Belt cleaning apparatus and image forming apparatus

A technology for cleaning devices and carrying belts, applied in the fields of electric recording technology using charge patterns, equipment for electric recording technology using charge patterns, and electrography, etc., which can solve the problem of uneven transfer electric field, low transfer efficiency, intermediate Problems such as transfer belt vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, the best embodiments of the present invention will be described in detail with reference to the accompanying drawings.

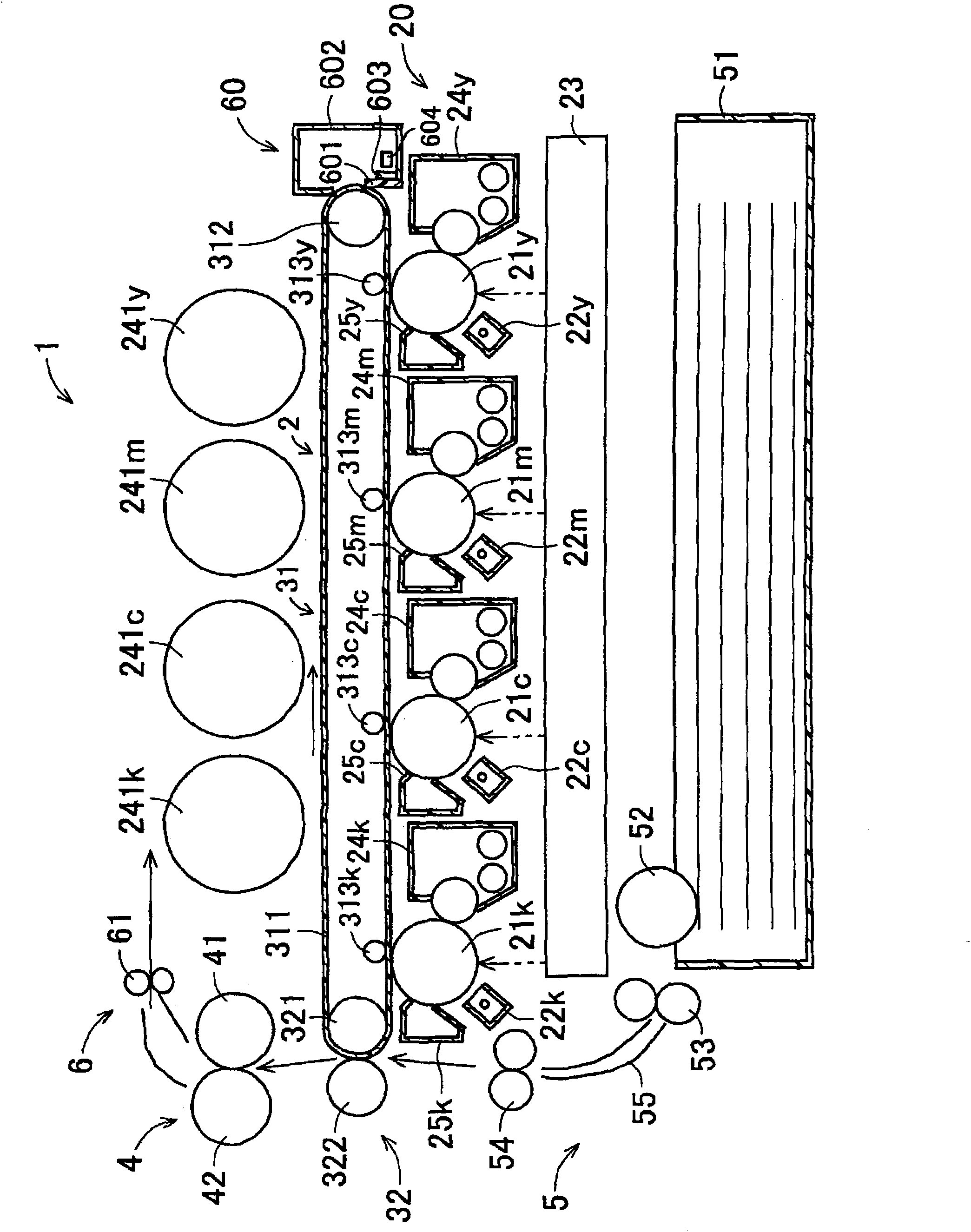

[0040] figure 1 It is a diagram showing the configuration of an image forming apparatus according to an embodiment of the present invention. The image forming apparatus 1 is a tandem color image forming apparatus capable of forming color images. The image forming apparatus 1 has a printing function, and can be printed on the basis of image data transmitted from various terminal devices such as a PC (personal computer) connected to the Internet, or image data read by a document reading device such as a scanner. A color image or a black-and-white image is formed on recording paper serving as a recording medium.

[0041] The image forming apparatus 1 includes an image forming station unit 2 , a secondary transfer station unit 32 , a fixing unit 4 , a paper supply unit 5 , and a paper discharge unit 6 . The image forming station unit 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com