Preparation method of transparent yttria ceramic

A technology of transparent ceramics and yttrium oxide, applied in the field of preparation of rare earth oxide transparent ceramics, can solve the problems of difficult yttrium oxide transparent ceramics, lower sintering temperature, complicated processing procedures, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

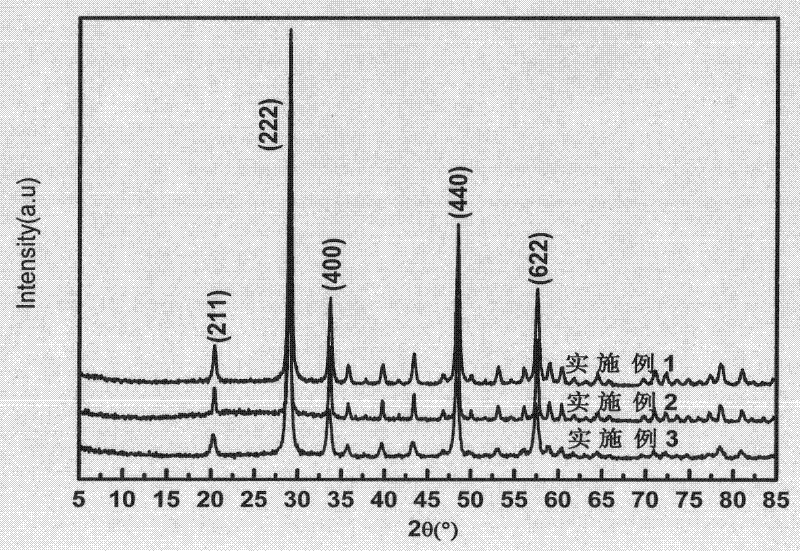

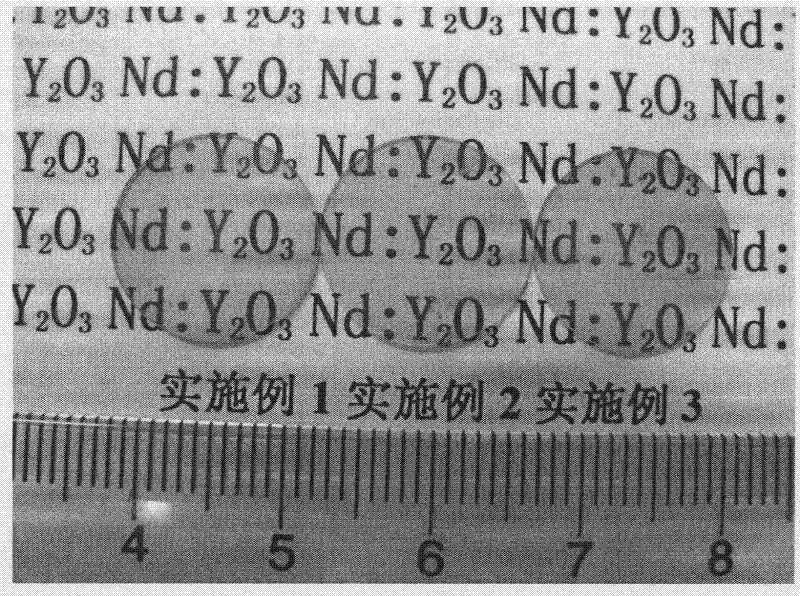

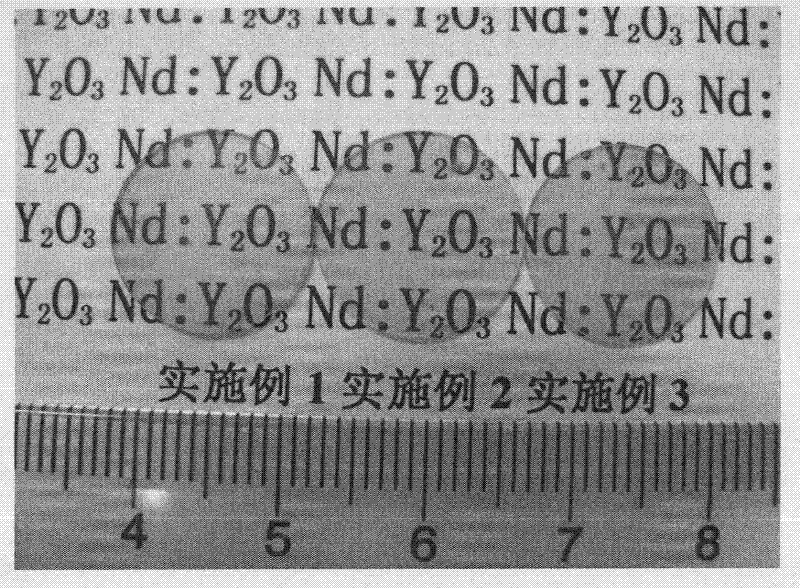

Embodiment 1

[0021] 1) Set Y(NO 3 ) 3 and Nd(NO 3 ) 3 According to the Nd content is 1% of the total molar amount of metal ions, while adding 10% of the total molar amount of metal ions (NH 4 ) 2 SO 4 And 0.06% PAA as composite dispersant, 0.5% MgSO in total molar amount of metal ions 4 ·7H 2 O was used as a sintering aid. After weighing the five medicines, they were dissolved in deionized water and stirred thoroughly to form a mixed solution with a total molar amount of metal ions of 0.2 mol / L.

[0022] 2) Weigh the ammonium bicarbonate by 3 times of the total molar amount of metal ions, keep the volume of the ammonium bicarbonate solution to be 2 times that of the mixed mother liquor, add deionized water, stir to make it fully dissolved.

[0023] 3) At room temperature, using the forward titration method, slowly drop the precipitant ammonium bicarbonate solution into the mixed solution of metal ions at a rate of ≤5mL / min, and stir, and it will appear milky white turbid at the begi...

Embodiment 2

[0031] 1) Set Y(NO 3 ) 3 and Nd(NO 3 ) 3 According to the Nd content is 2% of the total amount of moles of metal ions, while adding 20% of the total amount of moles of metal ions (NH 4 ) 2 SO 4 and 0.04% of PAA as a composite dispersant, and 0.5% of MgSO in total molar amounts of metal ions 4 ·7H 2 O was used as a sintering aid. After weighing the five medicines, they were dissolved in deionized water and stirred thoroughly to form a mixed solution with a total molar amount of metal ions of 0.4mol / L.

