Integrated processing system and method thereof of improving use value of coal-fired boiler ash

A technology for coal-fired boilers and treatment systems, which is applied in the treatment of combustion products, combustion methods, combustion of solid fuels, etc., can solve the problems of large maintenance, reduce boiler combustion efficiency, affect furnace design, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

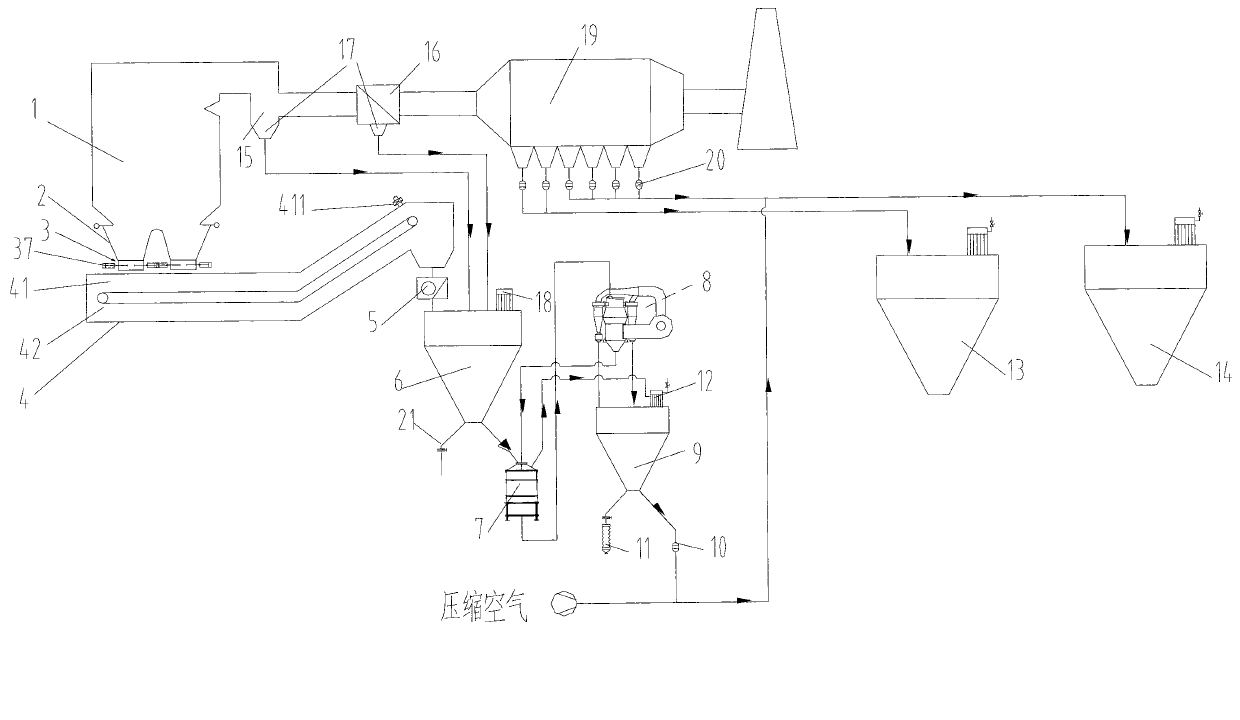

[0093] Such as figure 1 As shown, it is mainly suitable for coal-fired boilers with a small amount of slag discharge and low combustibles in the ash. The furnace bottom combustion device 3 provided by the present invention is used for recombustion of unburned carbon in the boiler output ash;

[0094] The ash processing system is used for crushing the received boiler 1 ash and making it into usable raw materials, such as cement raw materials;

[0095] The ash handling system includes:

[0096] The ash grinding device is connected to the discharge port of the furnace bottom combustion device 3, and is used to receive the cooled ash and grind it;

[0097] Sorting device 8, its feed port is connected with the ash outlet of the ash grinding device, and is used for sorting the ground ash, qualified ash is output from its discharge outlet as available raw materials , the unqualified ash is returned to the ash inlet of the ash grinding device for further grinding.

