Method for filling polyurethane sole with waste rubber

A technology of waste rubber and polyurethane, which is applied in the direction of shoe soles, footwear, applications, etc., can solve problems such as complex process, and achieve the effect of simple process, high tear strength and uniform cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

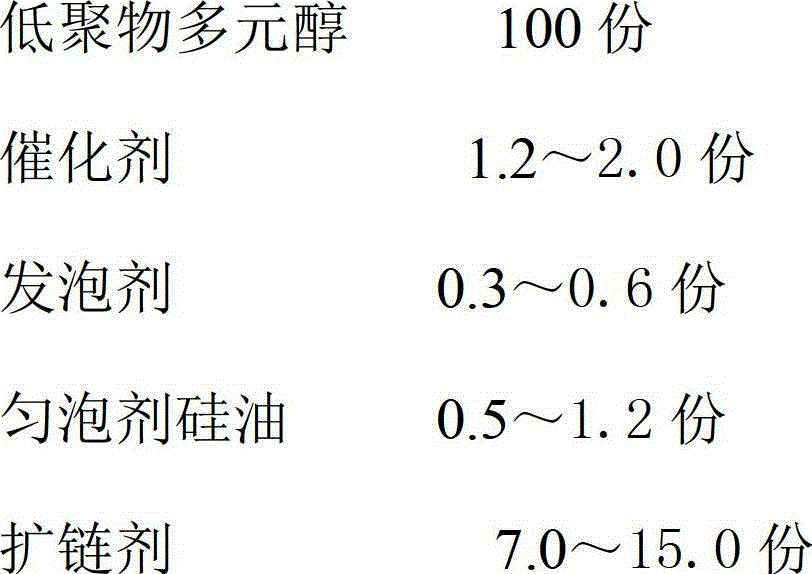

Method used

Image

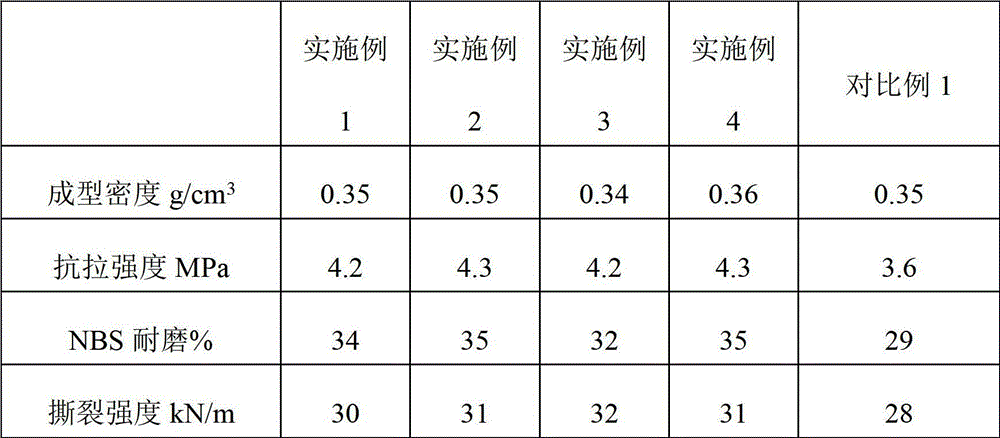

Examples

Embodiment 1

[0033] (1) After removing impurities, the waste rubber is crushed to 40 mesh particles for use; (2) 7.00 kg of polycaprolactone glycol with a molecular weight of 1500 and 3.00 kg of polyethylene adipate glycol with a molecular weight of 1500 , 0.20kg of triethylenediamine, 0.04kg of distilled water, 0.12kg of silicone foam stabilizer, 0.70kg of 1,2-propanediol, 0.80kg of 1,4-butanediol and mix it evenly, as component A, set aside; (3) 0.71kg polycaprolactone diol, 1.41kg polyglycol adipate, 7.05kg 4,4'-xylene methane diisocyanate (MDI) were mixed and reacted, and the reaction temperature was controlled to 60°C, and the reaction time was 4 hours later. Component B is ready for use; (4) Mix component A, component B and 1.68kg of rubber particles uniformly, inject them into the mold for reaction molding, after demolding, aging in an oven at 60°C for 24 hours to obtain polyurethane filled with waste rubber particles Sole.

Embodiment 2

[0035] (1) After removing impurities, the waste rubber is crushed to 30 mesh particles for use; (2) 5.00 kg of polycaprolactone diol with a molecular weight of 3000 and 5.00 kg of polyethylene adipate glycol with a molecular weight of 3000 , 0.16kg of triethylenediamine, 0.05kg of distilled water, 0.08kg of silicone foam stabilizer, 0.50kg of 1,2-propanediol, 0.60kg of 1,4-butanediol and mixed uniformly, as component A, set aside; (3) 1.48kg polycaprolactone diol, 1.48kg polyglycol adipate, 4.94kg 4,4'-xylene methane diisocyanate (MDI) were mixed and reacted, the reaction temperature was controlled at 70°C, and the reaction time was 3 hours later. Component B is ready for use; (4) Mix component A, component B and 2.31kg rubber particles uniformly, inject them into the mold for reaction molding, after demolding, aging in an oven at 70°C for 23 hours to obtain polyurethane filled with waste rubber particles Sole.

Embodiment 3

[0037] (1) After removing impurities, the waste rubber is crushed to 20 mesh particles for use; (2) 4.00 kg of polycaprolactone glycol with a molecular weight of 2000 and 6.00 kg of polyethylene adipate glycol with a molecular weight of 2000 , 0.12kg of triethylenediamine, 0.06kg of distilled water, 0.05kg of silicone foam stabilizer, 0.30kg of 1,2-propanediol, 0.40kg of 1,4-butanediol and mixed uniformly, as component A, set aside; (3) 1.72kg polycaprolactone glycol, 2.15kg polyglycol adipate, 4.30kg 4,4'-xylene methane diisocyanate (MDI) were mixed and reacted, the reaction temperature was controlled to 80°C, and the reaction time was 3 hours later, as Component B is ready for use; (4) Mix component A, component B and 2.86kg rubber particles uniformly, inject them into the mold for reaction molding, after demolding, aging in an oven at 70°C for 22 hours to obtain polyurethane filled with waste rubber particles Sole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com