[0032] 2) Weigh the ammonium bicarbonate by 4 times the molar weight of the metal ions, keep the volume of the ammonium bicarbonate solution at 2.5 times the volume of the mixed mother liquor, add deionized water, stir to make it fully dissolved.

[0033] 3) At room temperature, using the forward titration method, slowly drop the precipitant ammonium bicarbonate solution into the mixed solution of metal ions at ≤5mL / min, and stir. As the reaction progresses further, th...

Embodiment 3

[0041] 1) Set Y(NO 3 ) 3 and Nd(NO 3 ) 3 According to the Nd content is 2% of the total amount of moles of metal ions, add 30% of the total amount of moles of metal ions (NH 4 ) 2 SO 4 and 0.03% of PAA as a composite dispersant, and 0.5% of MgSO in the total molar amount of metal ions 4 ·7H 2 O was used as a sintering aid. After weighing the five medicines, they were dissolved in deionized water and stirred thoroughly to form a mixed solution with a total molar amount of metal ions of 0.3mol / L.

[0042] 2) Weigh the ammonium bicarbonate according to 3.5 times the molar weight of the metal ions, keep the volume of the ammonium bicarbonate solution twice that of the mixed mother liquor, add deionized water, and stir to make it fully dissolved.

[0043] 3) At room temperature, using the forward titration method, slowly drop the precipitant ammonium bicarbonate solution into the mixed solution of metal ions at a rate of ≤5mL / min, and stir, and it will appear milky white tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com