[0098] In order...

Embodiment 2

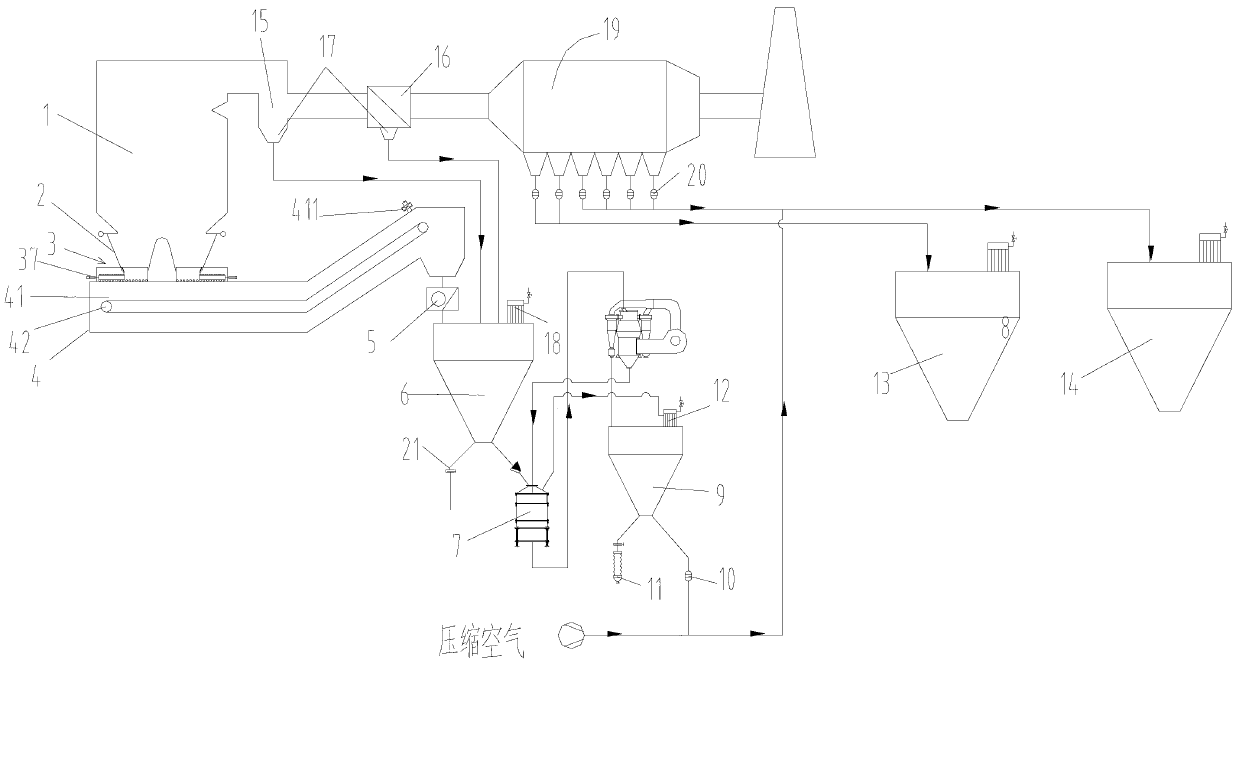

[0109] Such as figure 2 shown, with figure 1 The difference of the marked embodiment 1 is: this embodiment is mainly used when the combustibles in the ash are relatively high, and a combustion-supporting furnace bottom combustion device 3 is provided at the bottom of the slag hopper 2, where the furnace bottom combustion device 3 The combustion bed structure is different from embodiment 1, specifically as Figure 11 to Figure 14 shown.

