Cover-die hole-drilling device

A technology for drilling devices and mold sets, which is applied in positioning devices, drilling molds for workpieces, and clamping. Production links, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

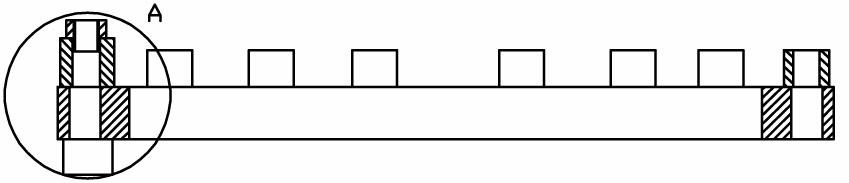

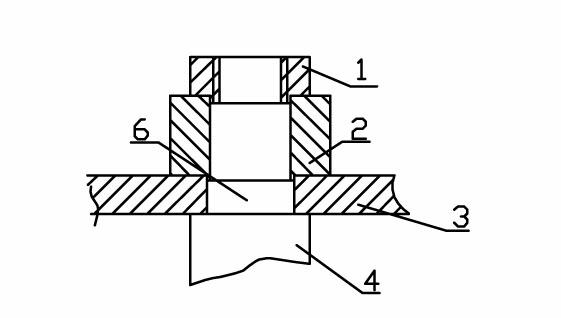

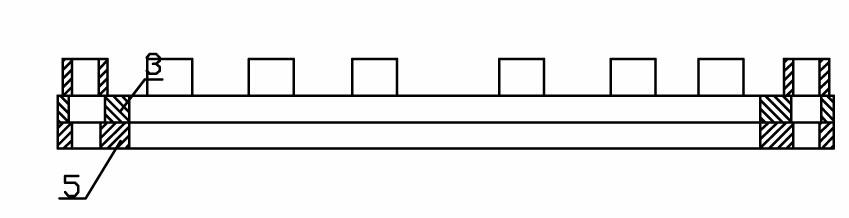

[0019] like figure 1 Among them, a mold drilling device, the template 3 is provided with at least one positioning hole 6, and the positioning hole 6 is coaxially provided with a positioning sleeve 2;

[0020] The positioning hole 6 is larger than the aperture of the processing hole, and the aperture of the positioning sleeve 2 is equal to the aperture of the processing hole.

[0021] The positioning sleeve 2 is provided with a step, and the step extends into the positioning hole 6 . The outer edge of the step is used as the positioning datum of the positioning sleeve 2 . to ensure positioning accuracy.

[0022] The positioning sleeve 2 and the template 3 are connected by welding.

[0023] The bottom surface of the template 3 is a reference plane. To ensure machining accuracy, one of the datum surfaces must be the bottom surface of the template 3 .

[0024] like figure 1 , figure 2 During production, first use precision machining, such as: boring and milling methods to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com