Full-automatic crawler loader for pig moulding machine

A fully automatic, ingot-casting machine technology, applied in ingot-casting workshops, mechanical cleaning, casting workshops, etc., can solve problems that damage the image of corporate civilized production, affect the health of workers, increase the number of workers, etc., to achieve high work efficiency, The slag removal is clean and the slag removal action is uniform and gentle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

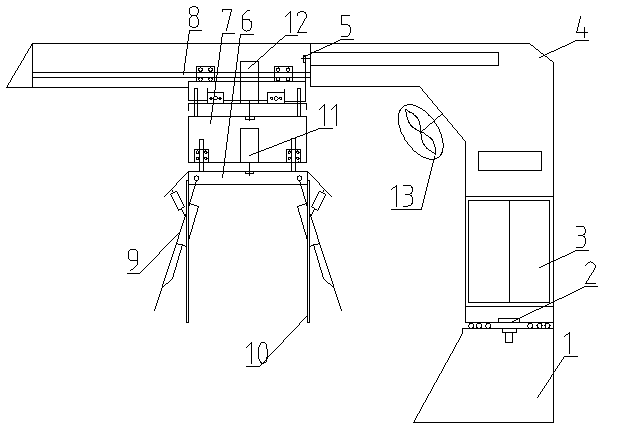

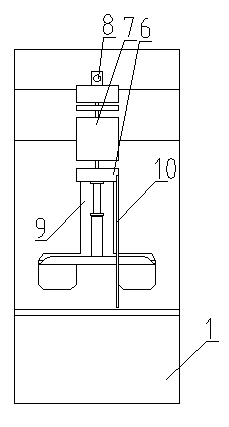

[0014] like Figure 1~2 As shown in , the whole set of equipment adopts pneumatic as power, the cantilever (4) is installed on the base (1) through the pressure bearing (2), the following mechanism is installed on the cantilever (4) through the feed rod (8), and the positioning mechanism is installed on the Below the following mechanism, a cooling fan (13) is installed at the root of the cantilever (4) to reduce the working environment temperature of the mechanical arm (9).

[0015] Among them, the following mechanism includes: a support frame (7) and a light rod (8), the light rod (8) is fixed on the cantilever (4), and the support frame (7) is connected to the light rod (8) through the cylinder 2 (12) .

[0016] The positioning mechanism consists of a probe rod bracket (6), a mechanical arm (9), a probe rod (10) and a cylinder 1 (11), wherein: the probe rod (10) is installed on both sides of the probe rod bracket (6) and is located on the mechanical The front end position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com