[0110] The combustion bed 32 has a hollow chamber 322, and a plurality of air outlet holes 323 communicating with the hollow chamber 322 are formed on the wedge-shaped bed surface 321; , for introducing the combustion-supporting gas into the combustion bed 32 to realize the reburning of the carbon in the ash on the combustion bed 32 .

[0111] Such as Figure 11 with Figure 12 As shown in the structure, the wedge-shaped bed surface 321 is provided with a plurality of airtight ventilation pipes 34 arranged at intervals, and the plurality...

Embodiment 3

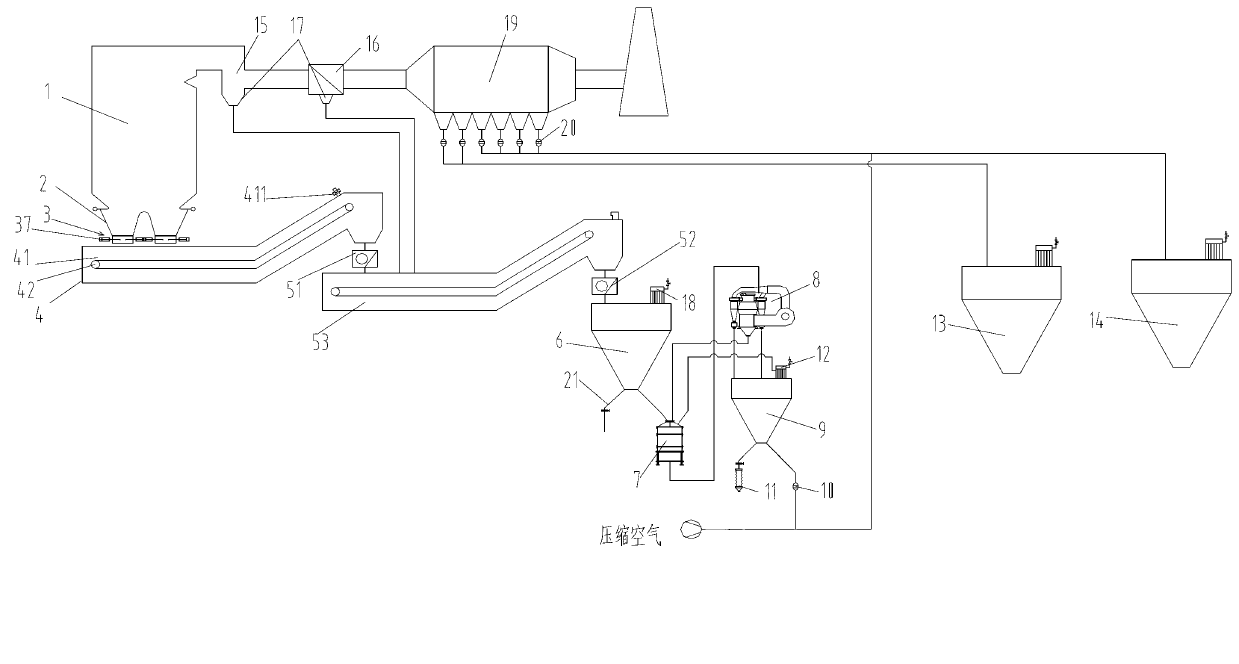

[0116] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment is applicable to the situation where the amount of boiler bottom slag is large.

[0117] The crushing device 5 in this embodiment includes a coarse slag crusher 51, a fine slag crusher 52, and an ash conveying device 53. At the slag outlet, the outlet of the coarse slag crusher 51 is connected to the ash inlet of the slag conveying device 53, and the ash outlet of the fine slag crusher 52 is connected to the ash inlet of the grinding device 7; The fly ash discharged from the air preheater 15 and the air preheater 16 and the ash outputted by the slag conveyor 42 are transported to the fine slag crusher 52 through the slag conveying device 53 . In this embodiment, secondary crushing is performed on the ash and slag, which is beneficial to sufficient cooling of the ash and slag and maintenance of subsequent devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com