Long-acting water-based anti-loose fastener liquid glue processing precision coating device

A technology for loosening fasteners and coating devices, which is applied to devices and coatings that apply liquid to the surface. Good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The following method and the preferred embodiment of the invention are further illustrated in the present invention to achieve the technical means taken by the present invention.

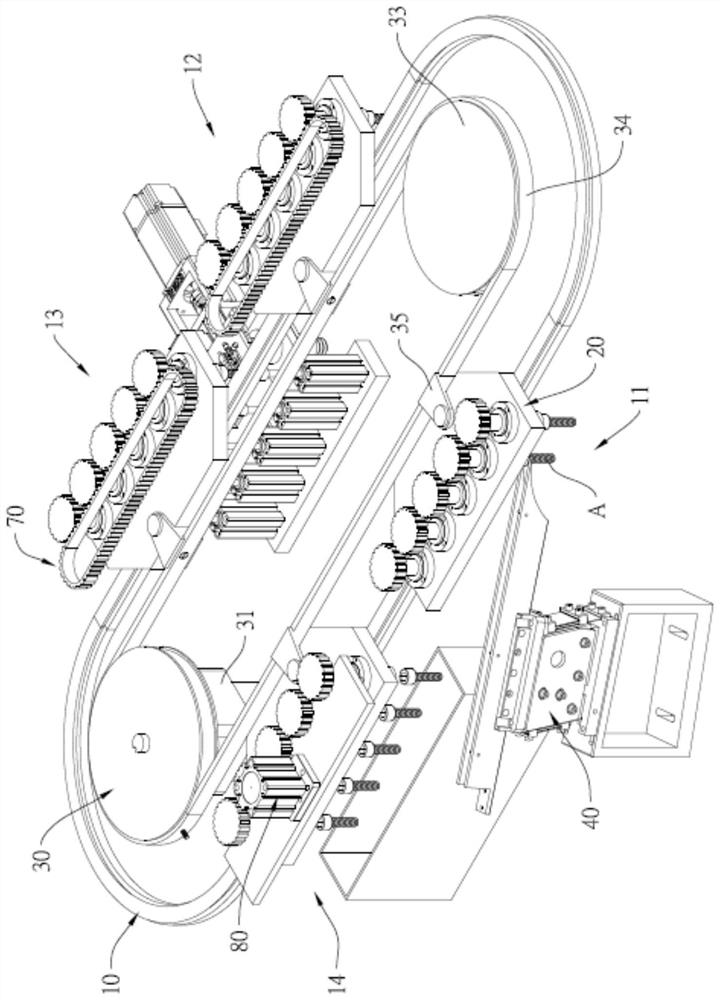

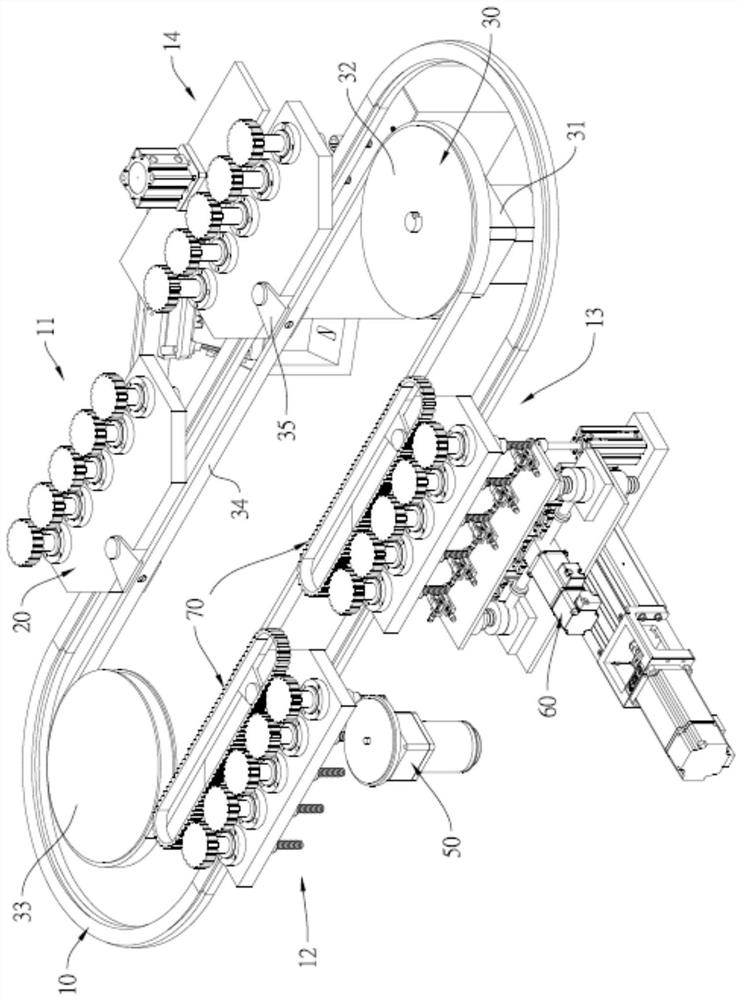

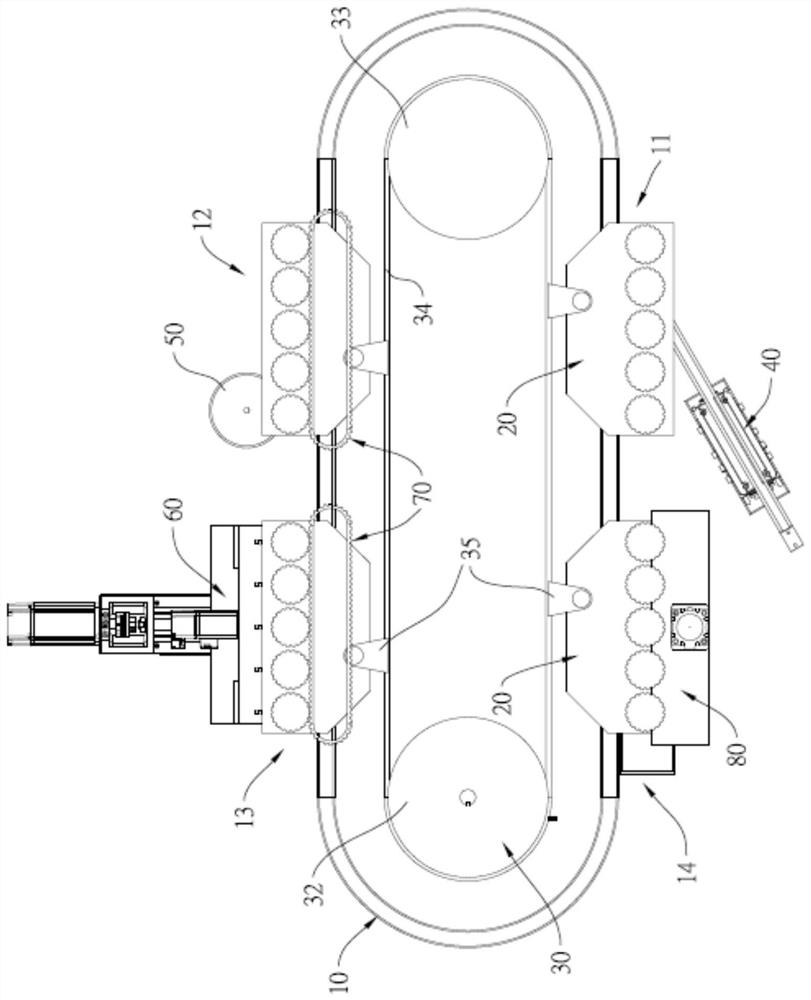

[0090] Please refer to figure 1 , figure 2 and image 3 , The long-acting water-based anti-laminating fastener liquid glue processing of the present invention includes a rail 10, at least one mobile station 20, a moving assembly 30, a sheet assembly 40, a pair of cardiac assembly 50, a coating assembly 60 , Two rotating assemblies 70 and a lower material assembly 80.

[0091] The track 10 passes through a super material region 11, a pair of heart zone 12, a coating region 13, and a lower material region 14. That is, an upper region 11 is provided on the circulating path of the track 10, the center region 12, the coating region 13, and the lower material region 14.

[0092] Please refer to figure 2 and Figure 4 Each mobile station 20 includes a piece of body 21 and at least one transfer 22. The tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com