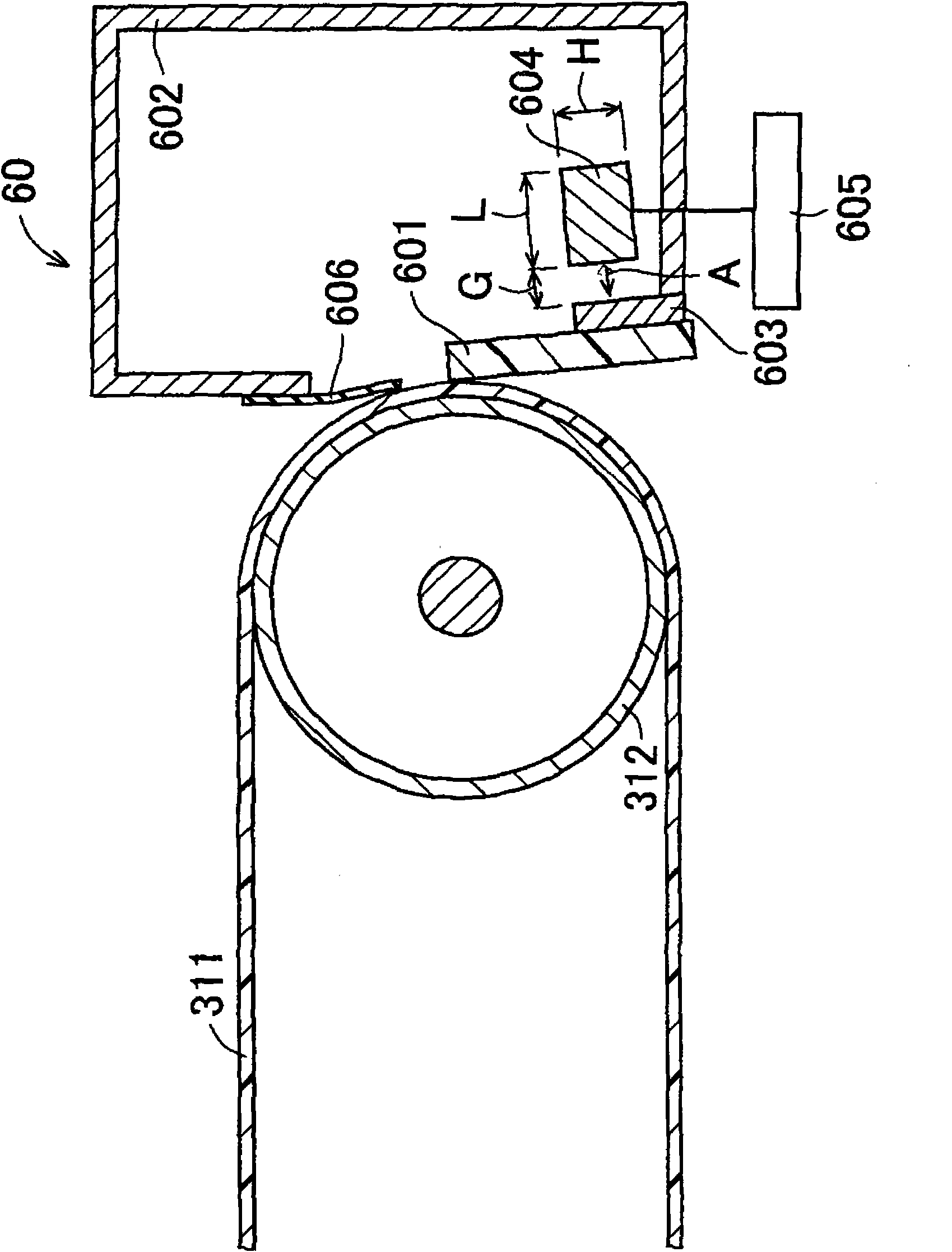

Belt cleaning apparatus and image forming apparatus

InactiveCN102012666AImprove removal efficiencyWear will notElectrographic process apparatusForeign matterAC - Alternating current

The invention provides a belt cleaning apparatus and an image forming apparatus. The belt cleaning apparatus is excellent in removing efficiency of removing residual toner as well as is capable of efficiently removing foreign matters which are more difficult to be removed than the residual toner such as paper powder, talc and kaolin adhered to a cleaning section from the cleaning section, which makes it possible to form a high quality image over a long term. A belt cleaning apparatus (60) is, when removing the residual toner by abutting on an outer circumferential surface of an intermediate transfer belt (311) by a cleaning blade (601), configured to vibrate the intermediate transfer belt (311) by applying alternating current voltage to an electrode member (604) by a power source (605) through a blade supporting member (603).

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com