Wear-resisting centralizer structure of sucker rod of oil well

A sucker rod and centralizer technology, used in drill pipes, drilling equipment, earthwork drilling and other directions, can solve the problems that the centralizer cannot be made too large, wear and tear, and have high maintenance costs, so as to improve the overall anti-corrosion performance and durability. Grinding performance, extended service life, extended life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

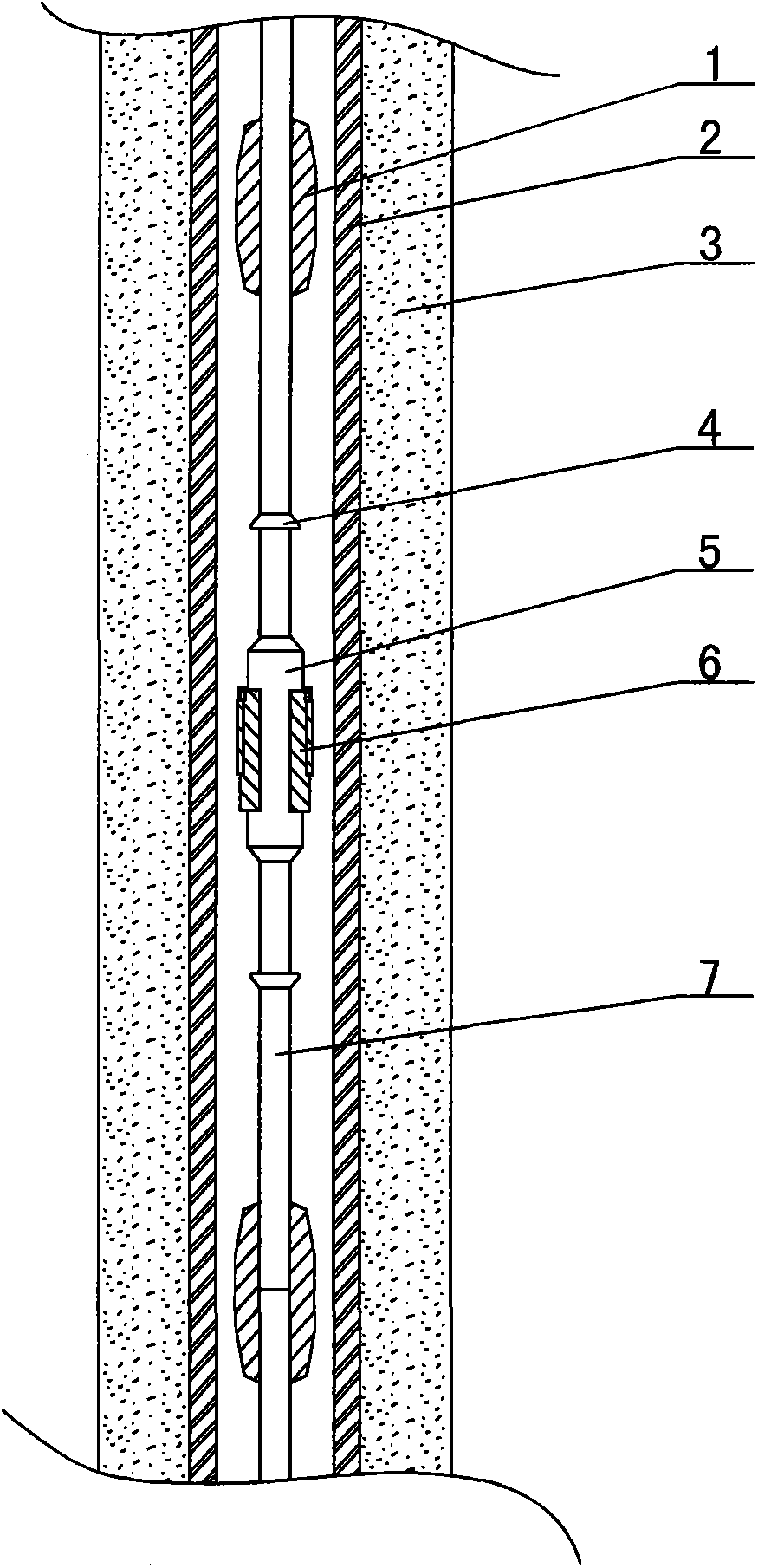

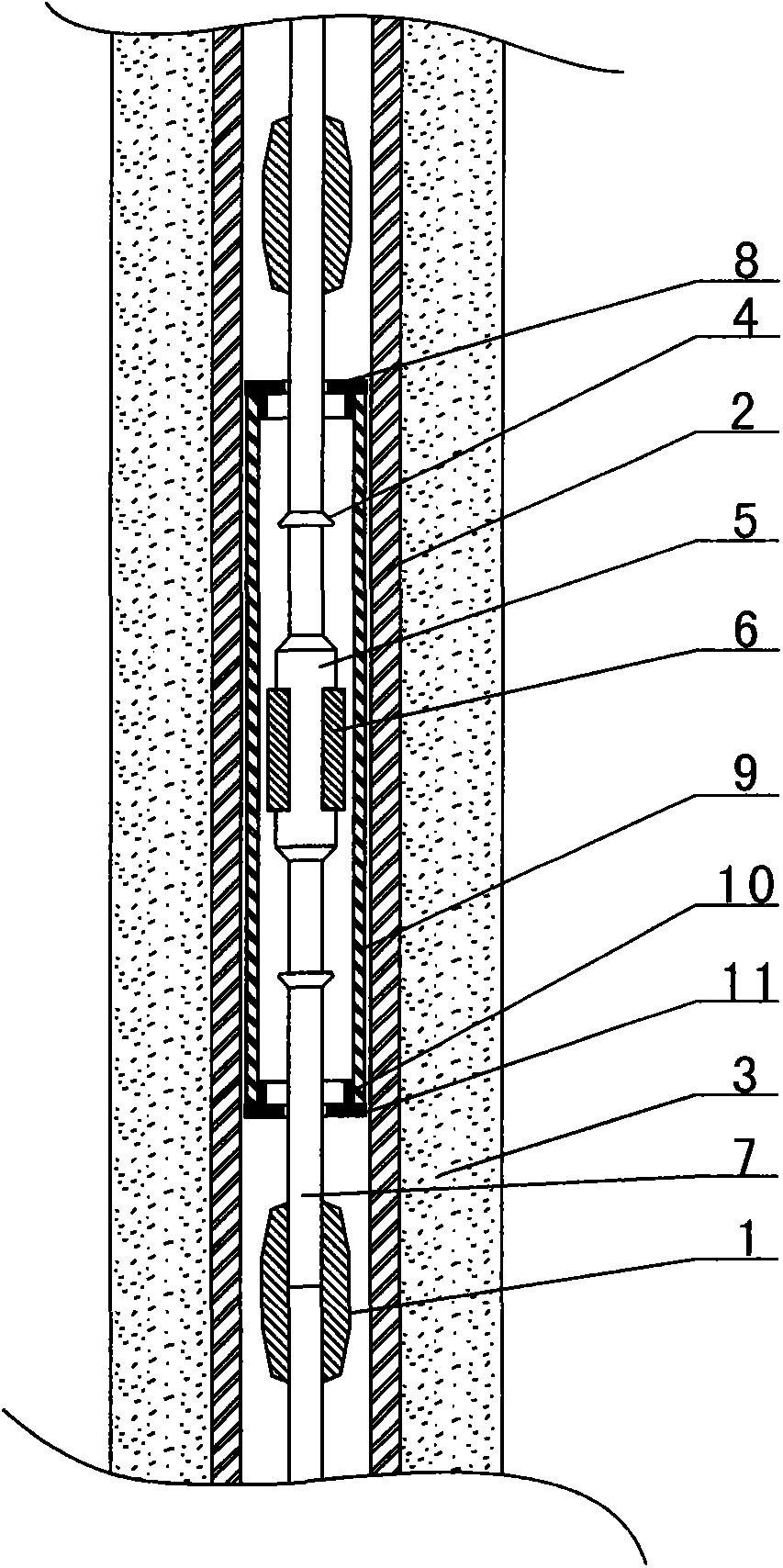

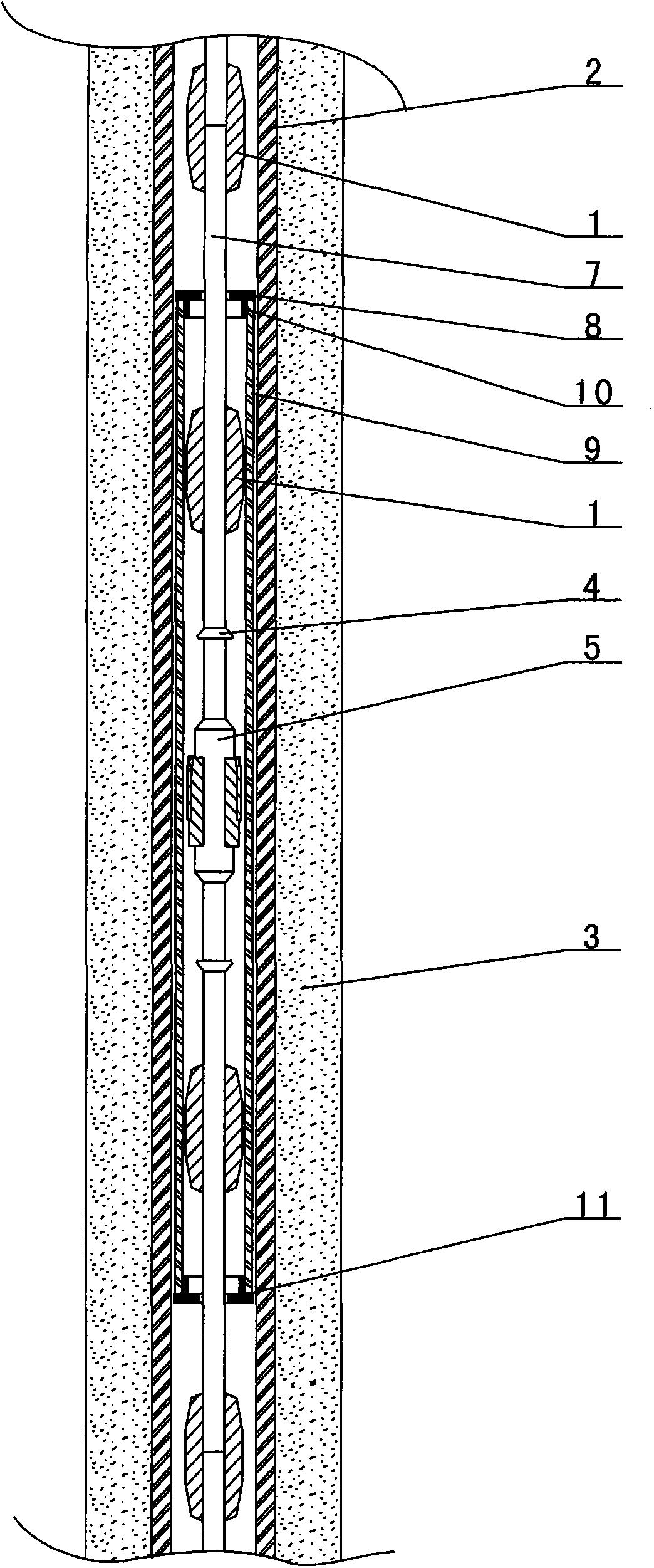

[0028] combined with Figure 1~5 The wear-resistant centralizer structure of the oil well sucker rod includes a sucker rod 7, a collar 8 at one end, a collar 11 at the other end, and a centralizing pipe 9. On the sucker rod 7, an end collar 8 and another One end collar 11, the inner hole 12 of the one end collar 8 and the other end collar 11 are in clearance fit with the sucker rod 7, and the opposite surfaces of the one end collar 8 and the other end collar 11 are respectively provided with protruding Ring 10, the two ends of the centralizing pipe 9 are fixedly connected on the protruding ring 10 of the collar 8 at one end and the collar 11 at the other end, and the outer edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com