Bobbin tray seat for containing bobbins

A bobbin seat and bobbin technology, which is used in transportation and packaging, thin material processing, textiles and papermaking, etc., can solve the problems of bobbin edge damage, high manufacturing cost, insufficient mechanical strength of the bobbin seat, etc., and achieve good surface quality. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

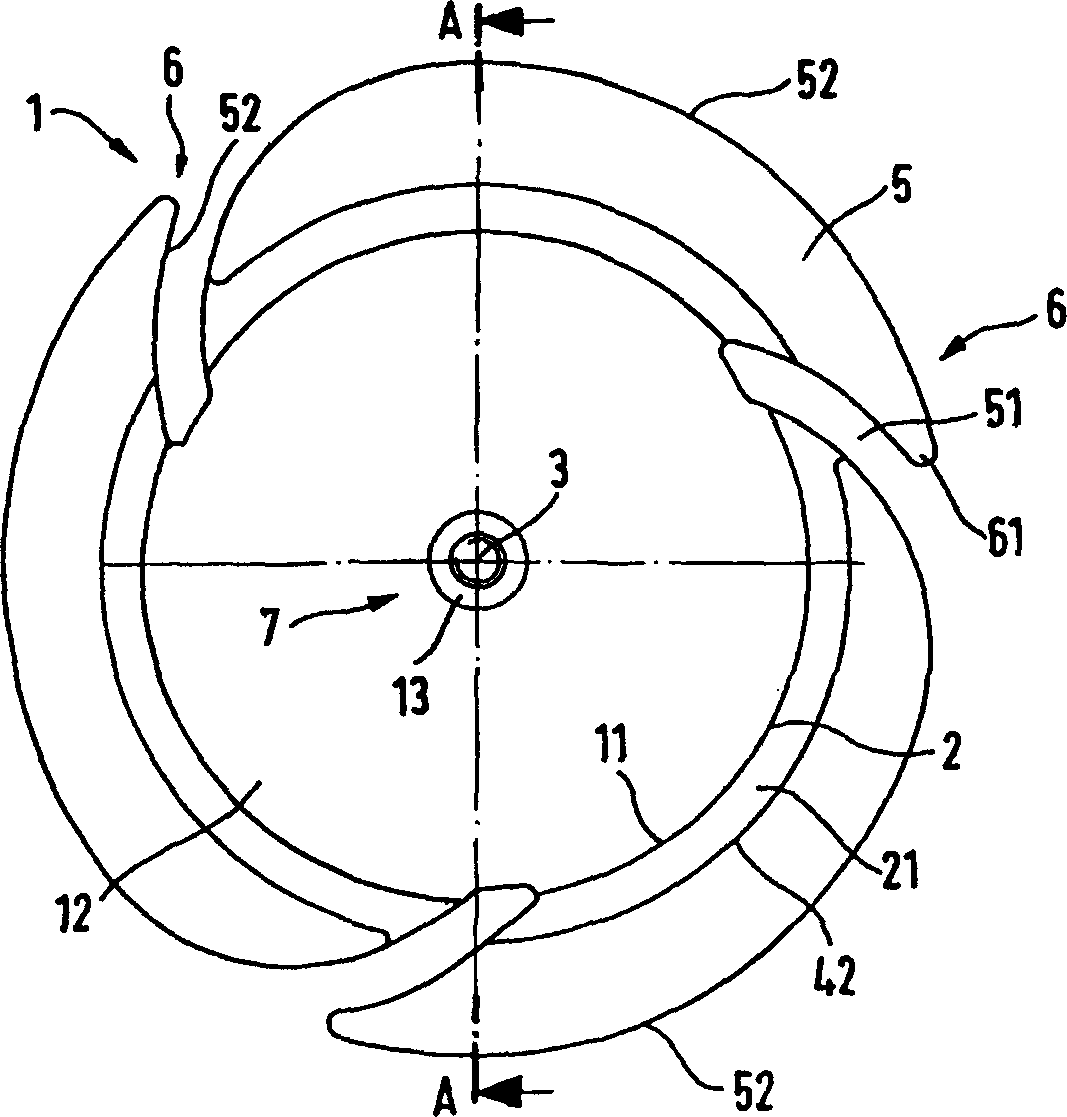

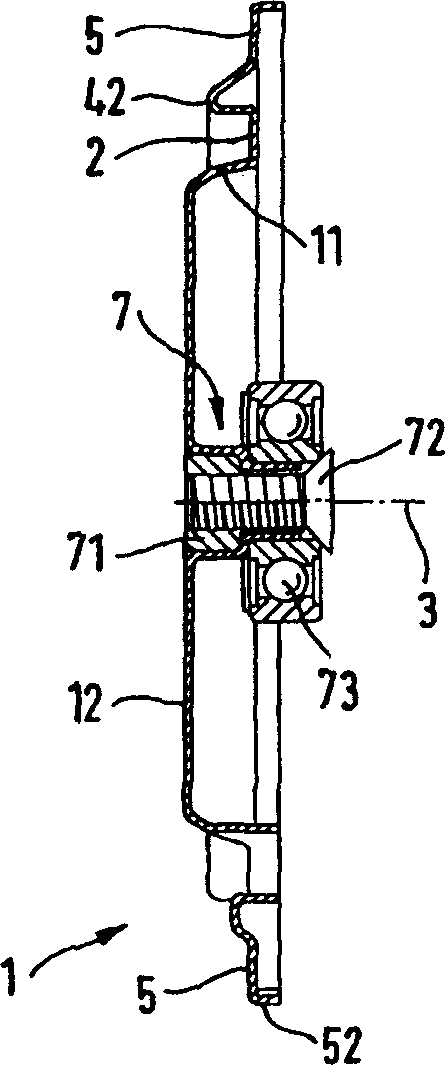

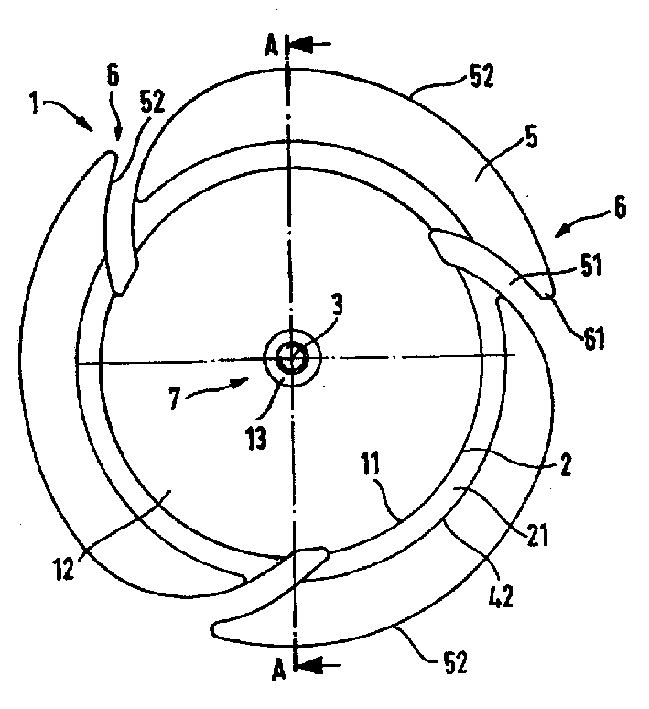

[0019] figure 1 The top view showing the bobbin tray seat of the present invention is viewed from the side facing the bobbin. The bobbin (not shown) is accommodated in the bobbin holder and a groove 2 delimited by a centering shoulder 11 on the side facing the axis of rotation 3 . The groove 2 is delimited on the other side by a peripheral shoulder 42 . The function ensured by this edge shoulder 42 is that the position of a yarn is precisely maintained for forming a ready winding on the bobbin, so that the yarn is not drawn into the bobbin when the bobbin turns. Between the disc seat and the edge of the bobbin. Form a prepared yarn, as it is described in DE-A3344645, also as an example, is applicable to the bobbin holder of the present invention of the present application. The centering shoulder 11 opposite the groove 2 forms, in the present embodiment, a receiving structure for bobbins on the bobbin tray base 1 .

[0020] In the edge region 5 of the bobbin carrier 1 , a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com